رافعات علوية اقتصادية بوزن 3 أطنان للرفع الصناعي الخفيف

جدول المحتويات

سلسلة رافعات دافانغ العلوية متعددة الاستخدامات بسعة 3 أطنان، تشمل رافعة LD العلوية أحادية العارضة، ورافعة LDY المعدنية العلوية، ورافعة LDZ العلوية ذات القابض، والرافعة العلوية اليدوية لمناولة المواد الصناعية الخفيفة. صُممت هذه الرافعات بهيكل أحادي العارضة، وتتميز بأبعاد مدمجة، ومتطلبات ارتفاع منخفضة، وثبات معزز للحمل، مما يضمن دقة وضع المواد حتى 3 أطنان. صُممت هذه الرافعات لضمان المتانة وكفاءة الطاقة، وتلبي مختلف متطلبات سير العمل، من خطوط التجميع إلى البيئات ذات درجات الحرارة العالية. تواصل معنا لتلبية احتياجات ورشتك الخاصة، سواءً كانت الأولوية لمقاومة التآكل، أو عمليات القابض، أو التحكم اليدوي الملائم للميزانية!

6 أنواع من الرافعات العلوية بوزن 3 أطنان

رافعات معلقة بوزن 3 أطنان

رافعات علوية يدوية سعة 3 أطنان

صناعة تطبيقات الرافعات العلوية سعة 3 أطنان

رافعة علوية سعة 3 أطنان للتحميل باستخدام الحاسب الآلي في ورشة الأدوات

في ورش تصنيع الآلات ذات التحكم الرقمي (CNC)، تُعد المناولة الدقيقة للمواد أمرًا أساسيًا لتحميل وتفريغ ونقل القوالب المعدنية والأدوات الدقيقة والمكونات المخرطة بدقة عالية. غالبًا ما تعمل هذه الورش في بيئات محدودة المساحة، مما يتطلب حلول رفع مدمجة تُعزز الخلوص الرأسي وتتجنب التداخل مع خطوط الإنتاج الحالية. تُعد الرافعة العلوية أحادية العارضة بوزن 3 أطنان خيارًا عمليًا نظرًا لصغر حجمها ومرونة تركيبها (غالبًا باستخدام نظام مسار بدون أساس)، وتحكمها ثنائي السرعة بمحرك تردد متغير (VFD)، مما يضمن حركة سلسة ودقيقة.

في عمليات التصنيع باستخدام الحاسب الآلي، تتعامل الرافعات العلوية بشكل أساسي مع: قوالب الفولاذ وسبائك الألومنيوم المستخدمة في التصنيع الدقيق، والتي يتراوح وزنها عادةً بين 0.8 و2.5 طن للوحدة. أعمدة الفولاذ المقاوم للصدأ، ومكونات هيكلية من سبائك التيتانيوم، وقطع تروس كبيرة، يتراوح وزن كل منها بين 0.5 و2.7 طن. أقراص قاطعة طحن متينة (1-1.8 طن) ووحدات نظام تغيير الأدوات باستخدام الحاسب الآلي (0.5-1.2 طن).

نظراً لطبيعة هذه المواد الحساسة وضرورة تحديد المواقع بدقة، تدعم رافعة 3 أطنان التثبيت على دفعات أو مناولة وحدة واحدة، مما يُسهّل عمليات التحميل والتفريغ بكفاءة في جميع الأحوال الجوية. وهذا يجعلها حل رفع أساسي لورش العمل عالية الدقة والإنتاجية باستخدام الحاسب الآلي، حيث يكون التحكم في الحركة وتحسين مساحة العمل أمراً بالغ الأهمية.

رافعة علوية منخفضة الارتفاع سعة 3 أطنان في ورشة الخرسانة

تتميز الرافعة العلوية منخفضة الارتفاع، التي يبلغ وزنها 3 أطنان، بتصميمها المدمج ذي العارضة الواحدة (المتوافق مع معايير FEM الأوروبية) ومتطلباتها الدنيا لارتفاع الرأس، مما يتيح التكيف مع المساحات الرأسية المحدودة في المنشآت القائمة مع زيادة ارتفاع الرفع إلى أقصى حد (أعلى من الطرز التقليدية بواقع 20-30%). صُممت هذه الرافعة للتعامل مع أكياس الأسمنت (1-2 طن لكل منها)، ومكونات الخرسانة الجاهزة (≤2.7 طن)، والقوالب الثقيلة، وتغطي 90% من متطلبات الأحمال النموذجية في هذا القطاع. هيكلها خفيف الوزن (15% ذات وزن ذاتي مخفّض) ووحدة التحكم VFD ثنائية السرعة (دقة تحديد المواقع ±5 مم، وسرعة رفع 15 مترًا في الدقيقة) يعززان الكفاءة بشكل كبير في البيئات المتربة وعالية الحرارة مع تقليل مخاطر المناولة اليدوية. مثالية لإعادة تأهيل الورش القديمة أو العمليات محدودة المساحة، فهي توفر حلاً آمنًا وعالي الأداء لتحديات مناولة المواد.

رافعة علوية أحادية العارضة LD سعة 3 أطنان لمصنع معالجة الأنابيب الفولاذية

في صناعة معالجة الأنابيب الفولاذية، أصبحت الرافعة العلوية أحادية العارضة سعة 3 أطنان (نوع AQ-LD) الخيار الأول لورش الأنابيب الفولاذية الصغيرة والمتوسطة الحجم نظرًا لهيكلها المدمج وفعاليتها من حيث التكلفة. تم تصميم الرافعة خصيصًا لرفع الأنابيب الفولاذية التي يبلغ طولها 6 أمتار (فردية ≤ 2.7 طن) والقضبان المعدنية وهي مناسبة لارتفاع تحميل الشاحنات (رفع 6 أمتار). يفي مستوى العمل A3 بالعمليات اليومية متوسطة الكثافة من 8 إلى 10 ساعات. استقرار المواد طويلة الحجم ومرونة التشغيل يضمن وضع التحكم عن بعد + التحكم المزدوج عن بعد استقرار ومرونة التشغيل للمواد طويلة الحجم عند الرفع. يمكنه تحديد موقع 1-3 أطنان من الأنابيب الفولاذية ونقلها بدقة (تزن الحزمة الفردية الشائعة 1.5-2.8 طن) في وقت واحد، ويبلغ متوسط سعة المعالجة اليومية 30-50 مرة.

كم تكلفة رافعة علوية سعة 3 أطنان؟

لضمان حصولك على النوع المناسب من الرافعة العلوية لشركتك، يجب أن تكون مستعدًا لمعالجة المعلومات التالية عندما تتصل بشركة مصنعة للرافعات العلوية لتقديم عرض على مشروعك:

- المهمة التي تحتاج الرافعة الخاصة بك إلى القيام بها.

- احتياجات توسيع الأعمال التي ستحتاج إلى تلبيتها.

- القدرة أو أقصى حمل مصنف تحتاج إلى رفعه بواسطة الرافعة الخاصة بك.

- المسافة التي تحتاج إلى تغطيتها تحت الرافعة، أو المسافة الأفقية، من المركز إلى المركز، لقضبان المدرج.

- القدرة أو أقصى حمل مصنف تحتاج إلى رفعه بواسطة الرافعة الخاصة بك.

- كم مرة سوف تستخدم الرافعة الخاصة بك؟

- الارتفاع المقدر لرافعتك أو الرفع المطلوب.

- إذا كنت بحاجة إلى مدرج، فيجب أن يكون طول الممر الذي ستحتاج الرافعة إلى عبوره.

- أية متطلبات خاصة بالبناء أو الهيكلية للتشغيل أو التثبيت.

هناك العديد من العوامل التي تؤثر على كفاءة نظام الرافعات العلوية. أهم عاملين هما الامتداد والسعة. يُحدد هذان العاملان كمية العمالة والمواد اللازمة للمشروع، كما يُحددان تعقيد وتصميم الرافعة، والعربة، والجسر، وأجهزة التحكم، ونظام الطاقة - وهي عوامل رئيسية في تحديد تكلفة الرافعة.

قائمة أسعار الرافعات العلوية سعة 3 أطنان

| منتج | امتداد/م | عمل نظام | مزود الطاقة الجهد االكهربى | السعر/دولار أمريكي |

|---|---|---|---|---|

| رافعات علوية أحادية العارضة سعة 3 أطنان | 7.5-31.5 | A3 | 3 مراحل 380 فولت 50 هرتز | $2,130-7,470 |

| رافعات علوية منخفضة الارتفاع بحمولة 3 أطنان | 10.5-25.5 | أ6 | 3 مراحل 380 فولت 50 هرتز | $2,337-7,677 |

| رافعات علوية بحمولة 3 أطنان | 4.5-28.5 | أ5 | 3 مراحل 380 فولت 50 هرتز | عرض أسعار مخصص |

| رافعات معلقة بوزن 3 أطنان | 5-14 | A3 | 3 مراحل 380 فولت 50 هرتز | عرض أسعار مخصص |

في دافانغ كرين، نتخصص في حلول الرافعات العلوية المصممة خصيصًا لسعة 3 أطنان، والمصممة للرفع الدقيق في ورش العمل والمستودعات الصغيرة أو البيئات ذات درجات الحرارة العالية. شاركنا متطلباتك الخاصة، مثل ارتفاع الرفع ودورة العمل، وسيقدم فريقنا الهندسي دعمًا شخصيًا فرديًا لتصميم نظام فعال من حيث التكلفة، حاصل على شهادة CE، يتميز بهياكل أخف وزنًا من نوع 30% أو عناصر تحكم تدعم إنترنت الأشياء. احصل على عرض سعر مخصص خلال 24 ساعة، مصمم خصيصًا لميزانية سير عملك ومساحتك.

لماذا تختار رافعة دافانغ العلوية 3 أطنان؟

تقدم شركة دافانغ كرين مجموعة كاملة من الرافعات العلوية بوزن 3 أطنان، بما في ذلك الرافعات أحادية العارضة القياسية من نوع LD، والرافعات ذات الطراز الأوروبي، والرافعات منخفضة الارتفاع، والرافعات اليدوية، المصممة بدقة ومتانة وكفاءة عالية. بفضل أطوالها القابلة للتخصيص (5-28.5 متر)، وخيارات التحكم المتقدمة في الرافعات (محرك تردد متغير، ثنائي السرعة)، وشهادات CE/GOST/ASME، صُممت رافعاتنا لتلبية احتياجات مناولة المواد المتنوعة في الورش والمستودعات ومصانع المعالجة. اختر من بين هياكل مدمجة موفرة للمساحة أو تصاميم متينة للأعمال الشاقة. تتميز رافعاتنا بمكونات عالمية موثوقة (SEW، ABB، Siemens) ومراقبة متوافقة مع إنترنت الأشياء في طرز مختارة. ندعمها بضمان هيكلي لمدة عام واحد، ودعم تركيب كامل، وقطع غيار مُحسّنة. بفضل خبرتنا في أكثر من 50 دولة، دعنا نقدم لك حلول رفع مصممة خصيصًا وفعّالة تناسب سير عملك وميزانيتك.

رافعات دافانغ العلوية سعة 3 أطنان

رافعات علوية أحادية العارضة سعة 3 أطنان مُصدَّرة إلى أوزبكستان

تم الانتهاء من العارضة الرئيسية للرافعة العلوية التي يبلغ وزنها 3 أطنان

تم الانتهاء من إنتاج عوارض نهاية الرافعة العلوية

سكة موصلة بدون درزات تم تعبئتها

- المنتج: رافعة علوية أحادية العارضة LX

- البلد: أوزبكستان

- السعة: 3 طن

- طول الامتداد: 8 م و 15 م و 9 م

- ارتفاع الرفع: 7.5 متر و 15 متر

- سرعة الرفع: 8 م/دقيقة

- سرعة السفر المتقاطع: 20 متر/دقيقة

- سرعة حركة الرافعة: 30 متر/دقيقة

- وضع التحكم: جهاز تحكم عن بعد لاسلكي

- مجموعة الواجب: A3

احتاج عميلنا الكازاخستاني إلى رافعة علوية بوزن 3 أطنان لورشته الضيقة ذات درجات الحرارة المرتفعة. كان تصميم دافانغ الأوروبي خفيف الوزن (30% أخف وزنًا!) مناسبًا تمامًا، كما أن نظام التحكم الذكي بالذكاء الاصطناعي وفّر عليه 40% من فواتير الطاقة. قبل بناء الرافعة، راجعنا جميع التفاصيل معهم بعناية، مثل تحسينات مقاومة الغبار وامتدادها البالغ 22 مترًا، لضمان تركيب سلس. والآن يستخدمونها يوميًا لتجميع المعدات الثقيلة دون أي متاعب.

4 مجموعات من الرافعات العلوية الأوروبية عالية الدقة تم تصديرها إلى منغوليا

تم الانتهاء من العارضة الرئيسية للرافعة العلوية التي يبلغ وزنها 3 أطنان

رافعة على الطراز الأوروبي معبأة وجاهزة للنقل

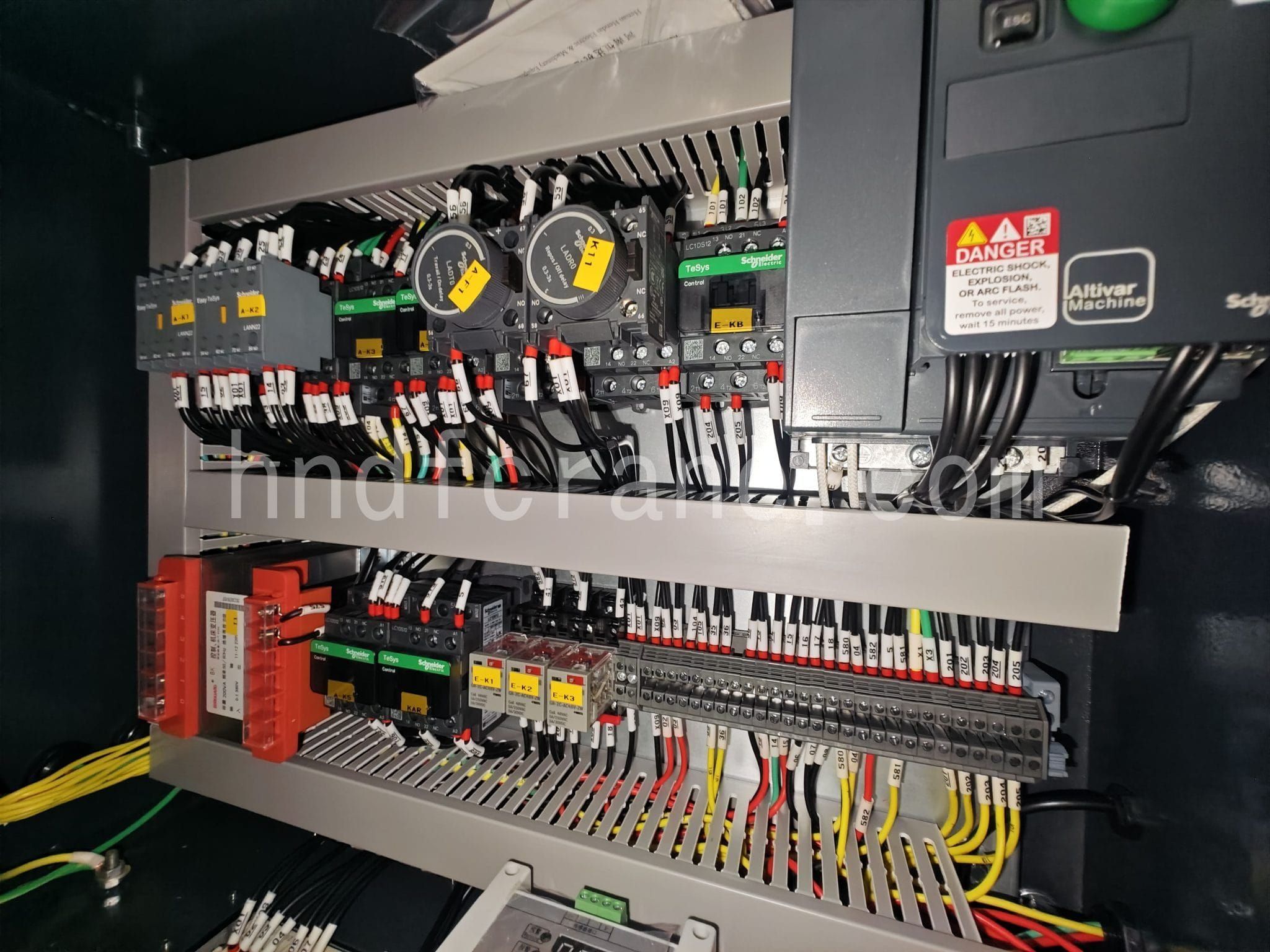

اكتمال إنتاج صندوق التحكم الكهربائي للرافعة العلوية

المشروع 1: رافعة علوية أوروبية 3 طن

- السعة: 3 طن

- الامتداد: 12.36 متر

- الارتفاع: 12.3م

المشروع 2: رافعة علوية أوروبية 3 طن

- السعة: 3 طن

- الامتداد: 15.66 متر

- الارتفاع: 15م

اختار عميل من آسيا الوسطى رافعات دافانغ العلوية الأوروبية بوزن 3 أطنان (بعرض 12.36 مترًا و15.66 مترًا) بعد مقارنة عدة موردين، وأُعجب بتصميمها خفيف الوزن (30% الموفر للمساحة) ودقتها المعززة بالذكاء الاصطناعي في رفع الأجزاء المعدنية في ورشته عالية الحرارة والغبار. خلال تعاونهما الأول، قام العميل بفحص الرافعات شخصيًا قبل التسليم لضمان سلاسة التركيب. تعمل هذه الرافعات الآن لمدة 10 ساعات يوميًا دون أي مشاكل، وهي مثالية للبيئات القاسية. شارك احتياجاتك - الحمولة، الارتفاع، العرض، وتفاصيل ورشة العمل - وسنصمم لك حلاً مقاومًا للغبار أو الحرارة!

رافعات علوية أحادية العارضة بوزن 3 أطنان تم شحنها إلى بيرو

تم الانتهاء من العارضة الرئيسية للرافعة العلوية LD التي يبلغ وزنها 3 أطنان

تم الانتهاء من إنتاج عوارض نهاية الرافعة العلوية

تم تعبئة الرافعة العلوية بأكملها

- السعة: 3 طن

- المدى: 11.56 م

- ارتفاع الرفع: 6 م

- واجب العمل: A3

بعد شراكة متينة دامت أربع سنوات، قدّم عميلنا في بيرو طلبه الأول لرافعة علوية بوزن 3 أطنان (بامتداد 11.56 مترًا، وارتفاع رفع 6 أمتار، وفئة عمل A3)، مصممة خصيصًا للعمليات متوسطة الكثافة في مصنعه. وحرصًا على الجودة، شدد على معايير صارمة لسُمك الطلاء، وطلب فحصًا من جهة خارجية قبل التسليم، لضمان مقاومة التآكل وخلوّه من العيوب. تُظهر صور المشروع المرفقة قوة هيكل الرافعة، وجاهزيتها للتعامل مع مهام مناولة المواد اليومية بموثوقية. خصص مواصفات رافعتك وبروتوكولات الفحص الخاصة بها، وسنلبي أعلى معاييرك!

رافعة علوية أحادية العارضة LD سعة 3 أطنان تم تصديرها إلى ماليزيا

تم تعبئة الرافعة العلوية بأكملها

تم الانتهاء من العارضة الرئيسية للرافعة العلوية التي يبلغ وزنها 3 أطنان

- قدرة الرفع: 3 طن

- المدى: 18 م

- ارتفاع الرفع: 8 م

- سرعة الرفع: 8 م / دقيقة

- سرعة السفر: 20 م / دقيقة

قام عميلنا الماليزي بتركيب رافعة علوية أوروبية بوزن 3 أطنان (بامتداد 18 مترًا، وارتفاع رفع 8 أمتار) بسهولة في ورشة التجميع الفسيحة الخاصة به، والمصممة خصيصًا لتركيب المعدات الثقيلة. ورغم سرعة حركتها البالغة 20 مترًا في الدقيقة ودقة رفعها البالغة 8 أمتار في الدقيقة، إلا أنه أدار التركيب الميكانيكي بمفرده - واستشارنا فقط بشأن التوصيلات الكهربائية - بفضل تصميمها المعياري سهل التركيب والتشغيل. هل تعلمت درسا؟ حتى الرافعات "القياسية" تحتاج إلى التخصيص: شارك تصميم ورشة العمل والمهام اليومية (مثل تشغيله لمدة 5 ساعات في اليوم)، وسنقوم بتعديل كل شيء من السرعة إلى الطلاء المقاوم للتآكل!

أسئلة وأجوبة

هل يمكن استخدام رافعة علوية سعة 3 أطنان في البيئات ذات درجات الحرارة العالية؟

نعم! رافعة دافانغ كرين المعدنية العلوية، التي يبلغ وزنها 3 أطنان، مصممة بطلاءات مقاومة لدرجات الحرارة العالية ومحركات محمية حرارياً، وهي مصممة خصيصاً للبيئات القاسية، مثل مصانع الصب أو مصانع الصلب التي تعمل في درجات حرارة تصل إلى 60 درجة مئوية (140 درجة فهرنهايت). تضمن الترقيات القابلة للتخصيص، مثل الأسلاك المعزولة بالسيراميك أو أنظمة التبريد المساعدة، أداءً مثالياً وعمراً افتراضياً طويلاً في الظروف القاسية.

ما هي الصناعات التي تستخدم عادة الرافعات العلوية التي يبلغ وزنها 3 أطنان؟

تُستخدم الرافعات العلوية بحمولة 3 أطنان على نطاق واسع في قطاعات مثل التصنيع (مثل تصنيع المعادن، وتجميع السيارات، وخطوط إنتاج الأغذية)، والخدمات اللوجستية والتخزين (مناولة الحاويات، وإدارة المخزون)، والطاقة وبناء السفن (تركيب المعدات، وتحديد مواقع المكونات الثقيلة). في البيئات المتخصصة، مثل ورش العمل عالية الحرارة أو البيئات المعرضة للغبار، تُعد التصاميم الوقائية المخصصة ضرورية لضمان عمليات آمنة وفعالة.

كيفية صيانة رافعة علوية سعة 3 طن؟

تتضمن الصيانة السليمة للرافعات العلوية بوزن 3 أطنان فحوصات دورية لمحاذاة المسار، وتآكل العجلات، والأنظمة الكهربائية لضمان السلامة التشغيلية. وتُعدّ الإجراءات الوقائية، مثل تشحيم مكونات ناقل الحركة واستبدال الحبال السلكية على فترات زمنية مُوصى بها، بالغة الأهمية لتقليل وقت التوقف عن العمل. في مهام الصيانة المُعقدة، يُفضّل اختيار موردين مثل شركة Dafang Crane الذين يُقدّمون الدعم الفني في الموقع، مع ضمان استكشاف الأخطاء وإصلاحها في الوقت المناسب والالتزام ببروتوكولات السلامة.

ما هي ميزات السلامة التي يجب أن تتمتع بها الرافعة العلوية التي يبلغ وزنها 3 أطنان؟

تشمل آليات السلامة الرئيسية للرافعات العلوية بوزن 3 أطنان نظام حماية من الحمل الزائد، والذي يوقف العمليات تلقائيًا عند تجاوز حدود الوزن المسموح به، ونظام كبح طارئ للإيقاف الفوري في الحالات الحرجة. ولمنع الحوادث في الرافعات متعددة الرافعات، تُعد أجهزة منع التصادم أساسية. بالإضافة إلى ذلك، تضمن المكونات الكهربائية الحاصلة على تصنيف IP54 مقاومة دخول الغبار والماء، مما يعزز المتانة على المدى الطويل. وأخيرًا، تأكد من أن الرافعة مطابقة للشهادات المعترف بها دوليًا مثل CE وISO9001 وRoHS، والتي تضمن الالتزام بمعايير السلامة والجودة.

كيفية اختيار المورد موثوق بها لرافعة علوية 3 طن في الصين؟

عند اختيار مورد موثوق لرافعة علوية بوزن 3 أطنان، أعطِ الأولوية لمن يتمتع بخبرة مثبتة في تصنيع الرافعات العلوية والقدرة على تخصيص حلول مثل النماذج المقاومة للانفجار أو عالية السرعة. تأكد من حصولهم على شهادات معترف بها دوليًا مثل ISO9001 أو CE أو SGS، والتي تُثبت امتثالهم لمعايير الجودة والسلامة. ومن الأهمية بمكان أيضًا توفير دعم شامل لما بعد البيع، بما في ذلك إرشادات التركيب وخدمات الصيانة الدورية والضمانات (عادةً من سنة إلى سنتين). وأخيرًا، تأكد من سمعتهم من خلال مراجعة شهادات العملاء، أو -في أفضل الأحوال- إجراء عمليات تفتيش في المصنع لتقييم قدرات الإنتاج وموثوقية التشغيل.

أرسل استفسارك

- بريد إلكتروني: sales@hndfcrane.com

- واتساب: +86-191 3738 6654

- هاتف: +86-373-581 8299

- فاكس: +86-373-215 7000

- إضافة: منطقة Changnao الصناعية ، مدينة Xinxiang ، مقاطعة Henan ، الصين