Hva er forskjellen mellom en havneportalkran og en portalkran?

Innholdsfortegnelse

I moderne industri og logistikk er det avgjørende å velge riktig løfteutstyr for å forbedre driftseffektiviteten og redusere driftskostnadene. Havneportalkraner og portalkraner er to vanlige løfteløsninger, som hver har unike fordeler og kan møte behovene til ulike driftsscenarier. Enten det er en travel havneterminal eller et sofistikert fabrikkverksted, kan det å forstå forskjellene mellom disse to krantypene gjøre et informert valg og gi bedriften din et betydelig konkurransefortrinn.

Sammenligning av grunnleggende informasjon

| Kategori | Havneportalkran | Traverskran |

|---|---|---|

| Klassifikasjon | Fire-link portal havnekran Single Boom Portal kran | Semi portalkraner Enkel bjelke portalkraner Gantry kraner med dobbel bjelke Container portalkraner Truss portalkraner Bærbare portalkraner Justerbare portalkraner |

| Arbeidsprinsipp | En havneportalkran er en helroterende bomkran installert på en portalbase som går langs et bakkespor. Jernbanekjøretøyer eller andre bakkekjøretøyer kan passeres under. Med dreibar bom. Det er mye brukt i mekanisk lasting og lossing av last i havner og brygger, montering av skip på verft og bygging av damprosjekter på store vannkraftstasjonsplasser. Løftevekten til havneportalkranen er vanligvis 10-40t; rekkevidden er 8,5-73m; arbeidsnivået er A4-A7. Det vil si middels eller tungt arbeidsnivå. Mest egnet for hyppige arbeidsanledninger. Driftsmetode: betjenes ofte av førerhuset. | En portalkran er vanligvis et slags skinnedrevet løftemaskineri med en portalkonstruksjon i stål. Den er mer utbredt og har større fleksibilitet. Bunnområdet på dørkarmen er åpen, noe som kan romme større gjenstander, og stedet har høy lagringshastighet. Ikke utstyrt med roterende bom, vanligvis med støtteben. Brukes hovedsakelig til lasting og lossing av utendørs lasterom, materialgårder og bulklast. Løftevekten til portalkraner er vanligvis 3-800t; spennet er 3-36m; arbeidsnivået er A3-A5. Det er lett eller middels arbeidsnivå. Egnet for sporadiske eller periodiske arbeid. Driftsmodus: betjening av håndtak med jordkabel, betjening av trådløs fjernkontroll på bakken og betjening av førerhus. |

| Fordel | Kan dekke et bredere arbeidsområde. Arbeidsområdet er fordelt i en sylindrisk form, 360. Roterende og bevegelig arbeidsområde. Egnet for spesifikke prosjekter eller steder, allsidigheten er ikke like omfattende som portalkranen. Løftehøyden varierer med svingarmens amplitude. Tonnasjen varierer med amplituden til den roterende armen. | Mange bruksscenarier. Arbeidsområdet er fordelt i rektangulær form, og arbeidsområdet beveger seg frem og tilbake + opp og ned + venstre og høyre. Stabil struktur, god stabilitet, et bredt spekter av tilpasningsevne. Sterk allsidighet. Mange kategorier. |

Applikasjonssammenligning

Havneportalkran

Lasting og lossing

- Den brukes hovedsakelig i havner og friluftslagre for lasting og lossing med grip eller kroker.

- Løftevekten overstiger generelt ikke 40 tonn, noe som varierer med amplituden.

- Arbeidshastigheten er høy, så produktivitet er ofte en viktig indikator.

Skipsbygging

- Den brukes hovedsakelig til skipsplattformer, flytebrygger og riggeplasser, skrogskjøting, utstyrsrigging og annet heisearbeid, og kroker som spredere.

- Maksimal løftevekt er 30 tonn, og løftevekten reduseres tilsvarende når amplituden er stor.

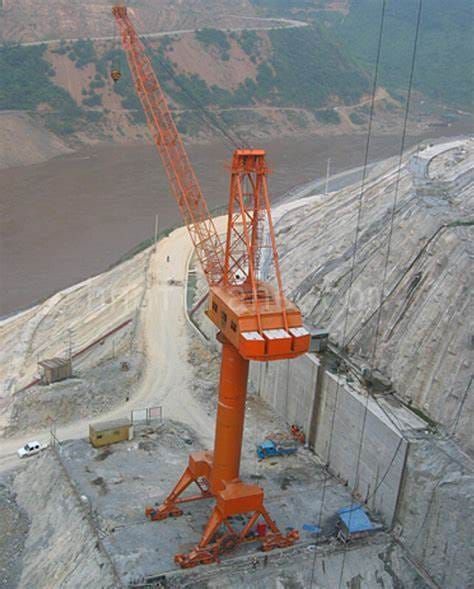

Konstruksjon og installasjon

- Den brukes hovedsakelig i vannkraftstasjoner for damvanning, utstyr, løfting av prefabrikkerte deler, etc, vanligvis med kroker.

- Løftevekten og arbeidshastigheten er vanligvis mellom de to første krantypene.

Gantry kran

Fabrikkproduksjonslinje

- Portalkraner brukes ofte for å hjelpe til med håndtering av tunge gjenstander og forbedre produksjonseffektiviteten.

- Fordi portalkranen har en stabil struktur og tåler stor vekt, spiller den en viktig rolle i industriell produksjon.

Havneterminal

- Portalkraner brukes til å laste og losse last som containere, noe som forbedrer laste- og losseeffektiviteten.

- Kortet ned lastomsetningstiden og bidro til utviklingen av logistikkbransjen.

Byggeplass

- Den brukes til å heise tunge gjenstander som byggematerialer, maskiner og utstyr.

- Kan gjennomføre løfteoppgaven raskt og sikkert.

Lager- og logistikksenter

- Den brukes til lasting, lossing, stabling og andre lagervareoperasjoner.

- Det forbedrer effektiviteten til lageret og reduserer arbeidskostnadene.

Oppsummer forskjellen gjennom påføring

Ulike bruksområder:

- Havneportalkraner brukes hovedsakelig i havner, friluftsverft, skipsbygging og andre felt, og er egnet for spesifikke profesjonelle formål, som lasting og lossing av gripe- eller krok, skjøting av skrog, installasjon av utstyr, etc.

- Portalkraner er mye brukt i industriell produksjon, byggeplasser, lager og logistikk og andre felt. De er egnet for generelle miljøer og har en lang rekke bruksområder. De brukes hovedsakelig til håndtering av tunge gjenstander, heising av byggematerialer og maskiner og utstyr, lasting, lossing og stabling av varer.

Løftevekt og struktur:

- Løftevekten til havneportalkranen er ikke fast, og den vil variere med endringen av amplitude, med en maksimal løftevekt på opptil 80 tonn.De er vanligvis komplekse i struktur, med flere løftehastigheter, og noen er også utstyrt med mikrobevegelsesenheter for å møte behovene til presis installasjon.

- Portalkraner er kjent for sin stabile struktur og tåler store vekter. De brukes vanligvis til å forbedre produksjonseffektiviteten og arbeidshastigheten.

Arbeidshastighet og produktivitet:

- Arbeidshastigheten til havneportalkranen er høyere eller lavere, avhengig av formålet. Havneportalkran for havner legger vekt på høy produktivitet, mens portalkraner for skipsbygging må oppfylle kravene til store løftehøyder og storskala operasjoner, arbeidshastigheten er lav og produktiviteten ikke høy.

- Portalkraner legger vekt på å forbedre arbeidseffektiviteten og redusere arbeidskostnadene innen industriell produksjon og logistikk, så de brukes ofte i situasjoner der det kreves raske og sikre løfteoppgaver.

Sammenlign og skille gjennom Dafang Cranes sak

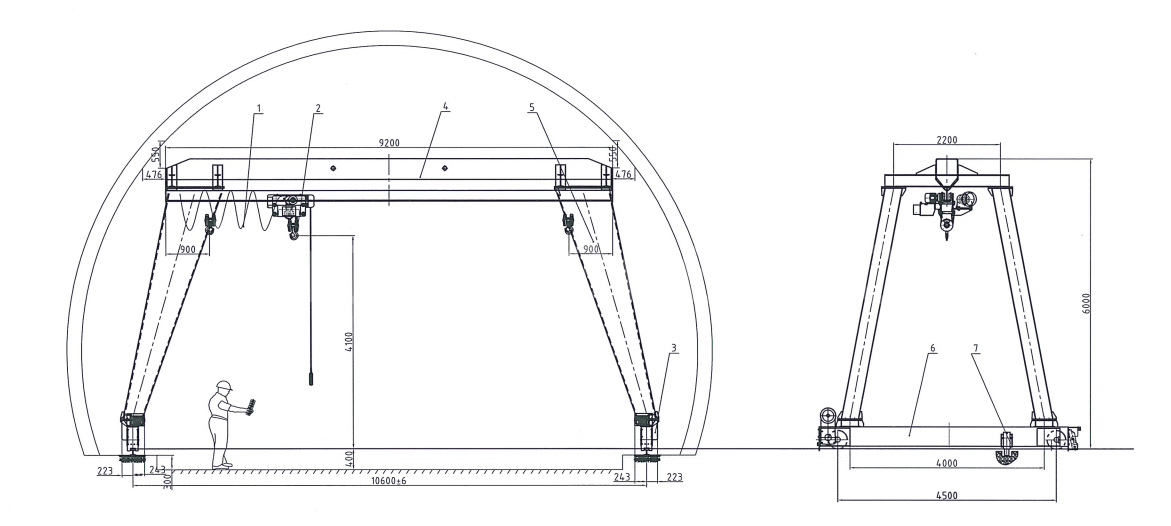

Elektrisk heisekran

China Railway Shanghai Engineering Bureau Group North Engineering

MH10t-10,6m

Arbeidsforhold

- Egnet for T-bane/tunnelkonstruksjon, spesielt for løfteoperasjoner i middels høyde (ca. 6 meter) og begrenset plass.

- Egnet for små og mellomstore materialhåndteringsbehov på ca. 5 tonn.

- Løftehastighetsområdet til den elektriske taljen er 0,8-8m/min, som oppfyller løftekravene til de fleste middels laster.

- Driftshastigheten er 2-20 meter/min, som er egnet for å fullføre heiseoperasjoner innen kort bevegelig avstand for å sikre jevn og sikker drift.

- Designstandarden er basert på JB/T5663-2008, som tilpasser seg driftsbehovene til ulike arbeidsforhold.

- Kan opprettholde god ytelse under ulike klimatiske forhold.

Fordel

- Enkel struktur, enkel å installere og betjene.

- Sterk tilpasningsevne, egnet for en rekke innendørs og utendørs arenaer.

- Kostnadseffektiv, rimelig, egnet for små og mellomstore bedrifter.

- Trygg og pålitelig, utstyrt med sikkerhetstiltak som bufferanordning, slagbegrensningsvern og overbelastningsbeskyttelse.

- Energisparing og miljøvern, elektrisk drift, lavt energiforbruk, lavt støynivå, grønt og miljøvennlig.

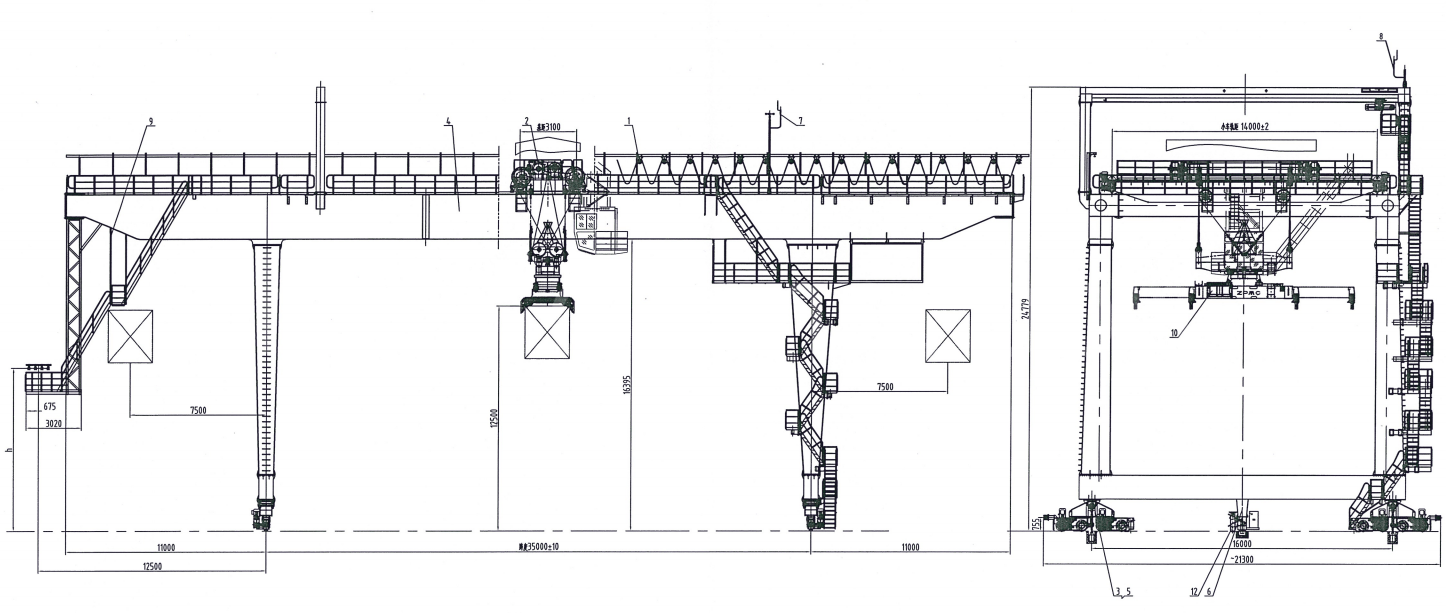

Skinnemonterte containerportalkraner

Jinchang Station Railway Comprehensive Cargo Yard Project

MG45T-35m

Arbeidsforhold

- Den skinnemonterte containerportalkranen brukes hovedsakelig i havneterminaler, jernbanelastegårder og logistikksentre, og brukes spesielt til containerlasting, lossing og håndtering.

- Designet er egnet for langdistanse- og langtidsoperasjoner, og kan effektivt håndtere omlasting av containere.

- Løftevekten er 45 tonn, noe som kan møte håndteringsbehovene til standard containere, inkludert fullastede 20 fots og 40 fots containere.

- Løftehastigheten er 12 (full last) m/min, 20 (uten last) m/min, og driftshastigheten til små biler og vogner er 50m/min, noe som kan fullføre løfte- og omlastingsoppgavene til containere på kort tid, og tilpasse seg høyintensive og høyfrekvente laste- og losseoperasjoner.

Fordel

- Effektiv lasting og lossing: rask løfting og bevegelse for å forbedre effektiviteten til containertransport.

- Langtidsdrift: egnet for brede lasterom og reduser frekvensen av utstyrsbevegelser.

- Stabil struktur: dobbel bjelkedesign for å sikre stabiliteten til tunge og høyhastighetsoperasjoner.

- Trygg og pålitelig: utstyrt med sikkerhetsinnretninger for å sikre sikker drift.

- Sterk tilpasningsevne: tilpasse seg driftsbehovene til forskjellige vær- og miljøforhold.

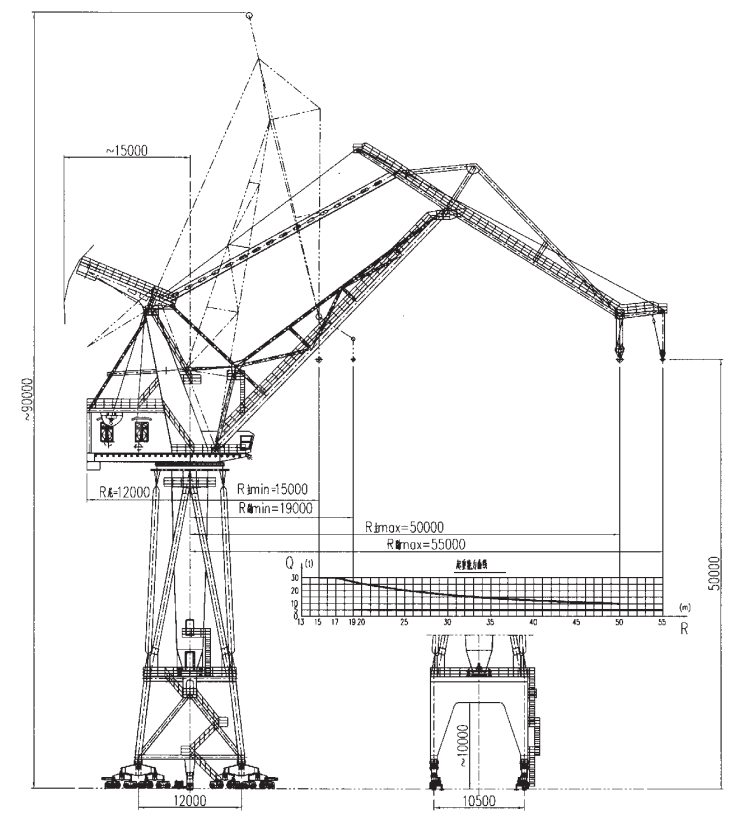

Guangzhou Changzhou Island 60t havneportalkran

Arbeidsforhold:

- Fire link portal havnekraner brukes hovedsakelig i havner, dokker, depoter og andre anledninger, og er egnet for lasting og lossing av tung last.

- Dens strukturelle design er egnet for håndtering av bulklast, containere og andre tunge materialer ved sjø- eller innlandshavner.

- Arbeidsradiusen til kranen varierer fra 15 meter til 55 meter, og dekker et bredt operasjonsområde, egnet for håndtering av en rekke forskjellige størrelser og vekter av last.

- Løftehøyden på kranen kan nå 50 meter, noe som er egnet for heiseoperasjoner på ruvende skip eller forhøyede anlegg.

Fordel:

- Et bredt spekter av operasjoner, som effektivt kan dekke lasthåndteringsområdet til store skip.

- Kan håndtere tung last og store containere, og tilpasse seg høyintensive driftskrav.

- Designet med fire lenker gir større driftsfleksibilitet og kan opprettholde stabil driftsytelse under forskjellige driftsradier.

- Havneportalkranen har en solid struktur, som gir god vindmotstand og veltemotstand for å sikre driftsikkerheten under harde værforhold.

- Utstyrt med et antisvingsystem, som er mer stabilt under drift, reduserer risting og vipping av godset, og er egnet for operasjoner med høy presisjon.

- Komplekse operasjoner kan vanligvis utføres i et mindre arbeidsområde.

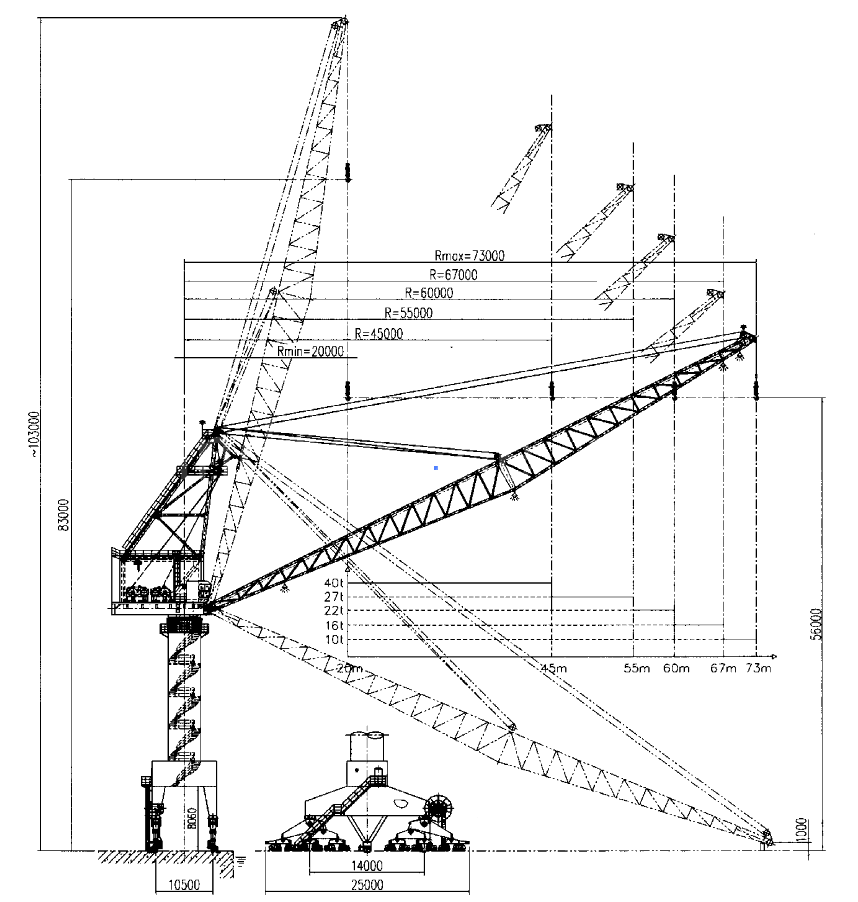

Guangzhou Pearl River Wharf Type 4073 Single Boom Portal kran

Arbeidsforhold:

- Single Boom Portal-kraner brukes hovedsakelig i havner, dokker, depoter og andre anledninger, spesielt egnet for lasting og lossing av tung last og bulklast.

- Designet er egnet for anledninger der lang bomforlengelse er nødvendig, for eksempel lasting og lossing av store skip.

- Arbeidsradiusen til kranen varierer fra 20 meter til 73 meter, som kan dekke et meget bredt operasjonsområde og er egnet for lasting og lossing av store skip.

- Løftehøyden på kranen kan nå 56 meter, noe som er egnet for heiseoperasjoner på ruvende skip eller forhøyede anlegg.

Fordel:

- Kan dekke et bredere arbeidsområde.

- Enkeltbomdesignet gjør at kranen kan ha god fleksibilitet under forskjellige operasjonsradier og kan løfte varene nøyaktig til det angitte stedet.

- Det er mer egnet for langdistanse og storskala operasjoner, spesielt ved drift av relativt tomme kaier eller store skip.

- Egnet for store havner som krever rask og effektiv lasting og lossing, og kan gjennomføre omlasting av et stort antall varer på kort tid.

- Amplituden og løftehøyden til portalkranen med enkelt bom er større enn den til havnekranen med fire ledd.

Sammenligning i samme miljø

Både havneportalkraner og portalkraner kan brukes til å flytte gods i havner, så hva er forskjellene og fordelene deres?

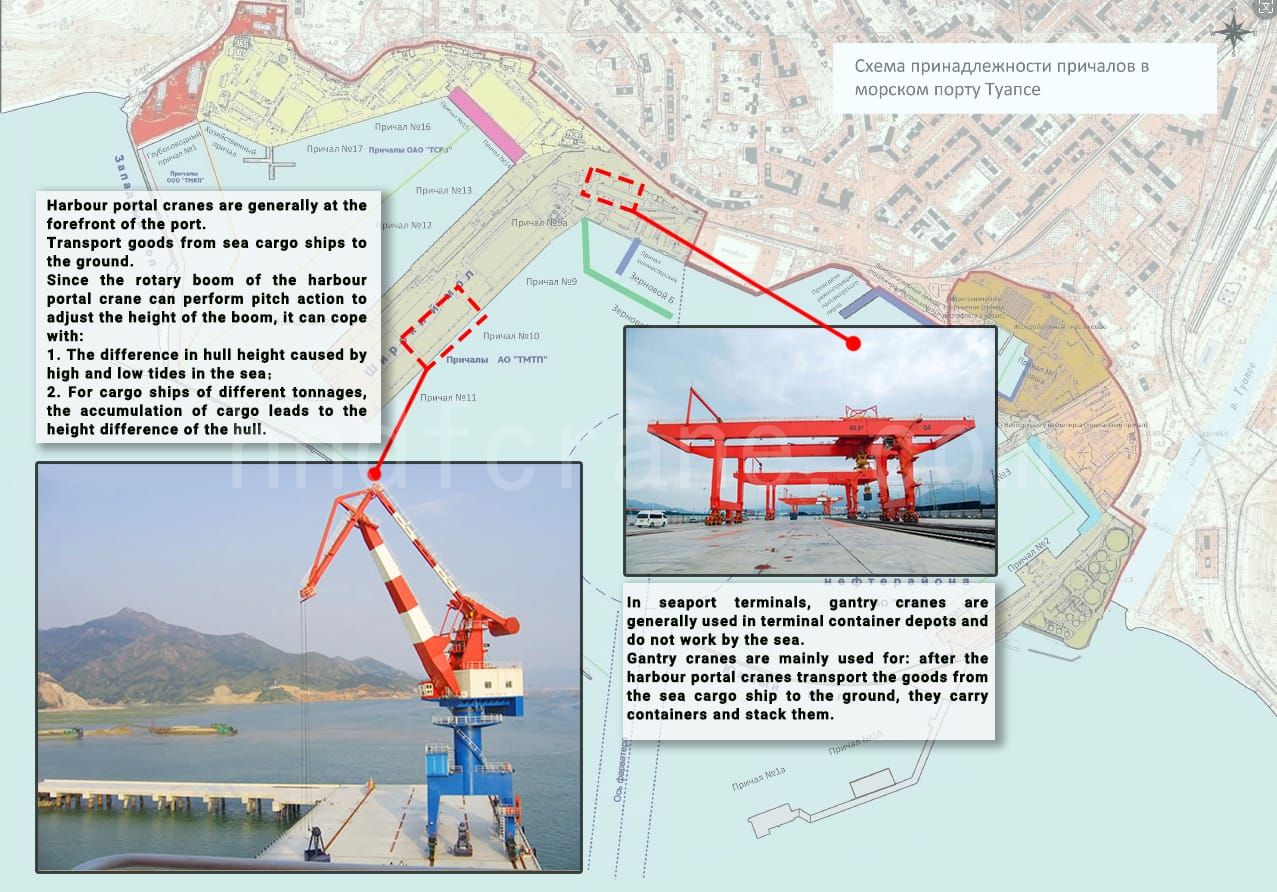

Havneportalkraner er generelt i forkant av havnen.

Transportere varer fra sjølasteskip til bakken.

Siden den roterende bommen til havneportalkranen kan utføre stigningshandlinger for å justere høyden på bommen, kan den takle:

1. Forskjellen i skroghøyde forårsaket av høy- og lavvann i sjøen;

2. For lasteskip av ulik tonnasje fører opphopning av last til høydeforskjellen på skroget.

I havneterminaler brukes portalkraner generelt i terminalcontainerdepoter og fungerer ikke ved sjøen.

Portalkraner brukes hovedsakelig til: etter at havneportalkraner transporterer godset fra sjølasteskipet til bakken, bærer de containere og stabler dem.

Vanligvis er terminalhåndtering delt inn i to trinn. Portalkraner og havneportalkraner må samarbeide med hverandre. Installasjonsstedene er forskjellige og hver utfører sine egne oppgaver.

Inkludert

Havneportalkraner og portalkraner har sine egne fordeler innen struktur og bruksområder. Med sin ruvende struktur og fleksible bomdesign har havneportalkraner blitt den foretrukne løsningen for langdistanseheising av tung last i havner og terminaler. Portalkranen, med sin stabile portaldesign, demonstrerer utmerkede og effektive materialhåndteringsevner i fabrikker og varehus. Å velge riktig kran kan ikke bare forbedre driftseffektiviteten, men også optimalisere driftskostnadene betydelig. Enten det er jakten på utmerket heiseytelse eller jakten på å forbedre den generelle logistikkeffektiviteten, er disse to kranene kraftige støttespillere for virksomhetens vekst.

Send din forespørsel

- E-post: sales@hndfcrane.com

- Hva skjer: +86-191 3738 6654

- Tlf.: +86-373-581 8299

- Faks: +86-373-215 7000

- Legg til: Changnao industridistrikt, Xinxiang City, Henan-provinsen, Kina