How To Customize A Perfect Gantry Crane?

Do you want to customize a gantry crane to meet your specific lifting needs? Do you wish to increase the level of your lifting? You’ve definitely come to the correct location, my friend! In this article, we’re going to show you how to customize a gantry crane that suits all your requirements. From choosing the right size to selecting the perfect accessories, we’ve got you covered.

Understanding The Purpose Of The Gantry Crane

Before customizing a gantry crane, it is crucial to determine the specific purpose for which it will be used. This includes identifying the type of load that will be lifted, the frequency of use, and the environment in which it will operate.

A gantry crane consists of a horizontal beam that spans between two uprights or legs. It is equipped with a trolley system that moves along the length of the beam, allowing the crane to lift and transport heavy loads horizontally. The crane is typically powered by electricity or diesel fuel, depending on the specific application.

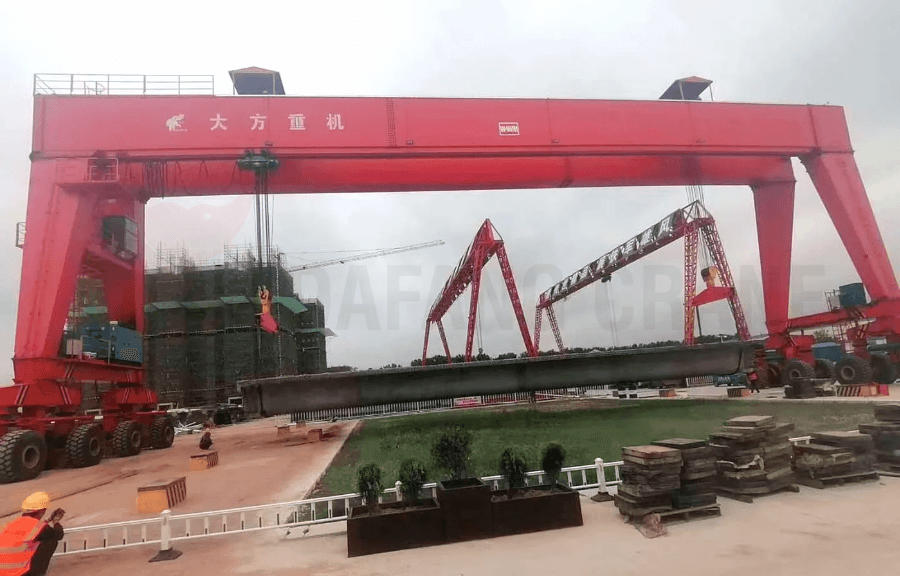

The primary purpose of a gantry crane is to move heavy loads that are too large or unwieldy for human workers to handle manually. This could include containers at a port, building materials at a construction site, or heavy machinery at an industrial facility. By using a gantry crane, these heavy objects can be transported safely and efficiently, reducing the risk of injury or damage to the workers or the equipment.

Knowing Your Specific Needs

The first step in selecting a gantry crane is to understand your specific needs fully. Consider the following factors:

- The weight and size of the load

- The height at which the load needs to be lifted

- The distance the load needs to be transported

- The frequency of use

- The environment in which the crane will operate

- Determining the Load Capacity Requirements

Once you have identified your specific needs, you need to determine the load capacity requirements of the gantry crane. This is determined by calculating the weight of the heaviest load that will be lifted and transported.

Choosing The Right Type Of Gantry Crane

Gantry cranes come in various types, and choosing the right one depends on your specific needs. Two essential factors to consider are the type of girder (single or double) and whether it is mobile or fixed.

Single Girder VS Double Girder Gantry Cranes

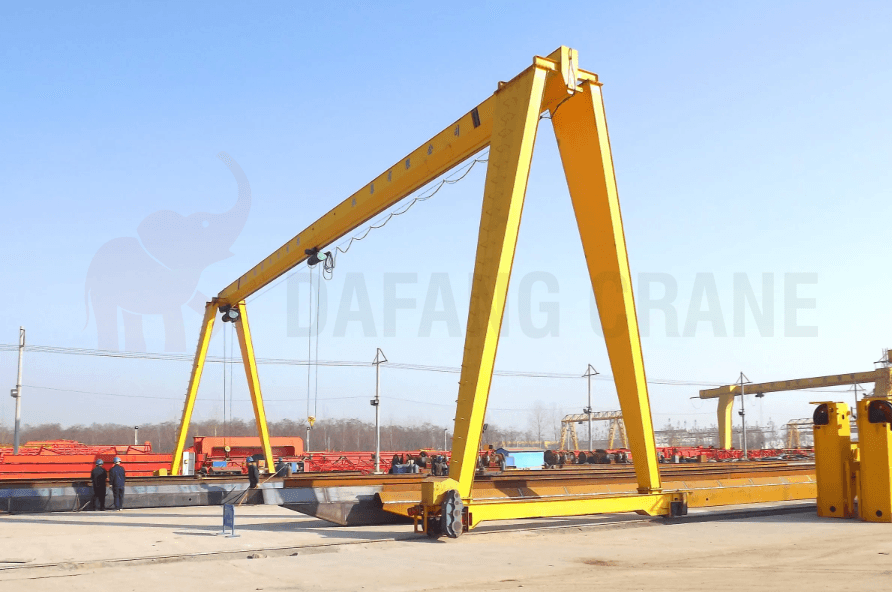

Single girder gantry cranes have one main beam that supports the hoist, while double girder gantry cranes have two beams that support the hoist. The primary advantage of single girder gantry cranes is their affordability. They are typically less expensive than double girder gantry cranes, making them a popular choice for smaller businesses or those with a limited budget.

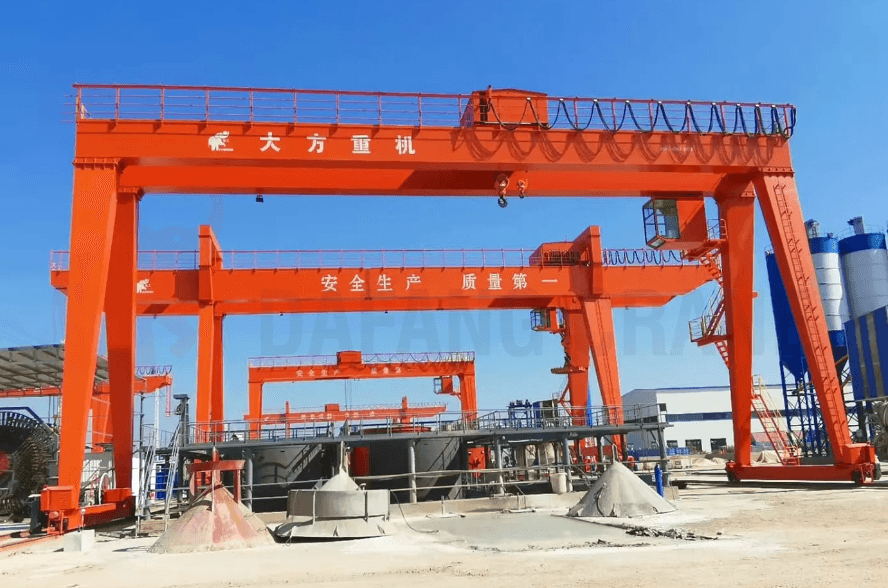

Double girder gantry cranes, on the other hand, offer greater lifting capacity and span width. Because they have two beams supporting the hoist, they can lift heavier loads and span wider areas than single girder gantry cranes. They also have better stability and safety features, making them ideal for use in high-risk environments.

When deciding between these two types of gantry cranes, it’s important to consider your specific needs and requirements. If you need a gantry crane with a lower lifting capacity and span width, a single girder gantry crane may be the best fit for your business. However, if you require a gantry crane that can handle heavier loads and has a wider span, a double girder gantry crane may be a better option.

Mobile VS Fixed Gantry Cranes

Mobile gantry cranes have wheels that allow them to be easily moved around your facility, making them ideal for businesses with limited space or those that require flexibility in their operations. They are designed for quick and easy assembly, making them a popular choice for temporary job sites or outdoor applications.

Fixed gantry cranes, as the name suggests, are stationary and cannot be easily moved. They are bolted to the ground and are typically used in large manufacturing facilities or warehouses where they are required to lift heavy loads on a regular basis. Unlike mobile gantry cranes, fixed gantry cranes can handle greater loads and have a higher lifting capacity.

It’s critical to take your unique operational requirements into account when choosing between a mobile and fixed gantry crane. A mobile gantry crane may be the best fit if your business requires flexibility. However, if you need a gantry crane with a high lifting capacity and stability, a fixed gantry crane may be more suitable.

Customizing The Gantry Crane

Customizing a gantry crane involves selecting the appropriate span length and height, choosing the best hoist and trolley system, and deciding on the most suitable power source.

Selecting The Appropriate Span Length And Height

The first step in customizing your gantry crane is selecting the appropriate span length and height. This will depend on several factors, including the size and weight of the loads you will be lifting, the space available in your facility, and any restrictions or regulations that may apply.

When selecting the span length, consider the distance between the legs of the gantry crane. This will determine how much clearance you have for moving loads and how stable the crane will be when in use. A longer span will generally provide greater stability, but it may also require more space.

The height of the gantry crane will determine how high you can lift loads. Take into account the height of the items you will be lifting as well as any barriers in the air that might prevent the crane from rising all the way. Although a higher crane could be more difficult to move and use, it will often be more stable.

Choosing The Best Hoist And Trolley System

When choosing a hoist and trolley system, consider the weight and size of the loads you will be lifting, as well as any speed or precision requirements. A chain hoist, for example, may be suitable for smaller loads, while a wire rope hoist may be better for larger loads. Similarly, a manual trolley system may be suitable for lighter loads, while a motorized trolley system may be better for heavier loads or more frequent use.

Deciding On The Most Suitable Power Source

Some options for power sources include electric motors, hydraulic systems, and pneumatic systems. Electric motors are typically the most popular option because they are dependable and effective, although they can need access to wire or electrical outlets. On the other side, hydraulic and pneumatic systems might be flexible and portable, but they might also need more upkeep and maintenance.

Ensuring Safety And Compliance

Finally, when customizing your gantry crane, it is essential to ensure safety and compliance with relevant regulations and standards. In particular, be sure to consider factors such as load capacity, stability, and overhead clearance.

In conclusion, customizing a gantry crane requires careful consideration of several factors, including load capacity requirements, type of girder, mobility, span length and height, hoist and trolley system, and power source. Ensuring compliance with industry standards and implementing proper maintenance and training programs are also vital for safe and efficient operation.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat