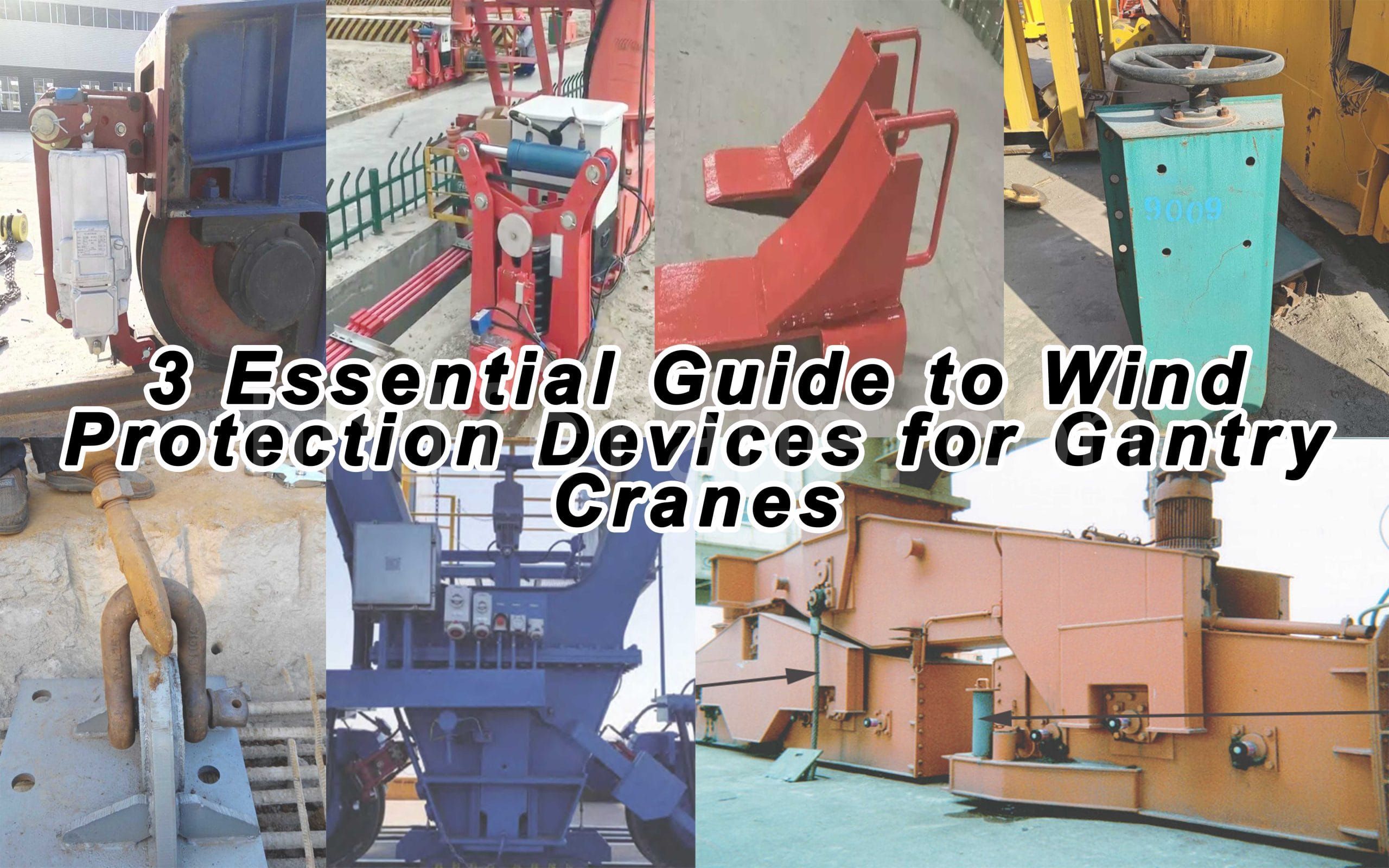

Portálové jeřáby Zařízení na ochranu před větrem: 3 základní průvodce typy, instalací a nejlepšími bezpečnostními postupy

Obsah

Portálové jeřáby Zařízení na ochranu proti větru hrají zásadní roli při zajišťování stability a bezpečnosti velkotonážních portálových jeřábů za různých povětrnostních podmínek. Důležitým faktorem, který je třeba vzít v úvahu, je vliv silného větru. Venkovní portálové jeřáby jsou základním vybavením používaným v přístavech, kontejnerových skladech a loděnicích. Hrají klíčovou roli při nakládání, vykládání a přepravě těžkých materiálů, kontejnerů a lodí. Provozování těchto jeřábů v nepříznivých povětrnostních podmínkách, jako jsou bouře, tajfuny a silný vítr, však může představovat velké problémy. Pro zajištění bezpečnosti pracovníků a strojů jsou proto portálové jeřáby instalovány na venkovních portálových jeřábech zařízení na ochranu proti větru. Při nesprávném zacházení mohou způsobit vážná rizika. Pro řešení tohoto problému jsou nezbytná zařízení na ochranu proti větru portálových jeřábů. Tento článek podrobně představuje tři hlavní portálové jeřáby na ochranu proti větru, jejich typy, správná místa instalace a klíčová bezpečnostní opatření. Pochopením a používáním tohoto zařízení můžete zlepšit bezpečnost a efektivitu provozu jeřábu a chránit zařízení a personál.

1. Co je to portálové jeřáby zařízení na ochranu proti větru?

Zařízení na ochranu proti větru portálových jeřábů zahrnuje dynamickou a statickou odolnost proti větru. To se rozlišuje podle toho, zda je jeřáb funkční. Když jeřáb nepracuje, je staticky odolný proti větru a zařízení na ochranu proti větru portálových jeřábů, která se mají provádět během práce, jsou dynamicky odolná proti větru. Během provozu jeřábu pracují všechny stroje, zařízení a operátoři a současně na ně působí síly větru. Jakmile tedy dojde k poškození větrem, přinese nepředvídatelné výsledky. To je důvod, proč je dynamická izolace proti větru naléhavější a důležitější než ochrana proti statickému větru. Při provádění větrotěsných prací je nutné chápat dynamickou větruodolnost z ideologického hlediska. Kombinujte, abyste zajistili bezpečnost výroby podnikového vybavení, monzunové charakteristiky přístavu a pobřežních oblastí, výkon zařízení odolného proti větru a hydraulická zařízení terminálu, abyste určili úroveň větruodolnosti jeřábu.

Jaká jsou zařízení na ochranu proti větru portálových jeřábů?

Svorkové portálové jeřáby zařízení na ochranu proti větru (kolejnicová svorka):

Zařízení na ochranu před větrem u tohoto portálového jeřábu používá svorky k upnutí obou stran dráhy, aby se zvýšilo tření dráhy, čímž se zabrání posunutí jeřábu. Tento druh portálových jeřábů proti větru se také nazývá kolejnicová svorka. Pro zlepšení stupně utažení upnutí se často používá k návrhu konstrukce páky. Existují následující běžné typy: typ ručního šroubu, typ hydraulické pružiny, typ elektrického šroubu a typ elektrického kladiva. Tyto čtyři typy.

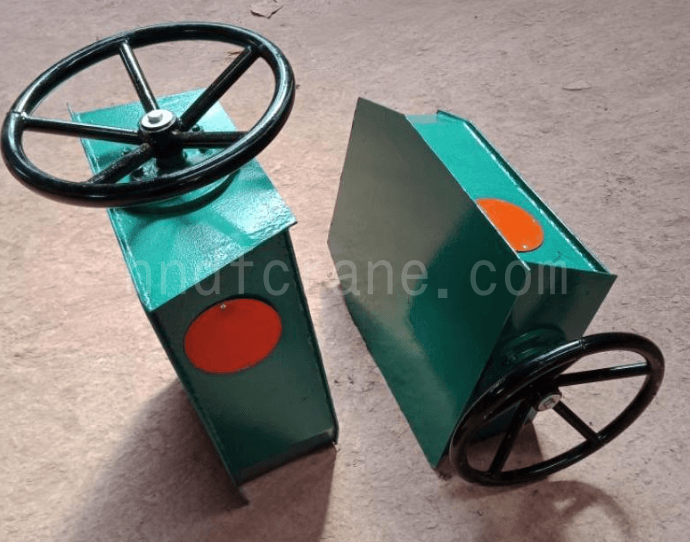

Ruční otočná kolejnicová svorka

Běžnější zařízení pro upínání kolejnic dosahuje těsnosti modulu upínání kolejnic ručním otáčením volantu. Nevýhodou je, že chybí elektrická ochrana řetězu, což obsluze usnadňuje obsluhu portálového jeřábu bez jeho uvolnění.

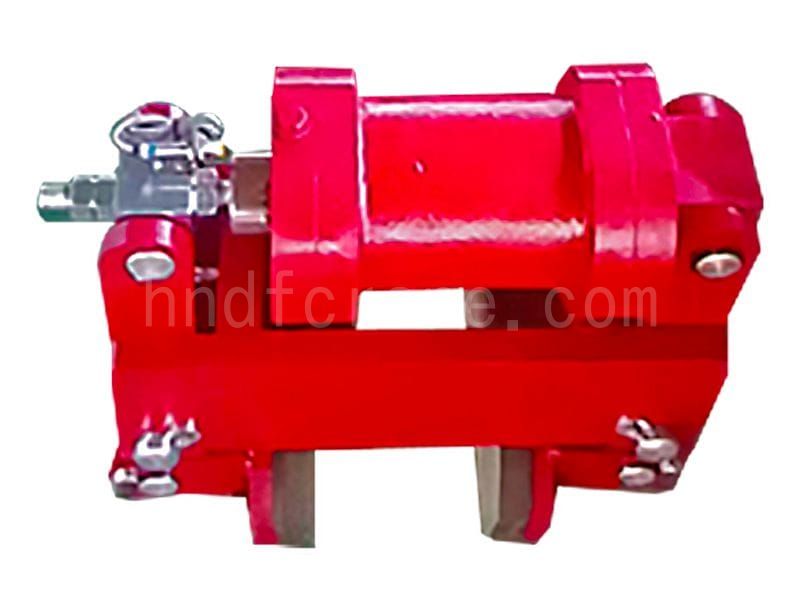

Elektrohydraulická kolejnicová svorka (typ s hydraulickou pružinou)

Výhody: Elektrický provoz šetří čas a námahu, má elektrickou blokovací ochranu, nelze jej ovládat bez uvolnění portálového jeřábu, krásný a bezpečný;

Nevýhody: Vysoká cena

Ruční svorka třmenové lišty

Elektrická kolejnicová svorka

Porovnání nákladů: ruční svěrka třmenové lišty

Větruodolné zařízení typu železné boty a větruodolné zařízení typu tlakové lišty

Větruodolná železná klínová brzda

Mezi koly a pásy je vražen kovový klín, aby se zabránilo pohybu jeřábu vzad vlivem větru. Když se kola otáčejí, síla vyvíjená na klín způsobí, že se valivé tření mezi koly a pásy přemění na kluzné tření mezi klínem a pásy. S rostoucím odporem slouží jako větruvzdorný efekt. Toto zařízení lze rozdělit na ruční a elektrické typy.

Toto zařízení využívá hmotnost samotného jeřábu působící na pásy ke zvýšení tření mezi koly a pásy, aby se zabránilo pohybu jeřábu. Protivětrné zařízení při stlačení dráhy není ovlivněno stranou dráhy a má lepší použitelnost než upínací typ. Toto zařízení proti větru však může poskytovat pouze omezený výkon proti větru a často se používá ve spojení s jinými zařízeními proti větru.

Jiné systémy větrolamu

Větrné lano

Drátěné lano nebo lano ze syntetických vláken používané k zajištění konce portálového jeřábu pro zlepšení odolnosti zařízení proti větru. Průměr větrného lana musí odpovídat požadavkům na typ a použití jeřábu a nesmí být menší než minimální průměr ocelového lana. Kotevní konec větrného lana by měl být pevně upevněn na konci portálového jeřábu nebo nosné konstrukci, aby se zajistilo, že při maximálním větru nedojde k žádnému posunutí a pádu.

Jeřábový anemometr

Alarm rychlosti větru. Namontováno na jeřábu pracujícím pod širým nebem.

Když je vítr větší než 6, lze vyslat poplachový signál a zobrazit okamžitou rychlost větru.

Jeřáby pracující na pobřeží lze nastavit tak, aby vysílaly poplašné signály, když je vítr vyšší než úroveň 7.

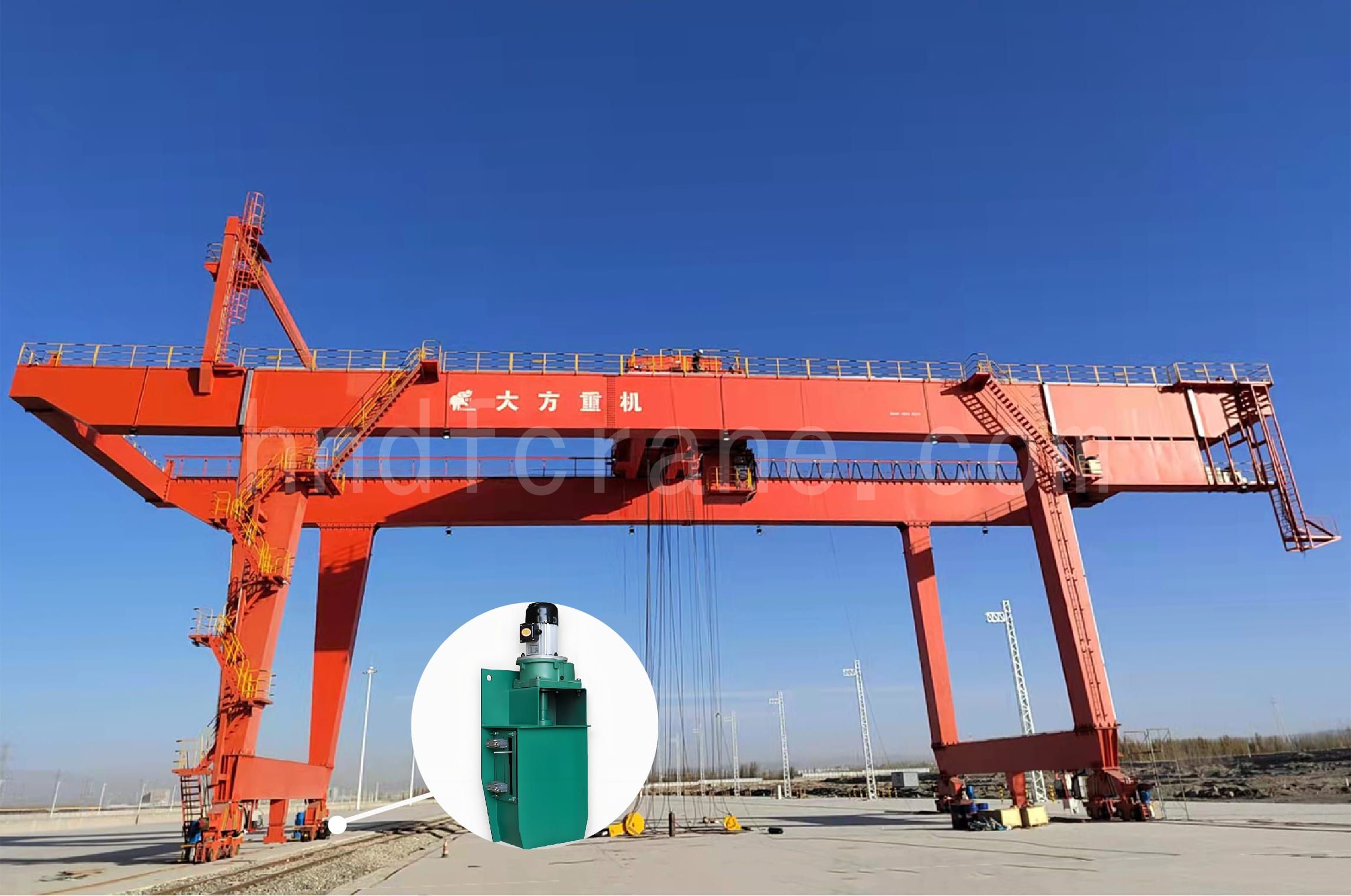

Kotevní zařízení odolné proti větru

Jedná se o běžně používané preventivní zařízení na ochranu proti větru portálových jeřábů. V případě příjmu varovného signálu větru nebo při jeho dlouhodobém nepoužívání se kotevní portálové jeřáby používají zařízení na ochranu proti větru, aby bylo dosaženo efektu větruodolnosti a protiskluznosti. Zařízení na ochranu proti větru kotevních portálových jeřábů vyžaduje, aby se jeřáb, který se v současné době nepoužívá, přemístil do předem určené polohy a jeřáb byl upevněn blokovacími částmi, jako jsou šrouby a vyhazovací tyče. Venkovní portálové jeřáby musí často čelit přírodním bouřím a jiným katastrofám. Spolehlivý kotevní systém dokáže bezpečně upevnit celou konstrukci jeřábu na staveništi, čímž zabrání převrácení jeřábu a zabrání velkým nehodám a ztrátám na životech a majetku.

Velkotonážní portálový jeřáb s integrovaným kotvícím větrným samosvorným protišplhacím zařízením

Schéma kotevního systému pro portálový jeřáb s malou tonáží

2. Kde je montážní poloha zařízení na ochranu proti větru portálových jeřábů?

Ruční otočná kolejnicová svorka

Instaluje se na vnější stranu čtyř rohů dveřního stroje. Obvykle je portálový jeřáb instalován se 4 ručními otočnými kolejnicovými svorkami.

Elektrohydraulická kolejnicová svorka (typ s hydraulickou pružinou)

Nainstalované na vnější straně čtyř rohů dveřního stroje, obvykle portálový jeřáb nainstalovaný 4 elektrohydraulické kolejnicové svorky (typ s hydraulickou pružinou)

Ruční svorka třmenové lišty

Portálový jeřáb instalovaný na vnější straně čtyř rohů dveřního stroje obvykle instaloval 4 ruční svorky třmenové kolejnice.

Elektrická kolejnicová svorka

Portálový jeřáb instalovaný na vnější straně čtyř rohů dveřního stroje obvykle instaloval 4 elektrické kolejnicové svorky.

Větruodolná železná klínová brzda

Může být instalován uvnitř i vně nohy portálového jeřábu. Podle síly větru pracovního prostředí se rozhoduje o několika větruodolných železných klínových brzdách

Boční brzda kola

Může být instalován uvnitř a vně nohy portálového jeřábu a stisknout boční brzdu několika kol podle síly větru v pracovním prostředí na místě.

Větrné lano

Nainstalujte jej doprostřed spodního nosníku portálového jeřábu.

Jeřábový anemometr

Instaluje se na horní nosník portálového jeřábu pro detekci síly větru.

Kotevní systém

Instaluje se uprostřed spodního nosníku portálového jeřábu.

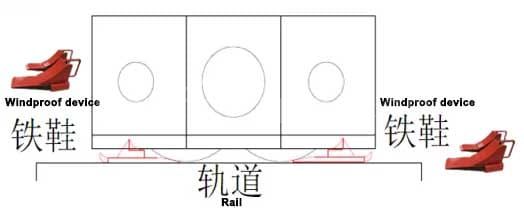

3. Opatření proti větru portálových jeřábů

Po použití portálového jeřábu, protože zapuštěná dráha v poli nosníku má určitý jednosměrný sklon, aby se zabránilo náhodnému sklouznutí portálového jeřábu, když se nepoužívá, lze na přední a zadní stranu čtyř skupin pochozích kol portálového jeřábu umístit „železné boty“. Schematický diagram „železných bot“ každého vycházkového kola je znázorněn na obrázku:

Do letního větru a jiného špatného počasí na práci portálového jeřábu pod širým nebem je poškození vážnější, zde používáme u portálových jeřábů opatření na ochranu proti větru, abychom provedli jednoduchý úvod, tradiční opatření proti větru jsou následující: kolejnicová svorka, svršek kolejnice, železné boty a kotvící zařízení několik, následující podrobnosti o kotvícím zařízení proti větru. Aby bylo možné účinně zabránit portálovému jeřábu při tajfunech, silném dešti a jiném špatném počasí, převrácení, poškození a dalším bezpečnostním nehodám, byl speciálně formulován program zesílení portálového jeřábu proti tajfunu.

Za normálních okolností zesílení (vítr není větší než šest)

(1) Portálový jeřáb se po každém použití zastaví v pevné poloze mola 9-10#, walkinsky carstop se zastaví v blízkosti nohy portálového jeřábu a kladkostroj je umístěn 3 metry nad zemí a upevněn lanem.

(2) Portálový jeřáb je upevněn protiskluzovými železnými botkami a obě strany nohou jsou ukotveny na betonovém kotevním ingotu pomocí lanového navíjecího lana p19,5. Při kotvení lanového navíjecího lana je aplikováno 5 tun obráceného řetězu pro utažení kabelového navíjecího lana. Je navrženo celkem 8 lanových navíjecích lan a Úhel mezi navíjecím lanem a zemí je asi 45 stupňů.

Posilující opatření před tajfunem

(1) Před tajfunem by měl být portálový jeřáb zvednut na konec mola8 tak, aby levá strana připevněné nohy k portálovému jeřábu byla v blízkosti betonu křídlové desky skříňového nosníku nájezdového mostu u pilíře 8 a 14kanálová ocel byla připojena k zapuštěné ocelové tyči skříňového nosníku.

(2) Závěsný nosník portálového jeřábu a podpěrná noha jsou na nosníku skříňového nájezdového mostu ukotveny na jedné straně lanovým navíjecím lanem p19,5 a na druhé straně na betonové zemní kotvě mimo pilíř č. 9. Obě jsou utaženy 10 tunami obráceného řetězu. Je navrženo celkem 8 lanových navíjecích lan (jedno na každé straně nosné nohy) a jsou spojeny dva ocelové úseky.

Nastavení kotevního ingotu a navíjecího lana kabelu

Kotevní ingot je zalit betonem C15. Dno kotevního ingotu je 1,5 metru široké, 2,5 metru dlouhé a 2 metry vysoké a váží asi 18 tun. Tři 2,5 metru dlouhé pražce jsou zapuštěny do kotevního ingotového betonu a spojeny se zemí přes jednolibrové lano. Lanové navíjecí lano je drátěné lano p19.5, jeden konec ocelového lana je upevněn na noze portálového jeřábu, druhá strana je spojena s obráceným řetězem a cívku navíjení kabelu lze odstranit na nosníku portálového jeřábu, když portálový jeřáb chodí.

Kotevní zařízení

Kotevní zařízení se vyznačuje jednoduchou konstrukcí, nízkou hmotností, vysokou spolehlivostí a pohodlnou obsluhou. Kotevní zařízení obvykle používá tuhé spojení. Přesto může také používat flexibilní spojení, jako je například drátěné lano nebo řetěz ke spojení zemního ukotvení. Teprve po pohybu jeřábu hraje roli napětí ocelového lana. Protože však existuje určitá kinetická energie, když jeřáb běží, má jeřáb stále možnost převrácení. Proto je naším primárním hlediskem pevné spojení, pokud ne pevné spojení, měli byste zvýšit napínací zařízení v ocelovém laně nebo řetězu, utáhnout ocelové lano nebo řetěz. Zabraňte nadměrné nárazové hybnosti způsobené jeřábem urychleným větrem. Kotevní zařízení obecně ukotví jeřáb jako celek před předpovědí tajfunu a tato metoda je relativně bezpečná.

Pošlete svůj dotaz

- E-mailem: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Přidat: Changnao Industrial District, Xinxiang City, provincie Henan, Čína