Portalkran vs. Brückenkran: 6 wichtige Vorteile, die Ihnen bei der Auswahl der besten Option helfen

Inhaltsverzeichnis

Bei der Auswahl von Hebezeugen ist es wichtig, die Unterschiede zwischen den verschiedenen Krantypen zu kennen. Portalkräne und Brückenkräne sind zwei gängige Typen, die jeweils einzigartige Designs und Anwendungen aufweisen. Aber was genau unterscheidet sie? Welcher ist für Ihre Anforderungen besser geeignet? In diesem Artikel untersuchen wir die Merkmale, Vorteile und Nachteile von Portalkränen und Brückenkränen, um Ihnen bei der Auswahl zu helfen.

1.Vergleich der Basisinformationen

Portalkran Definition:

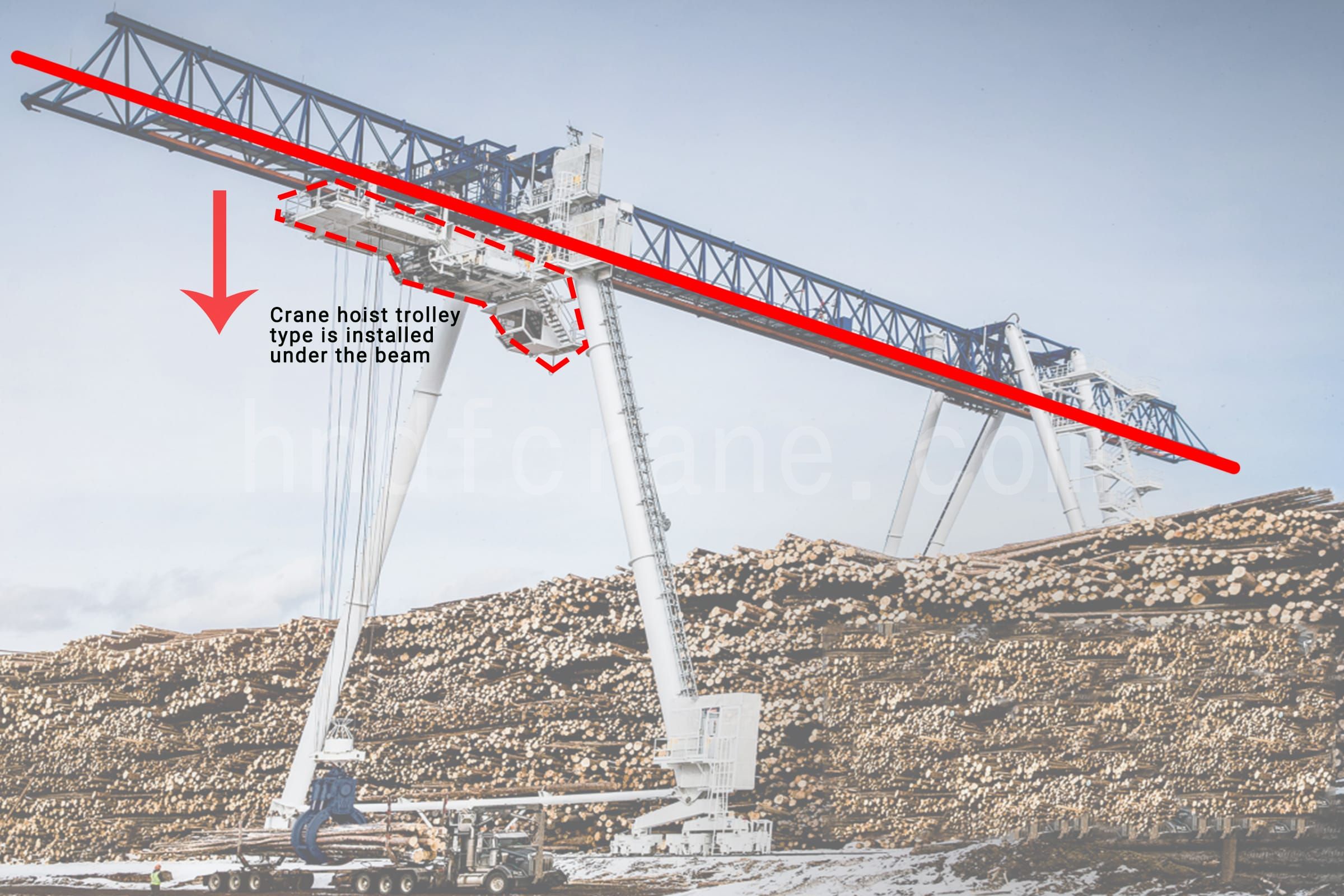

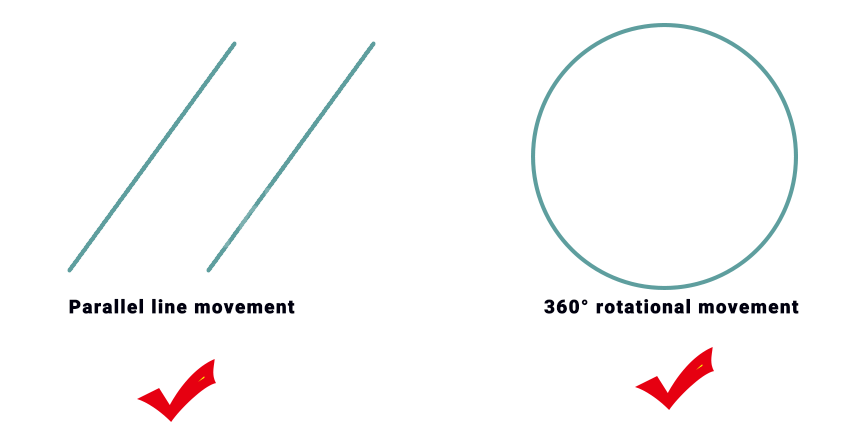

- Für lange Strecken konzipiert, kann es durch die Umlaufbahn um 360° gedreht werden.

- Wird häufig zum Stapeln von Holz und Holzlagern verwendet.

- Der Portalkran übernimmt das Entladen und Lagern des Holzes sowie die Holzzuführung in einer Einheit. Er kann bis zu 40 Abholungen pro Stunde durchführen (bei minimaler Fahrstrecke). Auf diese Weise können bei Bedarf viele LKWs entladen werden. Sie können eine LKW-Ladung Rohpfähle auf einmal greifen.

Portalkran Anwendbare Industrie:

- Für anspruchsvolle Anwendungen und Umgebungen in den Branchen Forstprodukte, Intermodal, Biomasse/Pellets, Beton und vielen anderen müssen Portalkräne robust gebaut sein.

Vorteile eines Portalkrans:

- Sicher, intelligent und effizient

- Energie wird gespart, die Leistung erhöht, regeneratives Bremsen wird genutzt und bei jeder Abwärts- oder Verzögerungsbewegung wird Energie ins Netz zurückgespeist, anstatt durch Widerstand verloren zu gehen. Wenn mehr Energie ins Netz zurückgespeist wird, muss weniger Energie erzeugt werden, was zu höheren Kosteneinsparungen führt.

- Die Fahrerkabine ist ergonomisch gestaltet. Wenn sich die Arbeiter wohlfühlen, können sie sich besser auf ihre Aufgaben konzentrieren. Das verringert die Unfall- und Verletzungsgefahr.

- Nutzen Sie intelligente Technologie.

- Vergrößerung der Lagerfläche.

- Der Portalkran nimmt nur 4% der Hoffläche ein

- Portalkrane ermöglichen außerdem eine vertikale Lagerung von bis zu 22,86 m, wodurch die Lagerkapazität des Endlagers erheblich erhöht wird.

- Der Portalkran ist mit Sturmbremsen ausgestattet und kann bei jedem Wetter, auch in Gebieten mit starkem Wind, eingesetzt werden.

- Portalkrane passen sich der Bewegung entlang der Landebahn an, sodass sowohl der Kran als auch die Landebahn über lange Strecken in gutem Zustand bleiben.

Portalkran Definition:

- Die Spannweite beträgt im Allgemeinen 35 m und ist für den allgemeinen Gebrauch geeignet.

Portalkran anwendbare Industrie:

- Güterbahnhof, Baustelle, Bahnübergabestation

- Werften und Häfen

- Trägerfabrik

Vorteile eines Portalkrans:

- Hohe Auslastung, breite Verwendung, starke Anpassungsfähigkeit, starke Vielseitigkeit, ist das am häufigsten verwendete Portalhebegerät mit einem Nenngewicht von 5 bis 500 Tonnen.

- Der Portalkran nimmt 251 TP1T der Hoffläche ein.

Portalkran

Portalkran

2.Klassifizierungsvergleich

Portalkran

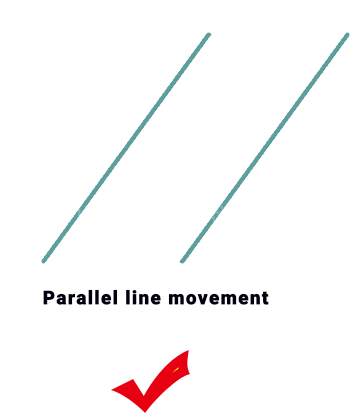

Portalkrane mit gerader Schiene

- Am beliebtesten und optimal für zukünftige Start- und Landebahnerweiterungen und die Erweiterung des Lagerraums.

- Sorgt für optimalen LKW-Verkehrsfluss und maximale Lagerkapazität.

Drehportalkrane

- Passt oft dorthin, wo gerade Schienenkräne nicht passen.

- Bietet Stauraum innerhalb und außerhalb der Schiene.

Holzauslegerkräne

- Der Kran dreht sich um die zentrale Lagerstütze. Die beiden großen Vorderbeine bewegen sich auf einer kreisförmigen Schiene, sodass der Kran die Stämme zur Lagerung stapeln kann, bis sie in den Trichter eingebracht werden müssen.

Portalkran

Doppelter Türrahmen mit außenliegendem Kragrahmen

Einseitiger Türrahmen mit äußerem Kragrahmen

Kein externer Auslegerrahmen

Traditionell Portalkräne ist weit verbreitet und es gibt viele Formen und Klassifizierungen. In dieser Kategorie können die oben genannten drei Typen auch als Fachwerk-Portalkrane hergestellt werden. Dafang Crane kann die Produkte, die Sie benötigen, eins zu eins anpassen. Sie können uns kontaktieren, wenn Sie etwas brauchen.

3.Kostenvergleich

Die Anfangsinvestition für den Portalkran ist im Allgemeinen geringer als bei einem herkömmlichen Portalkran, da der Portalkran leichter ist und auf Schienen betrieben werden kann, die nicht die gleichen Anforderungen an Parallelität und Geradheit stellen.

Der Portalkran benötigt lediglich Standard-Bodenschienen, die auf Gleisschwellen auf einem Kiesbett oder einem einfachen Betonfundament verlegt werden. Sie können sich an instabiles Gelände anpassen, wodurch der Bedarf an teuren Oberflächenarbeiten begrenzt wird und die Kräne überall dort mit voller Kapazität arbeiten können, wo Schienen verlegt werden können. Diese Art der Installation spart im Vergleich zum tiefen und schweren Fundament eines herkömmlichen Portalkrans viel Geld.

Einsparungen bei den Betriebskosten: Portalkrane kombinieren das Entladen, den Transport und das Stapeln von Materialien in einem effizienten Vorgang. Die Kombination dieser Aktivitäten reduziert den Bedarf an Ausrüstung, Wartung und Personal und senkt die Betriebskosten im Vergleich zu Werften mit Portalkranen erheblich.

Der Poral-Kran ist mit energieeffizienten Motoren und Steuerungen ausgestattet, die für einen langfristigen zuverlässigen Betrieb ohne großen Wartungsaufwand und die damit verbundenen Kosten ausgelegt sind.

4.Der Unterschied zwischen Hohlkastenträgerkonstruktionen und Blumenständerkonstruktionen (Fachwerkkonstruktionen)

- Diese Gitterkonstruktion ist kostengünstig im Vergleich zu Hohlkastenträgerkonstruktionen. Das offene Design ermöglicht außerdem eine einfache Inspektion kritischer Schweißnähte während der gesamten Lebensdauer des Krans.

- Der Fachwerkträger ist der Hauptträger aus gegenüberliegendem Material (z. B. U-Stahl, Winkelstahl, T-Stahl), dessen Winkel und Länge angepasst werden können und der sich besser für die Handhabung unregelmäßiger Objekte eignet.

- Diese Struktur kann die dem Wind zugewandte Fläche des Krans verringern und bietet starken Windwiderstand. Sie ist für den Einsatz in windigen offenen Gegenden geeignet.

- Das offene Design ermöglicht außerdem eine einfache Inspektion kritischer Schweißnähte während der gesamten Lebensdauer des Krans.

- Aufgrund der offenen Konstruktion der Fachwerk-Hauptträgerstruktur sind Überholung und Wartung relativ einfach, insbesondere bei einigen zu kleinen Strukturen, die besser beobachtet werden können und den toten Bereich im Wartungsprozess reduzieren.

- Die Fachwerk-Hauptträgerkonstruktion bietet eine größere Freiheit der Beinstruktur sowie bessere Anpassungsfähigkeit und Flexibilität.

- Die Fachwerk-Hauptträgerstruktur lässt sich aufgrund der abnehmbaren Beinstruktur leichter demontieren.

- Portalkrane mit Kastenstruktur weisen eine geringere Windbeständigkeit und Eigenlast auf und sind teurer als Fachwerkkrane.

- Der Kastenträger eines Portalkrans besteht aus zu einer Kastenstruktur verschweißten Stahlplatten.

- Der Portalkran mit Kastenstruktur ist vollständig geschlossen und seine innere mechanische Struktur kann nicht direkt beobachtet und geprüft werden.

- Der Portalkran in Kastenform verfügt über eine gute strukturelle Stabilität, wodurch die Sicherheit und Zuverlässigkeit des Gerätebetriebs besser gewährleistet werden kann.

- Der Portalkran mit Kastenstruktur hat aufgrund seiner guten Ermüdungsbeständigkeit eine längere Lebensdauer.

- Der Portalkran in Kastenbauweise muss über bestimmte Hardwareausstattungen und Bedingungen am Einsatzort verfügen, bevor er demontiert werden kann.

Quellen: 大跨度门式起重机刚性支腿对结构刚度的影响分析

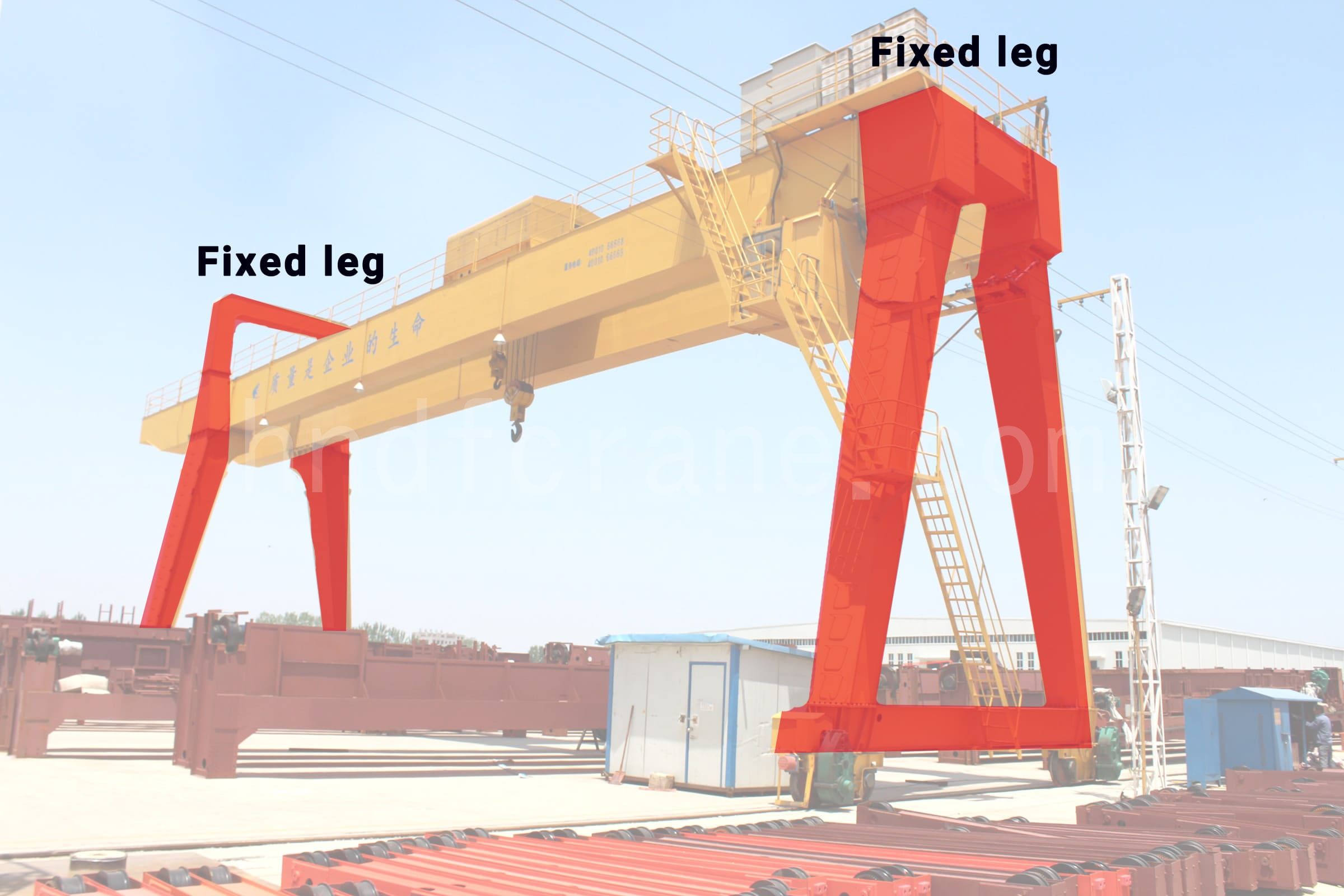

5.Der Unterschied zwischen flexiblen Beinen und Klappbeinen

- Der Portalkran ist auf maximale Flexibilität ausgelegt, wodurch die Wartung von Bauwerken und Gleisen auf ein Minimum reduziert wird. Der Portalkran ist auf maximale Flexibilität ausgelegt, wodurch die Wartung von Bauwerken und Gleisen auf ein Minimum reduziert wird.

- Die flexiblen Beine verfügen über einen gewissen Freiheitsgrad und sind gelenkig mit dem Hauptträger verbunden.

- Die flexiblen Beine sind mit zwei Stahlrohren gleicher Wandstärke verschweißt und die Unterseite ist mit dem Unterträger in einer dreieckigen Struktur mit guter Stabilität verbunden.

- Da die flexiblen Beine entlang der Ringbahn des Krans bewegt werden können, eignet er sich für einige Orte, an denen der Kran Kurvenarbeiten ausführen muss.

- Es ist besser für das Fundament geeignet und kann auf unebenem Boden angewendet werden.

- Flexible Beine eignen sich auch für Einsätze, bei denen der Kran andere Strukturen anfahren oder überqueren muss.

- Schwache Tragfähigkeit.

- Die starren Beine werden bei der Verbindung mit dem Hauptträger verschraubt, so dass der Freiheitsgrad vollständig eingeschränkt ist

- Das starre Bein ist ebenfalls eine kastenförmige Struktur und seine Querschnittsgröße verringert sich von oben nach unten.

- Aufgrund der starken Tragfähigkeit und Stabilität des starren Beins eignet er sich für einige Orte, an denen der Kran Operationen mit hoher Last und hoher Präzision ausführen muss.

- Die starren Beine tragen eine Menge Kranausrüstung, wie zum Beispiel elektrische Kontrollräume, Widerstände usw. Um dem Personal den Weg zum Fahrerhaus oder zum Hauptträger zu erleichtern, ist zwischen den beiden starren Beinen eine Rolltreppe installiert.

- Starrbeine eignen sich außerdem für zahlreiche Einsatzbereiche, wie etwa Bergbau und Handhabung in Tagebaugruben, großen Lagerplätzen usw.

- Hoher Wartungsaufwand und hohe Anforderungen an das Fundament

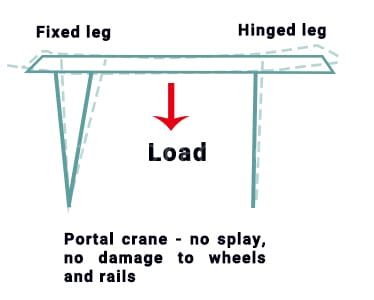

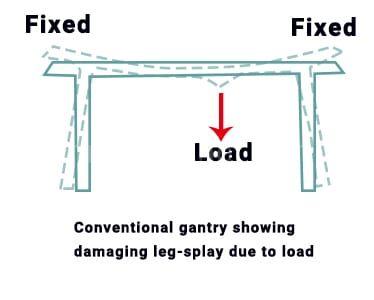

- Portalkrane verwenden ein starres und flexibles Beindesign. Dieses starre und flexible Design ermöglicht es den Beinen, sich relativ zum Hauptträger frei zu drehen, wodurch das Phänomen der Spannungskonzentration verringert werden kann, das durch den Ablenkvorgang des Portalkrans oder die Wärmeausdehnung des Hauptträgers verursacht wird.

- Portalkrane auf beiden Seiten haben normalerweise die Form eines starren und eines flexiblen Beins. Ein Bein des Portalkrans ist mit der Brücke verbunden, sodass das gesamte Portal ein statisch bestimmtes System ist, das den seitlichen Schub des Waggons auf die Schiene durch die Hublast eliminiert. Gleichzeitig ist der Spannungszustand des statisch bestimmten Portalsystems relativ klar, wenn der Waggon schief fährt.

- Allerdings weist diese Art von Struktur eine geringe strukturelle Steifigkeit und schlechte dynamische Eigenschaften auf. Beim Anheben wird durch den Hauptträger eine große seitliche Verschiebung erzeugt, und die dynamische Steifigkeit in vertikaler und horizontaler Richtung ist unzureichend.

- Die voll beladene Laufkatze des Portalkrans befindet sich in der Mitte des Hauptträgers. Aufgrund der fehlenden Synchronisierung der Laufkatze unter den Beinen auf beiden Seiten wird der Portalrahmen verdreht, was zu schweren Unfällen mit katastrophalen Folgen führt.

- Starre Strukturen wie Portalkräne mit Hohlkastenträgern reagieren äußerst empfindlich auf seitliche Belastungen durch die Ablenkung der Stützbeine, was zu Spurkranzverschleiß und schließlich zum Austausch der Ketten führen kann.

- Portalkrane haben eine doppelt starre Beinstruktur mit hoher Steifigkeit und guten dynamischen Eigenschaften. Aufgrund der statisch unbestimmten Struktur wird der untere Teil des Beins jedoch nach außen versetzt, wenn er die Hebelast trägt. Wenn der Versatz den Abstand zwischen Rad und Schiene überschreitet (unter normalen Umständen: Wenn der Abstand zwischen Rad und Schiene 15 mm nicht überschreitet, treten beim Kran keine gefährlichen Probleme auf), erzeugt der LKW einen großen seitlichen Schub auf der Schiene, der für den Betrieb des LKWs ungünstig ist und zum Phänomen des Nagens an der Schiene führt. Gleichzeitig werden höhere Anforderungen an die Befestigung der Schiene gestellt, insbesondere wenn die Spannweite groß ist. Auch im Leerlauf tritt das Phänomen des Schienennagens auf.

6.Kranbasisvergleich

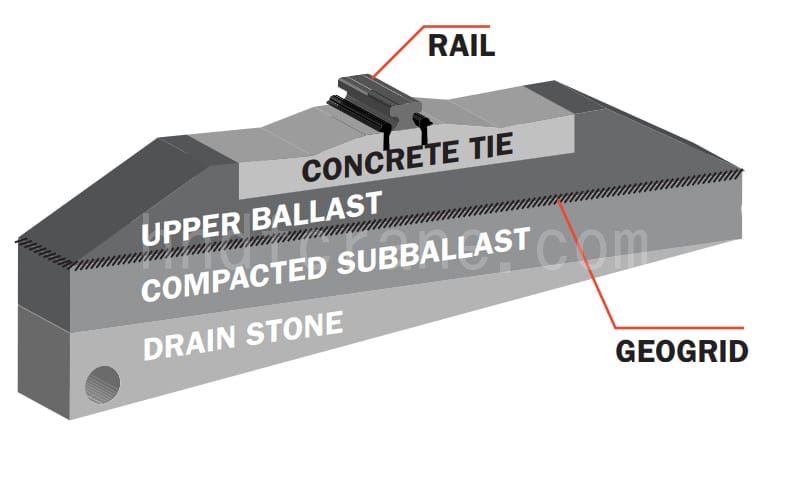

- Das Bild zeigt ein Querschnittsdiagramm eines Start- und Landebahnfundaments im „Bond and Ballast“-Stil, das zur Unterstützung eines Krans verwendet wird. Das Fundament besteht aus mehreren Schichten, von denen jede einem bestimmten Zweck dient, nämlich Stabilität, Haltbarkeit und ordnungsgemäße Entwässerung zu gewährleisten. Hier ist eine Aufschlüsselung der Schichten von unten nach oben:

- Abflussstein: Dies ist die unterste Schicht, die aus Steinen besteht, die für eine gute Entwässerung sorgen. Diese Schicht sorgt dafür, dass sich kein Wasser unter dem Fundament ansammelt, was andernfalls zu einer Schwächung oder Erosion führen könnte.

- Verdichteter Unterschotter: Über der Drainagesteinschicht befindet sich der verdichtete Unterschotter. Diese Schicht besteht normalerweise aus feineren Materialien und wird verdichtet, um eine stabile Basis für die oberen Schichten zu bieten. Sie hilft dabei, die Last der darüber liegenden Schichten gleichmäßiger zu verteilen und sorgt für zusätzliche Entwässerungsfähigkeit.

- Geogitter: Über dem verdichteten Unterschotter wird ein Geogitter platziert. Geogitter sind geosynthetische Materialien, die zur Verstärkung des Bodens verwendet werden und dem Fundament zusätzliche Stabilität und Festigkeit verleihen. Sie verhindern die Bewegung des Unterschotters und erhöhen die Gesamttragfähigkeit des Fundaments.

- Oberballast: Diese Schicht besteht aus größeren Steinen oder Schotter, die eine solide Basis für die Betonschwellen bilden. Der Schotter ist entscheidend für die Verteilung der Lasten von Schienen und Schwellen und für die Aufrechterhaltung der Gleisausrichtung, indem er seitlichen, längsgerichteten und vertikalen Kräften standhält.

- Betonanker: Betonschwellen (oder Schwellen) werden auf die obere Schotterschicht gelegt. Diese Schwellen sind wichtige Komponenten, die die Schienen an ihrem Platz halten und die Spurweite und Ausrichtung der Gleise aufrechterhalten.

- Schiene: Zum Schluss wird die Schiene auf die Betonschwellen gelegt. Die Schienen sind die Schienen, auf denen sich die Kräne bewegen. Sie werden mit Klammern oder anderen Befestigungsmitteln an den Betonschwellen befestigt, um sie sicher an ihrem Platz zu halten.

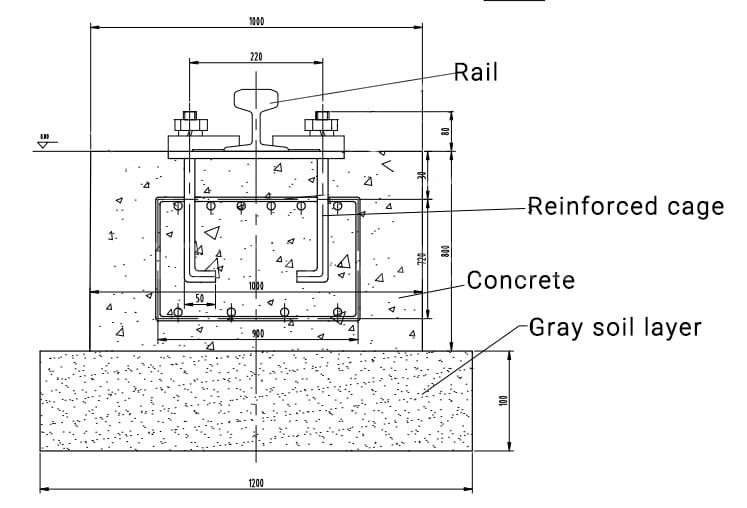

- Das bereitgestellte Bild zeigt eine technische Zeichnung eines Fundamententwurfs für ein Gleissystem. Es zeigt detailliert den Querschnitt des Fundaments und hebt die Schichten und Komponenten hervor, die bei seiner Konstruktion verwendet wurden. Hier ist eine Aufschlüsselung der in der Zeichnung gezeigten Elemente:

- Schiene:Dies ist die oberste Komponente des Fundaments. Die Schiene ist die Metallschiene, auf der sich Züge oder Kräne bewegen. Sie besteht normalerweise aus hochfestem Stahl und wird mit Bolzen und Befestigungselementen am Betonfundament befestigt. Die abgebildete Schiene wird direkt auf der Betonoberfläche montiert.

- Verstärkter Käfig:Unter der Schiene, eingebettet in den Beton, befindet sich ein verstärkter Stahlkäfig. Dieser Käfig besteht aus gitterartig angeordneten Bewehrungsstäben, die Zugfestigkeit verleihen und die allgemeine strukturelle Integrität des Betons verbessern. Der verstärkte Käfig verhindert Rissbildung und verteilt die Lasten gleichmäßiger im Beton.

- Beton:Die Betonschicht bildet den Hauptkörper des Fundaments. Es handelt sich um einen massiven, verstärkten Block, der die Schiene stützt und die von der Schiene übertragenen Lasten aufnimmt. Der Beton wird über den verstärkten Stahlkäfig gegossen und ist so ausgelegt, dass er erhebliche Druckkräfte aushält. Die Zeichnung gibt eine Dicke von 900 mm für das Betonfundament an, was für erhebliche Stabilität und Unterstützung sorgt.

- Graue Bodenschicht:Die graue Erdschicht ist die Basis, auf der das gesamte Fundament ruht. Diese Schicht besteht wahrscheinlich aus verdichteter Erde oder einem vorbereiteten Untergrund, der eine stabile Basis für das Betonfundament bietet. Die Zeichnung zeigt, dass diese Schicht eine Dicke von 100 mm hat, was darauf hinweist, dass sie gut verdichtet ist und als Basis dient, um die Last des Betonfundaments zu verteilen.

Der Portalkran benötigt lediglich Standard-Bodenschienen, die auf Gleisschwellen auf einem Kiesbett oder einem einfachen Betonfundament verlegt werden. Sie können sich an instabiles Gelände anpassen, wodurch der Bedarf an teuren Oberflächenarbeiten begrenzt wird und die Kräne überall dort mit voller Kapazität arbeiten können, wo Schienen verlegt werden können. Diese Art der Installation bietet erhebliche Einsparungen im Vergleich zur Stahlkonstruktion eines Portalkrans oder dem tiefen und schweren Fundament eines herkömmlichen Portalkrans.

Zusammenfassend

Wenn Sie die Platzersparnis im Lager, den geringeren Personaleinsatz, die schnellere LKW-Umschlagzeit, die geringere Anzahl an Ausrüstungsteilen, den geringeren Wartungsaufwand sowie die Vermeidung von Heizölverbrauch und Bodenverschmutzung berücksichtigen, ist der Portalkran die INTELLIGENTE Lösung.

Zusammenfassend lässt sich sagen, dass wir durch ein gründliches Verständnis der Unterschiede zwischen Portalkran und Brückenkran in fünf Aspekten (Klassifizierung, Kosten, Kastentyp und Fachwerk, starres Bein und flexibles Bein sowie Fundament) ihre Vorteile in verschiedenen Anwendungsszenarien besser bewerten können. Der Portalkran eignet sich mit seiner hohen Flexibilität und Anpassungsfähigkeit für den Einsatz in Umgebungen mit begrenztem Platz oder vielfältiger Handhabung, während der Brückenkran mit seiner überlegenen Tragfähigkeit und Vielseitigkeit ideal für schwere Hebeaufgaben ist. Bei Ihrer endgültigen Entscheidung können Sie basierend auf Ihren spezifischen Betriebsanforderungen, Ihrem Budget und den Standortbedingungen das für Sie am besten geeignete Hebegerät auswählen.

Ob Sie nach präziser Steuerung und Vielseitigkeit oder nach Stabilität und Kosteneffizienz suchen, das Expertenteam von Dafang Crane kann Sie individuell beraten und Ihnen Lösungen bieten, um sicherzustellen, dass Sie den Ertrag Ihrer Investition maximieren. Kontaktieren Sie uns und wir helfen Ihnen, die perfekte Kranlösung zu finden, um Ihre Betriebseffizienz zu verbessern!

Senden Sie Ihre Anfrage

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Hinzufügen: Industriegebiet Changnao, Stadt Xinxiang, Provinz Henan, China