How to Quickly Solve Overhead Crane Rail Gnawing

Overhead cranes are essential specialized equipment for production and manufacturing enterprises, responsible for daily lifting, maintenance, and installation of equipment and accessories. The condition of bridge cranes directly affects whether the enterprise can complete production tasks on time and smoothly. Therefore, ensuring the good condition of bridge cranes is an important job for production and maintenance. Rail gnawing is a common phenomenon in the use of bridge cranes. It is mainly caused by the deviation of the crane track or the deviation of the wheels exceeding the standard, resulting in rail gnawing. This can lead to derailment, which not only affects production progress but also may cause accidents. This article analyzes the causes of rail gnawing for bridge cranes and proposes corresponding preventive measures, helping you to quickly solve bridge cranes gnawing rails.

Manifestations and Adverse Effects of Overhead Crane Rail Gnawing

During the use of overhead cranes, the wheel rim of the crane and the rail rub against each other, causing severe wear on the wheel rim and the side of the rail. This phenomenon is referred to as rail gnawing. The main manifestations are as follows:

- The crane produces a squeaking or loud roaring sound during operation.

- There are spots or bright marks on the side of the rail, or there may be iron shavings around the rail.

- During the operation of the crane, there is a clear indication of misalignment between the edge wheel and the rail.

- The crane may experience resistance during operation, and due to the friction between the wheel rim and the rail, slow vehicle start-up and other phenomena may occur.

- Impact of Rail Gnawing on Workshop Structure: Once the crane wheel gnaws the rail, it will directly generate horizontal lateral forces, which will cause the rail to deviate laterally, resulting in equipment vibration and eventually causing the loosening of screws fixed on the rail. In addition, it can cause overall crane failures and varying degrees of impact on the stability of the structure inside the workshop.

- Impact of Rail Gnawing on Production, Safety, and Equipment: In cases where rail gnawing is severe, the damage to the rail will further increase, making it difficult for the crane to make good contact with the wheels during operation, ultimately affecting its use. Once the rail needs to be replaced, it requires a significant amount of manpower, material, and financial resources, causing a great disturbance to production safety.

- Impact of Rail Gnawing on Electrical Equipment: Once rail gnawing occurs, it will first cause significant resistance during crane operation, greatly increasing the electrical load and easily causing motor overload damage. At the same time, the increased running resistance of the crane will cause varying degrees of damage to various components in the transmission system.

Analysis of Causes of Overhead Cranes Rail Gnawing

There are various reasons for the operation of bridge cranes to gnaw the rails, mainly through the following reasons for theoretical analysis:

Gnawing of Rails Due to Orbital Causes

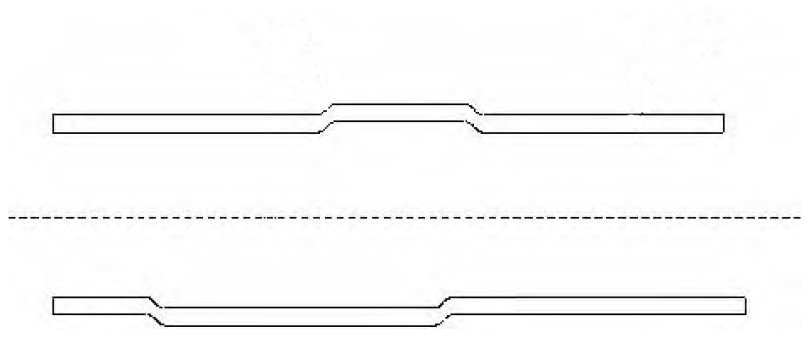

Cause1: Rail Tilt

When the rail beams are installed, if there is a tilt, it will cause the installed rail to tilt, resulting in lateral movement of the running wheels, and wear on the inside of one side of the wheel rim and the outside of the other side.

Cause2: The Horizontal Deviation Between Two Rails Exceeds Standard

Due to uneven settlement and deformation of the foundation of the workshop of some users, there is an exceeded standard height difference between the two rails at the same cross-section, leading to rail gnawing. If the relative elevation difference during rail installation is too large, it will cause lateral movement during crane operation, and rail gnawing often occurs on the inner side of the lower rail and the outer side of the higher rail. The elevation of the rail can be measured using a leveling instrument.

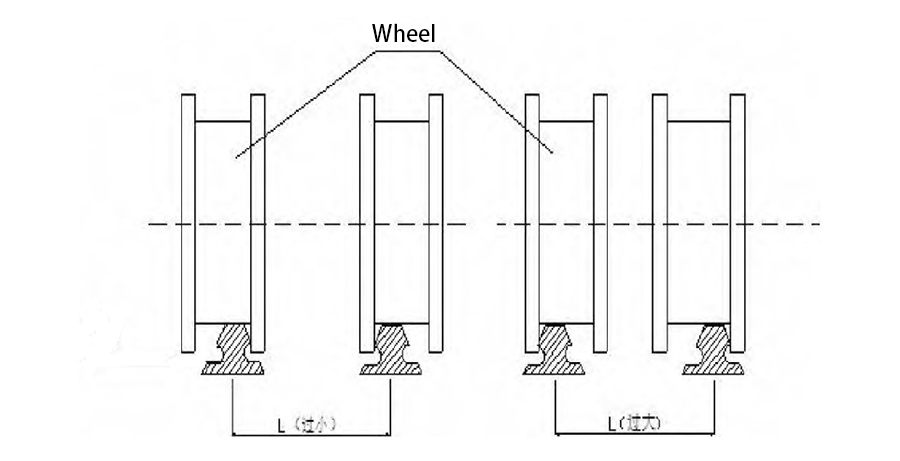

Cause3: Span Deviation Between Two Rails Exceeds Standard

Span is an important parameter in the design of bridge cranes. However, during actual rail installation, if there is an installation error, it will cause span deviation issues. If the rail installation span is too small, it will cause rail gnawing on the inner side of the wheel rim. If the rail installation span is too large, it will cause rail gnawing on the outer side of the wheel rim.

The span of the track can be measured with a steel tape measure, one end of the tape is fastened with a clamp, and the other end of the tape is tied to a spring scale with a tensile force of 0.7-0.8kg per meter, which is measured once every 5m. Before measuring, mark reference points at the center of the track, spring scale tension should be the same at each measurement point.

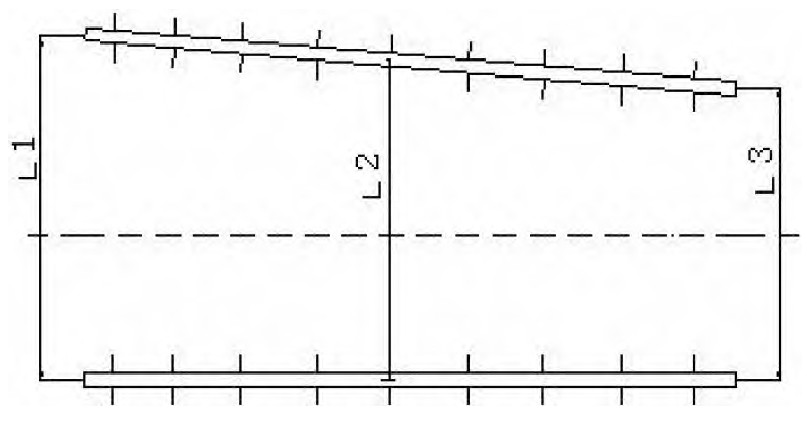

Cause4: Straightness Deviation Between Two Rails Exceeds Standard

1.Inconsistent rail span, one end with a larger gauge and the other end with a smaller gauge, causing the outer wheel rim to gnaw on the rail at the larger gauge and the inner wheel rim to gnaw on the rail at the smaller gauge.

2.Rail horizontal bending.

The straightness of the rail can be checked by pulling a 0.5mm steel wire between the rail stops at both ends and then measuring the wire’s position using a plumb bob. The measurement points can be spaced around 2m apart.

Wheel-related causes of rail gnawing

Cause1: Wheel Diameter Deviation

If there is a large difference in wheel diameter, when the wheels mounted on different end beams are moving, there will inevitably be a problem with the larger wheel running ahead, causing a horizontal deviation in the running trajectory. When the deviation exceeds 15mm, the wheel flange will be restricted by the rail, leading to the phenomenon of rail gnaw. The rail gnaw caused by the wheel diameter deviation is manifested as the larger wheel gnawing on the outer side of the rail during back-and-forth movement, while the smaller wheel gnaws on the inner side of the rail. In the initial stage, there is no sign of rail gnaw.

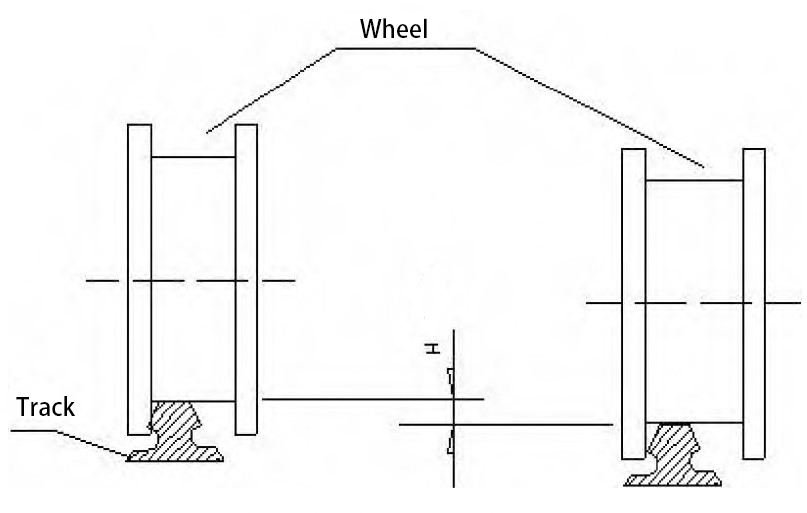

Cause2: Diagonal Deviation

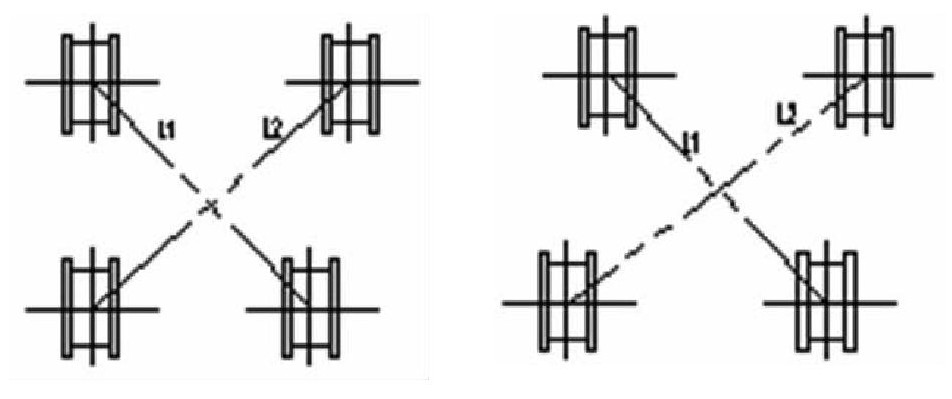

The two wheels are not equal in diagonal, a cause that often results in both tracks being chewed inside or outside at the same time.

Diagonal Deviation Inspection: Position the overhead crane on a section of rail with good linearity and find the center of the rolling surface of the wheels using a steel ruler. Hang a plumb bob at the center and mark the corresponding spot on the rail. Repeat this process for the other three wheels. These four points serve as the measurement points for the diagonal and span of the wheels. To reduce measurement errors, secure one end of the steel ruler with a clamp and attach a spring balance to the other end. The tension should be maintained at 0.7-0.8kg per meter of span.

Cause3: Wheel Horizontal Deviation

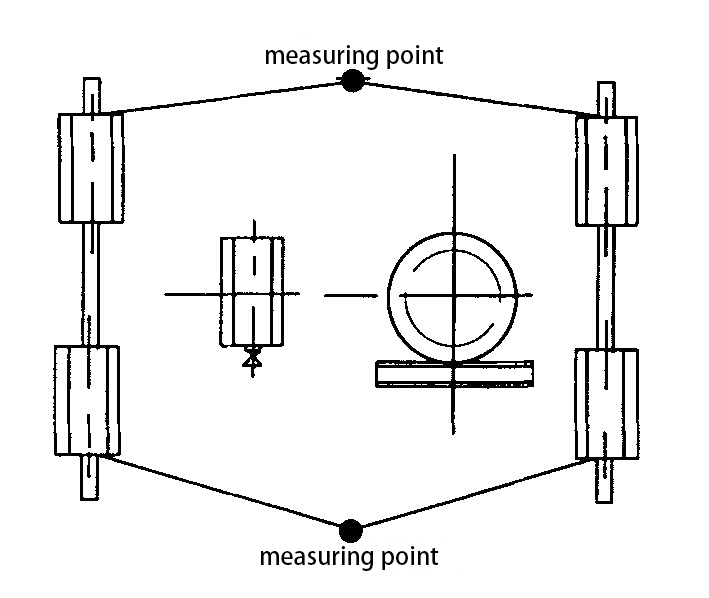

The factors that cause the wheel to deviate horizontally usually come from transportation, installation, and operational processes. For example, when one of the wheels is deviated, it will cause rail gnaw on one side of the wheel. When it moves in the opposite direction, rail gnaw will occur on the other side. Rail gnaw is usually more severe when there is a horizontal deviation.

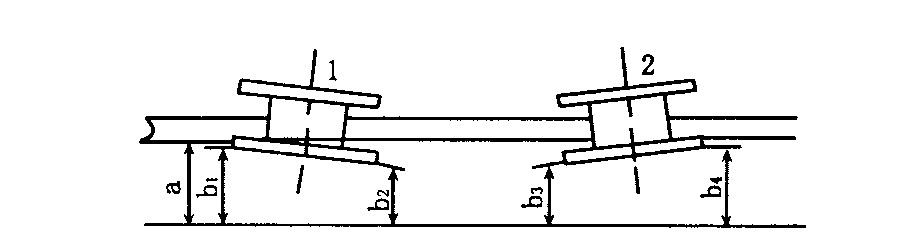

Inspection of Wheel Horizontal Deviation: Select a section of rail with good linearity as a reference and place a 0.5mm fine steel wire parallel to the outer surface of the rail at a distance equal to “a”. Then, measure the distances at points “b1”, “b2”, and “b3” using a steel ruler. The horizontal deviation of wheel 1 is “b1 – b2”, the horizontal deviation of wheel 2 is b4 – b3, and the straight deviation of the wheels is “(b1 + b2)/2 – (b3 + b4)/2”.

Cause4: Wheel Vertical Deviation

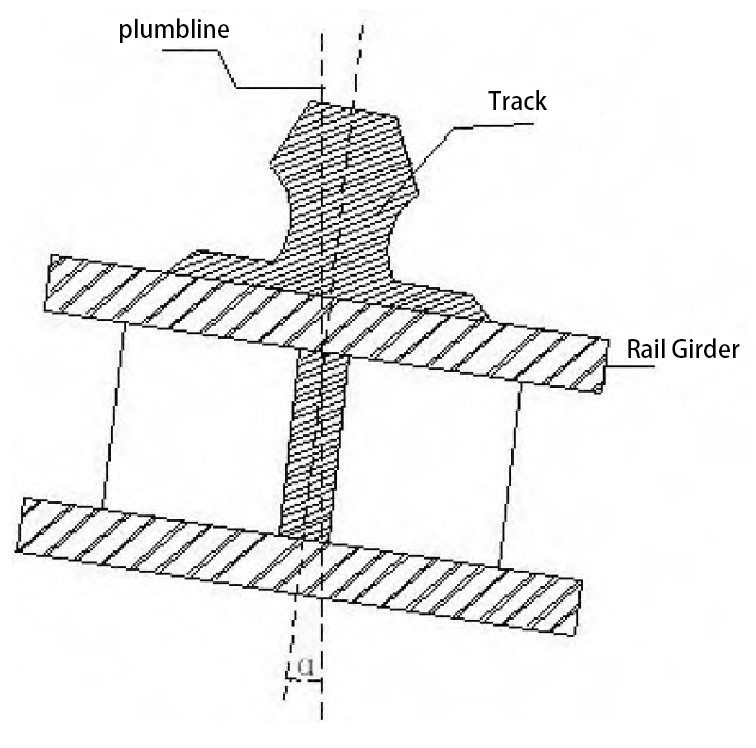

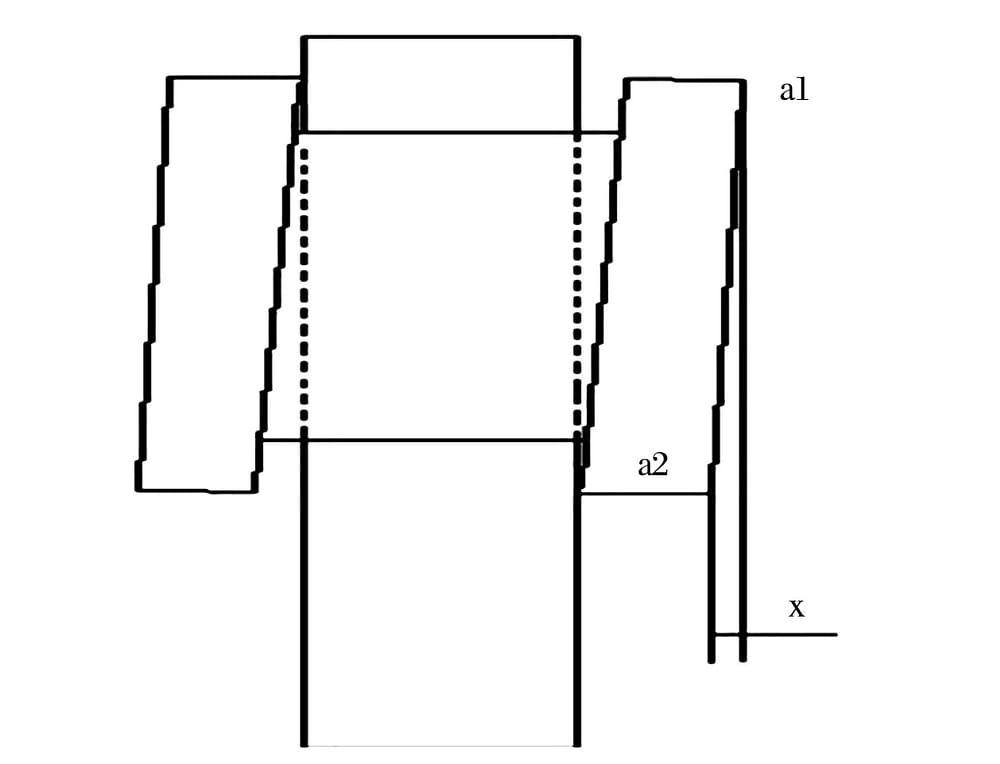

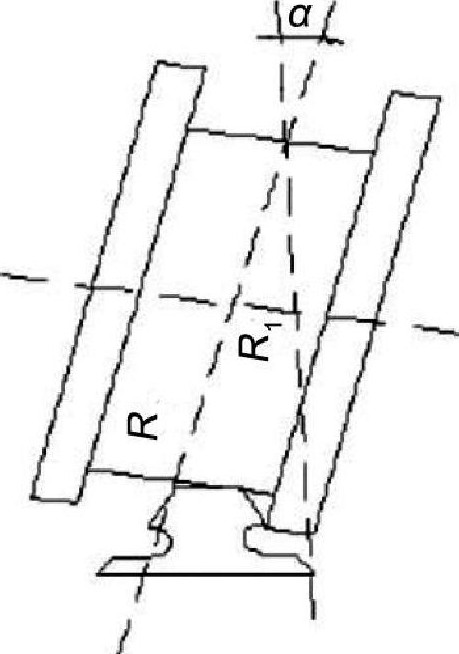

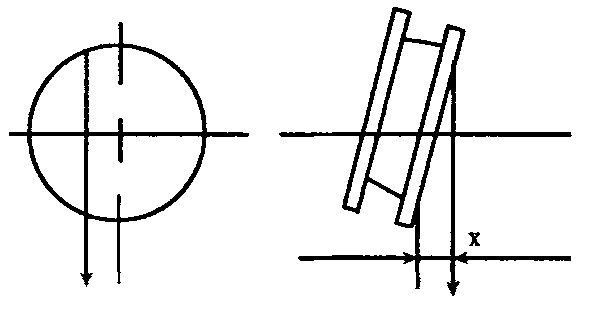

When the crane is in a tilted state, the gap between the rail and the wheel flange will significantly decrease. The center of the wheel tread will form an α angle with the vertical line. When the vertical deviation exceeds the specified value, rail gnaw will occur. Therefore, controlling the vertical deviation is crucial.

Inspection of Wheel Vertical Deviation: Measure X using a plumb bob to determine the vertical deviation of the wheels.

Bridge Deformation Causing Rail Gnawing

Cause1: Horizontal Bending of the End Beam Caused by Bridge Deformation

When there is an error in the diagonal and it is greater than 5mm, it will cause span deviation. If the difference is negative, it will lead to rail gnaw on the outer side of the wheel, and vice versa for rail gnaw on the inner side.

Cause2: Wheel Horizontal Deviation Caused by Horizontal Bending of the End Beam

The root cause of this phenomenon is that the large horizontal bending of the end beam will increase the tilt of the wheels, making the wheel alignment inconsistent with the center line of the rail, resulting in rail gnaw.

Cause3: Vertical Deformation of the Bridge

As the vertical deformation amplitude of the bridge increases, it will induce a series of structural changes, including vertical inclination of the vehicle, the emergence of the angle between the tread surface and the plumb line, so that changes in the rolling radius of the wheels. When the crane has the load, this change also increases, and a larger amount of deflection will also lead to the phenomenon of gnawing the rail.

Rail Gnaw Caused by the Transmission System

Based on the analysis of the application experience of the overhead crane, problems with the drive system and braking system can also cause rail gnaw.

- Drive system: When the crane is driven by multiple motors, inconsistent speeds can cause deviation in the wheel’s travel speed, leading to rail gnaw.

- Braking system: Inconsistent deceleration ratios of the crane can also result in different braking efficiency of the wheels, making it difficult for the wheels to brake smoothly. When the deviation exceeds the limit, rail gnaw occurs due to unsynchronized braking.

Other Reasons

Improper operation, such as the trolley frequently working on one side, causes increased pressure and resistance on the wheels on that side, resulting in rail gnaw. Abrupt starting or stopping can cause wheel slippage, leading to rail gnaw.

Long-term overloading of the crane, unauthorized operations, and other reasons can cause deformation of the main beam, end beam, or trolley frame, resulting in changes in the verticality and span of the wheels, causing rail gnaw during operation.

Deviations in the wheel alignment may occur if the wheels and bearings are not properly adjusted after maintenance and replacement.

The solution strategy of the Overhead Cranes Rail Gnawing

Solution for Rail Problems

- Rail Tilt: Use the way of adding steel mat to adjust the amount of error to ensure that the rail level, height, and curvature are in accordance with the standard.

- Rail Horizontal Deviation: For the same cross-section of the two rails relative height difference is too large caused by the gnawing rail, should be adjusted with high and low error, using the method of adding pads to adjust the choice of ordinary steel plate, the thickness of which is selected according to the track measured high and low error, pads require a flat surface, no bumps and dimples, the width of the external dimensions should not be more than the track pressure plate 20mm, The underside of the track should be filled in without overhangs, and fixed to the beam below with a pressure plate with bolts; this method is economical, reliable, effective and simple in structure.

- Rail Span Deviation: Adjust the pressure plate screws of the rail, and then adjust the rail on the other side with the adjusted rail as the benchmark, pay attention to the elevation of the guide rail in the adjustment to make it conform to the standard.

- Rail Straightness Deviation: calibrate the deviation position of the rail, loosen the fishtail clamping plate and pressurized rail bolts, and then use the hand hammer and some other hard instruments to hammer the inclined pins of the pressurized rail, prompting the inclined pins side pressure to change the position of the rail, and then reinforce the pressurized rail bolts, and so on repeat the check for a few times, so that it reaches the corresponding level, and rectify the phenomenon of horizontal bending.

Solution for Wheel Problems

- Wheel Diameter Deviation: When the wheel diameter deviation exceeds the standard, it needs to be reprocessed or replaced. The diameter deviation between the active and passive wheels after replacement should not exceed 3mm, otherwise, it will affect the overall structure of the crane.

- Wheel Diagonal Deviation:

If the gnawing rail is caused by the horizontal deviation of the wheel, the thickness of the left and right shims of the bearing seat can be adjusted. If the gnawing rail is caused by the verticality of the wheel, thin shims can be added under the bearing seat.

Gnawing caused by wheel span, wheelbase, diagonal or straightness deviation of wheels on the same track can be solved by moving the position of the driven wheel. - Wheel Horizontal Inclination: There are two methods for adjusting the horizontal inclination of the wheel. The first method is to adjust the shim thickness of the positioning key on the angular bearing box to correct the horizontal inclination. The second method is to re-make suitable positioning keys and weld them in position to eliminate the horizontal inclination.

- Wheel Vertical Inclination: The method to adjust the vertical inclination of the wheel is to add shims to the angular bearing box and horizontal positioning key, or add shims between the horizontal positioning key and the end beam bending plate. Depending on the direction of the wheel’s vertical inclination, add shims to the corresponding side of the angular bearing box. If the thickness of the shim is greater than 2/3 of the depth of the angular bearing box’s positioning slot, add the shim directly to the end beam bending plate to solve the rail gnawing problem.

Solutions for Bridge Deformation Problems

Bridge deformation includes many factors, such as transportation, installation, use and other links. When the bridge is found to have a small degree of deformation, you can prioritize the adjustment of the wheels, and in some cases only need to adjust a single wheel to eliminate the gnawing phenomenon, such as adjusting the horizontal skew of the wheels, vertical skew, span and diagonal and so on. If the bridge deformation exceeds a certain interval, and there is a more obvious gnawing rail phenomenon, it is necessary to repair the deformed parts of the bridge. The general treatment method is to correct the under disturbance of the beam, side bending, end beam horizontal bending, etc., such as taking measures such as pre-stress correction or flame correction. Among them, the prestressing correction method refers to the main girder under the cover plate welding support seat, and using high-quality steel wires as tension reinforcements to counteract the deformation of the overhead crane rail. Flame correction method is the use of oxyacetylene flame, the bridge deformation parts of the implementation of heating treatment, so that the deformation parts of the contraction effect, in order to achieve the purpose of correction of the bridge.

The Solution for the Transmission System Leading to the Gnawing of Rails

For separately driven overhead cranes, both ends should be selected with the same model, the same parameters of the motor, its 2 groups of drive mechanism bearings and brakes should be adjusted to the same degree of tightness. At the same time, in the process of installation and use, the reducer, coupling and related transmission components should be tested to ensure that the installation tightness, clearance, wear and so on to maintain consistency, to maximize the avoidance of operational errors.

Rail gnawing is a significant concern for industries relying on overhead cranes. By understanding the causes behind rail gnawing and implementing suitable solutions, companies can mitigate this issue, ensuring smooth and safe crane operations while minimizing maintenance costs.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China