Green, Smart and Special︱ Ang Dafang Group ay Tumutulong sa Tangsteel na Bagong Distrito na Ilagay sa Produksyon

Sa matagumpay na pag-aapoy ng No. 1 blast furnace sa Tangsteel New District, isang berde at matalinong bagong steel mill ang nagsimula ng produksyon.

Mula sa disenyo, konstruksyon hanggang sa pagpapatakbo, ang Tangsteel New Area ay magpapakalat ng berde at matalino sa pinakamagandang "panimulang linya" ng mataas na kalidad na pag-unlad, at makakamit ang napakababang emisyon at hindi pinapatakbong kontrol sa buong proseso sa pamamagitan ng buong saklaw ng lugar.

Ang Tangsteel New District ay opisyal na inilagay sa produksyon

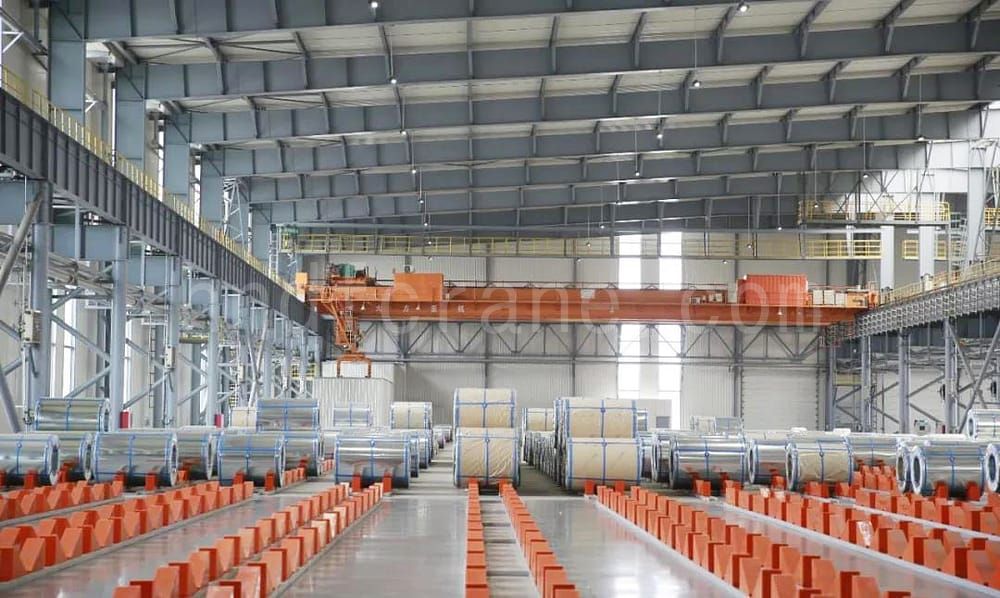

Sa ikatlong quarter ng taong ito, dose-dosenang mga “ultra-low emission unmanned overhead crane” na ginawa ng Dafang Group ang inilagay sa pagawaan ng Tangsteel New Area, at sabay-sabay na inilunsad ang pagsuporta sa intelligent control system, na maaaring awtomatikong pamahalaan ang pag-roll ng mga steel coil at i-pack ang mga ito sa storage, shipment, at stacking. Ito rin ang pangalawang batch ng "low-emission unmanned overhead cranes" na inihatid ng aming grupo para sa Tangsteel. Tumpak nitong nahahanap ang target nito sa malaking bodega at sa libu-libong steel coils, at mabilis itong itinaas sa itinalagang lokasyon.

Nagse-serve ng low-emission unmanned overhead crane sa Tangsteel New Area

Grupo ng Dafang ay nagtatag ng isang estratehikong kooperatiba na relasyon sa Tangsteel mula nang itatag ang pabrika. Hanggang ngayon, 30% ng lifting equipment ng Tangsteel ay mula sa Dafang. Sa pagtatayo ng Tangsteel New District, bilang pagkilala sa teknolohiya at serbisyo ng Dafang, walang pag-aalinlangan na pinili ng Tangsteel Group ang Dafang. Natupad ng Dafang Group ang misyon nito at naghatid ng malaking bilang ng berde at matalinong espesyal na kagamitan sa pag-angat para sa maayos na operasyon ng Tangshan Iron and Steel New Area.

Ipadala ang Iyong Pagtatanong

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Idagdag: Changnao Industrial District, Xinxiang City, Henan Province, China