Havneportal kransvingelager: årsaker til feil og effektive reparasjonsløsninger

Innholdsfortegnelse

Uansett hvilken type kran det er, vil det være havneportalkran svinglager. Det er en viktig del av krankonstruksjonen. svinglager for havneportalkran kan ikke bare holde kranen stabil og sikker under drift, men også forbedre arbeidseffektiviteten. Naturligvis vil det uunngåelig være feil. For å sikre ytelsen til kranen under bruk, er det nødvendig å analysere årsaken til feilen og foreslå målrettede modifikasjonsmetoder.

Portalkraner er en type kranutstyr som er mer brukt i kranutstyr, og deres bruksområde er svært bredt. Havneportalkranens svinglager er selvfølgelig også en spesielt kritisk struktur. Det er to vanlige former for svinglager for havneportalkraner for portalkraner, den ene er roterende og den andre er roterende søyletype, og førstnevnte er mer stabil og den mekaniske strukturen er enklere. Derfor, når det er visse påvirkninger fra omverdenen, er det spesielt utsatt for feil, noe som er bundet til å påvirke kranens arbeid.

Driftsprinsippet for svinglager for havneportalkran

Det er mange strukturer i havneportalkran, og svinglagre til havneportalkran er en spesielt kritisk struktur. Det er forskjellige typer og spesifikasjoner av svinglagre for havneportalkran, så installasjonsmetodene er også forskjellige. Selv om valgt lagertype og spesifikasjoner er de samme, må det fortsatt analyseres på forhånd under installasjonen. De to parametrene for mekanisk bæreevne og aksial størrelse undersøkes vanligvis nøye for å sikre jevn installasjon av lageret og møte de faktiske produksjonsbehovene.

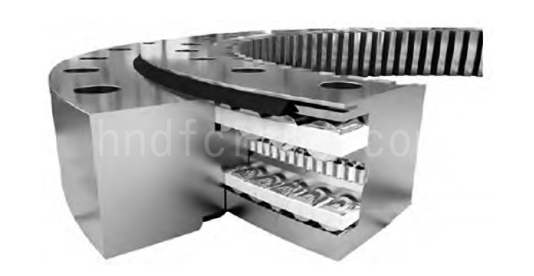

Avhengig av typen og arrangementet av rulleelementer, kan svinglager for havneportalkran deles inn i dobbeltrads rulletype, enkeltrads kryssrulletype, etc. På grunn av den store belastningen har svinglageret for havneportalkranen som kreves for krandrift, høyere krav, så generelt velges tre rader med rullesvinger for portdrift (Figure). Dette er fordi den indre ringen og den ytre ringen til svinglageret for havneportalkranen i denne metoden er festet i bunnen av henholdsvis dreieskiven og den øvre delen av det sylindriske portalen. Sammenlignet med den aksiale størrelsen er den radielle retningen til svinglageret mye større, og slagkapasiteten og den dynamiske belastningsmotstanden er betydelig sterkere slik at kranens sikkerhet kan garanteres under arbeid.

I en havneportalkran er delen som er koblet til den øvre støtten den indre roterende delen, og delen som er koblet til den nedre støtten er det store ringgiret, som vanligvis er boltet. Det er bruk av bolter for å fikse det, og det vil ikke rotere mens du arbeider.

Vanlige feil ved svinglager for havneportalkran

Feil design

Portalkraner svikter ofte på grunn av feil drift under drift eller mangel på normalt vedlikehold etter drift. Den bærende delen av svinglageret for havneportalkranen er spesielt utsatt for svikt. På grunn av den spesielt store belastningen den har, vil det påvirke driftsprosessen når en feil oppstår. For å løse disse problemene utføres generelt analyser og forskning fra utformingen av komponentene, for eksempel at installasjonskvaliteten ikke er høy nok under installasjonsprosessen, produksjonen er for grov, etc., noe som vil føre til deformasjon av visse deler av løpebanen til utstyret i faktisk drift.

Feil sent vedlikehold

Årsaken til svikt i de fleste svinglager for havneportalkraner skyldes svikt i den standardiserte operasjonen og unnlatelse av å utføre rettidig vedlikehold etter endt operasjon, noe som gradvis utvider de skjulte farene som eksisterte i begynnelsen. De skjulte farene som nevnes her kan være at det er små hull i koblingsstrukturen til svinglageret, eller det kan være at koblingsboltene er sprukket osv. Disse små skjulte farene er vanskelige å virkelig oppdage i begynnelsen. Imidlertid, med den kontinuerlige veksten av brukstiden, fortsetter disse hullene og sprekkene å bli hardt rammet, noe som til slutt fører til at fullstendig brudd eller delvis deformasjon av støttestrukturen svikter.

Strukturell deformasjon

Det er generelt to situasjoner med strukturell deformasjon. Den ene er at under den første utformingen er stivheten til støtterammen den har ikke nok, og den er spesielt utsatt for deformasjon over en lang periode (selvfølgelig er det ikke mange slike situasjoner); den andre er forårsaket av unormale krefter under arbeid, vanligvis på grunn av det store gapet i høyden på skinnene på begge sider, som får dørmaskinen til å vippe. Hvis vibrasjonen er forårsaket av den andre situasjonen, har det noe å gjøre med endringsverdien til stivhet.

Hvis rotasjonshastigheten til enheten er jevn, betyr det at denne typen vibrasjoner har sikkerhet. Når signalet slår ut etter en tid, kan disse sees visuelt i tidsakselerasjonsdiagrammet til vibrasjonen.

Havneportalkran svingende lagerbytteordning

Utskifting av svinglagre for havneportalkran er ikke en enkel oppgave, det må utføres i de følgende 6 trinnene.

Det første trinnet er å bruke jekklager. Totalt 4 jekklager må klargjøres, og deretter sveises de direkte til den øvre delen av sylinderen. Det må være større avstand mellom de to lagrene foran. Vanligvis er denne avstanden større enn den ytre diameteren til det store ringgiret. Samtidig må mange puter klargjøres. Disse putene trenger ikke å være av samme størrelse og tykkelse. Bommen skal plasseres der amplituden er størst. På dette tidspunktet må du bruke amplitudeindikatoren for å måle vekten til den maksimale belastningen som kreves på dette tidspunktet, og deretter bruke kroken til å løfte den.

Det andre trinnet er å løfte kroken som hekter motvekten for å sikre at det er en avstand på ca 10 cm mellom den og bakken, og så la den ikke bevege seg lenger. Dette krever at den vindtette forankringsanordningen for dreieskive er direkte låst, løfte den roterende girkassen og de roterende tannhjulene som er fjernet fra fotskruene, og sette dem alle på dreieskiven. Vær forsiktig så du ikke lar den rotere på dette tidspunktet, og hold den stabil.

I det tredje trinnet må 16# kanalstål brukes, hovedsakelig for å spille en støttende rolle i fremtiden, fordi det må la den nysveisede jekkstøtten lene seg på kanalstålet. På dette tidspunktet er det nødvendig å bestemme om den sentrale sleperingen skal fjernes basert på den faktiske situasjonen. For å lette den fleksible glidningen av det store ringgiret er det også behov for en liten plattform, som vanligvis bygges rett foran dreieskiven. Da må du direkte fjerne de store ringgirboltene, og etter å ha åpnet jekken vil du oppdage at dreieskiven sakte hever seg. Etter å ha fjernet alle boltene som eies av det store ringgiret, må kjettingtaljen installeres sideveis slik at det store giret vises direkte på den lille plattformen.

I det fjerde trinnet kan det forrige store ringgiret fjernes direkte av en bilkran, og deretter testes flyet, og det kreves et laserinstrument for testing. Hvis ujevnhetene overstiger standarden, må reparasjonstiltak tas i bruk umiddelbart for å reparere den. Det nye store ringgiret må fylles med smøreolje, selvfølgelig, dette trinnet må utføres på bakken.

Det femte trinnet er å installere det nye ringgiret. Alle installasjonstrinnene er nøyaktig det motsatte av det forrige. Selvfølgelig må alle høyfaste bolter som må installeres oppdateres for å sikre sikkerhet, og installasjonstrinnene må strengt følge spesifikasjonene. Etter at alt er installert, må aksept utføres, og stagene må fjernes etter at resultatene er fastslått å være kvalifisert.

Det sjette trinnet er å sette hele maskinen i produksjon og laste på nytt, slik at du etter 4 timer må sjekke alle høyfaste bolter på nytt, og forsikre deg om at det ikke er tegn til å løsne før du offisielt kan overlevere maskinen.

Konklusjon

Oppsummert, i kranutstyr har svinglagre en spesielt viktig rolle og kan sies å være en nøkkelkomponent. Hvis det mislykkes, vil det definitivt påvirke driften av kranen. Bare ved å analysere og forstå årsakene til feilen og finne løsninger på disse årsakene kan portalkranen garanteres å være trygg nok i fremtidig arbeid.

Send din forespørsel

- E-post: sales@hndfcrane.com

- Hva skjer: +86-191 3738 6654

- Tlf.: +86-373-581 8299

- Faks: +86-373-215 7000

- Legg til: Changnao industridistrikt, Xinxiang City, Henan-provinsen, Kina