Ungewöhnliche Geräusche bei Brückenkränen: 5 häufige Ursachen und wirksame Reparaturlösungen

Inhaltsverzeichnis

Ungewöhnliche Geräusche von Brückenkränen sind ein häufiges Problem beim Betrieb von Brückenkränen. Dieser Artikel analysiert die Ursachen für ungewöhnliche Geräusche bei Brückenkränen und nennt fünf mögliche Faktoren: Kranfahrmechanismus, Kranschienen, Kranbahnträger, Fundamentsetzung und elektrische Systeme. Er bietet auch einige Lösungen für die aufgeführten Geräuschprobleme und hofft, Ihnen dabei behilflich zu sein.

Analyse der Ursachen für ungewöhnliche Geräusche bei Brückenkränen

Der in diesem Artikel beschriebene ungewöhnliche Lärm bezieht sich auf Brückenkräne in ihrem ursprünglichen Zustand, bei denen keine Komponenten wie Räder, Antriebsmechanismen oder Motoren ausgetauscht wurden. Ungewöhnlicher Lärm, der durch den Austausch von Kranausrüstung verursacht wird, fällt nicht in den Geltungsbereich dieses Artikels.

1. Ursachen des Brückenkran-Fahrmechanismus

(1) Kranrad Ursachen

Ungewöhnliche Geräusche durch die Kranräder von Brückenkränen kommen in der Praxis häufig vor. Zu den Hauptursachen zählen:

- Übermäßiger horizontaler oder vertikaler Fehlausrichtung der Räder, was während des Kranbetriebs zu ständiger Reibung und Kollision zwischen Rädern und Schienen führt.

- Schlechte Schmierung der Radlager, die den Laufwiderstand erhöht, und Lagerschäden, die zum Feststecken und ungewöhnlichen Geräuschen führen.

- Übermäßiger Verschleiß des Spurkranzes und der Kranbahnschiene.

(2) Ursachen für Führungsräder

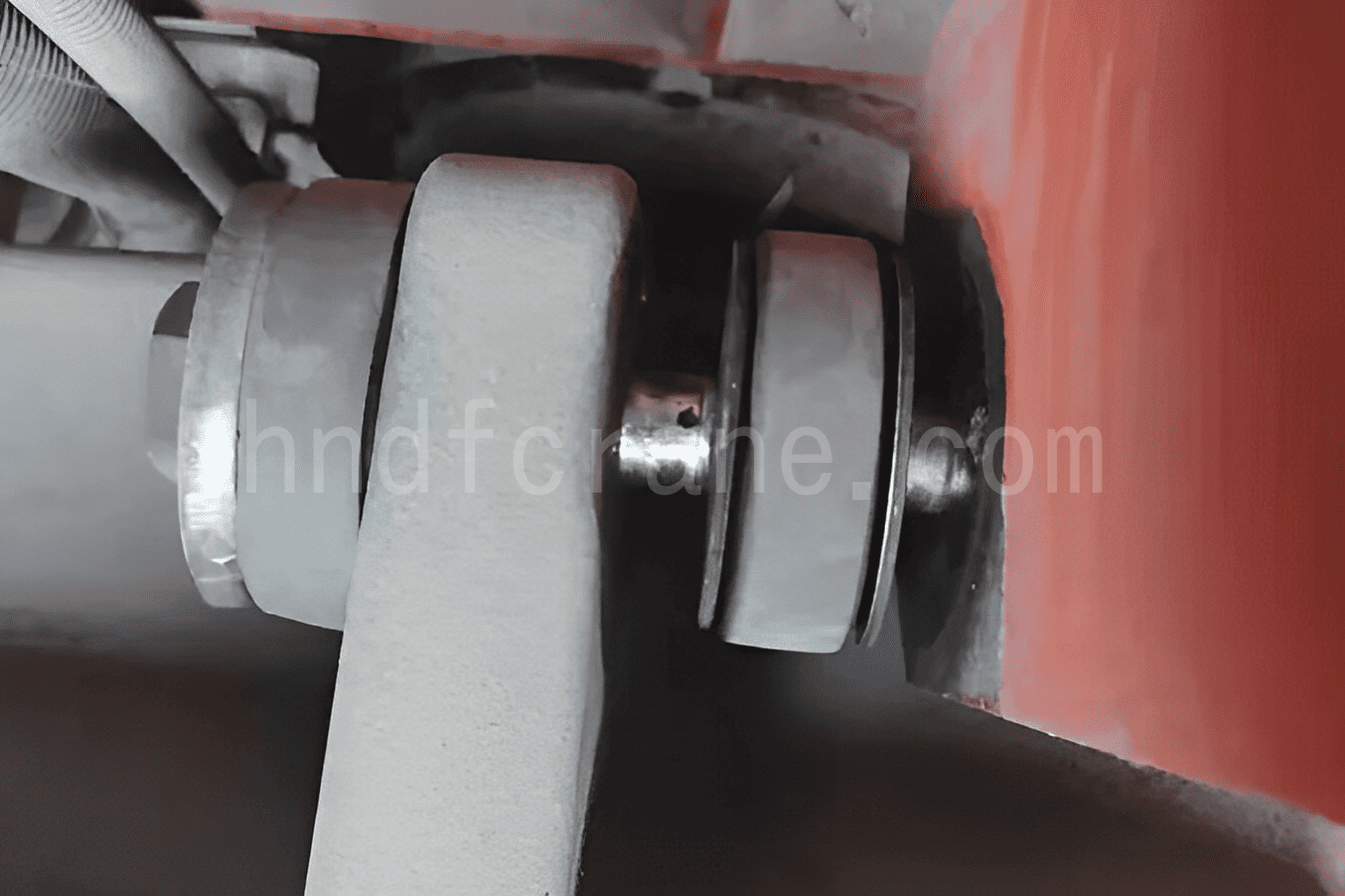

Die Führungsräder eines Krans sind Räder mit vertikaler Achse, die dafür sorgen, dass der Kran oder die Laufkatze in der richtigen Richtung auf der Spur bleibt. Eine unsachgemäße Installation oder Einstellung der Führungsräder kann zu Reibung oder Kollision zwischen den Führungsrädern und den Kranschienen führen, was zu ungewöhnlichen Geräuschen führt. Wie in Abbildung 1 dargestellt, kann der Verschleiß der Führungsräder recht stark sein.

(3) Antriebsmechanismus Ursachen

Der in diesem Artikel besprochene Antriebsmechanismus des Krans verwendet den „Drei-in-eins“-Antriebsmechanismus als Beispiel, obwohl auch separat angeordnete Systeme verwendet werden können. Die Hauptursachen für ungewöhnliche Geräusche im Antriebsmechanismus sind:

- Ungewöhnliche Geräusche vom „Drei-in-Eins“-Getriebe, Zahnradverschleiß oder gebrochene Zähne.

- Zwei oder mehr Bremsen sind nicht synchronisiert, beschädigt oder fehlen (wie in Abbildung 2 dargestellt).

- Abgenutzte Pufferpolster (wie in Abbildung 3 gezeigt).

(4) Kranhauptträger Ursachen

Zu den Hauptgründen für ungewöhnliche Geräusche im Fahrmechanismus des Krans, die durch den Hauptträger des Krans verursacht werden, gehören:

- Übermäßige horizontale Biegung des Kranhauptträgers, die zu einer diagonalen Fehlausrichtung führt.

- Erhebliche Änderungen der Wölbung des Hauptträgers, die zu Abweichungen im Radstand des Krans führen.

2. Kranschienenursachen

Nach längerem Kranbetrieb, insbesondere unter Volllast, steigt die Belastung der Schienen, was zu ungewöhnlichen Geräuschen während des Kranbetriebs führen kann. Bei unzureichender Wartung können die Probleme noch ausgeprägter werden. Die wichtigsten schienenbezogenen Ursachen für ungewöhnliche Geräusche sind:

- Unzureichendes Anziehen oder Lösen der Schienenklemmmuttern (siehe Abbildung 4), was zu einer Verformung der Schiene an den losen Stellen und zu ungewöhnlichen Geräuschen während der Kranbewegung führt.

- Zu große Abstände zwischen Schiene und Kranträger, fehlende oder falsch platzierte Ausgleichsbleche.

- Vertikale Fehlausrichtung der durch Laschen verbundenen Schienenstöße, die die zulässige Toleranz überschreitet und nicht geschliffen oder eingestellt wurde, was zu ungewöhnlichen Geräuschen führt, wenn der Kran darüber fährt.

- Horizontale Fehlausrichtung der durch Laschen verbundenen Schienenstöße, die zu anormalem Lärm führt; Laschenverbindungen mit übermäßig großen Abständen (siehe Abbildung 5).

- Unzureichende Glätte der Schweißnähte an Schienenstößen, die zu Rissen oder Ablösungen der Stöße führen können.

- Fehlende Schienenklemmen verursachen ungewöhnliche Geräusche.

- Übermäßige Abweichung der horizontalen oder vertikalen Ausrichtung der Schiene entlang ihrer Länge.

- Schienenspannweite überschreitet die zulässige Abweichung.

- Übermäßiger Höhenunterschied zwischen den Oberseiten zweier paralleler Schienen.

- Falscher oder zu geringer Längsversatz der Schienenstoßpositionen zwischen den beiden parallelen Schienen.

- Starker Verschleiß an den Schienenseiten.

3. Kranbahnträger Ursachen

- Übermäßige Abwärtsbiegung des Stahlträgers der Landebahn oder seitliche Biegung des Trägers.

- Lose Verbindungen im Laufbahnträger.

- Lose oder fehlende Schrauben zur Verbindung des Landebahnträgers.

- Zu großer Höhenunterschied zwischen benachbarten Trägern (siehe Abbildung 6).

- Rissbildung oder Bruch der Betonmörtelschicht bzw. Ausgleichsschicht zwischen Betonkranträger und Schienen.

4. Ursachen für Fundamentsetzung

Unter Fundamentsetzung versteht man die Kompression von Bodenschichten unter zusätzlicher Belastung, was zu Oberflächenabsenkungen führt. Übermäßige Setzungen, insbesondere ungleichmäßige Setzungen, können dazu führen, dass Gebäude kippen, Risse bekommen und unbrauchbar werden. Fundamentsetzungen sind ein allgemeines Problem, das sich auf die gesamte Fabrikstruktur bezieht. Sie können von einigen Metern kleiner lokaler Setzungen bis hin zu mehreren zehn Metern großer Gesamtsetzungen reichen.

Lokale Setzungen können dazu führen, dass Teile des Kranbahnträgers absinken, wodurch Lücken zwischen dem abgesunkenen Träger und der Kranschiene entstehen (siehe Abbildung 7). Diese Lücke führt aufgrund der erhöhten Belastung der Schiene zu ungewöhnlichen Geräuschen während des Kranbetriebs. Wenn sie im Laufe der Zeit nicht ordnungsgemäß repariert und verbessert wird, kann sie zu dauerhaften Verformungen oder Schäden an der Kranschiene in den betroffenen Bereichen führen.

Die Gesamtsenkung ist eine schwerwiegendere Form der Fundamentsenkung, die zu einem großflächigen Absinken des Laufbahnträgers führt. Die Ungleichmäßigkeit der Setzung führt zu Höhenschwankungen oder horizontalen Verformungen im Laufbahnträger, was wiederum entsprechende vertikale oder horizontale Verformungen in den Kranschienen verursacht. Während des Kranbetriebs wird das ungewöhnliche Geräusch stärker, was den Hochgeschwindigkeitsbetrieb erschwert oder sogar unmöglich macht.

5. Elektrische Ursachen

Während die meisten Fälle von ungewöhnlichen Geräuschen während des Kranbetriebs auf mechanische Probleme zurückzuführen sind, können auch einige elektrische Faktoren dazu beitragen. Dazu gehören lose oder schlechte Verbindungen in der Motor- oder Bremsverkabelung sowie Schäden oder Verschleiß der Bremsbeläge.

Lösungen für ungewöhnliche Geräusche von Brückenkränen

Für jede Ursache ungewöhnlicher Geräusche beim Betrieb von Brückenkränen gibt es entsprechende Lösungen.

1. Lösungen für Kranfahrwerke

(1) Kranradlösungen

- Bei Problemen mit übermäßiger horizontaler oder vertikaler Fehlausrichtung der Kranrädermuss zunächst der Anpassungsbetrag gemessen werden. Siehe GB/T 14405-2011, und nehmen Sie Anpassungen auf Grundlage der gemessenen Werte vor. Platzieren Sie bei der Anpassung horizontaler Fehlausrichtungen Unterlegscheiben in der vertikalen Ebene des Radsatzes und bei vertikaler Fehlausrichtung Unterlegscheiben in der horizontalen Ebene. Führen Sie nach der Anpassung einen Testlauf durch und prüfen Sie den Abstand zwischen den Kranrädern und der Schiene.

- Bei Problemen, bei denen eine schlechte Schmierung der Radlager den Laufwiderstand erhöht, sollte umgehend Schmierfett hinzugefügt werden. Führen Sie anschließend einen Test durch, um die Flexibilität der Lager zu prüfen. Wenn Lagerschäden zum Feststecken oder zu ungewöhnlichen Geräuschen führen, sollten die Lager sofort ausgetauscht werden, um weitere Probleme zu vermeiden.

- Bei übermäßigem Verschleiß des Kranradflansches und der Schiene untersuchen Sie zunächst die Ursache des Verschleißes, z. B. übermäßige Radfehlstellung oder unsachgemäße Schienenmontage. Normaler Verschleiß am Radflansch kann unbehandelt bleiben, wenn der Verschleiß jedoch 40 % der Konstruktionsdicke des Flansches überschreitet, sollte das Rad ausgetauscht werden.

(2) Führungsradlösungen

Bei ungewöhnlichen Geräuschen, die durch unsachgemäße Installation oder Einstellung der Führungsräder verursacht werden, passen Sie den Abstand zwischen Führungsrad und Schiene an, um sicherzustellen, dass während des Kranbetriebs entweder ein Abstand oder minimale Reibung oder Kollision vorhanden ist. Prüfen Sie, ob der Positionierungsblock geeignet ist, und stellen Sie ihn ggf. neu ein. Siehe GB/T 10183.1-2018, um die Achsparallelitätstoleranz der horizontalen Führungsräder sowohl in der Richtung senkrecht zu und entlang der Kranschienen als auch die Höhentoleranz zu prüfen. Passen Sie alle Bereiche an, in denen die tatsächlichen Werte die Toleranz überschreiten.

(3) Antriebslösungen

- Bei ungewöhnlichen Geräuschen vom „Drei-in-eins“-Reduzierstück überprüfen Sie die Stelle, an der das Geräusch auftritt. Wenn die Zahnräder abgenutzt sind oder gebrochene Zähne aufweisen, müssen die Zahnräder ausgetauscht werden.

- Wenn zwei oder mehr Bremsen nicht synchronisiert sind, prüfen Sie, ob die Bremsen ordnungsgemäß funktionieren. Messen Sie mit einer Fühlerlehre die Bremsabstände und stellen Sie sicher, dass sie den erforderlichen Spezifikationen entsprechen. Wenn nicht, passen Sie die Abstände entsprechend an.

- Bei Beschädigungen der Bremsen oder Pufferbeläge sollten diese ausgetauscht und regelmäßige Kontrollen durchgeführt werden.

(4) Kran-Hauptträgerlösungen

Kranhauptträger verformen sich normalerweise nicht leicht. Wenn es zu Verformungen kommt, muss überprüft werden, ob die Konstruktion angemessen ist, ob die Herstellung den Konstruktionsanforderungen entspricht, ob der Herstellungsprozess den Konstruktionsstandards entspricht und ob die Kraninstallation dem Standard entspricht. Bei Problemen wie übermäßiger horizontaler Biegung des Hauptträgers oder erheblichen Wölbungsänderungen werden im Allgemeinen Reparaturmethoden wie die Verstärkung der Schweißnähte oder die Verwendung von Flammenerhitzung verwendet. Reparaturen erfordern normalerweise die Einbeziehung des Herstellers oder professioneller Teams. Die Inspektion des Hauptträgers kann in Bezug auf GB/T 14405-2011 durchgeführt werden.

2. Kranschienenlösungen

Beim Umgang mit Kranschienen sollte auf eine regelmäßige Wartung und Instandhaltung geachtet werden, um Probleme frühzeitig zu erkennen und so Schäden an der Anlage vorzubeugen.

- Bei Problemen mit nicht ausreichend festgezogenen oder losen Schienenklemmmuttern sollte eine Kombination aus regelmäßigen Inspektionen und planmäßigen Wartungsarbeiten durchgeführt werden, um sicherzustellen, dass die Muttern richtig festgezogen sind.

- Bei übermäßigen Abständen zwischen Schiene und Laufbahnträger oder wenn der Abstand zu lang ist, passen Sie den Laufbahnträger aus Stahl so an, dass die Schienenunterseite näher an die Trägeroberseite heranrückt. Wenn der Abstand 200 mm überschreitet, verwenden Sie Unterlegplatten mit einer Länge von mindestens 100 mm und einer Breite, die 10–20 mm breiter ist als die Schienenbasis. Es sollten nicht mehr als drei Unterlegplatten pro Satz verwendet werden, und sie sollten fest mit dem Stahlträger verschweißt werden. Verwenden Sie für Betonträger eine ähnliche Methode wie für Stahlträger. Elastische Unterlegplatten werden aufgrund häufigen Verschleißes im Laufe der Zeit nicht empfohlen.

- Bei übermäßiger vertikaler oder horizontaler Fehlausrichtung an Schienenverbindungen der Laschen prüfen Sie, ob die Laschen abgenutzt sind. Wenn übermäßiger Verschleiß festgestellt wird, ersetzen Sie die Laschen. Passen Sie dann die Schienenverbindungen und Schienen an, um sicherzustellen, dass die vertikale und horizontale Fehlausrichtung 1 mm und der Abstand an den Schienenverbindungen 2 mm nicht überschreitet. In Regionen mit Temperaturunterschieden von 20 °C oder mehr oder bei Winterinstallationen sollten Sie einen Abstand zwischen den Verbindungen von 4–6 mm einhalten. Verwenden Sie zum Messen ein Stahllineal und eine Fühlerlehre.

- Bei unzureichender Glätte an geschweißten Schienenstößen verwenden Sie eine Schleifscheibe, um die Oberseite und die Seiten des Stoßes zu glätten und so den erforderlichen Schienenstoßstandards zu entsprechen. Bei Problemen, bei denen geschweißte Schienenstöße reißen oder sich lösen, sollte die Reparatur von spezialisiertem Schweißpersonal mit speziellen Materialien und Verfahren durchgeführt werden. Aufgrund der Komplexität von Kranschienensystemen besteht nach dem Schweißen immer noch die Gefahr von Rissen oder Lockerungen. Daher werden Laschenverbindungen gegenüber Schweißen für Brückenkranschienenstöße empfohlen.

- Bei ungewöhnlichen Geräuschen, die durch fehlende Schienenklemmen verursacht werden, prüfen Sie, ob Komponenten fehlen und sichern Sie diese, um einen normalen Kranbetrieb sicherzustellen.

- Bei übermäßigen horizontalen oder vertikalen Krümmungsabweichungen entlang der Schienenlänge passen Sie die Schiene so an, dass die horizontale Abweichung auf einer Länge von 2 Metern 1 mm und die vertikale Abweichung 2 mm nicht überschreitet. Die Messung kann mit einer Stahldrahtmethode durchgeführt werden.

- Bei Kranschienen-Spannweitenabweichungen, die die zulässige Toleranz überschreiten, sind die Schienen so einzustellen, dass die maximal zulässige Spannweitenabweichung ΔS wie folgt beträgt:

- Wenn S≤16 m, △S =±5 mm

- Wenn S>16 m, △S =±[5+0,25(S-16)]mm

- ΔS: Kranschienen-Spannweitenabweichung

- S: die Kranschienenspanne

- Die maximale Abweichung darf ±15 mm nicht überschreiten. Informationen zur spezifischen Umsetzung finden Sie in GB/T 10183.1-2018. Die Spannweite der Kranschiene kann mit einem Stahlband und einer Federwaage gemessen werden.

- Bei zu großen Höhenunterschieden zwischen den Oberkanten zweier paralleler Kranschienen müssen Laufbahnträger und Schiene so eingestellt werden, dass der Höhenunterschied 10 mm nicht überschreitet. Nehmen Sie dazu mehrere Messungen mit einer Wasserwaage vor.

- Bei parallelen Schienenstößen, die nicht in der Länge versetzt sind oder den falschen Versatzabstand aufweisen, müssen die Schienen so eingestellt werden, dass der Abstand mindestens 600 mm beträgt und nicht mit dem Radstand der Vorder- und Hinterräder des Krans übereinstimmt.

- Beträgt der Verschleiß an den Schienenseiten mehr als 15 % der ursprünglichen Schienenbreite, müssen die Schienen ausgetauscht werden.

3. Lösungen für Start- und Landebahnträger

Die Qualität des Laufbahnträgers ist die Grundlage für die Sicherstellung der Qualität der Schieneninstallation. Vor dem Einbau der Schienen muss unbedingt sichergestellt werden, dass die Einbauabweichung des Laufbahnträgers den erforderlichen Standards entspricht. Vor dem Einbau der Schienen muss eine detaillierte Inspektion des Laufbahnträgers durchgeführt werden, und die Grundlinie des Laufbahnträgers sollte während der Inspektion markiert werden. Dies kann mit einem Theodoliten gemessen werden, während die Höhe mit einem Nivelliergerät gemessen werden kann.

Die Abnahme von Stahl-Startbahnträgern muss der GB 50205-2017 entsprechen, während die Abnahme von Stahlbeton-Startbahnträgern der GB 50204-2015 entsprechen muss. Derzeit gibt es keinen spezifischen Standard für hybride Stahl-Beton-Startbahnträger.

- Bei Problemen wie übermäßiger Abwärtsbiegung oder seitlicher Biegung des Stahlbahnträgers muss überprüft werden, ob die Konstruktion den erforderlichen Normen entspricht und ob die Installation qualifiziert ist. Bei Reparaturen können Heizmethoden verwendet werden, um den Träger zu korrigieren.

- Bei losen Verbindungen oder losen und fehlenden Schrauben im Laufbahnträger sollten Schweißreparaturen und Schraubenfestziehen durchgeführt werden. Wenn zwischen benachbarten Trägern übermäßige Höhenunterschiede bestehen, passen Sie die Höhe der benachbarten Laufbahnträger an, um die Höhenabweichung zu verringern.

- Wenn die Betonmörtelschicht oder Ausgleichsschicht zwischen dem Betonkranträger und der Schiene beschädigt ist, überprüfen Sie die Dicke der sekundären Gussschicht. Wenn die Dicke nicht ausreicht, wird empfohlen, andere Methoden anzuwenden. Wenn die Dicke ausreichend ist, sollten neue Formen zum Gießen des Zements aufgestellt werden. Nachdem der Zement richtig ausgehärtet ist, kann der Kran seinen Betrieb wieder aufnehmen.

4. Lösungen zur Fundamentsetzung

Setzungen im Frühstadium sind ein relativ häufiges Phänomen. Da die Fundamenttechnologie immer weiter fortschreitet, sind großflächige Setzungsprobleme seltener geworden, obwohl es gelegentlich noch zu lokalen Setzungen kommt. Lokale Setzungen treten in der Regel in kleinem Maßstab auf, müssen aber dennoch verhindert und behandelt werden.

(1) Vorbeugung: Durch die Einrichtung von Setzungsüberwachungspunkten können Setzungen überwacht werden. Zur Messung des Setzungsausmaßes werden üblicherweise Präzisionsnivellierungsmethoden eingesetzt.

(2) Behandlung: Bei örtlichen Absenkungen des Laufbahnträgers, die durch eine Absenkung des Fundaments verursacht werden, sollten professionelle Reparaturen durchgeführt werden, um das Absenken zu beseitigen und so ungewöhnliche Geräusche während des Kranbetriebs zu beheben. Wenn die örtlichen Absenkungen gering sind, können Ausgleichsplatten zwischen dem Laufbahnträger und den Schienen verwendet werden. Die Ausgleichsplatten müssen jedoch sicher befestigt werden, damit sie sich während des Kranbetriebs nicht lösen.

5. Lösungen für elektrische Störungen

Bei ungewöhnlichen Geräuschen von Brückenkränen, die durch lose oder fehlerhafte Verbindungen im Kranmotor oder in der Bremsverkabelung verursacht werden, sollten die Anschlussklemmen sofort festgezogen und regelmäßige Inspektionen geplant werden. Wenn die Bremsbeläge beschädigt sind, sollten sie ausgetauscht werden. Wenn die Bremsbeläge abgenutzt sind, überprüfen Sie zuerst die Verkabelung, um sicherzustellen, dass sie ordnungsgemäß funktioniert, und beobachten Sie dann die Bremsbeläge. Wenn zeitweise Fehler auftreten, ersetzen Sie die Bremsbeläge, und wenn genügend Ersatzteile verfügbar sind, führen Sie den Austausch durch, um zukünftige Probleme zu vermeiden.

Abschluss

Die Beseitigung ungewöhnlicher Geräusche bei Brückenkränen ist entscheidend, um einen reibungslosen Kranbetrieb zu gewährleisten und weitere mechanische Probleme zu vermeiden. Durch das Verständnis der häufigsten Ursachen und die Umsetzung der entsprechenden Lösungen können Betreiber Ausfallzeiten und kostspielige Reparaturen erheblich reduzieren.

Referenz: Analyse und Lösungen für ungewöhnliche Geräusche beim Betrieb von Brückenkränen

Senden Sie Ihre Anfrage

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Hinzufügen: Industriegebiet Changnao, Stadt Xinxiang, Provinz Henan, China