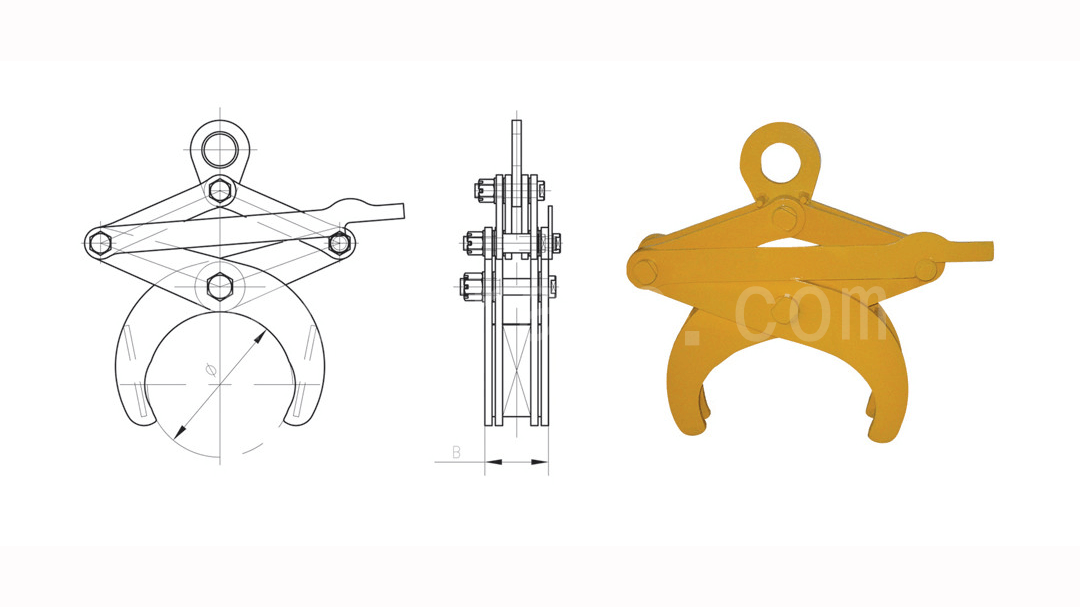

Pipe Tong

- Application: Horizontal lifting and transporting of round steel

- Structural Features: The gripping part of the lifting device should be at the middle of the round steel being lifted. According to the operation mode, it can be divided into manually operated round steel lifting device and automatically operated round steel lifting device

- Rated Load Range: 1 to 25 tons, this crane lifting tongs can be specially designed according to user requirements.

| Capacity(t) | Application Range(mm) | Design Opening(mm) | Weight(kg) |

| 1 | Φ50~Φ100 | 105 | 6.3 |

| 1 | Φ100~Φ160 | 170 | 16 |

| 2 | Φ80~Φ130 | 145 | 18.5 |

| 2 | Φ100~Φ200 | 210 | 33 |

| 3 | Φ120~Φ220 | 240 | 56 |

| 3 | Φ160~Φ250 | 270 | 57.5 |

| 5 | Φ200~Φ320 | 340 | 113 |

| 5 | Φ250~Φ400 | 440 | 138 |

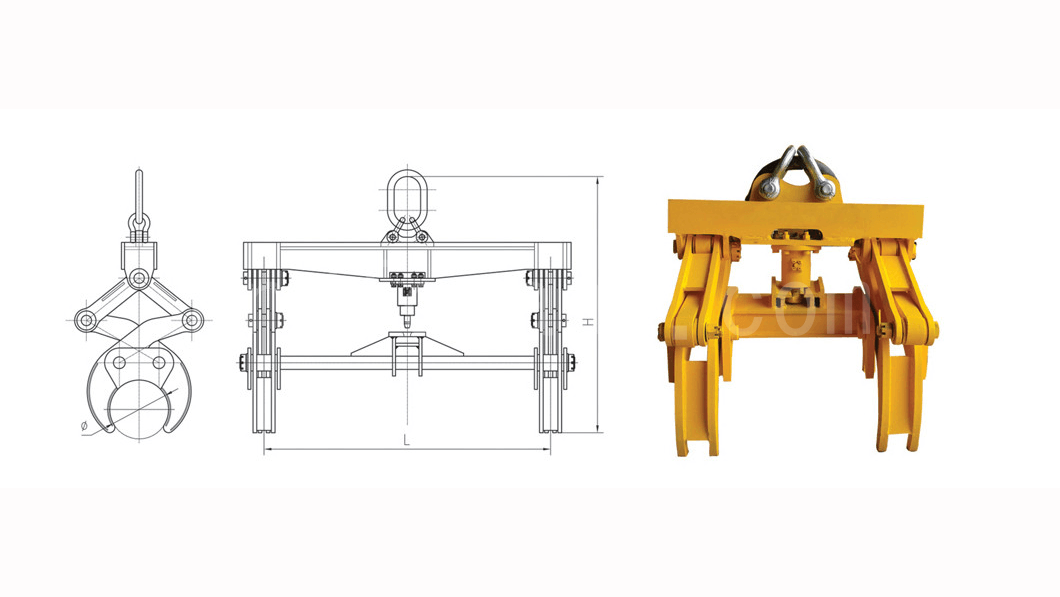

| Capacity(t) | Application Range(mm) | Design Opening(mm) | Width L(mm) | Weight(kg) |

| 5 | Φ250~Φ420 | 440 | 2000 | 2460 |

| 10 | Φ320~Φ450 | 490 | 2500 | 2590 |

| 15 | Φ380~Φ550 | 600 | 3000 | 2680 |

| 20 | Φ450~Φ700 | 750 | 3000 | 3050 |

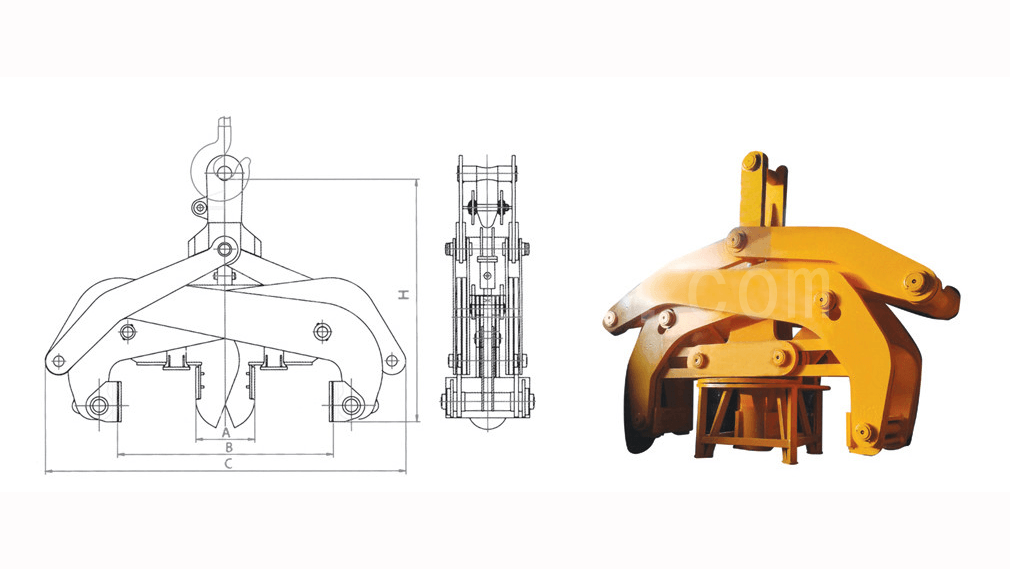

Vertical Coil Tongs

- Application: Vertical lifting and transporting of steel coils. The vertical coil clamp is a specialized lifting device used for transporting and stacking cold and hot steel coils in a vertical position at steel mills, port docks, railway freight yards, warehouses, etc.

- Structural Features: Grips the steel coil through the mechanical lever principle.

- Rated Load Range: 3.2 to 35 tons, with special designs available according to user requirements.

| Capacity(t) | For Coil Thickness(mm) | Size (mm) | |||

| A | B | C | H | ||

| 25 | 450~600 | 450 | 1810 | 2610 | 3250 |

| 30 | 500~650 | 600 | 2100 | 3000 | 3630 |

| 35 | 550~700 | 650 | 2250 | 3250 | 3869 |

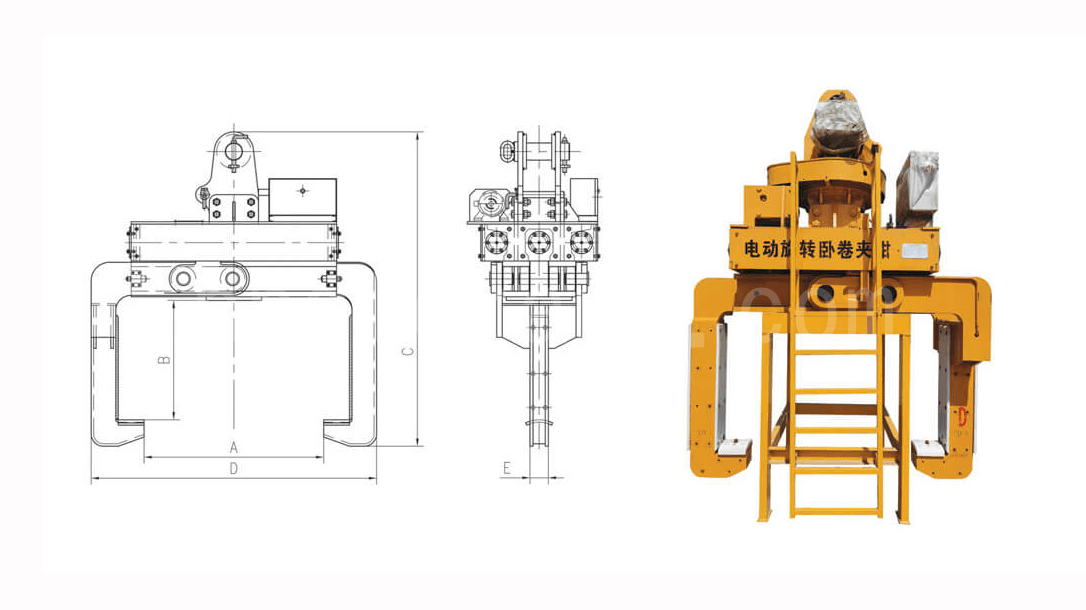

Horizontal Coil Tongs

- Main Components: This clamp consists of parts such as a lifting lug, clamp legs, clamp leg drive system, electrical and control systems, and a cable reel.

- Features: Compact structure, lightweight, high load capacity, precise clamping, high efficiency, safe and reliable, advanced technology, strong adaptability, easy maintenance.

- Applications: Widely used for horizontal coil handling in steel plants, warehouse stacking, and loading and unloading in automotive and railway contexts.

- Customization: Special designs available according to user requirements.

| Capacity(t) | Coil Parameters(mm) | Maximum Opening A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Weight(Kg) |

| 10 | Inner Diameter: Φ500 Outer Diameter: Φ2200 | 250~1900 | 1000 | 2700 | 2900 | 120 | 2800 |

| 15 | Inner Diameter: Φ500 Outer Diameter: Φ2200 | 250~1900 | 1000 | 2700 | 2900 | 150 | 3000 |

| 20 | Inner Diameter: Φ500 Outer Diameter: Φ2200 | 250~1900 | 1000 | 2700 | 2900 | 150 | 3200 |

| 25 | Inner Diameter: Φ500 Outer Diameter: Φ2200 | 250~1900 | 1000 | 2700 | 2900 | 150 | 3400 |

| 35 | Inner Diameter: Φ500 Outer Diameter: Φ2200 | 250~1900 | 1000 | 2700 | 2900 | 150 | 3660 |

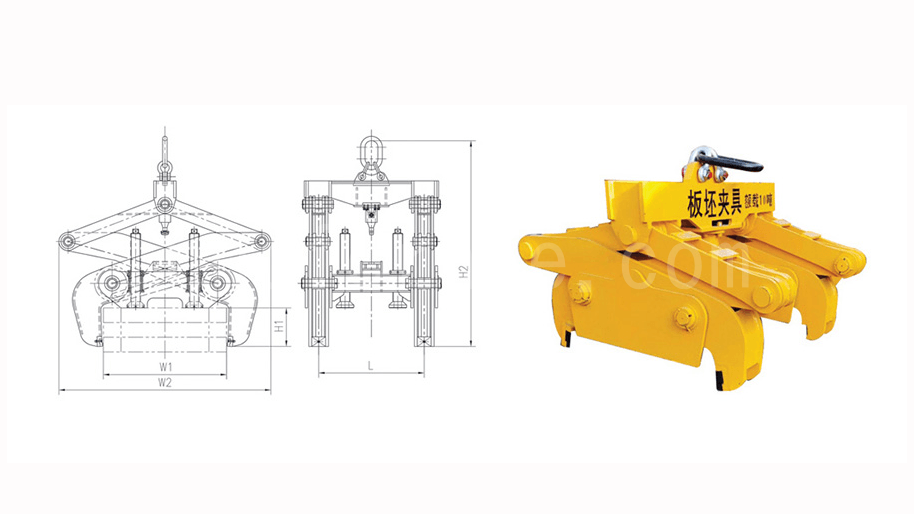

Slab Tongs

- Application: Suitable for horizontal lifting and transporting of medium and thick steel plates or slabs at normal or high temperatures.

- Features: Automatic opening and closing, flexible movement, safe and reliable operation, no need for ground personnel assistance, adjustable mechanisms can be added to accommodate different specifications and layers of slabs.

- Rated Load Range: 5 to 80 tons, with special designs available according to user requirements.

| Capacity | Application Range(mm)W1 | Clamp Leg Height(mm)H1 | Span(mm)L | Maximum Overall Dimensions(mm) | |

| W2 | H2 | ||||

| 5T | 250~450 | 150 | 600 | 1350 | 1750 |

| 5T | 450~750 | 150 | 1000 | 1600 | 2200 |

| 8T | 600~900 | 300 | 1200 | 1650 | 2200 |

| 8T | 900~1200 | 300 | 1200 | 2210 | 3200 |

| 12T | 1200~1600 | 300 | 1600 | 2560 | 3370 |

| 12T | 1300~1800 | 300 | 1600 | 2880 | 3450 |

| 16T | 1200~1600 | 450 | 1600 | 2560 | 3500 |

| 16T | 1300~1800 | 450 | 1600 | 2880 | 3750 |

| 20T | 1600~2100 | 450 | 1600 | 3360 | 3780 |

| 20T | 1800~2300 | 450 | 1600 | 3680 | 3980 |

| 25T | 1300~1800 | 550 | 1800 | 2880 | 4000 |

| 25T | 1600~2100 | 550 | 1800 | 3360 | 4030 |

| 32T | 1800~2300 | 550 | 1800 | 3680 | 4230 |

| 32T | 2100~2600 | 550 | 1800 | 4160 | 4500 |

| 50T | 1800~2300 | 750 | 2000 | 3680 | 4280 |

| 50T | 2100~2600 | 750 | 2000 | 4160 | 4800 |

| 80T | 1800~2300 | 750 | 2000 | 3680 | 4580 |

| 80T | 2400~3200 | 750 | 2000 | 5120 | 5900 |

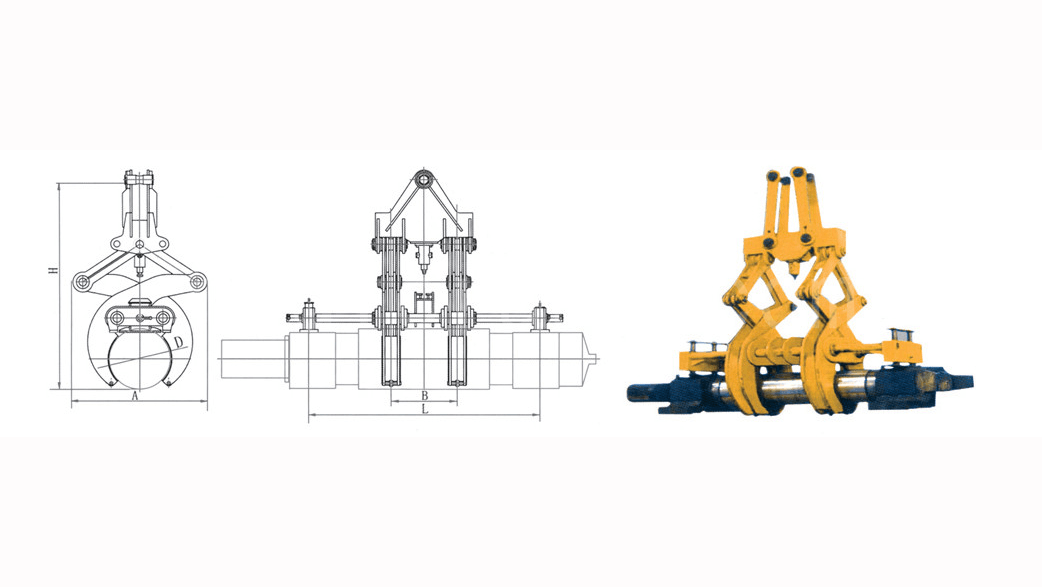

Tongs for Roll

- Application: Used for lifting and transporting individual rolling mills onto grinding machines and during the use of individual rolling mills in rolling mill workshops.

- Structural Features: Relies on the mechanical lever principle to grip the roll through clamp arms. Automatic opening and closing control actions. Removable copper plates are installed at contact points to prevent surface scratches. Adjustable mechanisms allow for lifting rolls of different diameters.

- Customization: Special designs available according to user requirements.

| Capacity(t) | Roll Diameter(mm) | Size (mm) | |||

| A(max) | B | L | H(max) | ||

| 20 | Φ560~Φ620 | 1860 | 860 | 3000 | 2930 |

| 30 | Φ720~Φ950 | 2150 | 860 | 3000 | 3430 |

Ingot Tongs

Ingot lifting and handling tongs can be mechanical or electrohydraulic. They are typically used in challenging workplaces characterized by burdensome working conditions and hard handling. These tongs are suitable for all industrial applications in various environments and are most commonly used in steel mills.

- maximum load: 500 ton

- maximum diameter: 3000 mm

- maximum temperature: 950℃