Crane Spreaders Types: Everything You Need

Crane spreaders are essential equipment used in various industries for load lifting and handling operations. From container terminals to construction sites, different types of crane spreaders are employed to suit specific requirements. In this article, we will explore the different types of crane spreaders.

Crane Spreaders 1: Crane Hook

Hook spreaders are one of the most commonly used types of crane spreaders. Their design features a hook-shaped attachment that securely grasps and lifts loads. This straightforward design allows for quick and efficient load handling.

According to the shape of hooks, it can be divided into single and double hooks:

Single Hook

The feature of single hook hangers is a simple design with a single curved arm and a pointed tip, providing a secure attachment point for lifting equipment. The single hook is simple to manufacture and easy to use, but the force situation is not good, mostly used in a lifting capacity of 80 tons or less work occasions.

Double Hook

As the name suggests, a double hook possesses two curved arms instead of one. This design enhances the stability and load-bearing capacity of the hook, making it ideal for heavier lifting tasks. The double hook provides a balanced lifting point and ensures even weight distribution, reducing the risk of load shifts or imbalances. This type of hook excels in applications where added stability and a higher load capacity are required. You will commonly find double hooks used in industries such as shipbuilding, aerospace, and heavy machinery manufacturing.

According to the manufacturing method of hooks, it can be divided into forging hooks and laminating hooks:

Forged Hook

Forged hooks are made by heating and shaping a solid piece of metal using a forging press or hammer. This method ensures that the hooks have exceptional strength and durability. The forging process eliminates weak points or potential areas of failure, making forged hooks highly reliable and resistant to deformation. These hooks are commonly used in industries such as industrial, construction, and logistics. Forged hooks are simple to manufacture and easy to use, but the force is not good, and once a forged hook is damaged, it is basically a total write-off.

Laminated Hook

Laminated hooks are specially constructed using layers of steel plates that are welded together. This unique design provides exceptional strength and load-bearing capacity. The layered construction of a laminated hook enables it to handle heavy loads without the risk of bending or breaking under stress. These hooks are known for their resistance to deformation, making them ideal for extreme lifting conditions. Laminated hooks are commonly utilized in sectors like shipping, offshore operations, and steel production.

Crane Spreaders 2: C Hook

The C hook is a specialized tool designed for handling cylindrical objects, such as coils or pipes. Its unique shape, resembling the letter C, provides a secure grip around these objects. The arms of the C hook cradle the cylindrical load, preventing it from slipping or shifting during lifting. The C hook is commonly used in industries that handle cylindrical materials, including the steel, paper, and textile industries.

Crane Spreaders 3: Crane Lifting Tong

Crane-lifting tong spreaders are specifically designed to handle heavy loads with a tong-like mechanism. They consist of two jaws that grip the load from both sides, providing a strong and secure hold during lifting.

Crane Spreaders 4: Grab Bucket

Crane grab buckets include hydraulic grab bucket, remote control grab bucket, mechanical grab bucket, and electrical grab bucket.

Hydraulic Grab Bucket

Hydraulic grab buckets utilize hydraulic power to operate the grabbing mechanism, allowing for a strong and reliable grip on the materials. The hydraulic system provides the necessary force to open and close the grab, facilitating efficient loading and unloading operations. With their versatility and advanced hydraulic technology, these grab buckets are ideal for handling a wide range of materials, including sand, gravel, coal, and scrap metal. The hydraulic grab’s ability to withstand high pressures and heavy loads ensures efficient and safe operations.

Remote Control Grab Bucket

In today’s technologically advanced world, remote control grab buckets offer an unprecedented level of convenience and precision. These grab buckets are equipped with wireless remote control systems, enabling operators to control the grabbing mechanism from a distance. Through the use of remote control, operators can manipulate the grab bucket with ease, ensuring accurate and efficient material handling without the need for direct physical contact.

Mechanical Grab Bucket

Mechanical grab buckets rely on mechanical force and leverage to perform material handling tasks. These buckets are typically operated manually or through the use of mechanical linkage systems. The mechanical grab bucket’s design features sturdy jaws that open and close manually or with the help of mechanical force, allowing for efficient and controlled material grabbing. These grab buckets are commonly used in smaller-scale operations where hydraulic or remote-controlled systems may not be necessary or feasible.

Electrical Grab Bucket

Electrical grab buckets combine the advantages of advanced technology with ease of operation. These grab buckets are powered by electricity and utilize an electrical control system to manipulate the grabbing mechanism. The electrical mechanism ensures precise control over the grabbing action, allowing for efficient material handling. Electrical grab buckets are often used in applications where a controlled and accurate grip on the materials is crucial. These may include industries such as waste management, recycling, and mining, where proper material sorting and handling are essential for optimal productivity.

Crane Spreaders 5: Electromagnetic Spreader

Electromagnetic Chuck

The key to the electromagnetic lifter is the electromagnet. When connected to an electric current, the electromagnet sucks up the steel object tightly and lifts it to a specific area. Disconnect the flow of electricity, magnetic subside, steel objects will be released. Electromagnetic crane is easy to use but must have the electric flow to use, and can be used in the scrap iron and steel recycling industry and iron production workshop.

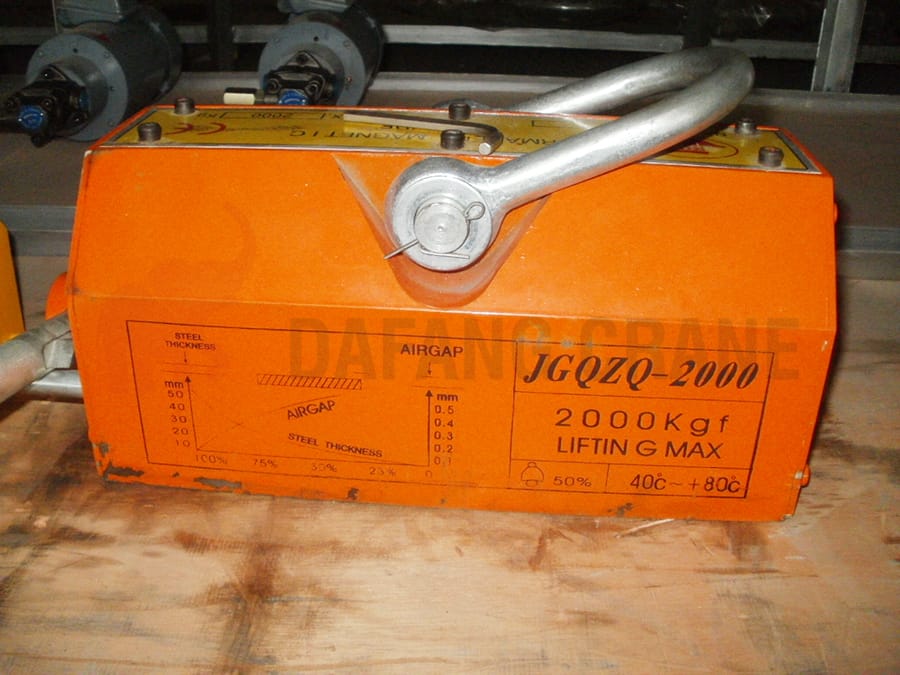

Permanent Magnet Chuck

In contrast to the electromagnetic chuck, a permanent magnet chuck is made of permanent magnets that maintain their magnetic field without the need for electrical current. It offers a reliable and constant magnetic force, making it suitable for applications where a continuous magnetic connection is required. Permanent magnet chucks are commonly used in machining and grinding operations.

Electro-permanent Magnetic Chuck

The electro-permanent magnetic chuck combines the advantages of both electromagnetic and permanent magnet chucks. It features a design where the magnetic force can be switched on and off using an electrical current, but once magnetized, it requires no additional power to maintain the magnetic field. The electro-permanent magnetic chuck offers the convenience of easy activation and deactivation while providing stability and reliability during the lifting process.

Crane Spreaders 6: Container Spreader

In the shipping and logistics industry, efficient handling of shipping containers is of utmost importance. Container spreaders are specifically designed to facilitate the loading and unloading of these containers.

Fixed Container Spreader

Fixed spreader is also called integral spreader, it can only load and unload a specification of container. It has no special power device, it is through the lifting and lowering of the wire rope to drive the ratchet mechanism drives the rotation of the rotary lock, so as to realize the automatic opening and closing of the locking pin by the way of mechanical movement of the wire rope. This kind of spreader is simple in structure and light in weight, but it is inconvenient to use, and it is generally used in multi-purpose gantry crane and general gantry crane.

Telescopic Container Spreader

The telescopic container hanger is a flexible and adjustable spreader that can accommodate containers of different sizes. It consists of multiple sections that can extend or retract to match the length of the container. This versatility makes it suitable for operations where containers with varying dimensions need to be handled.

Master-Slave Container Spreader

Master-slave spreaders are also known as combination spreaders. This type of spreader consists of a combination of upper and lower spreaders. Generally, the upper spreader is 20 ft and the lower spreader is 40 ft. The upper spreader is equipped with a power unit. When lifting containers of different sizes, just load or unload the lower spreader. Master-slave spreader compared with the fixed spreader, it is easy to use, but the weight is larger.

Submounted Container Spreader

The sub-mounted spreader is also known as a change-over spreader. This type of spreader is equipped with a power system on its special spreader beam, which is used to drive the rotary locking mechanism on the spreader below. Under the spreader beam, it can be changed to 20 ft, 40 ft and other specifications of container fixed spreader. Compared with the master-slave spreader, it has a lighter weight, but it takes a longer time to change the spreader.

Henan Dafang Heavy Machinery Co., Ltd. is a crane manufacturer with perfect testing equipment and advanced production equipment as well as a professional technical research and development team. Manufacture license has covered all types of cranes, include gantry crane, semi gantry crane, overhead crane, jib crane, electric hoists, cast crane, engineer crane, and beam launcher etc. If you have any questions or needs about cranes and crane spreaders, please contact us!

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat