Let portalkran: typer og funktioner

Lette portalkraner er alsidige og effektive løfteanordninger, der bruges i forskellige industrier til at håndtere byrder med lethed. Disse kraner er designet til at give en omkostningseffektiv løsning til løft og flytning af lettere byrder i en lang række miljøer. I denne artikel vil vi udforske de forskellige typer af lette portalkraner, deres funktioner, applikationer og sikkerhedsdriftsspecifikationer.

Typer af lette portalkraner

Der findes forskellige typer lette portalkraner på markedet:

Enkeltbjælke portalkran

Den enkeltstrålende portalkran er et populært valg til lette løfteoperationer. Den består af en enkelt vandret bjælke understøttet af to lodrette ben, der enten kan være faste eller justerbare. Denne type kran tilbyder fremragende manøvredygtighed og er velegnet til applikationer, hvor pladsen er begrænset. De enkeltbjælke portalkran bruges ofte i værksteder, lagre og små produktionsfaciliteter.

Semi portalkran

Det semi portalkran kombinerer funktionerne fra en traverskran og en portalkran. Den har den ene ende understøttet af en struktur, såsom en væg eller søjle, mens den anden ende fungerer på hjul eller skinner. Dette design giver mulighed for effektiv materialehåndtering i områder, hvor en komplet portalkranopsætning ikke er påkrævet. Den semi-portalkran er almindeligt anvendt på skibsværfter, byggepladser og udendørs lagerværfter.

- Kapacitet: op til 10t

- Spændvidde: op til 20m

- Vagtgruppe: A3-A5

- Arbejdsmiljøtemperatur: -25°C〜+50°C, relativ luftfugtighed ≤95%

Justerbar portalkran

Det højdejusterbar portalkran giver fleksibilitet til at justere løftehøjden efter specifikke krav. Den er udstyret med et hydraulisk eller mekanisk system, der gør det muligt at hæve eller sænke de lodrette ben. Denne funktion gør den ideel til applikationer, hvor der er behov for forskellige løftehøjder, eller når der arbejdes i områder med ujævnt terræn.

- Kapacitet: Op til 10t

- Spændvidde: Op til 10m

- Vagtgruppe: A3-A5

- Arbejdsmiljøtemperatur: -25°C〜+50°C, relativ luftfugtighed ≤95%

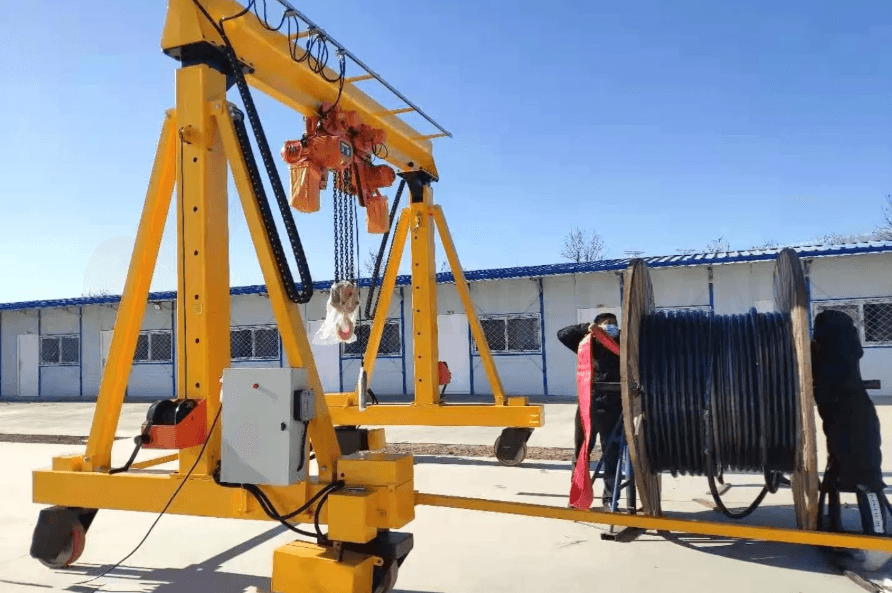

Bærbar portalkran

Det bærbar portalkran er designet til nem transport og hurtig montering. Den er typisk lavet af letvægtsmaterialer som aluminium eller stål og kan skilles ad til kompakte dele. Denne type kran er meget udbredt i udendørs omgivelser, byggepladser og vedligeholdelsesoperationer, hvor mobilitet er afgørende. Den bærbare portalkran giver bekvemmeligheden ved løft på stedet uden behov for permanent installation.

- Kapacitet: op til 10t

- Spændvidde: op til 10m

- Vagtgruppe: A3-A5

- Arbejdsmiljøtemperatur: -25°C〜+50°C, relativ luftfugtighed ≤95%

Funktioner af lette portalkraner

Lette portalkraner kommer med flere funktioner, der forbedrer deres anvendelighed og effektivitet:

Let og kompakt design

I modsætning til tunge kraner, der kræver betydelig infrastruktur og støtte, er disse kraner konstrueret til at være mere bærbare og adrætte. Deres lette vægt gør dem nemmere at flytte rundt på arbejdspladsen.

Det kompakte design af lette portalkraner gør det muligt for dem at passe ind i trange rum, hvor større kraner kan have svært ved at fungere effektivt. Denne funktion gør dem til et ideelt valg til værksteder, varehuse, byggepladser og små produktionsfaciliteter. På trods af deres mindre størrelse bevarer de evnen til at udføre vigtige løfteopgaver med lethed.

Nem montering og adskillelse

Enkelheden ved at samle og adskille lette portalkraner er en anden bemærkelsesværdig egenskab, der gør dem yderst bekvemme. Disse kraner er designet med brugervenlige komponenter og mekanismer, hvilket giver mulighed for hurtig opsætning og demontering uden at kræve specialværktøj eller ekspertise. Denne funktion sparer ikke kun tid, men gør det også muligt for virksomheder at optimere deres ressourcer effektivt.

Alsidighed og mobilitet

Lette portalkraner er meget alsidige, hvilket giver mulighed for en bred vifte af anvendelser. De kan bruges indendørs eller udendørs og er velegnede til at løfte forskellige typer materialer, herunder maskiner, udstyr og råmaterialer.

Omkostningseffektiv løsning

Ud over deres funktionelle fordele tilbyder lette portalkraner en omkostningseffektiv løsning for virksomheder. Deres lette konstruktion resulterer i reducerede materialeomkostninger, mens den lette montering og demontering eliminerer behovet for at ansætte specialiseret personale eller investere i dyrt udstyr. Desuden bidrager alsidigheden og mobiliteten af disse kraner til øget produktivitet, minimerer nedetid og maksimerer driftseffektiviteten.

Anvendelser af lette portalkraner

Lette portalkraner finder anvendelse i forskellige industrier og arbejdsmiljøer. Nogle almindelige applikationer omfatter:

- Pakhuse og lagerfaciliteter: Portalkraner bruges almindeligvis i lagre og lagerfaciliteter til at flytte tunge genstande, såsom paller, kasser og maskinkomponenter. Deres mobilitet og alsidighed muliggør effektive læsse- og aflæsningsoperationer.

- Værksteder og produktionsanlæg: I værksteder og produktionsanlæg bruges lette portalkraner til at løfte og transportere materialer under produktionsprocesser. De kan nemt manøvreres til at understøtte forskellige arbejdsstationer, hvilket sikrer problemfri arbejdsgang.

- Byggepladser: Byggepladser kræver ofte flytning af tunge byggematerialer og udstyr. Lette portalkraner tilbyder en praktisk løsning til at løfte og placere last i udfordrende miljøer.

- Vedligeholdelsesoperationer: Lette portalkraner bruges i vedligeholdelsesoperationer til at løfte og transportere maskiner, reservedele og andet udstyr.

Sikkerhedsdriftsspecifikationer for lette portalkraner

For at sikre sikker drift og forebygge ulykker skal visse specifikationer følges ved brug af lette portalkraner. Her er nogle vigtige sikkerhedsforanstaltninger:

- Kranføreren skal være uddannet før betjening af kranerne.

- Overbelastningsløft er forbudt, sideløft af ståltov er forbudt.

- Sluk under stokinspektion og vedligeholdelse.

- Krogen skal være over menneskehøjde, når kranen kører uden last.

- Belastningen skal være mindst 0,5 m højere end forhindringerne på kranens vej

løb. - Smid ikke noget fra kranen.

- Last er forbudt at bevæge sig over mennesket.

- Det er forbudt at løfte mennesker.

- Brandfarlige materialer er forbudt at sætte på kranen.

- Udendørskran bør ikke fungere, hvis vinden er større end grad 6.

- Værktøj, reservedele bør ikke sættes på krankonstruktionen i tilfælde af at den falder ned.

- Ståltov skal kontrolleres under hvert skift, detaljeret inspektion hver 7.-10

dage. - Sikkerhedsteknisk inspektion bør udføres hvert år.

Ofte stillede spørgsmål

- Hvad er en let portalkran?

En let portalkran er en type løfteudstyr designet til relativt lettere belastninger. - Hvad er anvendelsesområdet for lette portalkraner?

De bruges almindeligvis i lagre og værksteder til lastning og losning af varer. Derudover kan de findes i produktionsfaciliteter for at hjælpe i produktionsprocessen. - Hvordan sikrer jeg sikker drift af en let portalkran?

For at sikre sikker drift er det afgørende at give operatører ordentlig træning og certificering. Der bør udføres regelmæssige udstyrsinspektioner for at identificere potentielle problemer, der kan påvirke sikkerheden. Operatører skal også tage hensyn til kravene til lastkapacitet og stabilitet og til enhver tid følge sikker løftepraksis. - Kan en let portalkran nemt transporteres?

Ja, en af de bemærkelsesværdige egenskaber ved lette portalkraner er deres lette montering, adskillelse og transport. Disse kraner er designet med lette og kompakte funktioner, der giver mulighed for bekvem bevægelse mellem forskellige arbejdsområder. Denne mobilitet bidrager til deres overordnede alsidighed og brugervenlighed.

Send din forespørgsel

- E-mail: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tlf.: +86-373-581 8299

- Fax: +86-373-215 7000

- Tilføj: Changnao Industrial District, Xinxiang City, Henan-provinsen, Kina