Container Gantry Crane: Operation And Benefits

Container gantry cranes are heavy-duty machines designed to lift and move shipping containers in ports and container terminals. These cranes have become an essential part of the modern shipping industry, allowing for the efficient loading and unloading of cargo ships. Through this article, you can learn more about what is a container gantry crane, its main structure, benefits, operation, and how to choose the right container gantry crane.

What Is A Container Gantry Crane?

A container gantry crane (CGC) is a specialized type of crane used for loading and unloading intermodal containers from ships. These massive cranes are typically found in seaports and container terminals and are essential for efficiently moving large volumes of cargo between ships and trucks or trains.

The design of quay gantry cranes varies depending on the specific needs of the port or terminal where they will be used, but they generally consist of a large steel frame supported by four or more legs. The “bridge” of the crane spans the width of the ship, and a trolley system mounted on rails along the top of the bridge moves back and forth to position the crane over the desired container.

Container gantry cranes are capable of lifting and moving very heavy loads, often up to 50 tons or more. They can also stack containers several levels high and move them quickly from one location to another within the terminal.

Main Components Of Container Gantry Cranes

Main Beams

The main beams of container gantry cranes are the primary structures that span the width of the crane, providing support for all other components of the crane. These beams are typically made of high-strength steel, which allows them to withstand the immense weight of the containers being lifted. The main beams also provide a stable platform for the other components of the crane to operate on.

Support Legs

The support legs of container gantry cranes are large pillars that support the main beams and transfer the weight of the crane and its load to the ground. These legs are also made of high-strength steel and are designed to withstand the forces generated during the lifting and lowering of containers. The support legs are typically fixed to rails embedded in the ground, which allows the crane to move back and forth along the dock.

Ground Beam

The ground beam is another crucial component of container gantry cranes, which is a large horizontal structure bolted to the support legs and positioned parallel to the ship’s berth. The ground beam provides additional stability to the crane and supports the crane travel trolley.

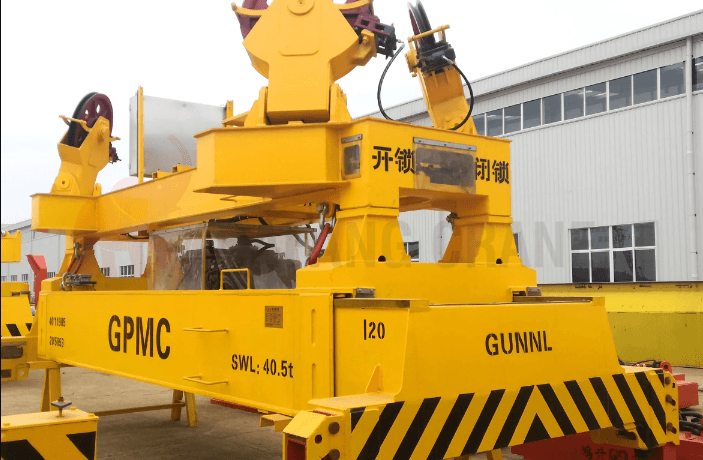

Container Hanger

The container hanger is a specialized piece of equipment that is attached to the main beams and used to lift and lower containers. The hanger consists of a spreader bar and a set of twist locks, which secure the container in place during lifting and transportation. The container hanger is designed to handle different types of containers, including 40′ containers, 20′ containers.

Crane Travel Trolley

The crane travel trolley is responsible for moving the container gantry crane horizontally along the dock. This trolley is situated on the ground beam and is powered by a set of electric motors. The crane travel trolley moves back and forth along the dock, positioning the container hanger over the containers to be lifted or lowered.

Winch

The container is lifted off the ship’s deck and onto the pier using the winch. A strong motor and a number of cables connecting to the container hanger make up the winch. The crane operator uses a set of joysticks inside the crane cab to control the winch, which lifts and lowers the container.

Benefits Of Container Gantry Cranes

Increased Efficiency And Productivity

One of the primary benefits of quay gantry cranes is their ability to increase efficiency and productivity. These machines are capable of unloading large ships and moving hundreds of containers in a matter of hours, a task that would take days or even weeks if done manually. This means that ports can handle more cargo in less time, allowing for faster turnaround times and increased profitability.

Cost-Effective

Container gantry cranes provide a cost-effective solution for handling cargo. They require minimal manual labor, reducing the operational costs associated with loading and unloading cargo ships. Additionally, their increased efficiency means that cargo ships spend less time in port, reducing the overall cost of shipping.

Safe And Reliable

Container gantry cranes are equipped with safety devices such as the Overload limit switch and Crane travel limit switch. Enables operators to control the movements of the crane, ensuring safe and precise positioning of the containers. This reduces the risk of accidents and damage to the cargo, improving overall safety and security at the port or terminal.

Automation

Container gantry cranes are capable of automation. This means that they can be programmed to perform certain tasks automatically, without the need for human intervention. This not only increases efficiency but also reduces the risk of human error, which can lead to costly mistakes and delays.

How To Operate Container Gantry Crane

The operation method of container cranes involves a few key steps. Firstly, the crane operator positions the crane over the container that needs to be moved. This is done using a set of controls that allow the operator to move the crane forwards, backward, left, and right. Once the crane is in position, the operator uses the crane’s hoisting system to pick up the container.

The hoisting system consists of a container hanger that is attached to a cable or chain. The hanger is lowered down to the container, and then it is hung onto the container’s corner casting. The operator then uses the hoist to lift the container off of the ship and onto the dock.

Once the container is clear of the ship, the operator uses the crane’s trolley system to move the container horizontally along the dock. This allows the crane to position the container exactly where it needs to go, whether that’s onto a waiting truck or into a storage area.

Finally, the crane operator lowers the container onto its new location using the hoist system once again. The container is carefully positioned and released from the hanger, completing the operation.

How To Select Container Gantry Crane

Capacity And Size

When choosing a container gantry crane, capacity and size should be taken into account first. The crane’s lifting capacity and the sizes of the containers it will be handling must be determined. You don’t want to purchase a crane that’s too small or too big for your needs.

Lifting Height

Another crucial aspect to think about is the crane’s lifting height. Make sure the crane can lift the containers high enough so they may be stacked on top of one another. The crane’s working height from the ship’s deck must also be taken into account.

Span Length

The crane’s span length is the distance between its legs. To fit the size of the ship that the crane will be working on, the span length needs to be wide enough. The crane won’t be able to access the containers on the side of the ship if the span length is too short.

Required Type

You also need to decide whether you want a rail-mounted crane or a rubber-tired crane. Although rail-mounted cranes require a fixed rail system to function, they are more stable and have greater lifting capacity. Rubber-tired cranes have lesser lifting capacity but are more mobile and flexible about the terminal.

Operating Environment

The operating environment is another important factor to consider. You need to ensure that the crane is suitable for the climate and weather conditions in your area. If you’re working in a coastal area, you need to consider the effects of saltwater corrosion on the crane.

Container gantry cranes have revolutionized the shipping industry by making container handling faster, safer, and more efficient. With their advanced design and working principle, these machines have become an integral part of ports and container terminals worldwide.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China