Light Duty Gantry Crane: Types And Features

Light duty gantry cranes are versatile and efficient lifting devices used in various industries to handle loads with ease. These cranes are designed to provide a cost-effective solution for lifting and moving lighter loads in a wide range of environments. In this article, we will explore the different types of light duty gantry cranes, their features, applications, and safety operation specifications.

Types Of Light Duty Gantry Cranes

There are different types of light-duty gantry cranes available in the market:

Single Beam Gantry Crane

The single beam gantry crane is a popular choice for light duty lifting operations. It consists of a single horizontal beam supported by two vertical legs that can be either fixed or adjustable. This type of crane offers excellent maneuverability and is suitable for applications where space is limited. The single beam gantry crane is often used in workshops, warehouses, and small manufacturing facilities.

Semi Gantry Crane

The semi gantry crane combines the features of an overhead crane and a gantry crane. It has one end supported by a structure, such as a wall or column, while the other end operates on wheels or rails. This design allows for efficient material handling in areas where a full gantry crane setup is not required. The semi gantry crane is commonly used in shipyards, construction sites, and outdoor storage yards.

- Capacity: up to 10t

- Span Length: up to 20m

- Duty Group: A3-A5

- Work Environment Temperature: -25°C〜+50°C, relative humidity ≤95%

Adjustable Gantry Crane

The adjustable height gantry crane offers the flexibility to adjust the lifting height according to specific requirements. It is equipped with a hydraulic or mechanical system that allows the vertical legs to be raised or lowered. This feature makes it ideal for applications where different lifting heights are needed or when working in areas with uneven ground levels.

- Capacity: Up to 10t

- Span Length: Up to 10m

- Duty Group: A3-A5

- Work Environment Temperature: -25°C〜+50°C, relative humidity ≤95%

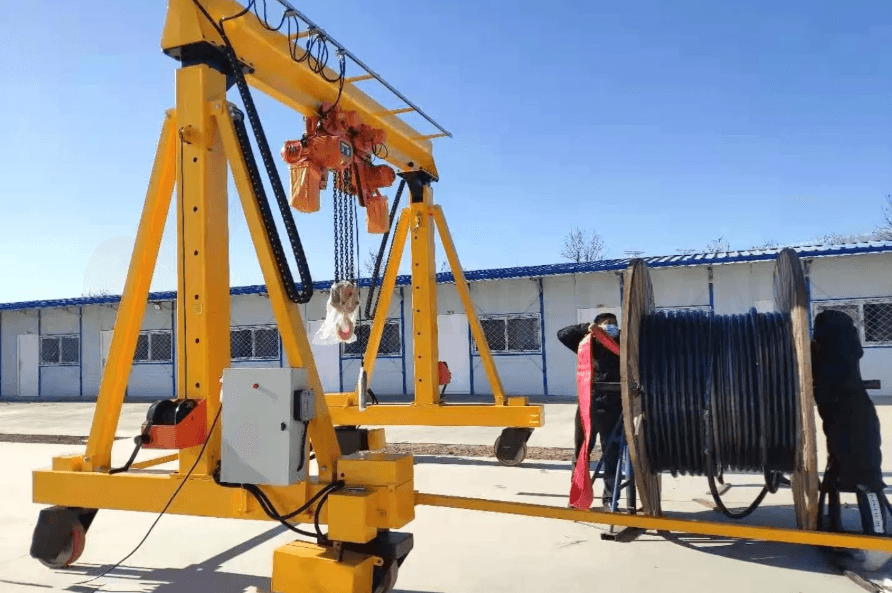

Portable Gantry Crane

The portable gantry crane is designed for easy transportation and quick assembly. It is typically made of lightweight materials such as aluminum or steel and can be disassembled into compact parts. This type of crane is widely used in outdoor settings, construction sites, and maintenance operations where mobility is crucial. The portable gantry crane provides the convenience of on-site lifting without the need for permanent installation.

- Capacity: up to 10t

- Span Length: up to 10m

- Duty Group: A3-A5

- Work Environment Temperature: -25°C〜+50°C, relative humidity ≤95%

Features Of Light Duty Gantry Cranes

Light duty gantry cranes come with several features that enhance their usability and efficiency:

Lightweight And Compact Design

Unlike heavy-duty cranes that require substantial infrastructure and support, these cranes are engineered to be more portable and agile. Their light weight makes them easier to move around the workspace.

The compact design of light duty gantry cranes allows them to fit into confined spaces where larger cranes may struggle to operate efficiently. This feature makes them an ideal choice for workshops, warehouses, construction sites, and small-scale manufacturing facilities. Despite their smaller size, they retain the capability to perform essential lifting tasks with ease.

Easy Assembly And Disassembly

The simplicity of assembling and disassembling light duty gantry cranes is another notable feature that makes them highly convenient. These cranes are designed with user-friendly components and mechanisms, allowing for quick setup and dismantling without requiring specialized tools or expertise. This feature not only saves time but also enables businesses to optimize their resources effectively.

Versatility And Mobility

Light duty gantry cranes are highly versatile, allowing for a wide range of applications. They can be used indoors or outdoors and are suitable for lifting various types of materials, including machinery, equipment, and raw materials.

Cost-Effective Solution

In addition to their functional advantages, light duty gantry cranes offer a cost-effective solution for businesses. Their lightweight construction results in reduced material costs, while the ease of assembly and disassembly eliminates the need for hiring specialized personnel or investing in expensive equipment. Furthermore, the versatility and mobility of these cranes contribute to increased productivity, minimizing downtime and maximizing operational efficiency.

Applications Of Light Duty Gantry Cranes

Light-duty gantry cranes find applications in various industries and work environments. Some common applications include:

- Warehouses and Storage Facilities: Gantry cranes are commonly used in warehouses and storage facilities to move heavy items, such as pallets, crates, and machinery components. Their mobility and versatility allow for efficient loading and unloading operations.

- Workshops and Manufacturing Plants: In workshops and manufacturing plants, light duty gantry cranes are used to lift and transport materials during production processes. They can be easily maneuvered to support different workstations, ensuring seamless workflow.

- Construction Sites: Construction sites often require the movement of heavy construction materials and equipment. Light duty gantry cranes offer a practical solution for lifting and positioning loads in challenging environments.

- Maintenance Operations: Light duty gantry cranes are employed in maintenance operations to lift and transport machinery, spare parts, and other equipment.

Safety Operation Specifications For Light Duty Gantry Cranes

To ensure safe operation and prevent accidents, certain specifications must be followed when using light duty gantry cranes. Here are some important safety precautions:

- Crane operator should be trained before operating the cranes.

- Overload lifting is forbidden, wire rope side lifting is forbidden.

- Power off during cane inspection and maintenance.

- Hook should be over human height when the crane is running without load.

- Load should be at least 0.5m higher than the obstacles on the path of crane

running. - Don't throw anything from the crane.

- Load is forbidden to move over human being.

- It's forbidden to lift human being.

- Flammable materials is forbidden to put on the crane.

- Outdoor use crane should not work in case the wind is greater than grade 6.

- Tools, spare parts should not be put on crane structure in case its falling down.

- Wire rope should be checked during every shift, detailed inspection every 7-10

days. - Safety technical inspection should be done every year.

FAQs

- What is a light duty gantry crane?

A light duty gantry crane is a type of lifting equipment designed for relatively lighter loads. - What are the applications of light duty gantry cranes?

They are commonly used in warehouses and workshops for loading and unloading goods. In addition, they can be found in manufacturing facilities to assist in the production process. - How do I ensure the safe operation of a light-duty gantry crane?

To ensure safe operation, it is crucial to provide operators with proper training and certification. Regular equipment inspections should be conducted to identify any potential issues that could affect safety. Operators must also consider load capacity and stability requirements and follow safe lifting practices at all times. - Can a light duty gantry crane be easily transported?

Yes, one of the notable features of light-duty gantry cranes is their easy assembly, disassembly, and transportation. These cranes are designed with lightweight and compact features, allowing for convenient movement between different work areas. This mobility adds to their overall versatility and usability.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China