Product Introduction

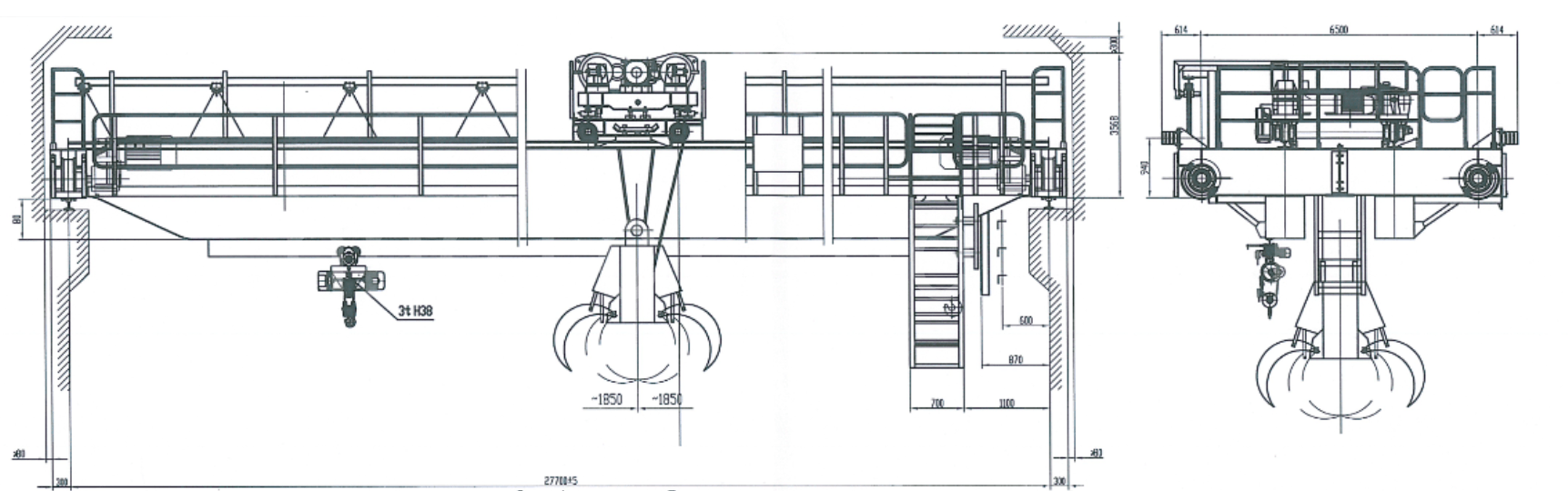

Electro hydraulic orange peel grabs are mostly used for overhead cranes and gantry cranes.

Hydraulic cactus grab is suitable for loading and unloading of any crane, and the maximum particle size does not exceed 100mm for bulk cargo, especially for supporting the use of container overhead cranes, and multi-function gantry cranes, which can greatly improve the comprehensive performance of cranes.

Hydraulic cactus grab is mainly used for the loading and unloading of irregular bulk cargo such as scrap steel, pig iron, stones, etc., and is suitable for steel mills, waste incineration treatment, ports, and railway transit occasions.

Electro hydraulic orange peel grabs relies on the electro-hydraulic system carried by the grab itself to complete the opening and closing action of the grab. It adopts a comprehensive combination of electro-hydraulic, mechanical technology, and system design. It has a high degree of automation, high efficiency and energy saving, and the digging force and closing force are higher than that of the rope grab of the same specification.

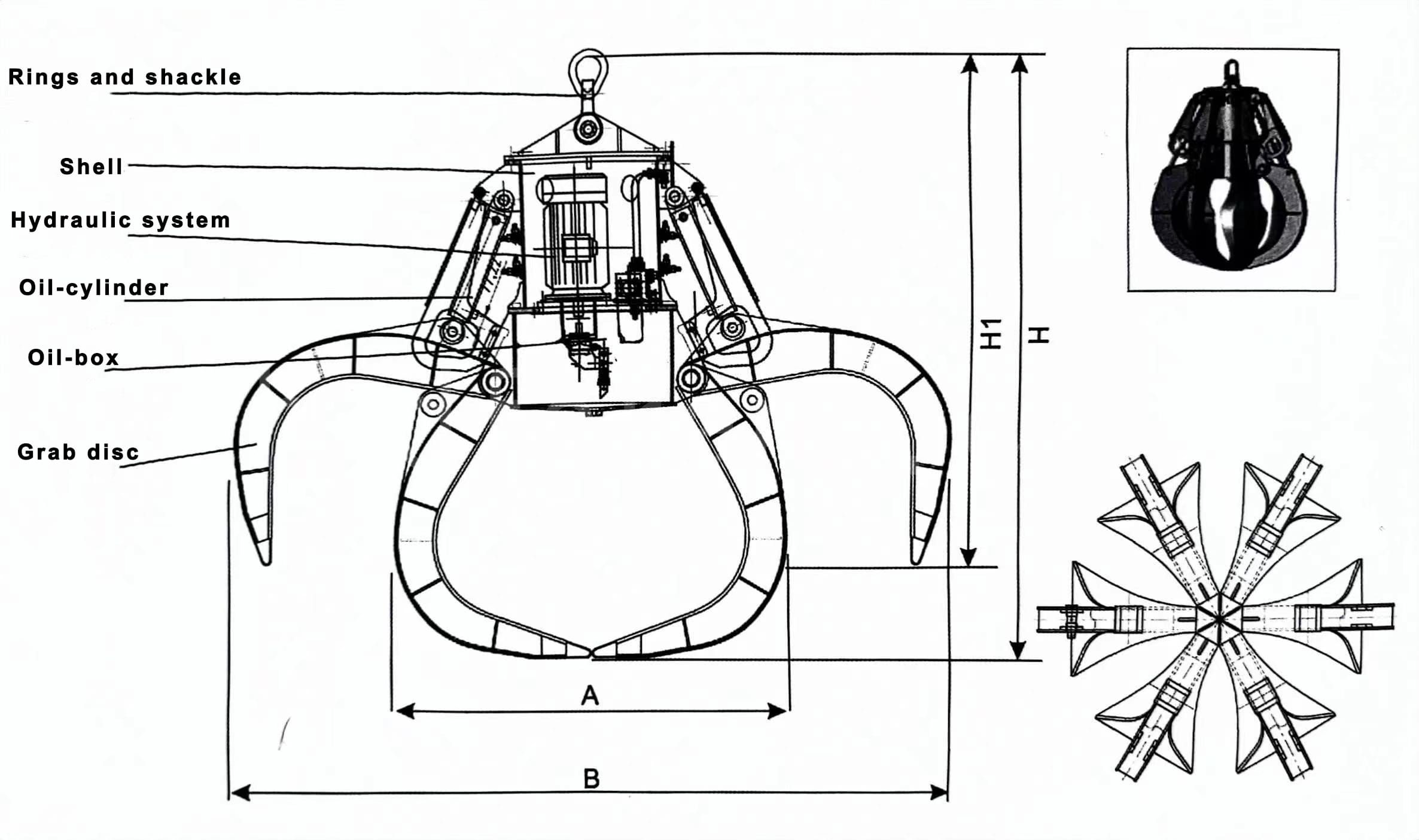

Technical parameter of electro hydraulic orange peel grabs

| Model | Volume (m3) | Grab self weight (t) | Using crane (t) | Motor power (Kw) | Operating pressure (bar) | Close time (s) | Image and size (mm ) | |||

| H | H1 | A | B | |||||||

| DYZ3[0.5]1.5 | 0.5 | 1.5 | 3.2 | 11 | 180 | 10 | 2180 | 1880 | 1570 | 2160 |

| DYZ3[0.6]1.6 | 0.6 | 1.7 | 3.2 | 11 | 180 | 11 | 2190 | 1900 | 1600 | 2220 |

| DYZ5[0.8]2.0 | 0.8 | 2.0 | 5 | 15 | 180 | 13 | 2380 | 1980 | 1700 | 2480 |

| DYZ5[1.0]2.5 | 1.0 | 2.5 | 5 | 15 | 180 | 14 | 2410 | 2070 | 1800 | 2700 |

| DYZ10[2.0]4.2 | 2 | 4.2 | 10 | 22 | 200 | 16 | 3330 | 2820 | 2220 | 3400 |

| DYZ5[2.5]2.6 | 2.5 | 2.6 | 5 | 18.5 | 180 | 17 | 3214 | 2895 | 2247 | 3572 |

| DYZ10[3.0]3.8 | 3.0 | 3.8 | 10 | 18.5 | 180 | 20 | 3214 | 2876 | 2500 | 3680 |

| DYZ10[5.5]4.3 | 5.0 | 4.3 | 10 | 22 | 200 | 19 | 3720 | 3295 | 3000 | 4400 |

| DYZ16[2.5]5.5 | 2.5 | 5.5 | 16 | 30 | 200 | 16 | 3690 | 3127 | 2420 | 3600 |

| DYZ16[8.0]5.6 | 8.0 | 5.6 | 16 | 30 | 200 | 19 | 3930 | 3294 | 3460 | 5280 |

| DYZ20[4.0]7 | 4.0 | 7 | 20 | 37 | 200 | 17 | 3820 | 3310 | 2680 | 4200 |

| DYZ20[12]8 | 12 | 8 | 20 | 37 | 200 | 25 | 4560 | 4100 | 3900 | 5500 |

| DYZ25[17]9 | 17 | 9 | 25 | 45 | 200 | 26 | 4780 | 4400 | 4200 | 6000 |

| DYZ30[20]11 | 20 | 11 | 30 | 45 | 200 | 28 | 4889 | 4550 | 4400 | 6300 |

Case of electro hydraulic orange peel grabs

Garbage collection

Scrap steel collection

Household waste collection

DAFANG CRANE project case-Electro hydraulic orange peel grabs are used on overhead cranes

- Grab type: Electro-hydraulic orange peel grabs, grab volume 4m3*A6

- Project type: Used in waste power generation projects, mainly used to deal with the mixing, dumping, handling, mixing, etc. of domestic waste to ensure uniform waste composition.Deal with 600t of garbage a day; the operation of the equipment is greater than 8000h.

- Material characteristics:

- The moisture content of domestic waste is 45%~65%

- The density of garbage in the grab is 0.6~0.9t/m3

- Garbage capacity (in the garbage compartment) 0.3~0.6t/m3

- Static accumulation angle 65 degrees

- Price reference:The hydraulic grab is more intelligent and more complex than the mechanical grab, so the price is 4.1 times that of the mechanical claw grab.

Why choose hydraulic grab

- Material diversity: The composition of domestic waste is complex, the moisture content is high, and the material diversity is rich, which requires a flexible grab for processing.The hydraulic grab is multifunctional and can effectively handle materials of different types and states.

- Grasping accuracy and efficiency: The hydraulic grab can accurately control the grasping force and angle, and adapt to the fine operations required in the garbage disposal process, such as mixing, dumping, handling and stirring, to ensure uniform garbage composition.

- Strong processing capacity: 600 tons of garbage are processed a day, and the equipment runs for up to 8,000 hours. The durability and efficient performance of the hydraulic grab meet the needs of high-intensity operations.

- Safety and stability: The hydraulic grab operates smoothly, which can reduce the risk of material spilling and operation, improve work safety, and is suitable for handling domestic waste with high moisture content and large density changes.

- Adapt to complex operating environments: The hydraulic grab can maintain efficient operation in a changeable working environment, especially suitable for garbage disposal, which requires frequent operation and flexible response to various materials.

- Long-term and high-frequency operations: The durability and stability of the hydraulic grab enable it to cope with long-term and high-frequency operations, reduce downtime and improve overall work efficiency.

In summary

The choice of hydraulic grab is based on its comprehensive considerations of flexibility, high efficiency, durability and safety, which can effectively meet the complex and high-intensity operation needs of waste power generation projects.