Buying Jib Cranes: Top Tips You Need To Know

Jib cranes are versatile lifting devices that can greatly enhance productivity and efficiency in various industries. Whether you need to lift heavy loads a manufacturing facility or streamline material handling processes in a warehouse, choosing the right jib crane is crucial. In this article, will provide you with top tips for buying a jib crane that meets your specific requirements.

Understanding Jib Cranes

What Is A Jib Crane?

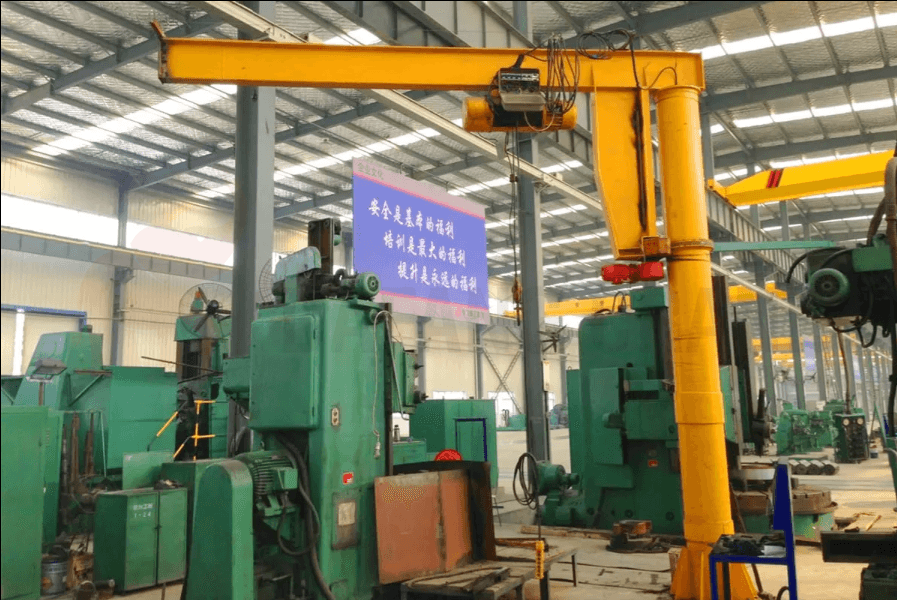

A jib crane is a type of crane that consists of a horizontal boom (jib) that is attached to a pivoting vertical mast or support pillar. The jib can rotate horizontally, allowing the crane to lift and move loads in a circular area. Jib cranes are typically used in industrial settings, such as warehouses, manufacturing plants, and construction sites, where there is a need to lift and transport heavy objects within a limited space.

Types Of Jib Cranes

Floor-mounted jib cranes: The floor-mounted jib crane is securely mounted to the floor, offering stability and a wide range of motion. It can rotate a full 360 degrees, providing excellent coverage for lifting and moving heavy loads within a designated area. Floor-mounted jib cranes are commonly used in manufacturing facilities, warehouses, and construction sites, where they enhance efficiency and productivity.

Wall Mounted Jib Crane: Wall mounted jib cranes are designed to be attached directly to a wall or vertical structure. They are ideal for applications where space is limited, as they conserve valuable floor space. The wall-mounted jib crane offers a fixed lifting solution, providing a consistent lifting radius and reach. It is commonly used in workshops, small production areas, and garages where maneuverability and accessibility are important factors.

Wall Travelling Jib Cranes: Wall traveling jib cranes combine the advantages of a wall mounted crane with the ability to move horizontally along a wall-mounted rail or track system. This type of jib crane offers increased coverage and versatility, as it can travel along the length of the rail to reach different work areas. It is particularly beneficial in large manufacturing facilities or warehouses where a single crane can serve multiple workstations.

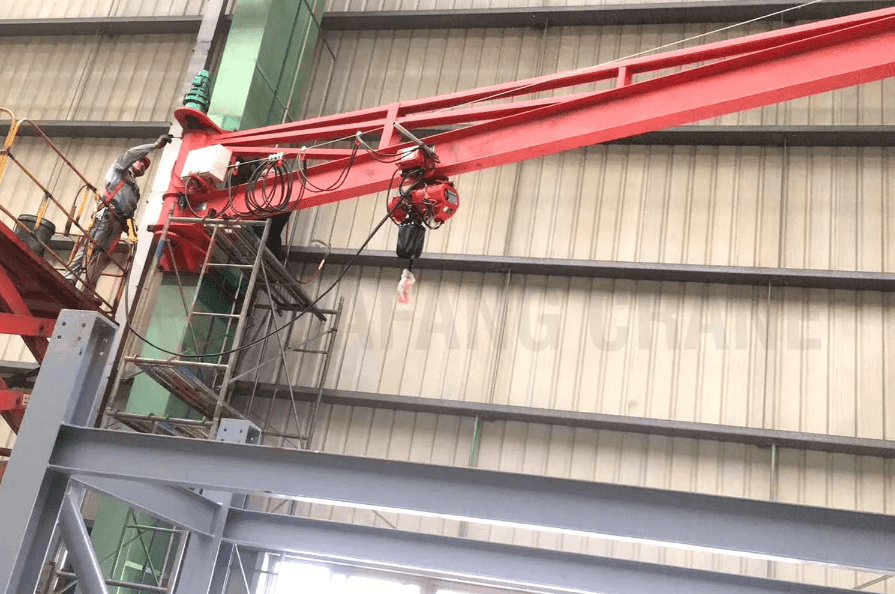

Articulated Jib Crane: An articulated jib crane, also known as a knuckle jib crane, features a multi-segmented arm that offers exceptional flexibility and maneuverability. It consists of a series of connected sections that can be telescoped or articulated to reach obstacles and access hard-to-reach areas. This type of jib crane is commonly used in industries where precise and intricate lifting operations are required, such as the automotive sector.

Benefits Of Using Jib Cranes

- Improved Efficiency: With their 360-degree rotation capability, jib cranes enable precise positioning and movement, eliminating the need for manual lifting and streamlining workflow. Whether you’re working in a manufacturing facility, warehouse, or construction site, a jib crane can significantly increase your productivity and save valuable time.

- Enhanced Safety: By reducing the need for manual lifting, jib cranes minimize the risk of injuries to workers. They provide a stable lifting platform, allowing operators to have better control over the load and reducing the chances of accidents and damages. Additionally, jib cranes can be equipped with safety features such as limit switches, anti-collision systems, and overload protection, further ensuring the safety of both the operators and the surrounding environment.

- Space Optimization: Jib cranes excel in space optimization, by utilizing walls or vertical structures, they free up valuable floor space, allowing you to maximize your workspace for other operations.

Assessing Your Requirements

- Determining the Load Capacity: Before purchasing a jib crane, it’s essential to assess the maximum load capacity you require. Consider the heaviest loads you will typically handle and ensure that the jib crane you choose can safely lift and maneuver them.

- Analyzing the Swing Radius: The swing radius of a jib crane refers to the area the jib arm can reach. Consider the layout of your workspace and ensure that the swing radius of the jib crane allows you to position loads precisely without any obstructions.

- Considering the Mounting Options: Evaluate your workspace and loads to determine the best mounting options for your jib crane. Wall-mounted jib cranes are ideal for limited spaces, while floor-mounted jib cranes offer greater versatility and coverage.

- Choose the Hoist on the Jib Crane: Electric wire rope hoists and electric chain hoists are the most common types of hoists used in jib cranes. Compared with electric wire rope hoist, electric chain hoist has small size and light weight, but speed is a little slower than electric wire rope hoist. If your required light height is high and fast lifting speed, we suggest using electric wire rope hoist.

Safety And Compliance Features

- Limit Switches and Safety Devices: Ensure that the jib crane is equipped with limit switches and safety devices to prevent overtravel and collisions. These features protect the equipment, the load, and the surrounding infrastructure.

- Overload Protection Systems: Invest in a jib crane that incorporates reliable overload protection systems, such as load cells or weight sensors. These systems prevent the crane from lifting loads beyond its safe capacity, enhancing operator safety.

- Compliance with Regulatory Standards: Verify that the jib crane meets all relevant regulatory standards and certifications. Compliance ensures that the equipment has undergone rigorous testing and meets established industry safety requirements.

Installation And Maintenance Considerations

- Site Preparation and Location: Ensure that the installation site is suitable for the jib crane, considering factors such as floor load capacity, ceiling height, and proximity to other structures. Adequate site preparation ensures optimal performance and safety.

- Assembly and Installation Process: Consider the ease of assembly and installation when choosing a jib crane. Opt for a supplier who provides clear instructions and support during the setup process to minimize downtime and disruptions.

- Maintenance Requirements and Cost: Regular maintenance is essential to keep the jib crane operating efficiently. Consider the maintenance requirements and associated costs, such as lubrication, inspections, and spare parts availability, before finalizing your purchase.

Price And Warranty Factors

- Determining the Budget: Determine your budget range based on your requirements and available funds. It’s important to strike a balance between quality and affordability, ensuring that the jib crane meets your needs without exceeding your budget.

- Comparing Prices and Quotes: Obtain quotes from reputable manufacturers and suppliers, comparing not only the price but also the quality of materials, features, and after-sales services. Don’t hesitate to negotiate for the best possible deal.

- Understanding Warranty Coverage: Review the warranty terms and conditions offered by different suppliers. A comprehensive warranty provides peace of mind and ensures that any potential defects or issues are covered during the specified warranty period.

Researching Reputable Manufacturers And Suppliers

- Reading Customer Reviews and Testimonials: Check online reviews and testimonials from customers who have previously purchased jib cranes from the manufacturers and suppliers you are considering. Positive feedback indicates a reliable and reputable provider.

- Checking Manufacturer’s Reputation and Experience: Research the manufacturer’s reputation and experience in producing jib cranes. Established manufacturers with a solid track record are more likely to deliver high-quality products and reliable customer support.

- Evaluating Supplier’s After-Sales Support: Consider the supplier’s after-sales support, including technical assistance, spare parts availability, and maintenance services. A responsive and supportive supplier ensures a smooth buying experience and timely assistance when needed.

Seeking Expert Advice And Consultation

- Collaborating with Industry Professionals: Engage with industry professionals, such as engineers or consultants specializing in jib cranes, to gain valuable insights and recommendations. Their expertise can help you select the most suitable jib crane for your specific application.

- Consulting with Crane Specialists: Consult with crane specialists or sales representatives from reputable manufacturers or suppliers(https://www.hndfcrane.com/). They can provide detailed product information, address specific concerns, and guide you through the selection process.

- Requesting Demonstrations and Trials: Whenever possible, request demonstrations or trials of the jib crane models you are interested in. Hands-on experience allows you to evaluate the equipment’s performance and suitability for your specific lifting requirements.

FAQs

- Are jib cranes suitable for indoor and outdoor applications?

Yes, jib cranes can be used in both indoor and outdoor applications, depending on the specific design and construction. - Can I install a jib crane on my own?

While it is possible to install a jib crane yourself, it is recommended to seek professional assistance to ensure proper installation and compliance with safety standards. - What is the average lifespan of a jib crane?

The lifespan of a jib crane can vary depending on factors such as usage, maintenance, and environmental conditions. With proper care, a well-maintained jib crane can last for many years. - Can a jib crane be customized for specific requirements?

Yes, many jib crane manufacturers offer customization options to tailor the crane’s specifications to your specific needs. - Are jib cranes suitable for lifting delicate or fragile items?

Yes, jib cranes can be used to lift delicate or fragile items by incorporating appropriate lifting attachments and ensuring proper load handling techniques.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat