Advantages Of Top Running Overhead Crane: Everything You Need To Know

Overhead cranes play an integral role in several industries such as manufacturing, construction, and warehousing. They are known for their ability to lift heavy loads and move them with ease, providing significant benefits in terms of time and productivity. One of the most popular types of overhead cranes is the top running overhead crane. In this article, we will discuss the advantages of top running overhead cranes and why they are a popular choice in modern industry.

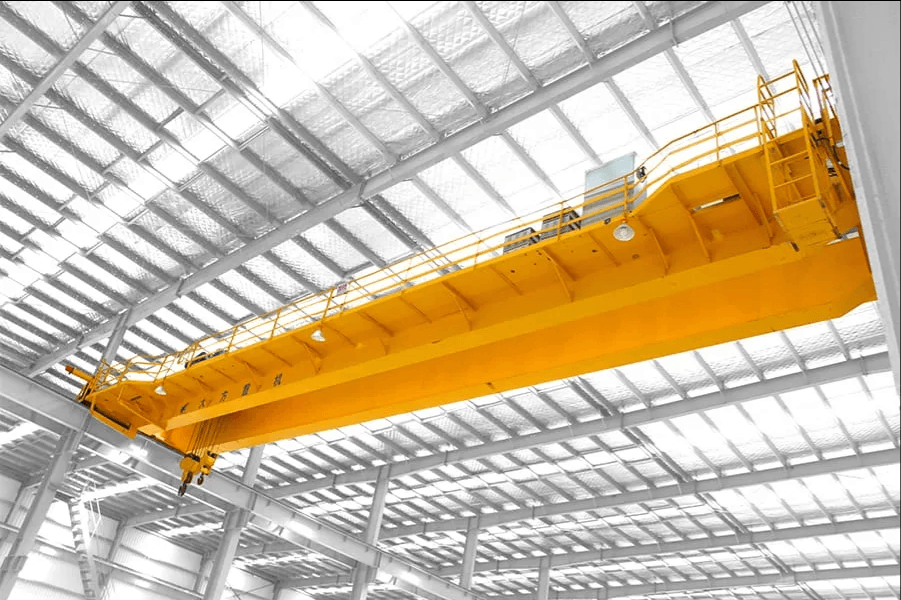

What Is The Top Running Overhead Crane?

The top-running overhead crane is widely used in industrial settings for heavy lifting and material handling. Unlike other types of cranes, the top-running overhead crane runs on rails mounted on top of a runway beam, making it capable of handling heavier loads than underhung cranes. The top running overhead crane consists of a bridge that spans the width of the area to be covered and one or more trolleys that run along the bridge. This design helps distribute the weight of the crane evenly across the length of the runway beam, which enables it to lift heavier loads with greater ease.

The Advantages Of Top Running Overhead Crane

Higher Lifting Capacity

One of the biggest advantages of a top-running overhead crane is its higher lifting capacity. Because it is mounted on top of the runway beam, it is capable of lifting heavier loads than other types of cranes. This is because the weight of the crane is evenly distributed across the entire length of the runway beam, rather than being concentrated in one spot.

Greater Clearance Height

Another advantage of top running overhead cranes is their greater clearance height. These cranes can lift loads higher without any obstructions, allowing them to operate more effectively and efficiently. A higher clearance height means they can lift goods over taller structures or obstacles, making them perfect for use in warehouses and factories where tall shelves house products that need moving. They can also operate in narrow aisles, making them ideal for businesses with limited space.

Top Running Overhead Crane Can Cover Larger Areas

A top-running overhead crane can cover larger areas than other types of cranes. Their runway system covers the entire facility, allowing them to access different workstations easily. They can also transport goods from one end of the facility to another, making them an efficient way of moving goods around the plant. This reduces delays caused by lengthy transportation times and ensures that all product destinations are met within set deadlines.

Better Load Control

Top running overhead cranes offer better load control than other types of cranes. This is because the trolley travels along the top of the crane, rather than underneath as with underhung cranes. This gives the operator better visibility of the load and precise control over the movement of the crane, ensuring that the load is always placed in the correct position.

Increased Safety

Top-running overhead cranes offer a higher level of safety than other types of cranes. This is because they are mounted on rails firmly attached to the building structure. This gives the crane a stable base, which reduces the risk of accidents and increases the overall safety of the workplace.

Applications Of Top Running Overhead Crane

Top running EOT cranes are heavy-duty machines that are designed to move and transport heavy loads across a wide range of industries. These cranes are versatile, flexible, and can be used in a variety of applications in different settings. Include:

Steel Stock Yard

Steel yards are facilities where large quantities of steel products are stored, manufactured or processed. The use of top travelling EOT cranes in steel yards is essential as they provide an efficient and reliable means of moving large and bulky steel products. Top running bridge cranes facilitate the lifting and moving of steel plates, beams, pipes and other materials, reducing the need for manual labour and minimising the risk of injury.

Warehouse

Warehouses are large buildings designed for the storage and distribution of goods. The use of top-running bridge crane in warehouses is essential as they provide an efficient means of moving heavy and bulky items from one location to another. Top running bridge crane can access the highest shelves, maximising the use of storage space while reducing the risk of injury to workers. Top running EOT crane also allow goods to be moved quickly and easily, making the loading and unloading of trucks and containers quick and efficient.

Harbor And Ship Building

Harbors and shipbuilding facilities require heavy-duty equipment to load and unload cargo ships, as well as maneuver large vessels in confined spaces. Top-running EOT cranes are ideal for these applications because they can move large, heavy containers and other cargo with ease. They offer precise control and accuracy when positioning loads, ensuring quick and efficient operations.

Machining Workshop

Machining workshops are facilities where machines, tools, and parts are manufactured or repaired. Top-running bridge cranes play a crucial role in facilitating the movement of heavy machinery and parts within the workshop. The crane can lift heavy loads, move them across the workshop, and precisely position them for repairs, maintenance, or assembly.

Power Station

Power stations are large facilities that generate electricity from various sources, such as coal, natural gas, nuclear, or renewable energy. The use of top-running EOT crane in power stations is essential because they provide an efficient means of moving heavy equipment and parts around the facility. Bridge cranes can lift and move large turbines, generators, transformers, and other equipment safely and quickly, minimizing downtime and maximizing productivity.

FAQs

- What is the maximum weight a top running overhead crane can lift?

The lifting capacity of a top running overhead crane depends on several factors, including the size of the crane and the strength of the runway beam. However, most top running bridge cranes can lift several tons. - How much clearance height does a top-running overhead crane offer?

The clearance height of a top-running overhead crane varies depending on the size of the crane and the height of the building. However, most top running EOT cranes offer significantly more clearance height than other types of cranes. - Can a top running overhead crane be used outdoors?

Yes, top running overhead cranes can be used outdoors as long as they are properly designed and constructed to withstand the elements. - How often does a top running overhead crane need to be serviced?

The frequency of maintenance and servicing for a top running overhead crane depends on several factors, including how often it is used and the conditions under which it operates. However, most manufacturers recommend regular inspections and maintenance at least once a year.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China