Pinzas mecánicas para grúas aéreas frente a pinzas hidráulicas: ¿cuál se adapta mejor a sus necesidades?

Tabla de contenido

¿Cuál es la diferencia entre las pinzas mecánicas y las pinzas hidráulicas? En términos de manipulación de materiales, elegir la pinza adecuada puede afectar significativamente la eficiencia y la productividad. Los dos tipos comunes de pinzas utilizadas en las grúas son las pinzas mecánicas y las pinzas hidráulicas. Exploremos sus diferencias y entendamos cuándo elegir cada tipo.

En primer lugar, echemos un vistazo a qué es una cuchara hidráulica y una cuchara mecánica:

Clasificación

Pinzas hidráulicas para grúas aéreas

Pinzas electrohidráulicas para cáscara de naranja

Pinzas electrohidráulicas tipo bivalva

Pinzas electrohidráulicas rectangulares

Cuchara hidráulica de punta redonda

Principio de funcionamiento

Pinzas hidráulicas para grúas aéreas

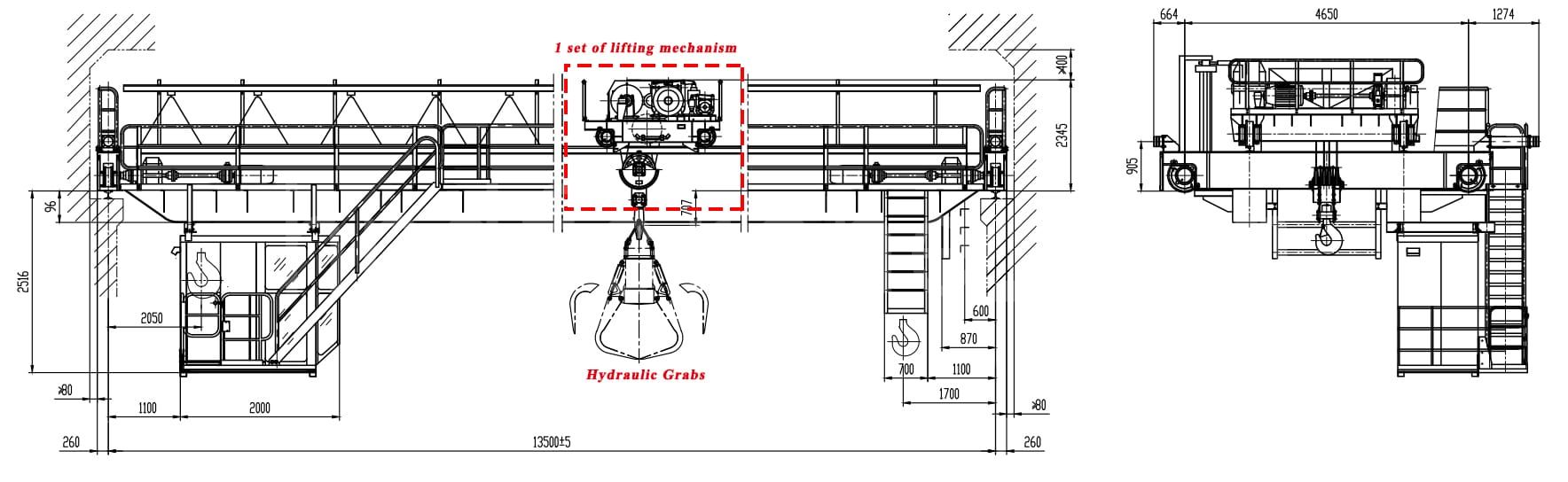

Un conjunto de mecanismos de elevación, la cuchara hidráulica se instala debajo del gancho mediante un gancho, que es fácil de desmontar, y la acción telescópica del cilindro hidráulico completa la apertura y el cierre del cucharón.

Tiene un motor, una estación de bombeo hidráulica y una válvula de control, que es impulsada por una fuente de energía externa para abrir y cerrar.

Las pinzas hidráulicas están conectadas al circuito hidráulico de la grúa.

El operador puede controlar la elevación, apertura y cierre, transferencia y otras acciones de la cuchara hidráulica en la sala de control.

Ampliar imagen: 1 mechanism","alt":"1 mechanism"}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Pinzas mecánicas para grúas aéreas

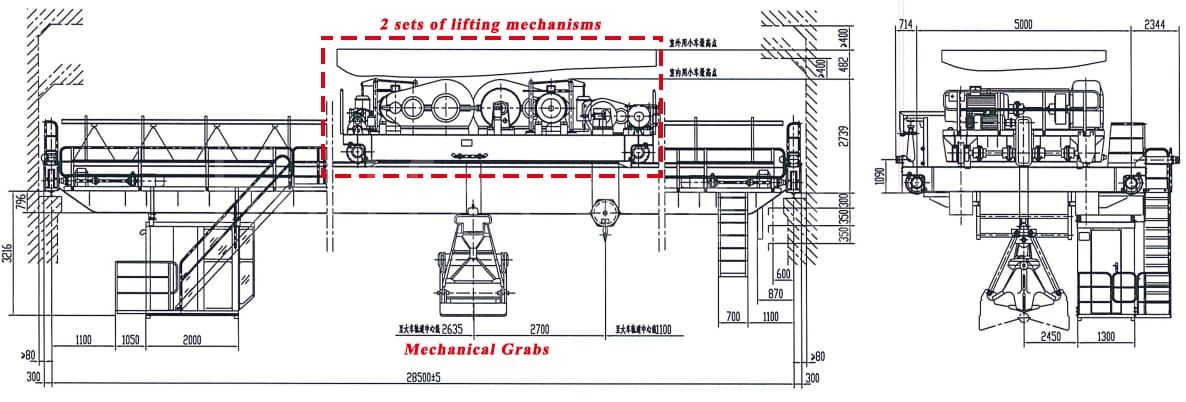

Debe estar equipado con 2 juegos de mecanismos de elevación para abrir y cerrar las pinzas mecánicas a través del carrete.

Las pinzas mecánicas se basan en bielas mecánicas, poleas y palancas para la acción de agarre.

Accionado por fuerza física directa, consta de dos o más brazos articulados con bordes afilados o dentados, similares a la mandíbula de una criatura, que pueden sujetar firmemente el material.

No se necesita energía hidráulica ni conexión eléctrica. El operador controla manualmente el movimiento de la pinza mecánica.

Ampliar imagen","alt":""}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Aplicación

Pinzas hidráulicas para grúas aéreas

Tratamiento de residuos domésticos:

Las grúas de cuchara utilizadas en la eliminación de residuos en proyectos de incineración de residuos domésticos y de generación de energía, recogen principalmente residuos domésticos.

Este es un producto inteligente que puede realizar operaciones sin supervisión.

Chatarra de acero y piedras grandes:

En los depósitos de chatarra y las plantas de procesamiento de piedras, se pueden controlar con precisión y procesar de manera eficiente materiales de diversas formas y tamaños.

Batería vieja:

Es más adecuado para un funcionamiento fino y preciso y reduce el riesgo de dañar la batería.

Industria de procesamiento de alimentos:

Coge encurtidos, encurtidos y bodegas para elaborar cerveza.

El acero inoxidable se utiliza habitualmente para reducir la contaminación.

Descontaminación de ríos:

Es muy adecuado para tareas de limpieza fina, proporcionando un control preciso para eliminar residuos sin perturbar demasiado el lecho del río.

Industria ligera:

El agarre de plásticos es muy adecuado para el procesamiento de plásticos de alta precisión, adecuado para la clasificación y el funcionamiento fino.

Ampliar imagen","alt":""}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Pinzas mecánicas para grúas aéreas

Tratamiento y clasificación de residuos:

Los ganchos de agarre mecánicos son buenos para manipular materiales a granel como troncos, chatarra, rocas y escombros.

Las instalaciones de gestión de residuos utilizan pinzas para clasificar y transferir materiales reciclables, residuos verdes y residuos de construcción.

Desmantelar y deconstruir:

Durante el proyecto de demolición, la pinza mecánica remueve la estructura del edificio agarrando y tirando del material.

La remoción de hormigón, vigas de acero y otros componentes minimiza la necesidad de mano de obra y acorta el cronograma del proyecto.

Carga y descarga:

La cuchara puede manipular eficazmente cargas a granel como carbón, granos y agregados.

Operaciones forestales:

Cargue y descargue troncos de manera eficiente para ayudar en la tala y el transporte de madera.

Mantienen a los operadores alejados de árboles caídos y troncos pesados, mejorando así la seguridad.

Ampliar imagen","alt":""}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Mantenimiento

Pinzas hidráulicas para grúas aéreas

El sistema hidráulico tiene muchos mecanismos y el mantenimiento es más engorroso que el de las pinzas mecánicas.

El sistema hidráulico es más complejo y el costo de mantenimiento es mayor, y es propenso a fugas de aire y otras fallas durante el uso.

Pinzas mecánicas para grúas aéreas

En comparación con las pinzas hidráulicas, las pinzas mecánicas son fáciles de mantener y duraderas. Las pinzas mecánicas suelen ser una cuestión de desgaste del cable de acero. En ese caso, solo es necesario reemplazar el cable de acero.

Las pinzas hidráulicas de la grúa están controladas por un sistema hidráulico, que tiene las ventajas de una alta precisión y un funcionamiento flexible. Es adecuada para cargar y descargar carga a granel y ocasiones que requieren un funcionamiento fino, pero su estructura es compleja y el coste de mantenimiento es alto. Las pinzas mecánicas se basan en el control de un cable de acero, que es adecuado para manipular grandes piezas de materiales y operaciones de servicio pesado en entornos hostiles. La estructura es relativamente simple y el coste de mantenimiento es bajo. Al elegir, el tipo de pinza a utilizar debe determinarse de acuerdo con los requisitos de operación, los requisitos de precisión y el entorno operativo.

Cómo elegir la garra adecuada

Aclare su propósito:Antes de profundizar en las opciones, aclare sus requisitos específicos. Pregúntese:

- ¿Qué materiales desea tratar? (Troncos, chatarra, piedra, etc.)

- ¿Qué tareas realizará la cuchara? (Carga, clasificación, desmontaje, etc.)

- ¿A qué tipo de dispositivo se conectará? (Grúa pórtico, grúa aérea)

- ¿Cuál es la gravedad específica del material que agarras? ¿El número de cubos del agarre?

- Según las características del material a agarrar, la pinza suele dividirse en cuatro tipos básicos: ligera, media, pesada y superpesada.

| El tipo de material a agarrar | Material de agarre | Capacidad de peso (t/m³) |

| Luz | Coque, escorias, cereales, patatas, cal antracita de calidad media, cemento, tierra, grava, arcilla, ladrillos rotos, etc. | 0.5~1.2 |

| Medio | Turba, grandes trozos de carbón antracita, carbón compactado, arcilla, caliza, grava, sal, grava, ladrillos, bauxita, copos de óxido de hierro, cemento, arena y ladrillos en agua, etc. | 1.2~2.0 |

| Pesado | Caliza, arcilla pesada, minerales de tamaño pequeño y mediano, roca dura, óxido de hierro en forma de varilla, mineral de hierro, polvo de concentrado de plomo, etc. | 2.0~2.6 |

| Sobrepeso | Minerales de gran tamaño, minerales de manganeso de gran tamaño, polvo de mineral de plomo aglomerado sedimentario, etc. | 2.6~3.3 |

- ¿Cuál es el tonelaje de su grúa equipada con pinza?

Compatibilidad de accesorios: Asegúrese de que la pinza sea compatible con el equipo existente.

Consideraciones presupuestarias: El rango de precios de la pinza es diferente. Equilibre su presupuesto en función de la función y la durabilidad de la pinza.

Comentarios y sugerencias: Investigue en línea, lea reseñas de usuarios y busque sugerencias de colegas de la industria.

Acuda al fabricante de la grúa para realizar una inspección y prueba en el lugar antes de comprar: Pruebe la pinza en condiciones reales tanto como sea posible. Evalúe su rendimiento, facilidad de uso y funcionalidad general.

Tenga en cuenta que elegir la pinza adecuada requiere un equilibrio entre funcionalidad, seguridad y costo. Al considerar estos factores, encontrará la pinza perfecta que puede aumentar la productividad y garantizar un funcionamiento sin problemas.

Elija las pinzas hidráulicas y mecánicas adecuadas según las necesidades de los diferentes proyectos.

Utilizamos 2 proyectos anteriores de Dafangcrane para ayudarle a distinguir la selección.

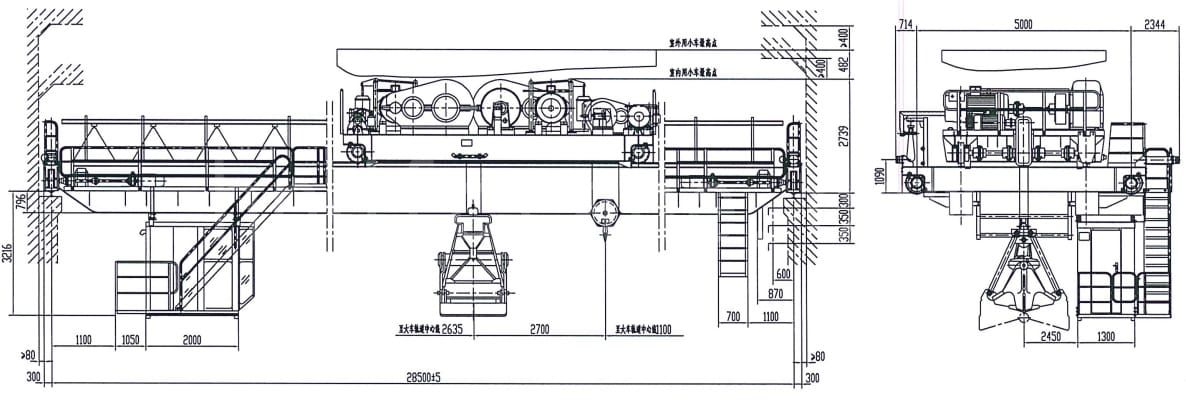

Caso 1: Se utilizan cucharas hidráulicas en grúas aéreas

Ampliar imagen","alt":""}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

- Tipo de agarre: Pinzas electrohidráulicas para cáscara de naranja , captar volumen 4m3*A6

- Tipo de proyecto: Se utiliza en proyectos de generación de energía a partir de residuos, principalmente para tratar la mezcla, vertido, manipulación, mezcla, etc. de residuos domésticos para garantizar una composición uniforme de los residuos. Trata 600 t de basura al día; el funcionamiento del equipo es superior a 8000 h.

- Características del material:

- El contenido de humedad de los residuos domésticos es de 45%~65%

- La densidad de basura en el triturador es de 0,6 a 0,9 t/m3.

- Capacidad de basura (en el compartimento de basura) 0,3~0,6t/m3

- Ángulo de acumulación estática 65 grados

- Referencia de precios: Las pinzas hidráulicas son más inteligentes y más complejas que las pinzas mecánicas, por lo que el precio es 4,1 veces el de la pinza de garra mecánica.

- ¿Por qué elegir pinzas hidráulicas?

Diversidad material: La composición de los desechos domésticos es compleja, el contenido de humedad es alto y la diversidad de materiales es rica, lo que requiere una pinza flexible para su procesamiento. Las pinzas hidráulicas son multifuncionales y pueden manipular eficazmente materiales de diferentes tipos y estados.

Precisión y eficiencia en el agarre: Las pinzas hidráulicas pueden controlar con precisión la fuerza y el ángulo de agarre, y adaptarse a las operaciones finas requeridas en el proceso de eliminación de basura, como mezclar, volcar, manipular y revolver, para garantizar una composición uniforme de la basura.

Fuerte capacidad de procesamiento: Se procesan 600 toneladas de basura al día y el equipo funciona hasta 8.000 horas. La durabilidad y el rendimiento eficiente de la cuchara hidráulica satisfacen las necesidades de operaciones de alta intensidad.

Seguridad y estabilidad: Las pinzas hidráulicas funcionan con suavidad, lo que puede reducir el riesgo de derrame de material y funcionamiento, mejorar la seguridad laboral y es adecuada para manipular residuos domésticos con alto contenido de humedad y grandes cambios de densidad.

Adaptarse a entornos operativos complejos: Las pinzas hidráulicas pueden mantener un funcionamiento eficiente en un entorno de trabajo cambiante, especialmente adecuadas para la eliminación de basura, que requiere un funcionamiento frecuente y una respuesta flexible a diversos materiales.

Operaciones de larga duración y alta frecuencia: La durabilidad y estabilidad de la pinza hidráulica le permiten hacer frente a operaciones a largo plazo y de alta frecuencia, reducir el tiempo de inactividad y mejorar la eficiencia general del trabajo.

En resumen, la elección de la cuchara hidráulica se basa en sus consideraciones integrales de flexibilidad, alta eficiencia, durabilidad y seguridad, que pueden satisfacer de manera eficaz las necesidades de operación complejas y de alta intensidad de los proyectos de generación de energía a partir de residuos.

Caso 2: Se utilizan cucharas mecánicas en grúas aéreas

Ampliar imagen","alt":""}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

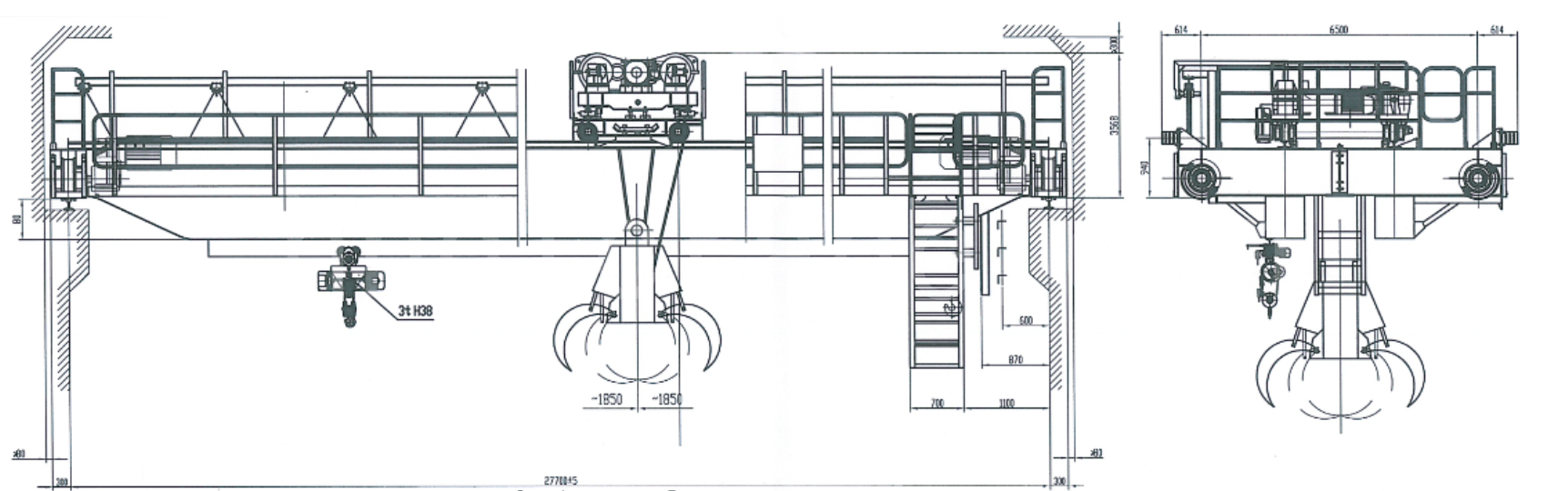

- Tipo de agarre: Cuchara mecánica de cuatro cuerdas con pinza tipo almeja ,captura volumen 4m3

- Gravedad específica del material: 2 t/m3

- Tipo de proyecto: Utilizado en empresas de materiales magnéticos de polvo metálico, el cable de agarre adopta un tipo de acero inoxidable resistente a la temperatura.

- Referencia de precio: La pinza mecánica tiene una estructura simple y cuesta aproximadamente 24.39% de la pinza hidráulica, lo que la convierte en la mejor opción si tiene un presupuesto limitado.

- ¿Por qué elegir una pinza mecánica?

Buen sellado: Los materiales como el polvo metálico son fáciles de dispersar durante la manipulación, y las pinzas mecánicas tienen una estructura simple y un buen sellado, lo que puede prevenir eficazmente que los materiales se derramen y mejorar la limpieza y la seguridad de las operaciones.

Rentabilidad: Los costos de compra y mantenimiento de las pinzas mecánicas son bajos y son adecuadas para operaciones con presupuestos limitados y uso a largo plazo y de alta frecuencia.

Durabilidad: El cable de agarre adopta un tipo de acero inoxidable resistente a la temperatura, que es adecuado para la manipulación de materiales como polvos metálicos que tienen altos requisitos de temperatura y resistencia a la corrosión.

Entorno aplicable: Para el polvo metálico en estado seco, la fuerza de agarre y la estabilidad de las pinzas mecánicas son suficientes para satisfacer las necesidades, y la operación es simple y fácil de mantener.

Eficiencia laboral: La pinza mecánica puede completar de manera rápida y eficiente la captura y manipulación de materiales, mejorar la eficiencia general del trabajo y es adecuada para las necesidades de operación rápida de las líneas de producción industrial.

En resumen, la elección de la pinza mecánica se basa en consideraciones integrales de cierre, rentabilidad, durabilidad, entorno aplicable y eficiencia operativa, que pueden satisfacer de manera efectiva las necesidades reales de las empresas de materiales magnéticos de polvo metálico.

Comparación completa

Se recomienda elegir pinzas mecánicas en los siguientes casos:

- Entorno operativo hostil: En entornos hostiles con alto nivel de polvo y humedad, las pinzas mecánicas son más confiables que las pinzas hidráulicas y se ven menos afectadas por el impacto ambiental.

- La simplicidad y la rentabilidad son prioridades: la pinza mecánica tiene una estructura sencilla y bajos costes de mantenimiento, lo que la hace adecuada para proyectos con presupuestos limitados.

- Fácil mantenimiento: Las pinzas mecánicas tienen una estructura simple y una pequeña carga de trabajo de mantenimiento, lo que puede reducir el tiempo de inactividad y mejorar la continuidad de la operación.

- Equipamiento disponible: Si el equipo de elevación existente no dispone de sistema hidráulico, se puede utilizar directamente la pinza mecánica sin necesidad de modificaciones o inversiones adicionales.

- Entrenamiento de operación: el funcionamiento de la pinza mecánica es relativamente simple, el costo de capacitación es bajo y es adecuado para una implementación y uso rápidos.

Se recomienda elegir pinzas hidráulicas en los siguientes casos:

- Cuando se requiere una mayor fuerza de agarre: las pinzas hidráulicas son flexibles en su funcionamiento, la fuerza y el ángulo de agarre se pueden controlar con precisión y la fuerza de agarre es más fuerte que la de las pinzas mecánicas.

- Opera maquinaria hidráulica: si ya dispone de equipo hidráulico, las pinzas hidráulicas se pueden integrar directamente para mejorar la eficiencia operativa.

- La manipulación segura y eficiente de materiales es esencial: las pinzas hidráulicas funcionan con suavidad, reducen los daños materiales y los riesgos operativos y mejoran la seguridad y la eficiencia del trabajo.

- Existen requisitos de automatización: la pinza hidráulica se puede integrar con el sistema de control de automatización para lograr operaciones más inteligentes y mejorar la eficiencia general de producción.

En resumen, las pinzas mecánicas y las pinzas hidráulicas tienen sus ventajas en la manipulación de materiales. Evalúe sus requisitos específicos, considere el equipo disponible y tome una decisión informada. Ya sea que elija la robustez y simplicidad de las pinzas mecánicas o la precisión de las pinzas hidráulicas, recuerde que la pinza adecuada puede aumentar la productividad y garantizar un funcionamiento sin problemas.

Dafang Crane ofrece una amplia gama de pinzas hidráulicas y mecánicas, incluidos varios tipos de pinzas automatizadas diseñadas para satisfacer diversas necesidades. Ya sea que esté buscando soluciones eficientes para levantamientos pesados o aplicaciones especializadas, tenemos el equipo adecuado para usted. Haga clic en el enlace de la imagen a continuación para explorar nuestra selección completa y encontrar la pinza perfecta para las necesidades de su negocio.

15 cucharas de agarre diferentes para aplicaciones de grúa.

Envíe su consulta

- Correo electrónico: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Dirección: distrito industrial de Changnao, ciudad de Xinxiang, provincia de Henan, China