20 Ton Overhead Crane for Sale: Reliable & Cost-Effective Options

Table of Contents

The 20 ton overhead crane is a crucial piece of equipment in industries such as mechanical manufacturing, steel smelting, power energy, and warehousing logistics, enabling efficient material handling tasks.

Dafang Crane has been deeply involved in the field of overhead cranes for nearly two decades, accumulating extensive design and manufacturing experience. We offer customers both single-girder economical and double-girder high-strength solutions. All models can be customized according to actual requirements for span, lifting height, explosion-proof rating, and automation functions, ensuring that the equipment perfectly matches your production scenarios.

If you have specific needs or would like to learn more about our products, please feel free to contact us at any time. We are committed to providing you with professional and practical solutions.

20 Ton Overhead Crane Solutions

Compact and rigid, it’s the most common single girder overhead crane.

Features a wire rope electric hoist, offering better cost-performance than standard double girder overhead cranes.

Better suited for heavy-duty tasks, it outperforms single girder overhead cranes in structural load capacity, work efficiency, and service life.

Smooth operation, low noise, maintenance-free, modular design, and high positioning accuracy.

Smooth operation, low noise, maintenance-free, modular design, high positioning accuracy, and suitability for heavy-duty tasks.

Equipped with an electromagnetic lifter, it is ideal for quick handling of magnetic materials such as steel and scrap iron.

Fitted with a grab bucket device, it is specifically designed for the loading, unloading, and handling of bulk materials such as coal and ore.

Explosion-proof design, suitable for flammable and explosive hazardous environments such as petroleum and chemical industries.

Insulated protection design prevents current conduction, making it suitable for electrolytic aluminum, magnesium, lead, zinc, and other smelting workshops.

High-temperature resistant design, ideal for lifting liquid molten metal in harsh environments with high heat and heavy dust.

20 Ton Overhead Crane Application Examples

20 Ton Double Girder EOT Crane for Billet Handling in Steel Plants

In the steel reinforcement production workshop of a steel plant, two 20-ton double-girder overhead cranes equipped with billet lifting devices are installed in the raw material bay, specifically responsible for handling continuous casting billets. These billets weigh approximately 2 tons each, measure 12 meters in length, and include both 700°C hot billets and room-temperature cold billets. Each crane lifts 8 billets (totaling 16.5 tons) to perform tasks such as loading, unloading, and stacking, ensuring the continuous production of 800,000 tons of hot-rolled steel reinforcement annually.

To withstand the high-temperature and high-intensity working environment, the cranes are equipped with heat-resistant lifting devices and fireproof cables. The main hook has a maximum load capacity of 20 tons, a span of 16 meters, and can operate at heights of up to 18 meters. With precise speed control and high-temperature resistance design, the cranes can quickly transport billets while adapting to the extreme conditions of 700°C hot billets. This ensures efficient and safe operation of the production line, meeting the steel industry’s demand for large-scale, high-stability raw material handling.

20 Ton European Double Girder Electric Hoist Crane for Paper Mills

In the production line of a paper mill, the 20 ton European double girder overhead crane with a wire rope hoist is primarily used for lifting large paper rolls, corrugated cardboard, and other heavy materials. The crane can be operated flexibly via pendant control or wireless remote control, meeting the needs of raw material transfer, finished product stacking, and equipment maintenance. Designed for A5 duty (moderate-intensity continuous operation), it ensures the efficient operation of the production line.

In daily use within the paper industry, the 20 ton crane typically handles loads ranging from 10 to 18 tons, adapting to various production requirements. Although the crane’s rated capacity is 20 tons, to ensure equipment stability and extend service life, prolonged full-load operation is generally avoided. Operators can flexibly adjust the lifting load based on production tasks to maintain efficient and safe working conditions.

The FEM standard overhead crane is equipped with a full variable frequency drive system, allowing flexible speed adjustment based on load and operational requirements. This effectively reduces mechanical stress during start-stop cycles, enhancing operational efficiency and extending equipment lifespan. Additionally, the crane features dual-speed lifting and traveling mechanisms, enabling operators to switch between fast and slow modes, significantly improving safety and precision during operations.

20 Ton Metallurgical Double Girder Overhead Crane for Foundry Workshops

In the foundry industry, the metallurgical double girder overhead crane is a core equipment for handling molten metal. The 20 ton metallurgical overhead crane is primarily responsible for key processes such as transferring and pouring 14-16 ton high-temperature ladles, as well as lifting and assembling 16-18 ton large sand molds.

To address the unique working conditions of the foundry industry, the metallurgical overhead crane incorporates several specialized designs: an insulation layer is installed beneath the main girder to effectively block high-temperature radiation; the lifting mechanism is equipped with overspeed protection and forward/reverse contactor fault protection to prevent runaway risks; and the entire crane uses high-temperature-resistant cables and conduits to ensure stable operation of the electrical system in dusty environments. Additionally, the crane can be configured with enclosed hooks and rolled sheaves to meet the high-temperature and high-load demands of molten metal handling. Its high-duty rating and multiple safety protection features significantly enhance the equipment’s reliability and safety in harsh environments, providing a solid foundation for efficient production in the foundry industry.

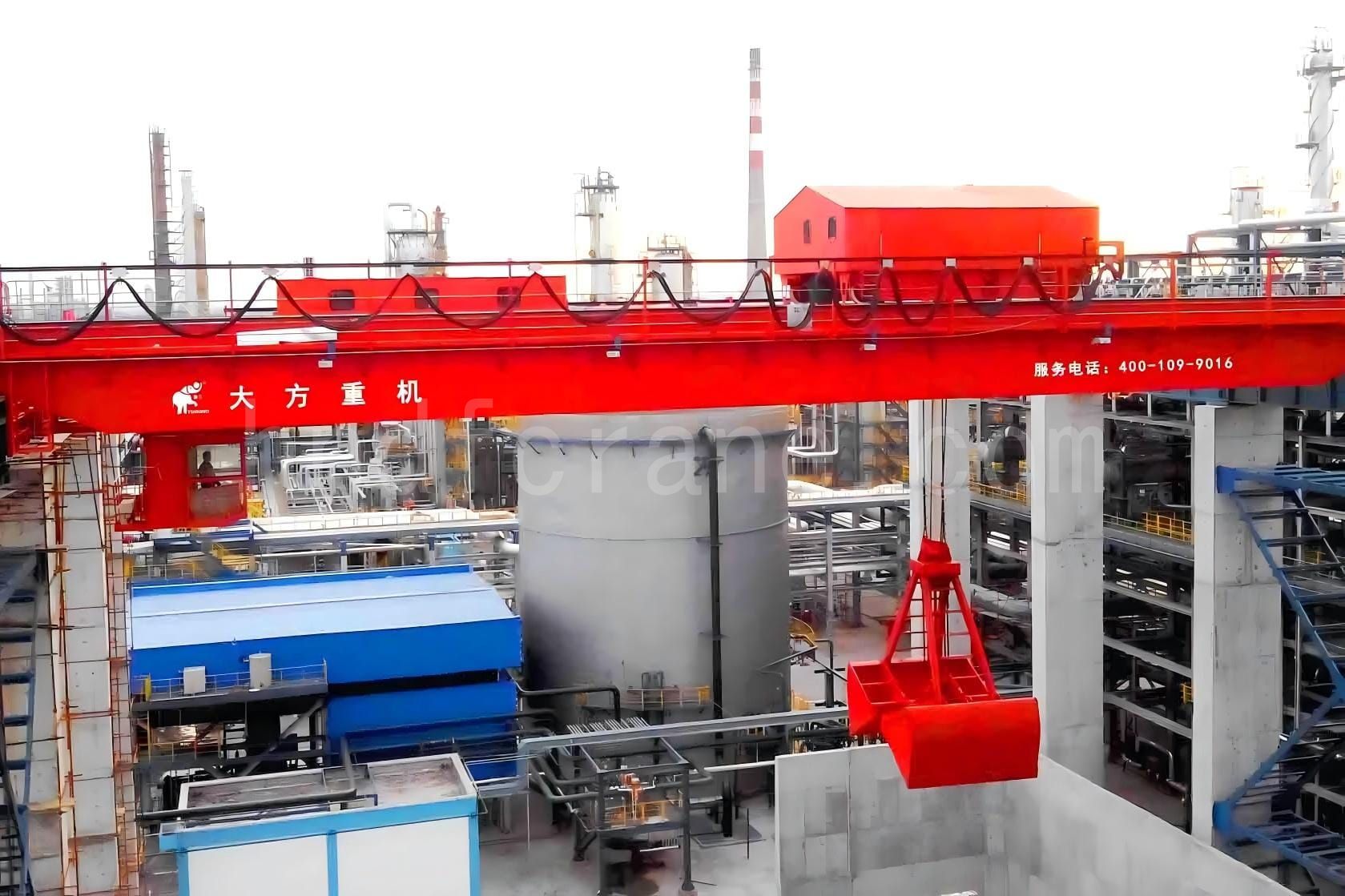

20 Ton Double Girder Grab Bucket Bridge Crane for Waste Handling Industry

In the waste handling industry, the 20 ton grab overhead crane is primarily used for grabbing, transferring, and stacking waste in storage pits. In waste-to-energy plants or landfills, the crane uses its grab bucket to collect loose municipal or industrial waste from the storage pit and transfer it to incinerators or compactors. It also performs waste stacking and sorting tasks, ensuring efficient operation of the waste treatment process. With a single grab capacity of 11 tons and a daily processing capacity of hundreds of tons, it meets the demands of large-scale waste handling. Thanks to its high-strength grabbing capability and precise control performance, the crane adapts to the complex composition and loose volume of waste, providing an efficient and reliable lifting solution for the waste treatment industry.

Why Choose Dafang Crane 20 Ton Overhead Crane

As a renowned brand in the crane manufacturing industry, Dafang Crane has earned a strong reputation and user trust through years of market experience. In the field of 20 ton overhead cranes, we offer the following advantages:

- Cost-Effectiveness: As a direct manufacturer of 20 ton overhead cranes, Dafang Crane eliminates middlemen, providing customers with the most competitive prices. We also offer discounted spare parts and wear-resistant components for crane maintenance.

- Fast Delivery: With an 850,000-square-meter modern facility, equipped with over 2,600 sets of machinery including a 1,500 ton press, welding robots, CNC machining centers, and laser cutting machines, we achieve an annual production capacity of 70,000 cranes, ensuring quick delivery and stable supply.

- Comprehensive Product Range: As a manufacturer, Dafang Crane can customize 20 ton overhead cranes of various types and spans. Features such as variable frequency speed control and anti-sway systems can be added as needed.

- High Quality: We implement strict quality control measures. Key welds undergo 100% ultrasonic non-destructive testing, main girder web flatness is controlled within 3.5-5.5 mm, and bridge diagonal differences are kept within 5 mm, ensuring long-term stable operation.

For nearly two decades, Dafang Crane has been dedicated to the R&D, design, manufacturing, and sales of single and double girder overhead cranes, gantry cranes, and electric hoists. Our 20-ton overhead cranes have been exported to over 100 countries and regions, including Pakistan, Uzbekistan, and Turkmenistan. Below are some case studies.

20T Single Girder Overhead Crane Shipped to Turkmenistan

- Country: Turkmenistan

- Product: Single girder overhead crane

- Capacity: 20t

- Span length: 18m

- Lifting height: 10m

- Lifting speed: 4.2m/min

- Hoist traveling speed: 20m/min

- Crane traveling speed: 20m/min

- Power voltage: 380V/50Hz/3Ph

- Duty group: A3

- Lifting mechanism: Electric wire rope hoist

- Control mode: Pendant with line + wireless remote

We provide customers with timely technical support and customized solutions, ensuring that the crane specifications fully meet their requirements. After order confirmation, we efficiently organize production and deliver on time, while closely following up on customer feedback to ensure service quality. Our professional responsiveness and meticulous service have earned high customer satisfaction, laying a solid foundation for future collaboration.

5/20T Double Girder Overhead Crane with Wire Rope Hoist Delivery to Pakistan

- Country: Pakistan

- Lift Capacity: 20t/5t

- Span: 22.7m

- Lift Height: 9m

- Main Hook Lift Speed: 0.8-3.3 m/min

- Auxiliary Hook Lift Speed: 0.8-8 m/min

- Crane Travel Speed: 3-30 m/min

- Hoist Travel Speed: 2-20 m/min

To ensure convenience for future installation and use, we have meticulously packaged the product and marked each connection point. Considering the crane will be used for lifting operations, we have specially equipped it with remote control devices, enabling synchronized operation of the two cranes. Additionally, we have included anti-deviation devices and rail clamps to further enhance safety and stability.

FAQs

How to choose the right 20 ton overhead crane for my workshop?

Selecting the right overhead crane depends on factors such as your workshop's layout, lifting height, span, duty cycle, and operational environment. Consider whether a single girder or double girder design suits your needs, as well as power supply options and control methods (e.g., pendant, remote, or cabin). It's also important to ensure compliance with safety standards and future scalability.

How to maintain a 20 ton bridge crane for optimal performance?

Regular maintenance is key to ensuring safe and efficient crane operation. This includes inspecting critical components such as the hoist, wire rope, motor, and brakes for wear and tear. Lubricate moving parts as recommended by the manufacturer, tighten loose bolts, and check electrical systems for proper functioning. Scheduled professional inspections can help detect potential issues early and extend the crane's service life.

What are the installation requirements for a 20 ton overhead crane?

Installing a 20t overhead crane requires a properly designed support structure, sufficient headroom, and a compatible power supply. The installation area must have adequate space for crane movement and maintenance access. It's crucial to follow local regulations and safety standards during installation, and professional engineers should handle the process to ensure structural integrity and alignment of the runway system.

What is the lifespan of a 20 ton overhead crane?

The lifespan of a 20t overhead crane typically ranges from 20 to 30 years, depending on its usage frequency, operating environment, and maintenance practices. Cranes used in heavy-duty applications or harsh conditions may have shorter lifespans, while well-maintained cranes in moderate conditions can last longer. Regular servicing and timely part replacements help maximize longevity.

Can a 20 ton bridge crane be customized for specific needs?

Yes, a 20t overhead crane can be customized to meet specific operational requirements. Customization options include varying spans, lifting heights, speed controls, special lifting attachments, automation features, and environmental protections (such as explosion-proof designs for hazardous areas). We can also tailor the crane's design to fit unique workspace constraints and production workflows.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China