4 Zničující selhání hydraulických drapáků, které musíte vědět

Obsah

Údržba hydraulické drapáky u jeřábů je zásadní pro zajištění jejich normálního provozu a prodloužení životnosti zařízení. Hydraulické drapáky jsou při práci často náchylné k různým poruchám. Většina poruch hydraulických drapáků běžných hydraulických systémů jeřábů v zařízení je způsobena přehřátím hydraulického oleje, nasáváním vzduchu, znečištěním a únikem oleje. V důsledku poruchy hydraulického systému povede porucha hlavního systému přímo k selhání hlavního systému, což má za následek vážnější ekonomické ztráty. Proto je důležité analyzovat příčiny těchto poruch hydraulických drapáků a přijmout odpovídající preventivní opatření. Tento článek podrobně představí 4 běžné poruchy a způsoby jejich opravy.

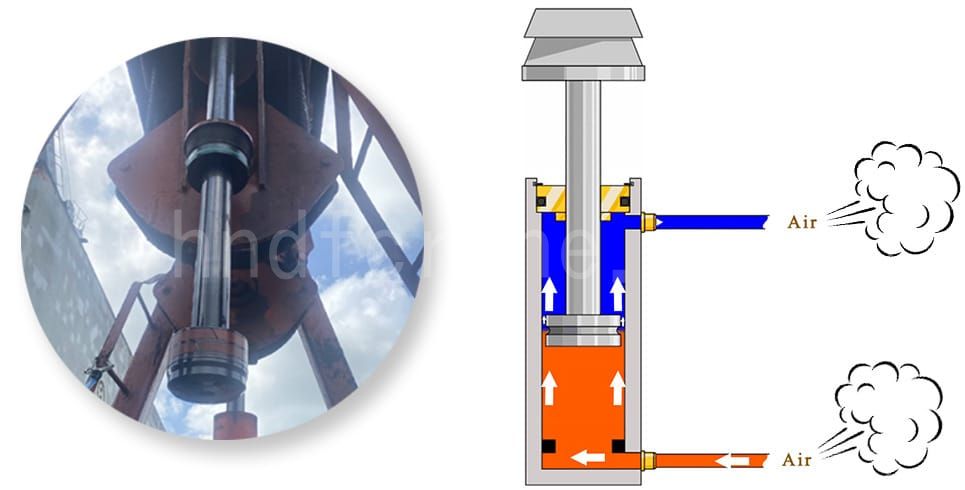

Selhání hydraulických drapáků 1: Do hydraulického systému se dostává vzduch

Způsobit hydraulické drapáky selhání:

- Poloha pístu hydraulického drapáku válce.

- Hydraulický válec hydraulických drapáků vibruje nebo dokonce vydává abnormální zvuky.

- Hydraulický válec hydraulických drapáků vytváří místní napětí a spékání.

- V důsledku toho středová osa hydraulického válce hydraulických drapáků není rovnoběžná s vodicí kolejnicí vodícího pouzdra a je zešikmená.

- Objemová účinnost hydraulického čerpadla hydraulických drapáků se snižuje, energetické ztráty se zvyšují a hydraulický systém nemůže uplatnit svou patřičnou účinnost.

- Tepelná vodivost hydraulického oleje v hydraulickém válci hydraulických drapáků se zhoršuje a teplota oleje stoupá, což způsobuje chemické změny.

| Důvod | Řešení |

| Vzduch je vdechován v důsledku uvolněných spojů nebo poškození olejových těsnění a těsnicích kroužků. | Každý spoj by měl být pevně připevněn a zajistit, aby byla palivová nádrž dobře utěsněna, aby se zabránilo vnikání vnějšího vzduchu, znečištění systému a současnému odsávání. |

| Potrubí absorbující olej a potrubí spojující systém jsou opotřebované, poškrábané nebo zkorodované, což způsobuje vnikání vzduchu. | Rozumně navrhnout strukturu hydraulického systému pro racionalizaci uspořádání potrubí. |

| Vzduchové bubliny vzniklé nepozorností při doplňování paliva jsou přiváděny do palivové nádrže a přimíchávány do systému. | Pro udržení čistoty potrubí a snížení vnější koroze je nutná úprava výfukových plynů. |

| V hydraulickém válci se mísí cizí předměty a vlhkost, což má za následek místní napětí a spékání. | Vnitřní stěnu válce je potřeba vyleštit a najít příčinu míchání cizích látek. |

| Nesprávná instalace hydraulického válce má za následek, že středová osa a vodicí lišta vodícího pouzdra nejsou rovnoběžné. | Nutno přeinstalovat. |

| Sportovní těsnění je příliš těsné. | Nutno upravit těsnění. |

| Píst a pístnice mají různé hřídele. | Nutno opravit podle návodu k instalaci. |

| Vodicí pouzdro a válec nejsou na stejné ose. | Nutno opravit podle návodu k instalaci. |

| Pístnice je ohnutá. | Chcete-li narovnat pístnici, musíte postupovat podle pokynů k instalaci. |

| Válcový stupeň vnitřního průměru válce je extrémně špatný. | Potřeba vyvrtat a vybrousit válec, znovu sladit píst. |

| Kluzná plocha dosedá příliš těsně nebo je povrch kartáčovaný. | Potřeba nabrousit kluznou plochu. |

| Pokud je těsnění pístu poškozeno, olej ve vysokotlaké komoře rychle stéká zpět do nízkotlaké komory a vydává zvuk „hučení“. | Je třeba vyměnit těsnění pístu. |

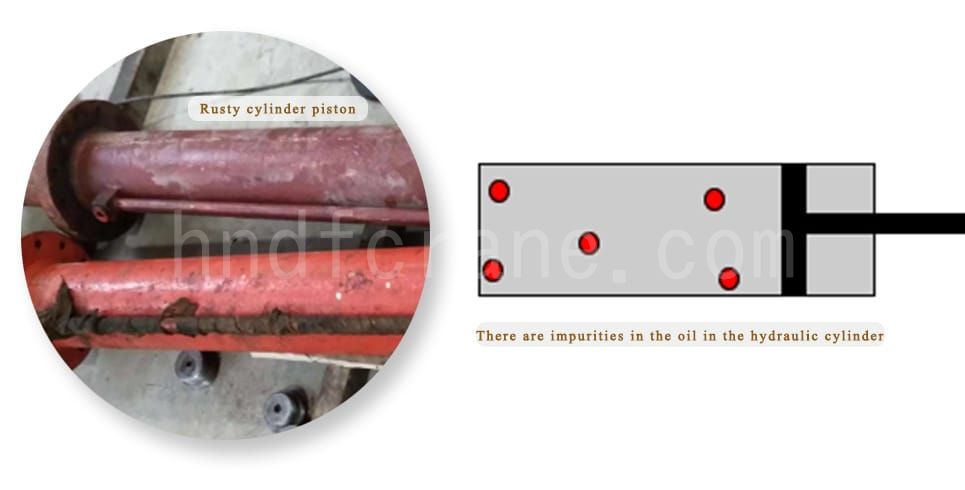

Selhání hydraulických drapáků 2: Znečištění hydraulického systému

Příčina selhání:

- Znečišťující látky ucpávají hydraulické součásti hydraulických drapáků dovnitř a ven z oleje nebo do mezer mezi nimi, což způsobí selhání pohybu, ovlivní pracovní výkon nebo způsobí nehody.

- Může také způsobit ucpání filtru a může způsobit, že filtr zcela ztratí svůj filtrační účinek, což způsobí začarovaný kruh hydraulického systému hydraulických drapáků.

- Hydraulický olej a voda hydraulických drapáků se mísí.

| Důvod | Řešení |

| V provozním prostředí je mnoho prachu a vnější povrch systému není čistý. | Pokud je hydraulický systém delší dobu v provozu na místě se silným prašným znečištěním, zkuste jednou za 2 měsíce přefiltrovat olej a přibližně za půl roku vyměňte vstupní olejový filtr. |

| Nečistoty se do systému dostávají během doplňování paliva, kontroly povrchu oleje a operací údržby. | Při údržbě dbejte na čistotu olejového válce a snažte se ji provádět v bezprašném prostředí. |

| Pokud je teplota příliš vysoká, hydraulický olej se znehodnotí. Pokud je teplota příliš vysoká, zrychlí se rychlost, při které se hydraulický olej zhorší. | Pokud k tomu dojde, elektrohydraulický drapák by měl být ochlazen. |

| Hydraulický olej a voda se mísí, a pokud je v hydraulickém systému voda, dojde k tomuto jevu. | Je třeba zkontrolovat těsnění hydraulického systému elektrohydraulického drapáku. |

| Pokud jsou v palivové nádrži elektrohydraulického drapáku nečistoty, dojde ke znečištění hydraulického oleje nečistotami a k jeho znehodnocení. | Včas kontrolujte a udržujte čisté prostředí v palivové nádrži a pravidelně kontrolujte. |

Selhání hydraulického drapáku 3: Únik oleje z hydraulického systému

Příčina selhání:

- Hydraulický válec hydraulických drapáků se může pohybovat, ale rychlost pohybu je příliš nízká.

- Jakmile dojde k vážnému úniku v hydraulickém systému hydraulických drapáků, tlak v systému bude nedostatečný, což způsobí, že se lopata nebude normálně otevírat a zavírat.

- Únik hydraulického oleje může také způsobit znečištění životního prostředí, ovlivnit výrobu a dokonce mít vážné následky, které nelze odhadnout.

| Důvod | Řešení |

| Brutální chod hydraulických komponentů v sestavě, nadměrná síla zdeformuje díly, zejména otlučením bloku válců a utěsněním příruby měděnými tyčemi atd. | Plná pozornost by měla být věnována návrhu a zpracování těsnících dílů v konstrukčních a zpracovatelských vazbách. Chcete-li zvolit správný způsob montáže. |

| Díly jsou poškozeny kolizí při práci, která poškrábe těsnicí prvek a způsobí netěsnost. | Vyberte si správné těsnění, abyste prodloužili dobu jeho stárnutí. Věnujte pozornost ochraně těsnění, aby nedošlo k jeho poškrábání jinými díly. |

| V provozním prostředí je prach a nečistoty a pokud není zvoleno vhodné prachotěsné těsnění, dochází k úniku. | Při výběru a návrhu těsnění zvažte kompatibilní typ hydraulického oleje a těsnícího materiálu, podmínky zatížení, pracovní rychlost, změny okolní teploty atd. a zvolte vhodná těsnění a vhodná těsnění odolná proti prachu. |

| Části jsou zdeformované nebo poškozené. | Nutno opravit nebo přímo vyměnit. |

| Přívod oleje hydraulického čerpadla je nedostatečný, což způsobuje, že tlak nestoupá. | Odstraňování závad hydraulického čerpadla. |

| Způsobeno nadměrným únikem systému. | Zkontrolujte těsnost každé součásti a potrubí. |

| Ve válci jsou dutiny tyčí a dutiny bez pístnice, to znamená, že část tlakového oleje ve vysokotlaké komoře uniká z těsnění pístu do nízkotlaké komory. | Je třeba vyměnit sestavu těsnění pístu. |

| Válec nebo píst olejového válce je příliš opotřebovaný. | Je třeba zvážit, zda jej nabrousit nebo rovnou vyměnit. |

Čtyři způsoby úniku hydraulického systému

- Únik mezery:Existují dva hlavní typy úniku mezery v hydraulickém systému stavebních strojů, únik na pevném těsnění (statický povrch spoje) a netěsnost na pohyblivém těsnění (povrch dynamického spoje). Mezi netěsné části pevného těsnění patří především spoj mezi hlavou válce hydraulického válce a válcem; pohybové těsnění obsahuje hlavně píst hydraulického válce a vnitřní stěnu válce válce, mezi pístnicí a vodicí objímkou hlavy válce. Velikost úniku mezery souvisí s faktory, jako je tlakový rozdíl a mezera.

- Porézní únik:Různé krycí desky v hydraulických součástech, kvůli vlivu drsnosti povrchu není možné plně se dotýkat obou povrchů. V mikroskopických prohlubních, kde se dva povrchy nedotýkají, se tvoří mnoho dutin různých tvarů průřezu a různých velikostí. Velikost průřezu dutin souvisí s drsností povrchu. Uniká více dutin a kapalina musí protékat mnoha zakřivenými dutinami. Během testu těsnícího výkonu trvá určitou dobu zdržení, než může být odhalena netěsnost.

- Únik úponu hlenu:Mezi viskózní kapalinou a pevným ramenem existuje určitá adheze. Poté, co se oba dostanou do kontaktu, na pevném povrchu přilne tenká vrstva kapaliny. Pokud je film na pevném povrchu silnější, dojde k seškrábnutí olejového filmu těsnicím kroužkem v důsledku vzájemného pohybu. Netěsnost adheze. Základním způsobem, jak zabránit úniku adheze, je kontrola tloušťky vrstvy adheze kapaliny.

- Únik proudu:Pokud jsou na utěsněném povrchu rotujícího hřídele stopy po spirálovém zpracování, když se hřídel otáčí, kapalina proudí podél drážky spirálové stopy působením rotační síly rotujícího hřídele. Pokud je směr spirálové dráhy konzistentní se směrem otáčení hřídele, dojde k úniku energie v důsledku účinku „čerpadlového oleje“ spirálové dráhy. Charakteristickým rysem úniku energie je, že čím vyšší je rychlost hřídele, tím větší je únik. Aby se zabránilo úniku energie, je třeba se vyvarovat přítomnosti stop zpracování „čerpadlového oleje“ na těsnicím povrchu hřídele a břitu těsnicího kroužku, nebo by se měl použít princip úniku energie a účinek čerpání oleje spirálových stop by měl být použit k čerpání uniklého oleje zpět, aby se zabránilo úniku.

Pokud jde o metodu úniku, můžete se dozvědět více v tomto článku:Únik a jeho účinky v různých hydraulicky poháněných systémech

Selhání hydraulických drapáků 4: Přehřátí hydraulického oleje

Způsobit selhání

- Viskozita hydraulického oleje a pracovní účinnost hydraulického systému se snížily a dokonce ani stroje a zařízení nemohou v těžkých případech správně fungovat.

| Důvod | Řešení |

| Okolní teplota je příliš vysoká a vysoké zatížení se používá po dlouhou dobu, což způsobí příliš vysokou teplotu oleje. | Je třeba se vyvarovat dlouhodobého nepřetržitého provozu a vysokého zatížení. Pokud je teplota oleje příliš vysoká, zařízení může být nějakou dobu provozováno bez zatížení a poté pracovat po poklesu teploty oleje. |

| Výkon odvádění tepla palivové nádrže je špatný, což způsobuje, že teplota oleje v palivové nádrži je příliš vysoká. | Objem palivové nádrže, tedy plocha pro odvod tepla, by se měl zvětšit a mělo by být instalováno zařízení na chlazení oleje. |

| Nesprávný výběr hydraulického oleje, kvalita a stupeň viskozity oleje nesplňují požadavky nebo smíchání různých druhů hydraulického oleje způsobuje příliš nízkou nebo příliš vysokou viskozitu hydraulického oleje. | Vybírejte hydraulické oleje, které splňují normy, a nemíchejte dvě značky hydraulických olejů. |

| Prostředí staveniště je drsné. Se zvyšující se pracovní dobou drapákového jeřábu se olej snadno mísí s nečistotami a nečistotami. Znečištěný hydraulický olej se dostane do spáry čerpadla, motoru a ventilu, což poškrábe a zničí přesnost a drsnost spojovacího povrchu, což způsobí zvýšení úniku a zvýšení teploty oleje. | Drapák pravidelně repasujte, včas vyměňte nový hydraulický olej a udržujte olej v hydraulickém válci čistý. |

Pochopení běžných poruch těchto 4 hydraulických drapáků vám může nejen pomoci rychle reagovat, když se vyskytnou problémy, ale co je důležitější, může zajistit bezpečnost a efektivitu provozu. Pravidelnou údržbou a včasným řešením těchto problémů můžete prodloužit životnost vašeho zařízení, snížit prostoje a zvýšit produktivitu.

Pokud se chcete dozvědět více o tom, jak optimalizovat výkon drapákových jeřábů nebo potřebujete profesionální opravy a údržbu, okamžitě nás kontaktujte. Dovolte nám, abychom vám pomohli udržet váš nezbytný doplněk v nejlepším stavu a zajistili hladký chod vašeho podnikání!

Pošlete svůj dotaz

- E-mailem: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Přidat: Changnao Industrial District, Xinxiang City, provincie Henan, Čína