pengenalan produk

Rebutan pemangkasan ialah jenis grab pukal baharu, yang sesuai untuk kren dwi-drum untuk memuat dan memunggah bijih besi, arang batu, baja pukal dan bahan lain.

Trimming Grab dicirikan oleh struktur baru, operasi mudah, berat ringan dan nisbah pemuatan tinggi. Apabila cengkaman pemangkasan dimuatkan dengan bijih besi, nisbah boleh mencapai 1:2.5.

Pukulan pembukaan dan penutupan cengkaman pemangkasan adalah pendek.

Kelebihan Trimming Grabs

1.Nisbah rebut tinggi

2. Kecekapan tinggi: Bukan sahaja meningkatkan nisbah cengkaman dapat meningkatkan kecekapan pengeluaran, tetapi daya cengkaman pegangan gunting adalah kecil apabila ia dibuka sepenuhnya dan mula mengambil barang. Dengan penutupan cengkaman, daya penggalian terus meningkat, yang sama dengan daya penggalian yang diperlukan untuk merebut barang, jadi kecekapan mencengkam bertambah baik. Hanya lejang pembukaan dan penutup yang lebih kecil diperlukan untuk melengkapkan penutupan, menjimatkan masa penutupan dan pembukaan serta meningkatkan kecekapan.;

3.Kondusif kepada pelepasan: disebabkan oleh bukaan besar pada cengkaman gunting, kawasan pegangan setiap baldi adalah 60% lebih tinggi daripada pegangan topang panjang, dan tiada penggali atau penumpuk diperlukan untuk menyelesaikan kerja pembersihan.

4. Kadar kegagalan yang rendah: Disebabkan oleh bilangan takal cengkaman ricih yang kecil dan pin yang lebih sedikit, ini mengurangkan kadar kegagalan beberapa bahagian yang haus. Disebabkan oleh kelebihan ambil gunting ini, banyak perebut kargo pukal besar di pelabuhan asing telah menggunakan pegangan gunting.

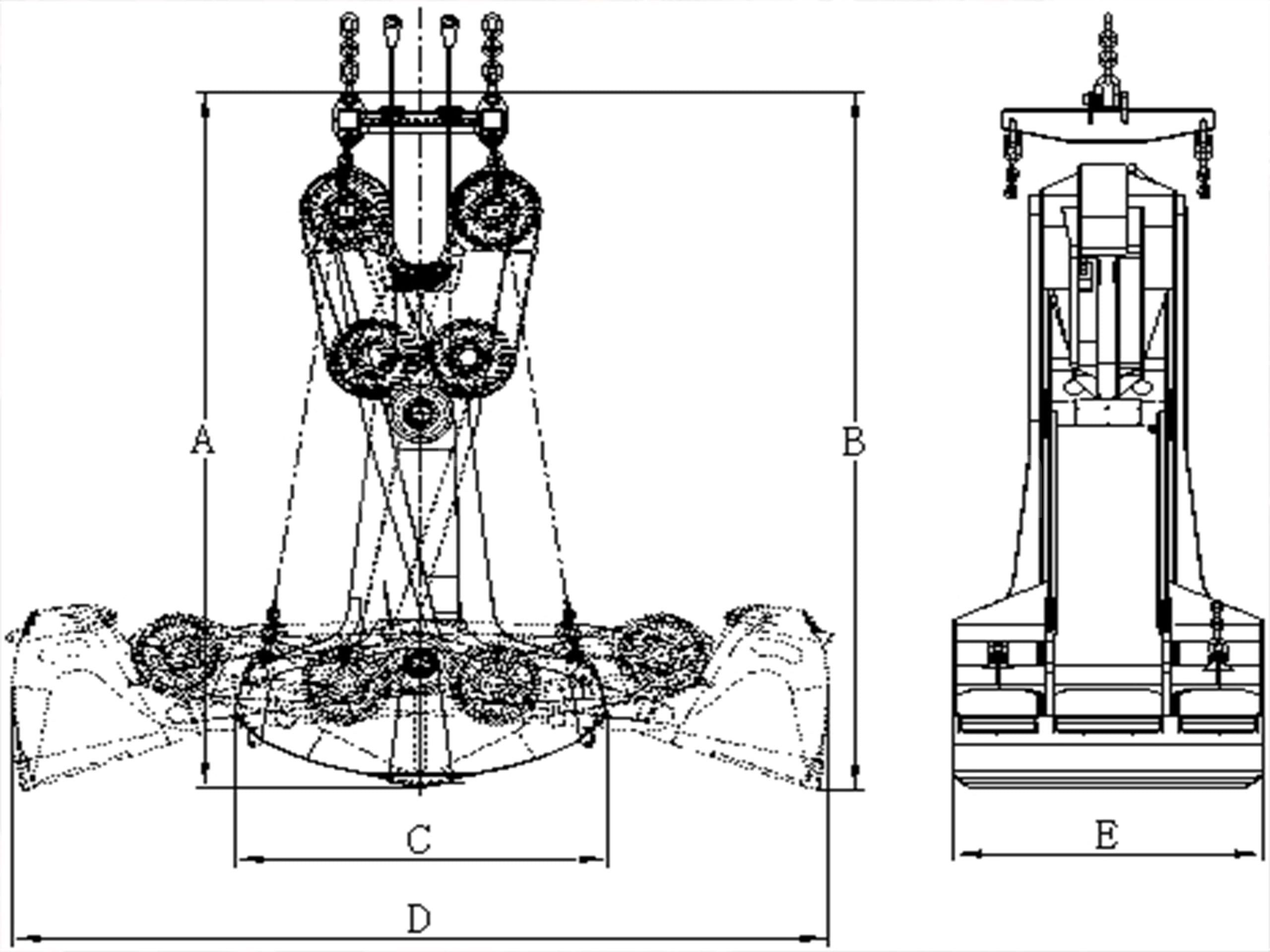

Parameter teknikal

| Model | Kapasiti(t) | Isipadu (m³) | Berat pukal bahant/m3 | Harga diri(t) | Dimensi(mm) | Diameter takal(mm) | Gunakan ketinggian(m) | Diameter tali dawai(mm) | ||||

| A | B | C | D | E | ||||||||

| CS16[4]5.5J | 16 | 4 | 2.5 | 5.5 | 4325 | 4475 | 2675 | 4590 | 2000 | ø560 | 10 | ø26 |

| CS20[5]6.6J | 20 | 5 | 2.5 | 6.6 | 4845 | 5000 | 2885 | 5110 | 2200 | ø650 | 11.5 | ø28 |

| CS25[6.5]8.3J | 25 | 6.5 | 2.5 | 8.3 | 5450 | 5600 | 3200 | 5730 | 2350 | ø720 | 12.5 | ø32 |

| CS32[8]11J | 32 | 8 | 2.5 | 11 | 6140 | 6290 | 3400 | 6400 | 2600 | ø800 | 14.5 | ø36 |

| CS40[10.2]13.5J | 40 | 10.2 | 2.5 | 13.5 | 6920 | 7070 | 3660 | 7200 | 2750 | ø880 | 16 | ø40 |

| CS52[13]17J | 52 | 13 | 2.5 | 17 | 7785 | 7935 | 3965 | 8065 | 3000 | ø920 | 18 | ø44 |

| CS63[16.5]21J | 63 | 16.5 | 2.5 | 21 | 8600 | 8815 | 4300 | 8930 | 3300 | ø1120 | 20 | ø48 |

Kes

Rebutan pemangkasan digunakan dalam adegan terminal pelabuhan

Pemangkasan cengkam untuk memuat dan memunggah bijih besi

Pegangan pemangkasan digunakan untuk merebut arang batu

Bagaimana untuk memilih grab yang betul

- Jelaskan tujuan anda:

Sebelum mendalami pilihan, sila jelaskan keperluan khusus anda. Tanya diri anda:

- Apakah bahan yang anda ingin berurusan? (Balak, besi buruk, batu, dll.)

- Apakah tugas yang akan dilakukan oleh grab? (Memuatkan, menyusun, membongkar, dsb.)

- Apakah jenis peranti yang akan disambungkan? (Kren gantri, kren atas)

- Apakah graviti tentu bahan yang anda ambil? Bilangan kiub rampasan?

Berapakah tonase kren anda yang dilengkapi dengan grab?

Mengikut ciri-ciri bahan yang direbut, rebut biasanya dibahagikan kepada empat jenis asas: ringan, sederhana, berat dan super berat.

| Jenis bahan untuk direbut | Ambil bahan | Berat kapasiti(t/m³) |

| Cahaya | Coke, slag, bijirin, kentang, kapur antrasit berkualiti sederhana, simen, tanah, kerikil, tanah liat, bata pecah, dsb. | 0.5~1.2 |

| Sederhana | Gambut, kepingan besar arang batu antrasit, arang batu padat, tanah liat, batu kapur, kerikil, garam, kerikil, batu bata, bauksit, kepingan oksida besi, simen, pasir dan batu bata dalam air, dsb. | 1.2~2.0 |

| berat | Batu kapur, tanah liat berat, bijih kecil dan sederhana, batu keras, oksida besi berbentuk rod, bijih besi, serbuk pekat plumbum, dsb. | 2.0~2.6 |

| Berat badan berlebihan | Bijih besar, bijih mangan besar, serbuk bijih plumbum terkumpul sedimen, dsb. | 2.6~3.3 |

- Keserasian aksesori: Pastikan grab serasi dengan peralatan sedia ada.

- Pertimbangan belanjawan: Julat harga grab adalah berbeza. Imbangkan bajet anda berdasarkan fungsi dan ketahanan grab.

- Komen dan cadangan: Penyelidikan dalam talian, baca ulasan pengguna dan dapatkan cadangan daripada rakan industri.

- Pergi ke pengilang kren untuk pemeriksaan dan ujian di tapak sebelum membeli: uji rampasan dalam keadaan sebenar sebanyak mungkin. Nilai prestasinya, kemudahan penggunaan dan kefungsian keseluruhannya.

Perlu diingat bahawa memilih rampasan yang betul memerlukan keseimbangan antara kefungsian, keselamatan dan kos. Dengan mengambil kira faktor-faktor ini, anda akan menemui rampasan sempurna yang boleh meningkatkan produktiviti dan memastikan operasi lancar.