Product Introduction

Our conductors and power supply lines and conductors are extremely rugged systems for supplying power and control signals to mobile equipment. They feature high transmission reliability and ease of installation and maintenance. Conductors and power supply lines are equally suitable for applications on cranes and other rail-mounted equipment. In harsh outdoor operating conditions and in dusty working environments.

Depending on requirements, our conductors and power supply lines can be supplied in various designs with different numbers of poles.

See all the performance details and benefits on the product pages.

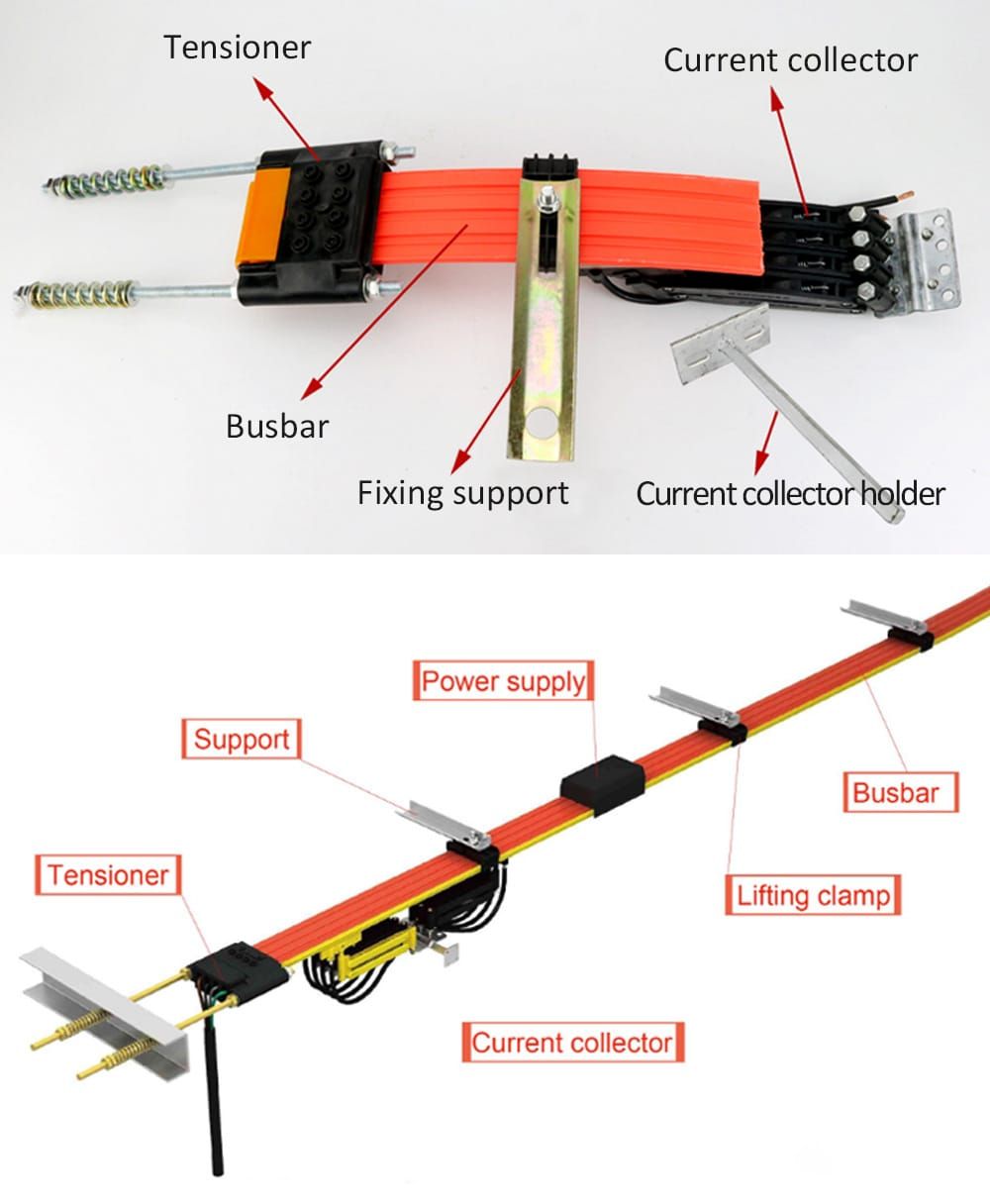

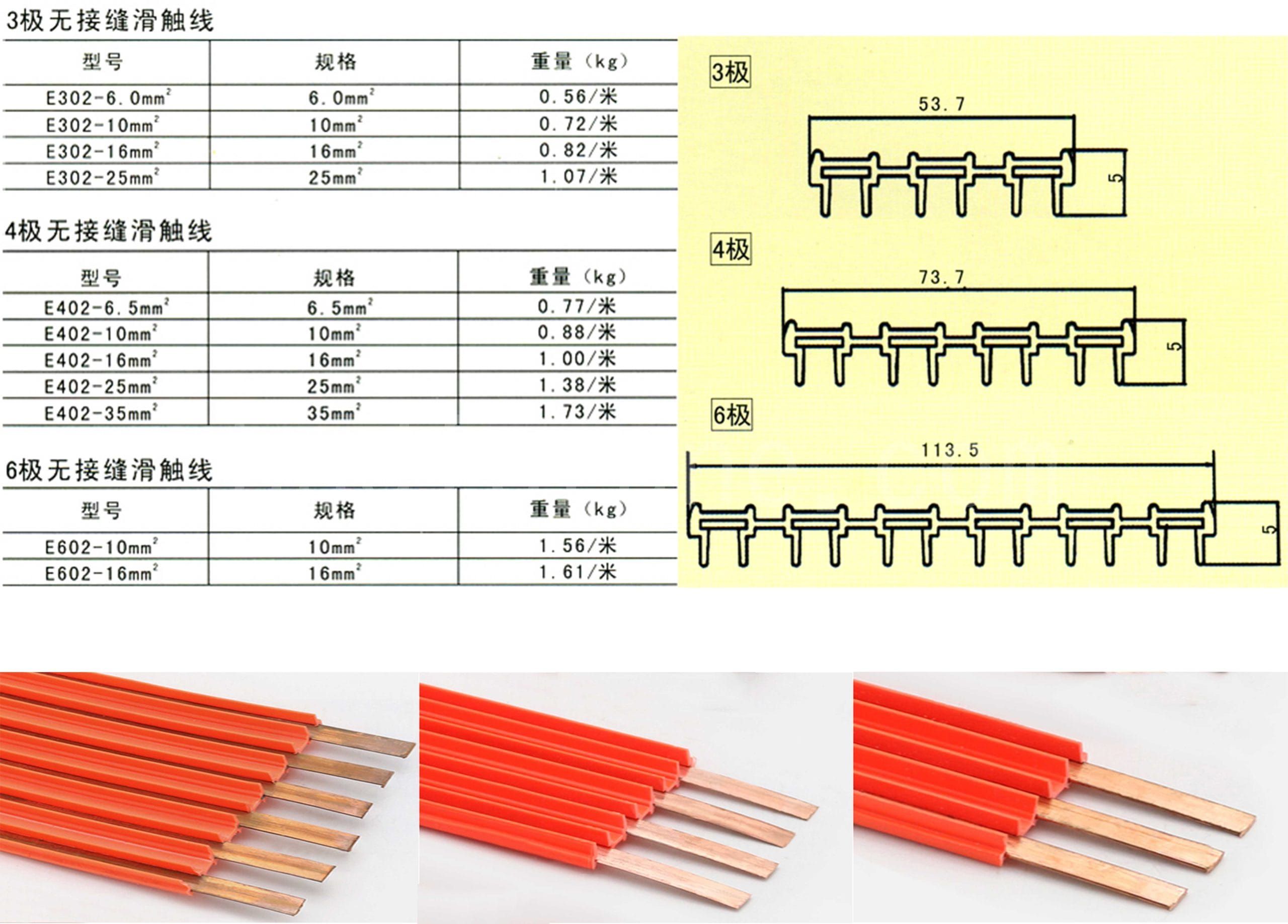

Seamless Conductor Rail

Features

- Conductors and power supply lines are anaerobic copper with good conductivity, quality, and bright color.

- Copper is in close contact with plastics and that busbar can’t be in poor contact because of vibrating.

- The conductors and power supply lines shell are PVC with shock resistance, UV resistance, and good physical.

- The installation bending radius is small, and the minimum bending radius is 750mm.

Advantage

- Low voltage drop.

- Long service life.

- Easy to install, replace, and transport.

- No joint, continuous power supply.

- Special material manufacturing, stable operation, fast speed, low noise.

- Stable operation, fast speed, good conductivity and contact performance.

Technical Parameter

Application

Seamless conductor Rail installation

Seamless conductor rail is used on monorail cranes

Seamless conductor rail is used on single girder overhead cranes

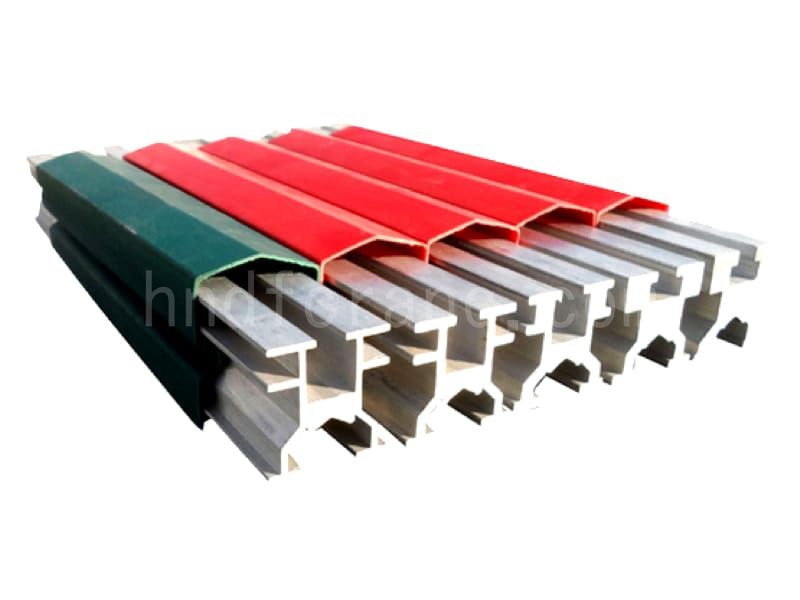

Single Pole Conductor Rails, Single powerline

Features

- Conductors and power supply lines complies with the latest regulations and provides the electric energy for material handling equipments such as overhead cranes.

- Single pole conductor rails, a key component of conductors and power supply lines, is composed of an H-shaped aluminum alloy body guide rail, a V-shaped stainless steel sliding belt, a PVC insulated shell, an external collector, and a combination of suspension, fixing, and other components.

- The product is widely used in situations where the current is large, the frequency of use is high, the operating speed is fast, and the environment is poor due to its novel design, reasonable structure, easy maintenance, and safe use.

Advantage

- Single pole conductor rails, an essential part of conductors and power supply lines, can be installed indoors or outdoors.

- For high temperature conditions, a high temperature insulating cover up to +115°C can be provided, and for low temperature conditions, covers that withstand temperatures as low as -40°C can be offered.

- The entire conductive rail system is insulated in accordance with current safety regulations to completely prevent direct contact.

Technical Parameter

| Type | Cross section size(mm) | Carrying capacity (A) | Suitable for external collector | ||

| A | B | C | |||

| HXPnR-H-150/200 | 26.5 | 20.0 | 7.0 | 200 | HJD-200 |

| HXPnR-H-250/400 | 42.0 | 32.5 | 10.0 | 400 | HJD-400 HJD-200 |

| HXPnR-H-400/600 | 42.0 | 32.5 | 10.0 | 600 | HJD-600 HJD-400 |

| HXPnR-H-500/800 | 42.0 | 32.5 | 10.0 | 800 | HJD-800 HJD-600 |

| HXPnR-H-700/1000 | 42.0 | 32.5 | 10.0 | 1000 | HJD-1000 HJD-600 |

| HXPnR-H-900/1250 | 42.0 | 32.5 | 10.0 | 1250 | HJD-1250 HJD-800 |

| HXPnR-H-1500/2000 | 65 | 50 | 12 | 2000 | HJD-1000 HJD-1250 |

| HXPnR-H-2000/2500 | 85 | 60 | 15 | 2500 | HJD-1250 HJD-1000 |

| HXPnR-H B -1600/2000 | 91.7 | 55 | 15.6 | 2000 | HJD-1000C HJD-1250C |

| HXPnR-H B -2500/3000 | 91.7 | 55 | 15.6 | 3000 | HJD-1500C HJD-1250C |

| 1、Standard length of sliding contact line:6m 2、HXPnR-H and HXPnR-H B and HXPnR-H A the performance is the same, the geometry and the power collection method are different. 3、HXPnR-H type are sliding wires of two materials, aluminum alloy and copper body. | |||||

Application

Single pole conductor rails is applied to QD overhead crane

Single pole conductor rails is used for hoist power supply

Single pole conductor rails is used for double girder overhead crane

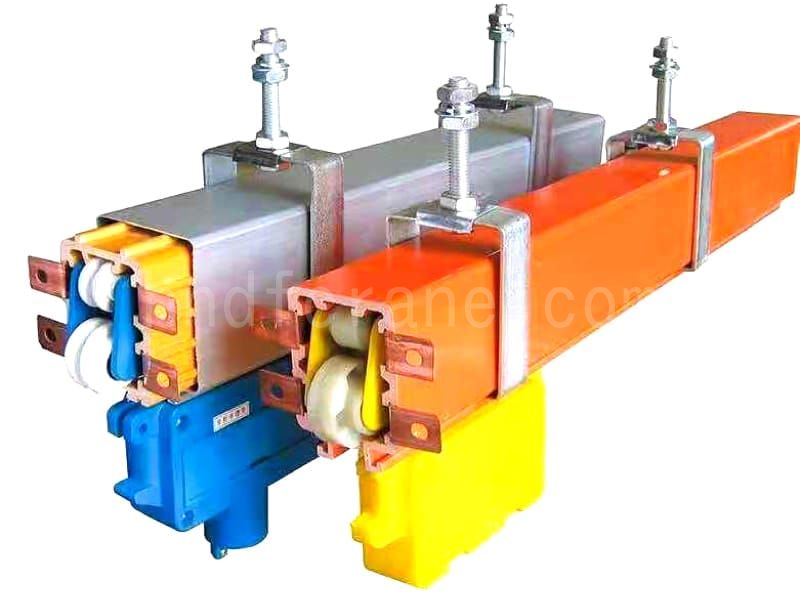

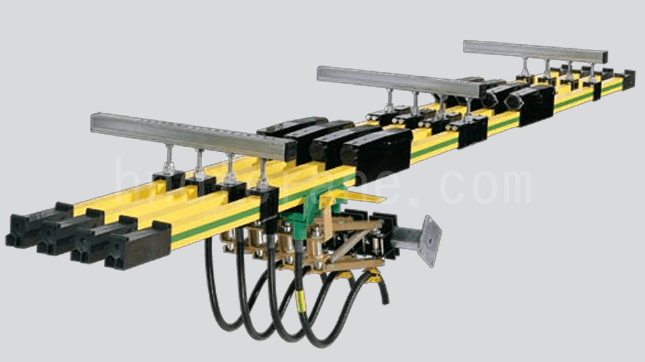

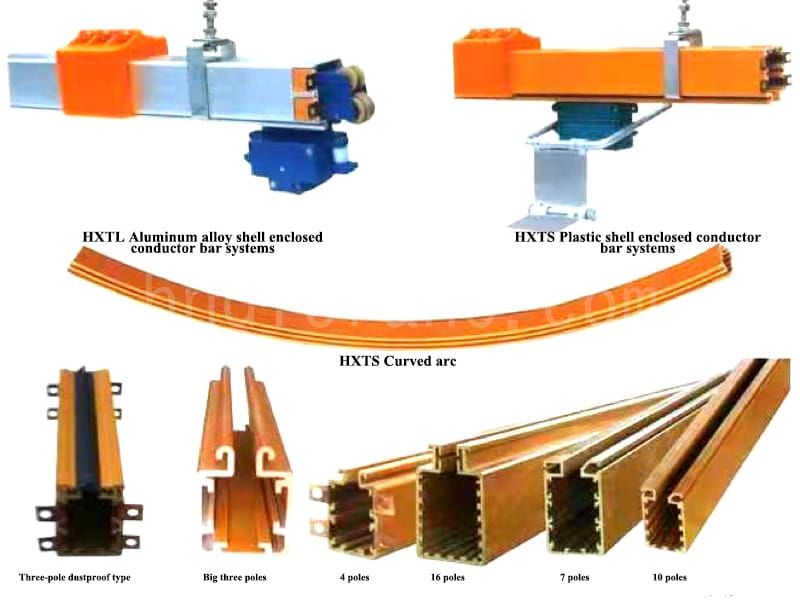

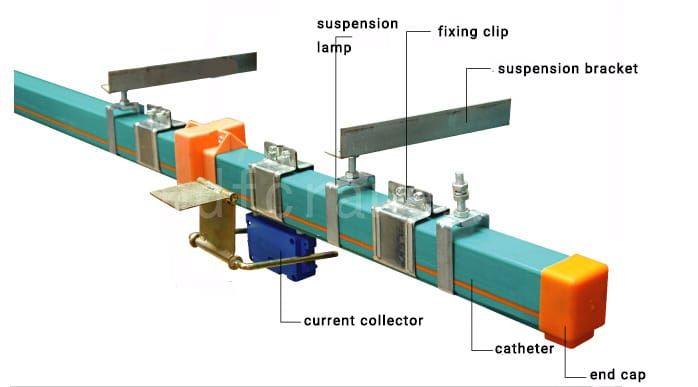

Enclosed Conductor Bar Systems

Features

- Enclosed conductor bar systems, a key component of conductors and power supply lines, is a safe, economical, and reliable mobile transmission device. It is an ideal product to replace cable coils and steel slip wires. The slip wires have a simple structure and easy installation.

- Multiple transmission copper conductive rails or copper guide rails with insulating plates are embedded in the conduits as transmission busbars, equipped with multi-stage brushes and flexible collectors. Because copper is used instead of bare steel conductors, it saves 25% of electricity compared with bare steel wires, and greatly saves materials and installation costs.

- This system of conductors and power supply lines has been widely used in port transportation, papermaking, tap water, automobile manufacturing, home appliances, and logistics industries.

- It is used as a sliding-contact busway in workshops, factories, and other power supply places. It has the characteristics of providing mobile power, easy maintenance, and reliable transmission.

Advantage

- Robust and inexpensive system

- Very compact dimensions

- IP23 contact protected (with sealing lip IP24)

- APOS Magnetic positioning system can be fully integrated

- Short delivery times and fast assembly due to prefabricated parts

- Suitable for applications in the deep-freeze range down to -30 °C

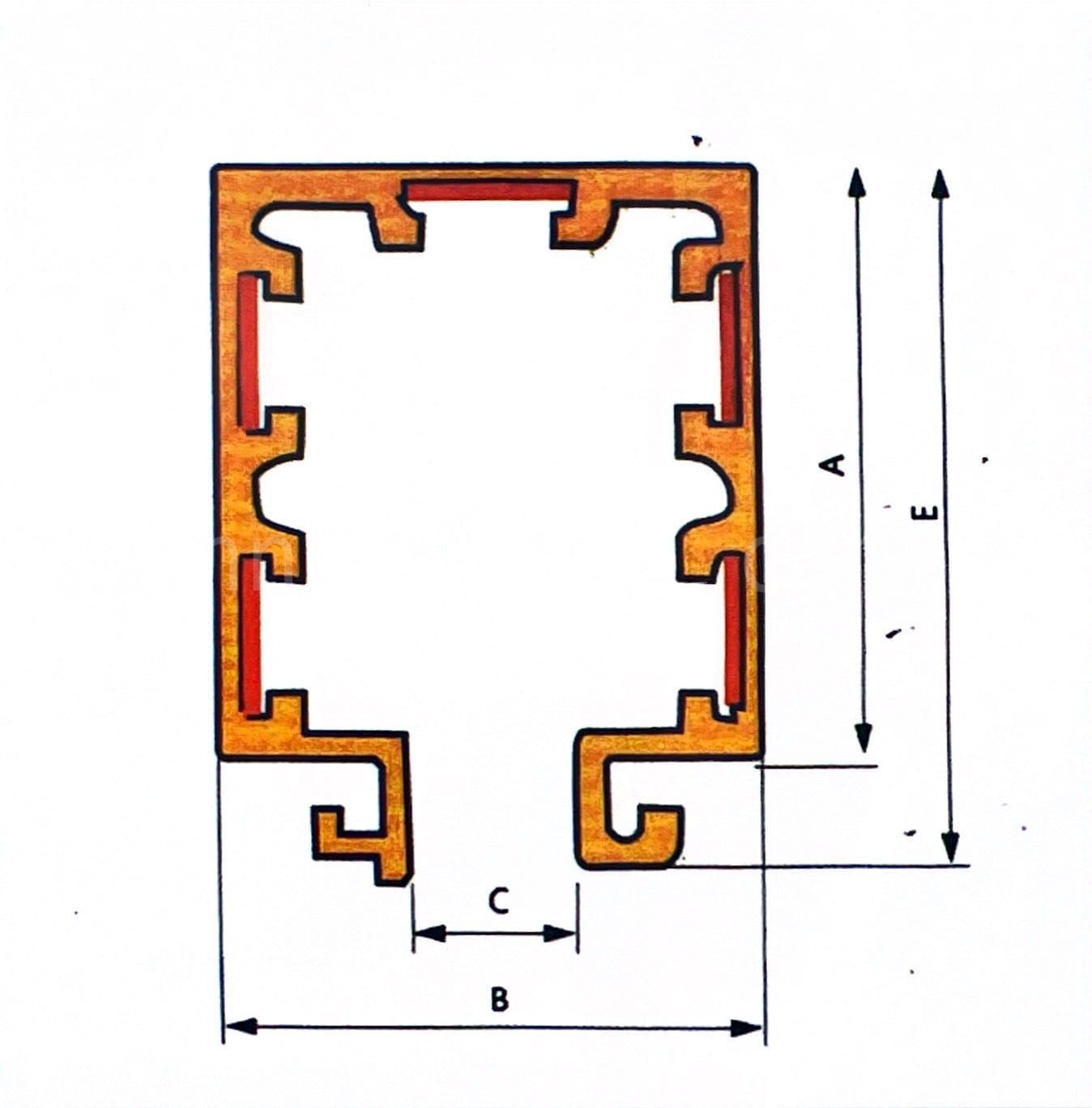

Technical Parameter

| Type | Cross section size(mm) | Number of poles | Carrying capacity (A) | Suitable for built in trolley type collector | ||

| A | B | C | ||||

| HL-101 | 94.0 | 64.5 | 17.0 | 3-16 | 50 | JD-(3-16)/25 |

| HL-102 | 69.0 | 62.0 | 12.5 | 3-16 | 80 | JD-(3-16)/50 |

| HL-103 | 67.0 | 57.0 | 17.0 | 3-10 | 100 | JD-(3-10)/50 |

| HL-104 | 70.0 | 62.0 | 15.0 | 3-7 | 140 | JD-(3-7)/50 |

| HL-105 | 67.0 | 57.0 | 17.0 | 3-5 | 170 | JD-(3-5)/50 |

| HL-106 | 67.0 | 57.0 | 17.0 | 3-5 | 210 | JD-(3-5)/50 |

| HL-107 | 77.0 | 77.0 | 18.0 | 3-5 | 300 | JD-(3-5)/100 |

| 1. Standard length of sliding contact line: 4m, 6m. 2.Number of poles of sliding contact line: 3-6 poles. 3.HXTS is the same as HXTL, the former shell is plastic, and the latter shell is aluminum alloy. | ||||||

Application

Enclosed conductor bar systems is used in single girder overhead cranes

Enclosed conductor bar systems is used in monorail cranes

Related products-Multiple tube type conductor systems

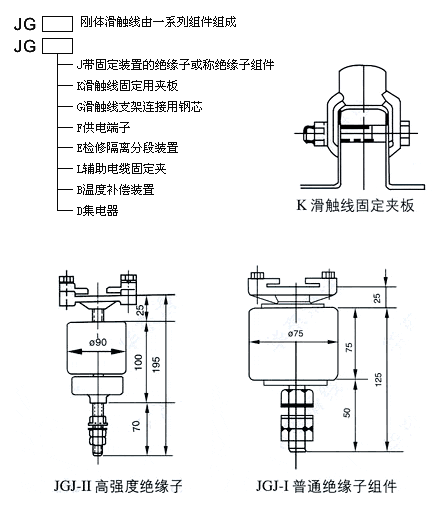

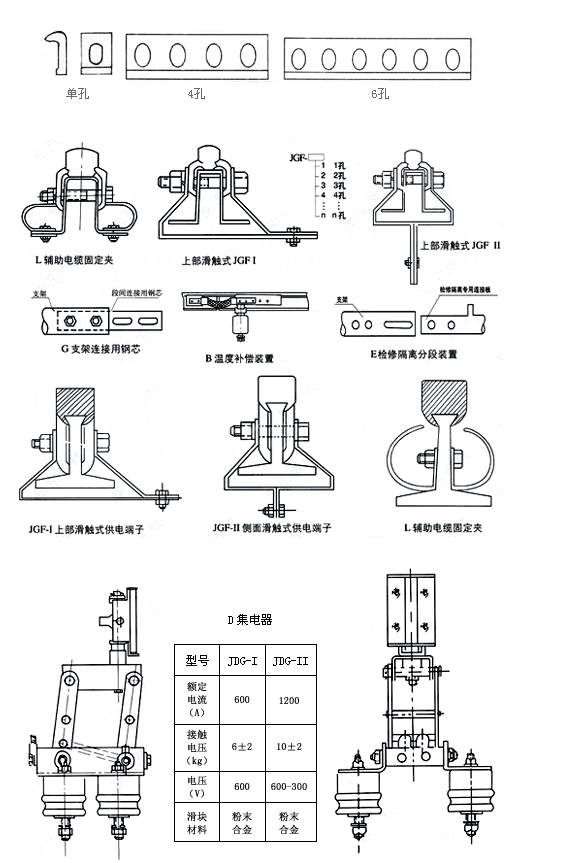

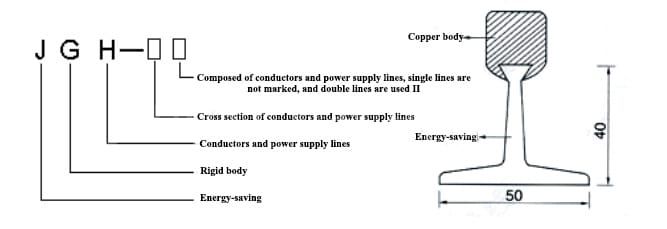

Heavy Duty Conductor Rail, Copperhead Conductor Rails

Features

- This product is composed of ladder-shaped copper rod and channel steel or a combination of “T”-shaped copper bar and groove-shaped aluminum.

- It is supported by high-strength special insulators to form a mobile sliding contact line that feeds power to various lifting machinery and equipment.

Advantage

- Reliable operation, not prone to power interruption, can be used in harsh environments such as high temperature, dust, and corrosion;

- After adopting the dovetail groove nesting process, the screw loosening phenomenon caused by the vibration of other rigid body sliding lines during operation is solved, to ensure that the sliding line as a whole is firm and reliable;

- High mechanical strength, not easy to bend and deform, and can withstand strong short-circuit inrush current;

- The carrying capacity can be set according to user needs;

- The use of the copper body to conduct electricity can greatly reduce the power consumption of the wire;

- After adding auxiliary cables, it can form a low-impedance sliding contact line, which reduces the impedance of the line;

- The heat dissipation area is large, the structure is compact and simple, and the installation and maintenance are convenient;

- The wiring can be slid on the upper part, slid on the lower part, or slid on the side;

- The collector adopts the torsion spring type, with uniform pressure and bipolar brush power, which has excellent continuous power; in actual use, the side slip is more stable and reasonable than the top slip. The advantage is that the service life of the collector is significantly increased, and the life of the brush is extended by 3 to 4 times.

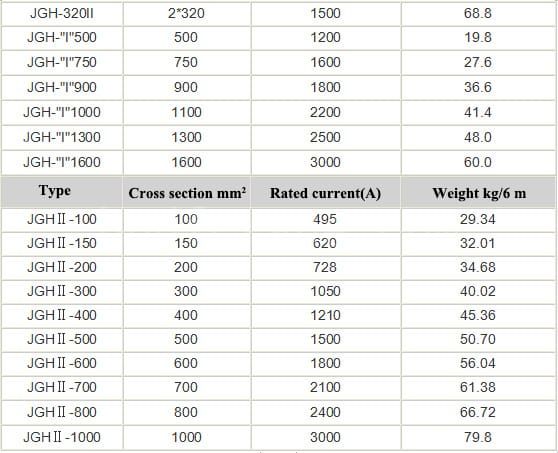

Technical Parameter

Application

Heavy-duty conductor Rail is used for double girder overhead crane

Heavy-duty conductor Rail is used for crane cart walking power supply

Related products