Jib Cranes: Everything You Wanted To Know

Jib cranes are versatile material handling devices that provide efficient lifting and maneuvering capabilities in various industrial settings. This article aims to provide a comprehensive understanding of jib cranes, including their types, components, installation and maintenance, as well as methods of use and places of application.

Chapter 1: What Are Jib Cranes?

A jib crane is a type of lifting device that consists of a horizontal arm (jib) that is attached to a vertical mast or support pillar. The arm can rotate horizontally, allowing the crane to reach different areas within its working radius. Jib cranes are commonly used in industrial settings, construction sites, warehouses, and shipyards for lifting and moving heavy objects.

Chapter 2: What Are The Jib Crane Types?

Jib cranes are mainly classified as floor-mounted jib crane, wall mounted jib crane, wall travelling jib crane, and articulated jib crane.

Floor Mounted Jib Crane

Floor-mounted jib cranes are widely used and can be installed anywhere indoors or outdoors, with a lifting capacity generally not exceeding 10t. This type of crane is safely fixed to the floor, and it usually consists of a vertical mast, a horizontal jib, a rotating mechanism and a hoisting mechanism. Free standing jib cranes offer 360-degree rotation, allowing efficient handling of materials within a large working radius, essential in environments where space is at a premium.

Pillar mounted jib cranes are categorized according to the product structure:

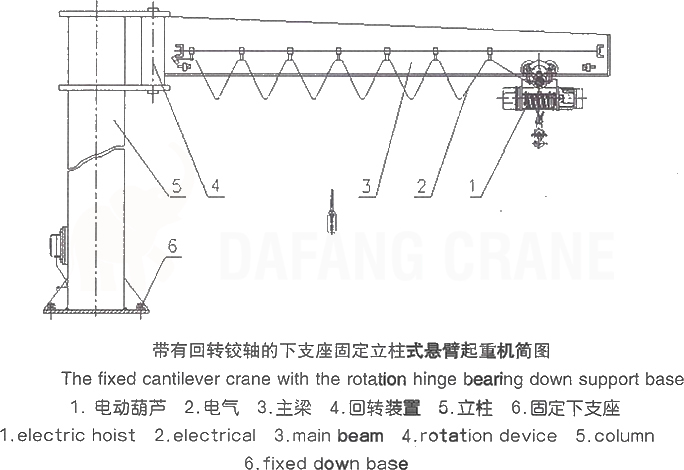

The floor-mounted jib crane with the rotation hinge bearing down support base: slewing angle ≤ 270 °, this type of crane jib rotates around the fixed column on the slewing hinge axis, and the general lifting capacity and the effective radius of gyration is small. Lifting capacity of 1 ton or less, the maximum effective radius of gyration in 5 meters or less.

The floor-mounted jib crane with the support beam down support base: Slewing angle ≤ 360 °, this type of crane due to the jib girder with jib, the corresponding main beam of the force condition has been improved. The lifting capacity is generally within 2 tons, the maximum effective radius of gyration is within 5 meters.

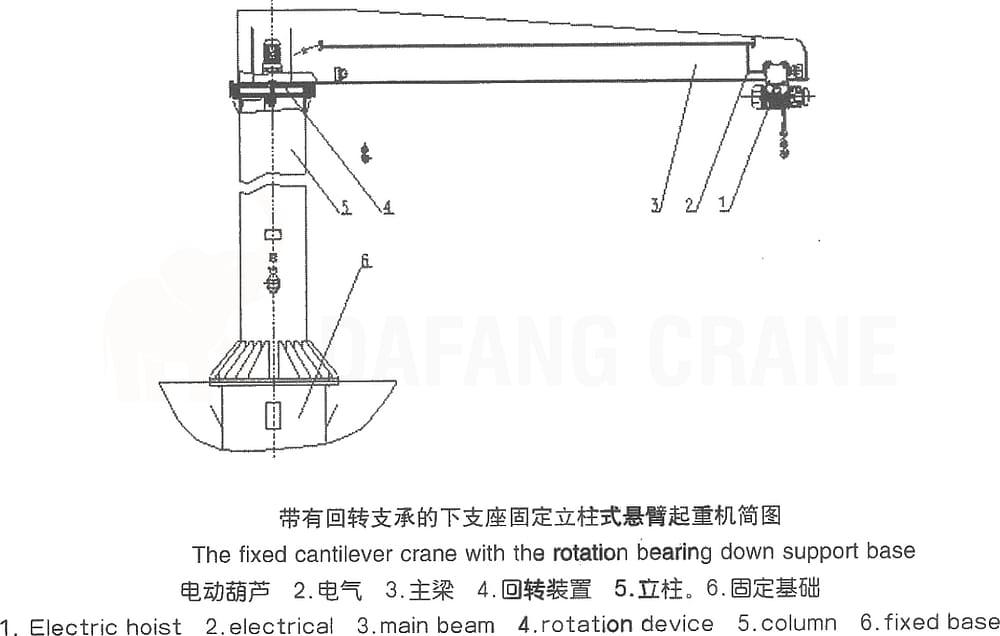

The floor-mounted jib crane with the rotation bearing down support base: slewing angle ≤ 360 °, this type of crane due to the use of slewing bearing structure with a large moment, the lifting capacity and effective cantilever greatly increased. Lifting capacity is generally up to 6 tons, the maximum effective radius of gyration up to 12 meters.

Wall Mounted Jib Crane

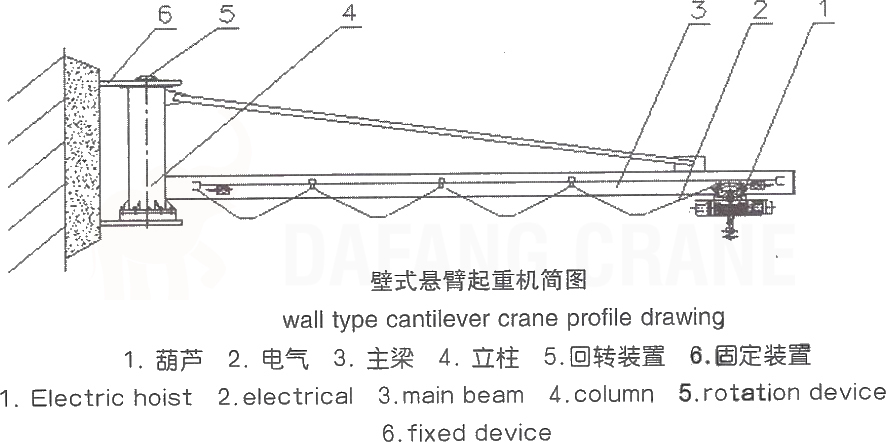

The wall-mounted jib crane has a column as one of the components of the arm support metal structure, which rotates with the arm on its axis.

The rotation part of cantilever jib crane mainly is arm support and drive device above it. The two ends of arm support column made of a stalk neck are inserted into the top and bottom bearing and bear all the weight of crane and the weight of product mourned. Top and bottom two bearings separately fixed on the building and the foundation can promise stability. When top and bottom bearings are fixed in corner of the wall inside the top of the factory premises wall, the derrick can revolve 90° s, packing in the outside corner of the wall, the derrick can revolve 270° s. The workability of this kind of derrick is subjected to conditional restriction of wall holding power. The lifting capacity is generally not over 5t.

The jib of wall jib cranes generally consists of a crossbeam and a tie rod. The hoisting mechanism is undertaken by the electric hoist running on the I-beam below the jib, which rotates together with the jib. And the rotation of the jib is driven by the gear reduction mechanism.

Wall Travelling Jib Cranes

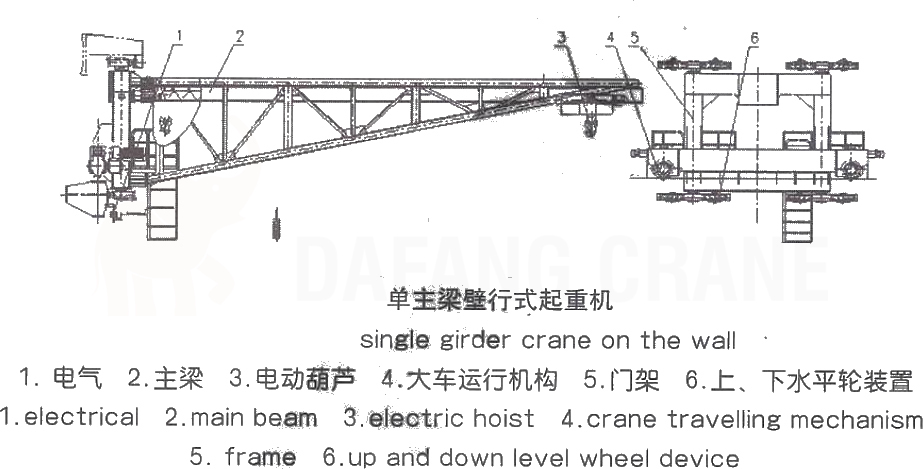

For increased mobility and extended coverage, wall travelling jib cranes are the go-to option. These cranes are designed to move along a track or rail system mounted on the wall or structure. By combining the features of a wall mounted jib crane with a travelling mechanism, this type of crane offers flexibility and efficiency in material handling operations. Wall-mounted jib cranes are generally used in workshops or warehouses with large building spans and building heights, especially when frequent lifting operations are carried out near the walls, the use of such cranes is the most suitable.

Articulated Jib Crane

Last but not least, the articulated jib crane, also known as a knuckle boom crane, stands out for its exceptional reach and maneuverability. This type of crane consists of multiple folding sections or arms that provide greater flexibility and precision during lifting operations. The articulated jib crane is commonly used in construction sites, shipyards, and other outdoor applications where access to hard-to-reach areas is essential. With its ability to navigate obstacles and reach over structures, this crane enables efficient material handling in challenging environments.

Chapter 3: Safety Devices For Jib Cranes

- Distribution protection: jib crane power distribution main circuit with a total power automatic air switch, total contactor and other protective components.

- Short-circuit protection: the total power circuit set up automatic switch as short-circuit protection, control circuit set up small capacity automatic air switch as short-circuit protection.

- Phase sequence protection: phase sequence protector is adopted to monitor the quality of power supply in real time. When the power supply is over-voltage, under-voltage, phase loss or phase error due to external reasons, the control system cuts off the main circuit to protect the safety of equipment and personnel.

- Lifting limit protection: When the hook rises or falls to the limit position, the power supply of the lifting mechanism will be cut off automatically.

- Lifting overload protection: When the load reaches 90% of the rated lifting capacity, a prompt alarm signal will be issued; when the load reaches 110% of the rated lifting capacity, the power supply of the hoisting mechanism will be cut off immediately and an alarm signal will be issued.

- Slewing angle limit protection: the slewing mechanism will automatically cut off the power supply of the slewing mechanism when it reaches the limit angle position.

- Emergency power-off protection: the power supply can be cut off at any time in case of accident to ensure the safe operation of the jib crane.

- Loss of voltage protection: When there is a sudden power failure or the power supply voltage is too low, the contactor will self-locking disconnect.

Chapter 4: Install And Maintenance Of Jib Cranes

Installation of Jib Cranes

The installation of jib cranes is divided into free standing jib crane installation and wall jib crane installation of two parts, wall jib crane installation is as follows:

Install the upper and lower shafts of the column in the bearings of the upper and lower supports respectively and apply lubricating grease.

The connection between the crossbeam and the column is fastened with bolts, and then the tie rod is connected and hoisted to the fixed installation on the wall and fixed with through-wall bolts. After installation, you can use the adjusting nut on the tie rod to adjust the level of the beam, and after adjustment, you can carry out various experiments.

Maintenance of Jib Cranes

In order to ensure the normal use of cranes and extend the service life of cranes, it is necessary to carry out regular inspections and adjustments.

1. Inspection of Hoist and Metal Structure

The metal structure of the crane should be inspected 1~2 times a year, focusing on the connection part with or without loosening and falling off; structural materials and welds with or without cracks and cracking; cantilever with or without deformation; corrosion of structural parts, etc.

2. Lubrication of Cranes

The parts of the crane that need to be lubricated are as follows:

- The two ends of the hook shaft and the thrust bearing under the hook nut.

- Wire rope

- Reducer

- Wheel bearings and motor bearings

Chapter 5: Use Of Jib Cranes

How Jib Cranes Move Cargo

Jib cranes utilize various mechanisms to move cargo efficiently. Here are some common methods:

- Rotation: Jib cranes have a rotating arm that allows them to cover a wide area. The arm can rotate horizontally or vertically, depending on the crane’s design.

- Lifting and Lowering: The hoist mechanism enables vertical movement by raising or lowering the load using a hook, grabber, or other lifting attachments.

- Slewing: Slewing is the lateral movement of the jib crane. It enables the crane to transport loads horizontally within its range.

Who Can Operate a Jib Crane

Operating a jib crane requires specialized skills and training. Generally, The person operating the jib crane has to fulfill the following conditions:

- Physical health, at least 18 years of age, eyesight of 0.7 or more, no color blindness, hearing to meet the requirements of specific working conditions

- Familiar with the safety regulations and master the relevant safety precautions

- Be familiar with the basic structure and performance of the operating crane

- Be familiar with the role of crane safety devices, and master the corresponding knowledge of lifting operations.

How to Operate a Jib Crane

Operating a jib crane requires knowledge of its components and a focus on safety. Here’s a step-by-step guide to help you navigate the process:

- Pre-operation Inspection: Before using a jib crane, thoroughly inspect it for any visible damage or wear. Check the controls, wires, chains, and hooks to ensure they are in proper working condition.

- Load Assessment: Determine the weight and dimensions of the load to be lifted. Ensure that the jib crane’s capacity meets or exceeds these requirements.

- Safety Measures: Wear appropriate personal protective equipment (PPE), including hard hats, safety gloves, and steel-toed boots. Familiarize yourself with emergency procedures and ensure the work area is clear of obstacles.

- Crane Controls: Understand the jib crane’s control panel, including buttons, levers, and joysticks. Practice using the controls, such as hoisting, lowering, swinging, and stopping the crane smoothly.

- Lifting Techniques: Position the crane’s hook or grabber above the load carefully. Lift the load gradually, avoiding sudden movements. Use hand signals or communication devices to coordinate with other personnel during the lifting process.

- Load Placement and Unloading: Ensure that the load is positioned correctly and securely before moving it. When unloading, follow proper procedures to prevent accidents or damage.

Chapter 6: Applications Of Jib Cranes

Jib cranes find applications in various industries due to their versatility and compact design. Some common applications include:

Industrial and Mining Enterprises

In industrial and mining enterprises, jib cranes are utilized for loading and unloading materials, transferring components between workstations, and facilitating maintenance operations. By improving efficiency and reducing manual labor, jib cranes enhance productivity while ensuring worker safety.

Warehouses

Jib cranes have become an integral part of modern warehouse operations. With their ability to handle heavy loads with ease, jib cranes aid in stacking and organizing inventory efficiently.

Production Line

Jib cranes are invaluable assets in production lines where the timely movement of components is vital to maintaining workflow continuity. These cranes assist in the precise placement of parts, tools, and equipment, enabling seamless assembly processes. The ability to rotate and extend the jib arm allows for accessibility to different areas of the production line, improving overall efficiency.

Assembly Line

In assembly line operations, jib cranes facilitate the smooth transfer of heavy components, reducing the risk of accidents and ensuring precise positioning. They assist in the installation of large machinery and aid workers in aligning parts accurately during the manufacturing process. Jib cranes’ maneuverability and versatility make them instrumental in speeding up production while maintaining quality standards. By minimizing downtime and enhancing worker productivity, jib cranes contribute to overall cost savings and operational effectiveness.

Henan Dafang Heavy Machinery Co., Ltd. is a crane manufacturer with perfect testing equipment and advanced production equipment as well as a professional technical research and development team. If you have any questions or needs about jib cranes, please contact us!

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat