360-Grad-Auslegerkran: Unverzichtbares Werkzeug zur Effizienzsteigerung

In today’s fast-paced industrial environment, optimizing efficiency is crucial for businesses to stay competitive. One tool that has proven to be essential in achieving this goal is the 360 degree jib crane. This article explores the type, benefits, highlighting its role as an indispensable tool for improving efficiency.

What Is a 360 Degree Jib Crane?

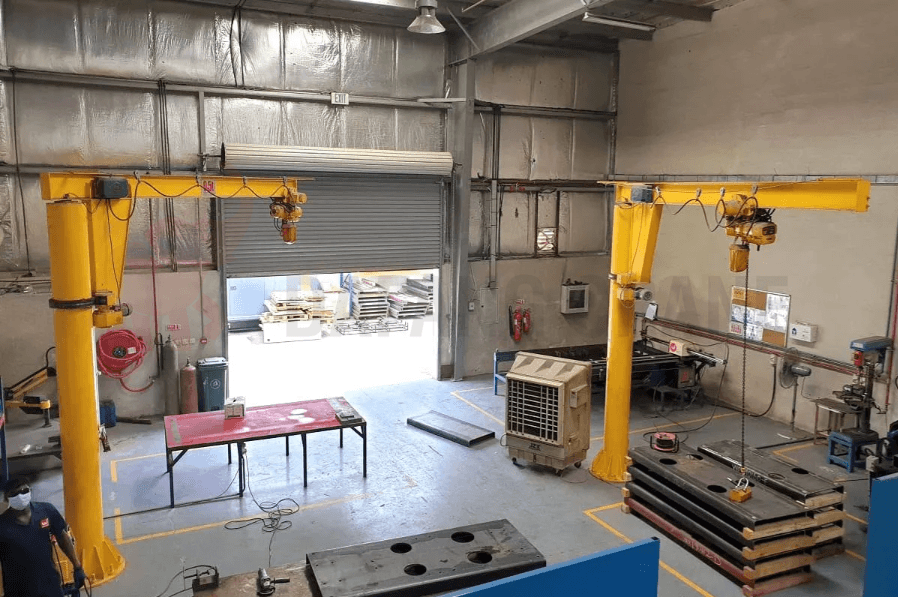

A 360 degree jib crane is a type of material handling equipment designed to lift, move, and position heavy loads within a specific radius. Unlike traditional cranes that have limited movement capabilities, a 360-degree jib crane offers complete rotation, allowing for precise and efficient load handling in any direction.

Types of 360 Degree Jib Cranes

There are three main types of 360 degree jib cranes: BZ Type Jib Crane, BZZ Heavy-Duty Jib Crane, and mobile floor jib crane.

Auslegerkran vom Typ BZ

BZ type jib crane consists of column, swing arm, cantilever drive device and electric hoist. The base of the lower end of the column is fixed on the concrete foundation by anchor bolts, the motor drives the reducer drive device to make the cantilever rotate, and the electric hoist runs back and forth on the cantilever I-beam.

BZ type cantilever crane has the characteristics of a simple structure, convenient operation, small occupation space and large working range. Widely used for material hoisting operations in machinery manufacturing, automobile, shipbuilding and other modern industrial production lines, assembly lines and in warehouses, docks, laboratories and other occasions. It is an ideal lifting equipment for enterprises to improve efficiency and improve working conditions.

BZZ Heavy-Duty Jib Crane

BZZ heavy-duty jib crane is an extension product of free standing column jib crane. This model adopts slewing bearing and variable section arm structure, the lifting height is 2.5-6m, and the rotation radius is 7-12m. In operation mode, users can choose pendant control or wireless remote control. This model is suitable for material hoisting operations in metallurgy, railway, wharf and machinery manufacturing industries. It can replace bridge cranes and gantry cranes on many occasions, with low investment and high efficiency.

Mobile Floor Jib Crane

This type of jib crane mounted on a wheeled base, can run to the desired place in any direction. The mobile design eliminates the need for a fixed installation, the electric hoist can walk on the pillar, which is suitable for the occasion where the heavy object needs to walk and rotate. The Mobile Floor Jib Crane is characterized by simple structure, convenient operation, flexible operation, large operation space and wide application range, commonly used in maintenance workshops, and loading docks.

Benefits of Using a 360 Degree Jib Crane

Verbesserte Effizienz

A 360-degree jib crane significantly improves operational efficiency by streamlining material handling processes. With its ability to rotate a full 360 degrees, it provides unrestricted access to various work areas within its radius. This means that workers can easily position loads precisely, reducing the time and effort required for manual lifting and transporting heavy objects. By minimizing downtime and increasing productivity, businesses can achieve higher output levels and meet project deadlines more effectively.

Platzsparend

Limited floor space is a common challenge in many industrial settings. A 360-degree jib crane offers an effective solution by maximizing the use of available space. Unlike larger overhead cranes, jib cranes are compact and can be installed in areas with restricted headroom or narrow aisles. By utilizing vertical space instead of valuable floor space, businesses can optimize their layout and create more efficient workflows. This space-saving feature is particularly beneficial for small to medium-sized enterprises looking to maximize their operational capacity.

Erhöhte Sicherheit

Safety is a top priority in any workplace, especially when dealing with heavy loads. A 360-degree jib crane offers several safety features that mitigate risks and protect workers. The crane’s design allows for precise control during lifting and lowering operations, minimizing the chances of accidents or damage to goods. Additionally, many models come equipped with advanced safety mechanisms such as overload protection systems and emergency stop buttons, further ensuring the well-being of personnel and preventing equipment failure.

Versatility and Flexibility

One of the key advantages of a 360-degree jib crane is its versatility and flexibility. These cranes can be customized to suit specific requirements, making them suitable for a wide range of industries and applications. Whether you need to lift heavy machinery, transport materials across different workstations, or load/unload trucks, a jib crane can adapt to various tasks. Its ability to rotate horizontally and vertically enables operators to reach tight spaces and maneuver loads with precision, enhancing overall operational flexibility.

How to Optimize Efficiency with a 360 Degree Jib Crane

Integration with Other Equipment and Processes

Efficiency can be further enhanced by integrating the 360-degree jib crane with other equipment and processes within the material handling system. By streamlining workflows and eliminating unnecessary steps, companies can achieve smoother operations and increased productivity.

For instance, integrating the jib crane with automated systems or conveyor belts allows for seamless transfer of materials, reducing manual handling and minimizing the risk of errors. Furthermore, incorporating advanced technologies like sensors and remote monitoring systems enables real-time data collection, facilitating better decision-making and optimizing resource allocation.

Moreover, considering the specific requirements of the workspace and aligning the jib crane’s capabilities with other equipment, such as forklifts, palletizers or Brückenkran can create a synchronized workflow. This integration eliminates bottlenecks, reduces idle time, and maximizes overall operational efficiency.

Proper Training and Operator Skill

One of the fundamental aspects of optimizing efficiency with a 360-degree jib crane is ensuring that operators receive proper training and possess the necessary skills. Operating a jib crane requires knowledge of its controls, load capacities, and safety protocols. By investing in comprehensive training programs, companies can empower their operators to handle the equipment efficiently and safely.

Training should cover various aspects, including understanding load charts, calculating load weights, and mastering the use of control mechanisms. Additionally, operators should be trained on best practices for load positioning, lifting techniques, and safe maneuvering within the workspace. By equipping operators with these skills, companies can minimize the risk of accidents, reduce downtime, and enhance overall operational efficiency.

Regular Maintenance and Inspections

To ensure optimal performance and longevity, regular maintenance and inspections are crucial for a 360-degree jib crane. Routine maintenance tasks, such as lubrication, checking for wear and tear, and tightening loose components, help prevent breakdowns and extend the crane’s lifespan. Implementing a proactive maintenance schedule reduces the likelihood of unexpected failures and costly repairs.

In addition to regular maintenance, thorough inspections play a vital role in optimizing efficiency. Inspections should encompass critical components like cables, hooks, electrical systems, and structural integrity. Identifying and addressing potential issues early on prevents operational disruptions and ensures the crane operates at its peak performance.

The 360-degree jib crane has proven to be an essential tool in improving efficiency across various industries. Its ability to rotate a full 360 degrees provides unparalleled flexibility and accessibility, allowing for seamless movement of heavy loads in confined spaces. By eliminating the need for manual lifting and reducing the risk of accidents, this crane enhances worker safety while significantly increasing productivity. With its versatility, precision, and reliability, the 360-degree jib crane has undoubtedly become an indispensable asset in enhancing efficiency and driving success in today’s fast-paced industrial landscape.If you would like to purchase a 360 degree jib crane or have any questions, please visit our website at https://www.hndfcrane.com/ for more detailed information.

Senden Sie Ihre Anfrage

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Hinzufügen: Industriegebiet Changnao, Stadt Xinxiang, Provinz Henan, China