produkt introduksjon

Low headroom overhead cranes are specially tailored for workshops with restricted floor height. Generally speaking, the headroom height of the low headroom overhead crane is 0.3-0.5m higher than that of the traditional single girder overhead crane. The embedded track system of the low-headroom electric hoist accurately runs along the lower flange of the main beam. It is equipped with millimeter-level frequency conversion positioning technology, which is especially suitable for scenarios with millimeter-level error requirements such as auto parts assembly and precision mold processing. The fully enclosed dust-proof structure is combined with lubrication-free bearings, the maintenance cycle is extended 3 times, and the equipment overhaul can be easily completed in a narrow space.

Low Headroom Overhead Crane Price List

The price of low headroom overhead cranes will vary depending on factors such as lifting capacity, span length and work level. The following is the price list of some low headroom overhead cranes:

| Low Headroom Overhead Crane | Span/m | Working System | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,027-5,437 |

| 2 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,247-6,297 |

| 3 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,337-7,677 |

| 5 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,846-8,646 |

| 10 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $4,184-10,134 |

| 16 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $4,553-11,433 |

| 20 Ton | 7.5-27.5 | A3 | three-phase 380v 50Hz | $7,502-16,762 |

If you need more detailed parameters and price, please let us know your requirements (lifting weight, span, work level, workshop clearance height, with better on-site photos), Dafang Crane will have professional engineers, 1v1 according to your needs to provide quotation information.

Low Headroom Overhead Crane Features

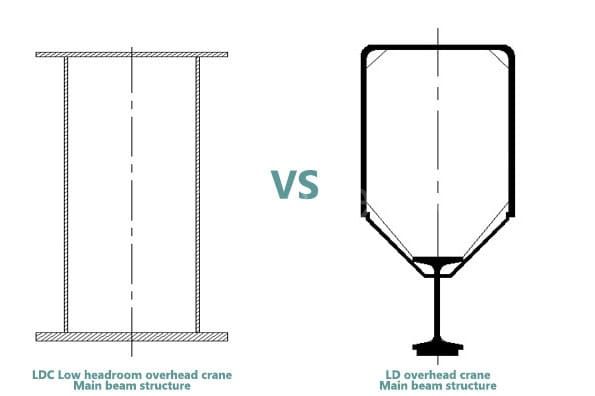

Square Box Shaped Main Beam

The main beam of the low headroom overhead crane is mostly in the form of a square box structure. The wheels of the low headroom electric hoist walking trolley can run back and forth on the lower flange plate of the main beam. This is different from ordinary LD single girder electric overhead cranes. The lifting trolley walks on the I-beam flange under the main beam. This difference in installation method allows the low-headroom electric hoist to provide a greater lifting height in a limited vertical space.

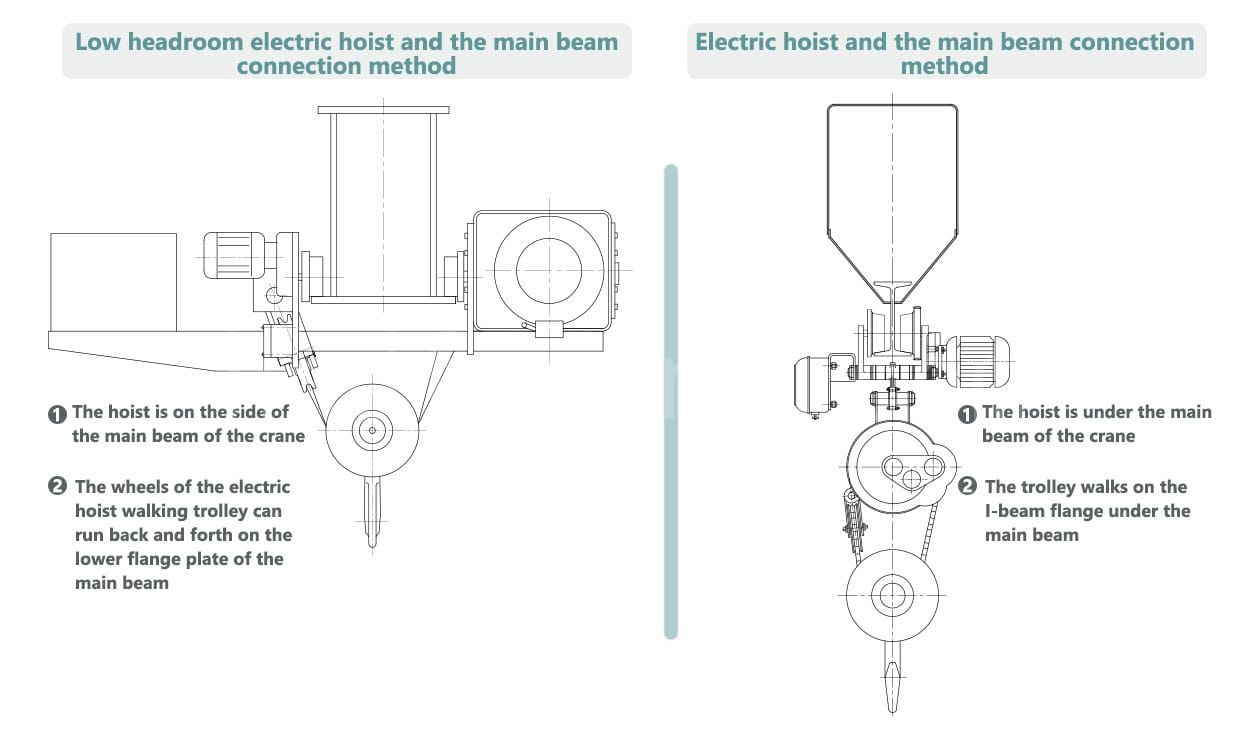

Side Suspension Installation

The the low headroom overhead crane adopts a partial hanging form and operates on one side of the main beam; the position of the hoist is raised from the traditional main beam to the upper side of the main beam, and the low headroom hoist is closer to the plane on the track, which effectively improves the lifting height; the limit size of the low headroom hoist hook is smaller than of ordinary hoist, so at the same plant height, the low headroom overhead crane can be raised higher; the installation method of the low-headroom hoist and the ordinary hoist is different. Schematic diagram:

3 Kinds of Low Headroom Electric Hoists

Elektriske taljer med lav takhøyde

- Nettohøyden økes med 200-500mm sammenlignet med vanlige CD-taljer.

- The lifting gearbox is made of high-quality alloy steel, featuring a three stage reduction mechanism, ensuring smooth operation, long service life, and reliable performance.

- The motor is a specially designed new self cooling cone-type motor. The motor housing is cast from aluminum alloy material with excellent heat dissipation properties. The motor has an insulation class of F and a protection rating of IP54, which is superior to standard motors.

- It can be customized according to user requirements, including single or dual speed hoist operation, variable frequency stepless speed control, remote control operation, overload protection, motor overheating protection, and other functions.

Elektrisk kjedetalje med lav takhøyde

- Karosseriet er kompakt og lite i størrelse, med lav plassbelegg. Det øker effektivt arbeidsområdet til utstyret innenfor begrensede områder, maksimerer plassutnyttelsen og minimerer blindsonedimensjonene til kroken.

- Den egner seg for arbeidsplasser med lave fabrikkhøyder og strenge krav til løftehøyde, spesielt i midlertidig oppførte fabrikker eller hvor det er behov for å utvide den effektive løfteplassen innenfor en fabrikk.

- Den kan brukes til traverskraner, svingkraner, heisekraner og mer.

Europeisk lav takhøyde elektrisk talje

- Modular Design: motor module, reducer module, wheel set module, reel module

- Compact structure with minimal dimensions: The use of a large diameter drum effectively increases the lifting height and reduces the left and right limits, minimizing the crane’s blind spots and providing users with a larger operational space.

- Maintenance-free: The high precision hard gear surface reducer comes pre-filled with international brand lubricating oil, eliminating the need for replacement throughout the product’s lifecycle. Utilizes international brand maintenance free steel wire ropes. High strength nylon rope guides transform from consumable parts to durable components. The electromagnetic disc brake features automatic brake gap compensation and is maintenance free.

- Motor power increase: Compared with traditional electric hoists, the motor power is reduced by 30%.

- Frequency conversion positioning technology: mature application, work efficiency increased by more than 20%.

- Noise optimization: The noise of the whole machine is less than 70 decibels.

- Safety protection: The brake pads are designed to be asbestos-free.

- Clean environment: nylon rope guide rail and wire rope, coupled with the sliding friction of the drum, will not produce metal dust, providing workers with a high cleanliness operating environment.

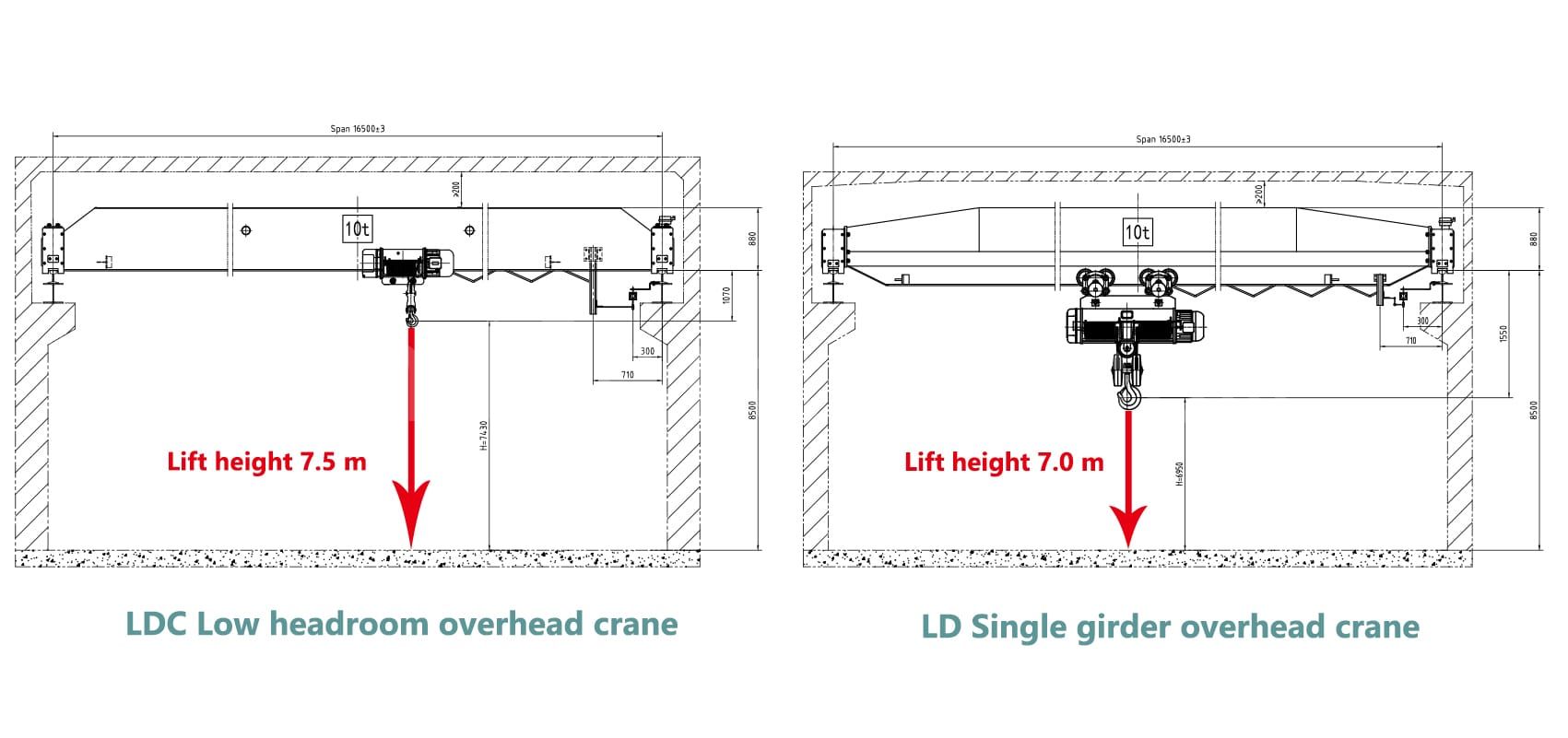

LDC Low Headroom Overhead Crane VS LD Single Girder Overhead Crane(Project comparison)

Compared with ordinary LD single girder overhead cranes, LDC low headroom overhead cranes have a better high space utilization rate. It is mainly used in situations where the headroom size in the height direction of the plant is limited, and the lifting height of the lifting equipment is required to be maximized as much as possible. Compared with the LD single girder overhead crane, the height of the plant is the same, but the lifting height is increased, which reduces the cost of the plant. For comparison through Dafang Crane’s project, the plant height of the two schemes is 9.5m:

| Parameter | LDC Low Headroom Overhead Crane | LD Enkel bjelke traverskran |

|---|---|---|

| Løftekapasitet | 10 Ton | 10 Ton |

| Spenn | 16.5 m | 16.5 m |

| Løftehøyde | 7.5 m | 7.0 m |

| Hook left limit size | 13.5 m | 13.5 m |

| Hook right limit size | 19.5 m | 19.5 m |

| Price | $5674 | $2674 |

As can be seen from the above, the low-headroom overhead crane is 0.5m higher than the ordinary overhead crane. The additional lifting height makes it easier for workers to assemble, reduces the space constraints in operation, and improves production efficiency. When the height and size of your plant are limited, the low-headroom overhead crane is your best choice.

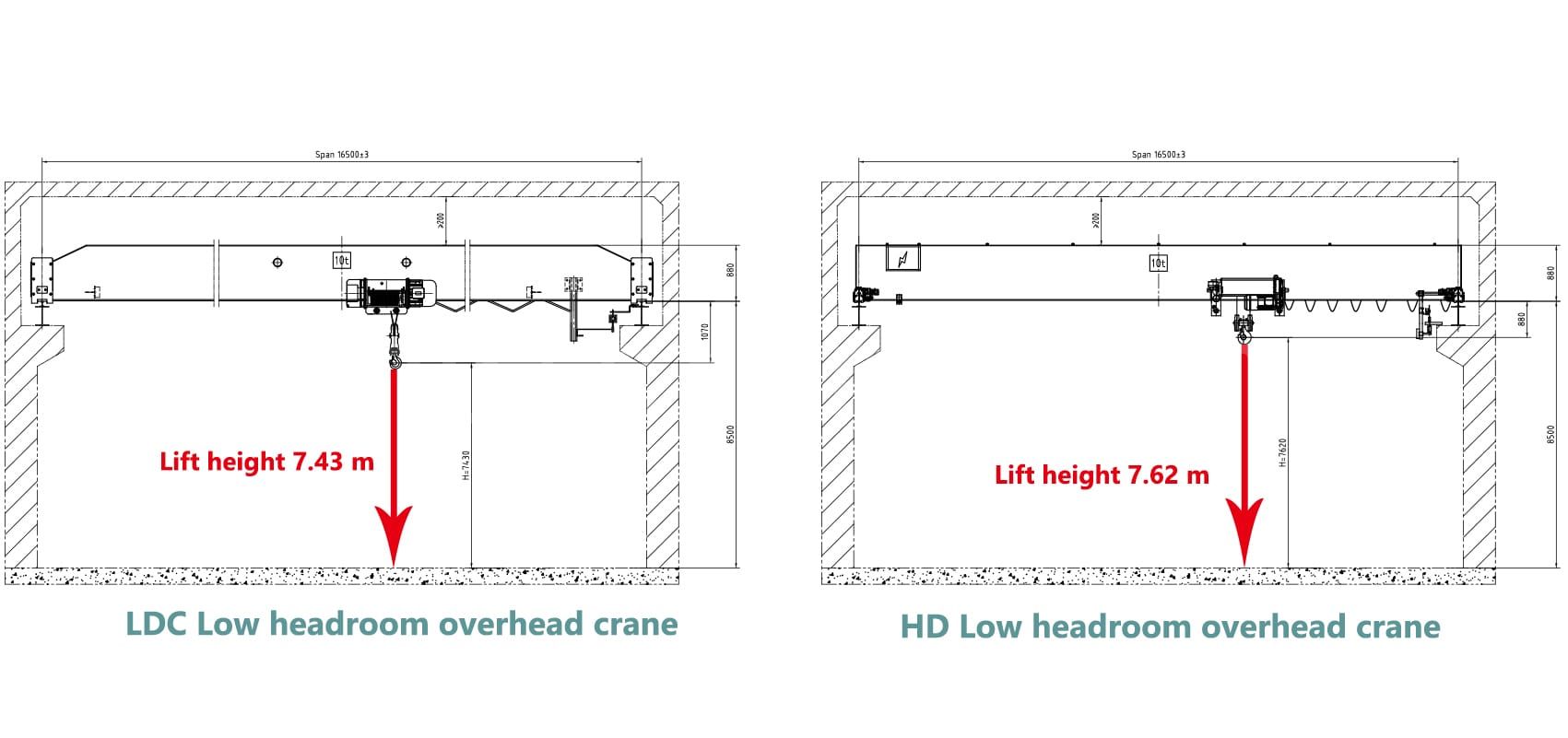

LDC Low Headroom Overhead Crane VS HD European Low Headroom Overhead Crane (Project comparison)

Compared with the HD European low headroom overhead crane, the low headroom hoist they use is different, and the lifting height will have a height difference of 0.19m. For comparison through the Dafang Crane’s project, the plant height of the two schemes is 9.5m:

| Parameter | LDC Low Headroom Overhead Crane | HD European Low Headroom Overhead Crane |

|---|---|---|

| Løftekapasitet | 10 Ton | 10 Ton |

| Spenn | 16.5 m | 16.5 m |

| Løftehøyde | 7.43 m | 7.62 m |

| Hook left limit size | 1.35 m | 0.95 m |

| Hook right limit size | 1.95 m | 1.28 m |

| Price | $5674 | $9599 |

As can be seen from the above, the HD European low headroom overhead crane is 0.19m higher than the LDC low headroom overhead crane, and the European style low headroom overhead crane adopts a modular design; compact structure, small size, and large diameter reel are used to effectively increase the lifting height, reduce the left and right limits, reduce the blind spots of crane operations, and provide users with greater operating space; European style low headroom hoist motor power is 30% lower than that of traditional low headroom electric hoists. According to your needs and budget, choose the appropriate low headroom bridge machine.

Dafang Crane Cases of Low Headroom Overhead Crane

Case 1:12.5 Ton Low Headroom Overhead Crane for Sale to Kenya

- Land: Kenya

- LDC12,5t-S6,9m-H9m

- Kontrollmodus: Pendellinjekontroll + Trådløs fjernkontroll

- Strømforsyning: 415V/50HZ/3Ph

- Løftehastighet: 0,35/3,5 m/min

- CT< hastighet: 20 m/min

- Med 44m P24 kranskinne og 44m rullebanebjelke (500*300*8*14/12mm)

In the 12.5 ton single girder overhead crane project in Kenya, the Sri Lanka customer upgraded the design to a low headroom overhead crane LDC type (up to 9 meters) due to the need for a lifting height of 8.6 meters and added wireless remote control, two speed operation, and seamless power conduction system. After 80 days of customized production and transportation, the equipment was successfully installed and the performance and service were highly recognized by customers. We provide customized design consulting for cranes based on workshop size to ensure that they are accurately adapted to project needs.

Case 2:10 Tons Low Headroom Overhead Crane Exported to Ethiopia

- Country: Ethiopia

- Kapasitet: 10t

- Spennvidde: 10m

- Lfit Høyde: 4,2m

- Løftehastighet: 7m/min

- Vinsjens reisehastighet: 20m/min

- Kranens reisehastighet: 30m/min

- Spenning: 380V, 50HZ, 3AC

- Sett på plass stativsøyle, asfaltere rullebanebjelke og skinner

- Add reinforcement structure to ensure crane’s stable travel.

Conventional overhead cranes require the plant to be equipped with support frames and track beams, but this project requires a new steel column and track system due to the lack of infrastructure on the site. All steel structure welding is completed before delivery, and customers only need to assemble it on site through high strength bolts. In order to ensure the accuracy of the design, please be sure to provide core parameters such as workshop span and lifting height, and our engineers will customize the adaptation plan accordingly.

Case 3:5 Sets Low Headroom Overhead Cranes Exported to Uganda

- Land: Uganda

- Kranspenn: 14,323 m (16 tonn og 5 tonn), 19,038 m (5 tonn)

- Løftehøyde: 5,1m

- Annet tilbehør: P24 og P38 kranskinner, rullebanebjelker, konsoller, 4 tonns og 16 tonns C kroker for spoleløfting, etc.

The project is for a Ugandan steel manufacturer to initiate a crane inquiry for the steel coil hoisting needs of the new warehouse. After recommending a low headroom overhead crane to reduce the height of the warehouse and ensure the working space, the two sides finalized the design and supporting rail beam, C-hook and other plans in August. After the customer confirmed the order in October, we completed the production efficiently, and all the goods were sent to Qingdao Port for shipment in November, and the project was coordinated smoothly throughout the process.

Case 4:10 Tons European Low Headroom Overhead Crane Exported to Mexico

- Land: Mexico

- Kranspenn: 10,9m

- Løftehøyde: 6m

- Annet tilbehør: P24 kranskinner

The customer is a distributor of steel products in Mexico and needs to build a new crane system in a workshop without a preset crane support structure for steel coil hoisting operations. In the first cooperation, we designed and delivered a complete solution including a 10-ton crane and supporting runway beams and columns to ensure the stable operation of the equipment. Based on the reliability verification of the first system, the customer urgently updated the crane of the same specification for the second time, requiring extremely fast production to meet the timeliness of its container transportation, and finally completed the customized delivery efficiently.

Sak 5:5 Ton European Low Headroom Overhead Crane Exported to Thailand

- Land: Thailand

- Kranspenn: 5,16m

- Løftehøyde: 5m

- Løftehastighet: 0,8/5m/min

- Trallens kjørehastighet: 2-20m/min

- Kranens reisehastighet: 3-30m/min

- Strømforsyning: 380v, 50hz,3ac

- Annet tilbehør: Innkapslet samleskinne, skinner, rullebanebjelke

The customer’s plant needs include the establishment of a crane system to lift steel coils without existing runway beams and pillars. The details of the project involve that the first order was for a set of 10-ton low headroom overhead crane and runway beam and column systems. Subsequently, due to good experience in use, a set of cranes of the same specifications were urgently ordered again, requiring production to be completed within 30 days and delivered on time.

Advantages of Dafang Crane Low Headroom Overhead Crane

1. Mature technology accumulation

As one of the earliest domestic companies to develop low headroom overhead cranes, Dafang Crane has rich and mature technical experience, nd has delivered more than 3,000 customized low-clearance solutions to 50+ countries around the world.

2. Service policy

Provide a variety of wearing parts required for standing low headroom overhead crane, such as rope guides, fan brake wheels, fire-breaking limiters, etc.

3. No routine quotation list

Including the installation cost of low headroom overhead crane cart track and safety sliding contact line.

Including the commissioning cost of the low headroom overhead crane after installation.

Includes 1 year warranty for structural parts.

4. International certification guarantee

Holds CE, GOST, ASME, and other multinational certifications. The core components adopt the global supply chain of Chint Electric/SEW/ABB/SIEMENS, and the design life of key structural parts is up to 20 years.