-

Industries

-

General Manufacturing

-

Waste Handling

-

Precast

-

Power

-

Stone

-

Papermaking

-

Metal Production

-

Bridge Construction

-

Port Cranes: For Container and Bulk Material Handling

-

Overhead Cranes for Petroleum and Gas Industry: Enhance Operational Efficiency

-

Marine Cranes for Efficient Cargo Loading on Ships

-

Overhead Cranes for the Automotive Industry: Efficient Automation Solutions

-

Overhead Crane Solutions for Railways: Track Laying, Rolling Stock Maintenance, and Container Handling

-

Overhead Cranes for Food and Beverages: Reliable Solutions for Efficient Handling

-

Overhead Cranes for Efficient Cement, Glass, Brick and Precast Concrete Manufacturing

-

Overhead Cranes for Aviation Industry: Aircraft Maintenance and Assembly

-

Aerospace Overhead Cranes: Precision Lifting for Rocket Launch and Transport

-

-

Products

-

Overhead Cranes

-

Single Girder Overhead Cranes

-

Double Girder Overhead Cranes

-

European Type Single Girder Overhead Cranes

-

Explosion Proof Overhead Cranes

-

Grab And Magnetic Overhead Cranes

-

Monorail Cranes

-

Foundry Overhead Cranes

-

Workstation Cranes

-

Insulation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Overhead Cranes

-

Ladle Overhead Cranes

-

Underhung Overhead Cranes

-

Electromagnetic Overhead Cranes

-

Manual Overhead Cranes

-

Ceiling Mounted Bridge Crane

-

Free Standing Workstation Bridge Cranes

-

-

Gantry Cranes

-

Semi Gantry Cranes

-

Single Girder Gantry Cranes

-

Double Girder Gantry Cranes

-

Container Gantry Cranes

-

Truss Gantry Cranes

-

Adjustable Gantry Cranes

-

Portable Gantry Cranes

-

European Gantry Cranes

-

Aluminum Gantry Cranes

-

Rubber Tyred Container Gantry Cranes

-

Rail Mounted Container Gantry Cranes

-

Shipyard Gantry Crane

-

- Jib Cranes

- Special Cranes

- Electric Hoists

- Transfer Carts

-

Overhead Cranes

-

Crane Parts

-

Grab Buckets

-

Electric Stainless Steel Grab Bucket

-

Mechanical Four Rope Orange Peel Grabs

-

Mechanical Four Rope Clamshell Grabs Bucket

-

Electro Hydraulic Rectangular Grabs

-

Electro hydraulic Clamshell Grabs

-

Electro Hydraulic Orange Peel Grabs,Hydraulic Cactus Grab

-

Electric Motor Grab

-

Electric Monorail Grab Bucket with Monorail Hoist

-

Remote Control Clamshell Grabs

-

Mechanical Two Rope Clamshell Grabs

-

Timber Grabs

-

Single Rope Grab Bucket

-

Trash Rack Cleaning Machines

-

Dredging Grabs

-

Trimming Grabs

-

- Crane Spreader

-

Crane Spare Parts

-

Wire Rope Sheaves

-

Crane Rope Drum

-

Crane Trolley

-

Electric Winch

-

Crane Operator Cabin

-

Overhead Crane Brakes

-

Overhead Crane Cables

-

Overhead Crane Rope Guides

-

Overhead Crane Conductors and Power Supply Lines

-

Overhead Crane Rails

-

Hand Chain Hoists

-

Manual Lever Hoists

-

Pneumatic Chain Hoists

-

Overhead Crane Rail Clips

-

Overhead Crane Motors

-

Overhead Crane Reducers

-

Couplings for Overhead Crane

-

- Crane Wheels

-

Grab Buckets

- Company

- Contact

-

Industries

-

General Manufacturing

-

Waste Handling

-

Precast

-

Power

-

Stone

-

Papermaking

-

Metal Production

-

Bridge Construction

-

Port Cranes: For Container and Bulk Material Handling

-

Overhead Cranes for Petroleum and Gas Industry: Enhance Operational Efficiency

-

Marine Cranes for Efficient Cargo Loading on Ships

-

Overhead Cranes for the Automotive Industry: Efficient Automation Solutions

-

Overhead Crane Solutions for Railways: Track Laying, Rolling Stock Maintenance, and Container Handling

-

Overhead Cranes for Food and Beverages: Reliable Solutions for Efficient Handling

-

Overhead Cranes for Efficient Cement, Glass, Brick and Precast Concrete Manufacturing

-

Overhead Cranes for Aviation Industry: Aircraft Maintenance and Assembly

-

Aerospace Overhead Cranes: Precision Lifting for Rocket Launch and Transport

-

-

Products

-

Overhead Cranes

-

Single Girder Overhead Cranes

-

Double Girder Overhead Cranes

-

European Type Single Girder Overhead Cranes

-

Explosion Proof Overhead Cranes

-

Grab And Magnetic Overhead Cranes

-

Monorail Cranes

-

Foundry Overhead Cranes

-

Workstation Cranes

-

Insulation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Overhead Cranes

-

Ladle Overhead Cranes

-

Underhung Overhead Cranes

-

Electromagnetic Overhead Cranes

-

Manual Overhead Cranes

-

Ceiling Mounted Bridge Crane

-

Free Standing Workstation Bridge Cranes

-

-

Gantry Cranes

-

Semi Gantry Cranes

-

Single Girder Gantry Cranes

-

Double Girder Gantry Cranes

-

Container Gantry Cranes

-

Truss Gantry Cranes

-

Adjustable Gantry Cranes

-

Portable Gantry Cranes

-

European Gantry Cranes

-

Aluminum Gantry Cranes

-

Rubber Tyred Container Gantry Cranes

-

Rail Mounted Container Gantry Cranes

-

Shipyard Gantry Crane

-

- Jib Cranes

- Special Cranes

- Electric Hoists

- Transfer Carts

-

Overhead Cranes

-

Crane Parts

-

Grab Buckets

-

Electric Stainless Steel Grab Bucket

-

Mechanical Four Rope Orange Peel Grabs

-

Mechanical Four Rope Clamshell Grabs Bucket

-

Electro Hydraulic Rectangular Grabs

-

Electro hydraulic Clamshell Grabs

-

Electro Hydraulic Orange Peel Grabs,Hydraulic Cactus Grab

-

Electric Motor Grab

-

Electric Monorail Grab Bucket with Monorail Hoist

-

Remote Control Clamshell Grabs

-

Mechanical Two Rope Clamshell Grabs

-

Timber Grabs

-

Single Rope Grab Bucket

-

Trash Rack Cleaning Machines

-

Dredging Grabs

-

Trimming Grabs

-

- Crane Spreader

-

Crane Spare Parts

-

Wire Rope Sheaves

-

Crane Rope Drum

-

Crane Trolley

-

Electric Winch

-

Crane Operator Cabin

-

Overhead Crane Brakes

-

Overhead Crane Cables

-

Overhead Crane Rope Guides

-

Overhead Crane Conductors and Power Supply Lines

-

Overhead Crane Rails

-

Hand Chain Hoists

-

Manual Lever Hoists

-

Pneumatic Chain Hoists

-

Overhead Crane Rail Clips

-

Overhead Crane Motors

-

Overhead Crane Reducers

-

Couplings for Overhead Crane

-

- Crane Wheels

-

Grab Buckets

- Company

- Contact

One Set of 12.5t LDC Model Low-headroom Single Girder Overhead Crane For Sale to Kenya

One Set of 12.5t LDC Model Low-headroom Single Girder Overhead Crane For Sale to Kenya

Key Facts

Detailed Specifications:

- LDC12.5t-S6.9m-H9m

- Control mode: Pendant line control + Wireless remote control

- Power supply: 415V/50HZ/3Ph

- Lifting speed: 0.35/3.5 m/min

- CT< speed: 20 m/min

- With 44m P24 crane rail and 44m runway beam(500*300*8*14/12mm)

Project Overview:

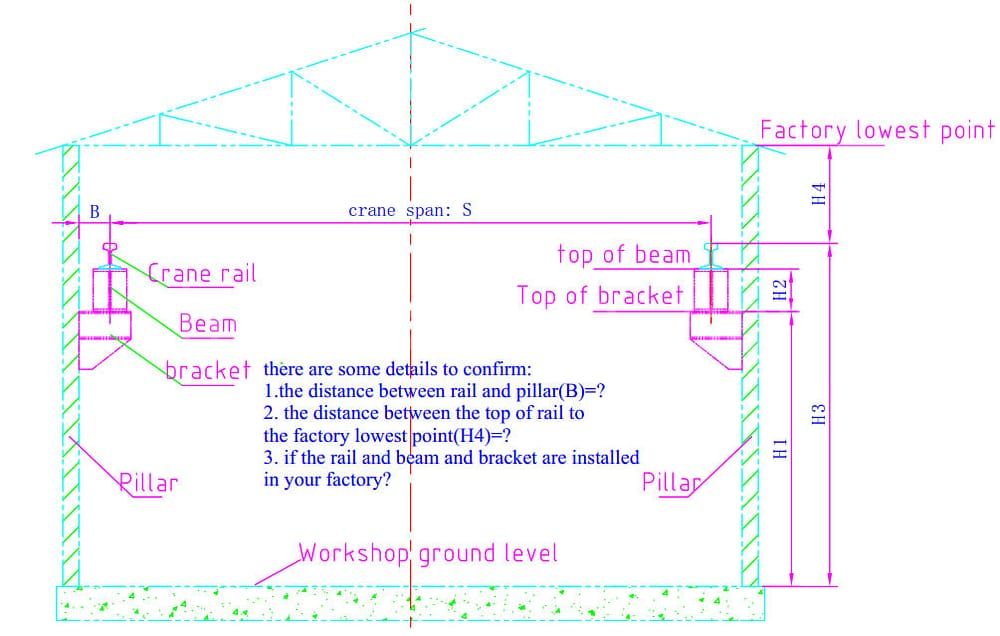

One of our clients in Sri Lanka told us they were having a project in Kenya where a single girder overhead crane would be used. The lifting capacity will be 12.5 ton,but runway beam and rail tracks were not yet set up, only brackets constructed. So we asked for the drawing of the workshop and got the dimensions such as the bracket height, wall to wall distance and headroom height. According to these data, we determined the span and lifting height of the crane, runway beam size and crane type. After sending our first design drawing to our client, they required a bigger lifting height up to 8.6 m to lift the loads high enough. In that case, a normal type LD overhead crane was no longer suitable for the project. Immediately we changed the design to low headroom type LDC overhead crane, which increased the lifting height to 9 m.

As the crane operator would be on a high platform most of the time rather than on the ground, we added a wireless remote control on the electric control box while keeping the pendant line control. We recommended dual speed for lifting and single speed for both cross travel and long travel because lifting requires precision operation sometimes.We also provided power supply conducting system for the crane, which included seamless busbar, current collector, strainer and other accessories .

After 80 days of production and transportation, our client received the products. Now they have installed the crane and been using it for a period of time . They are very satisfied with the performance of the machine and our assistance during the installation and commissioning. We will keep in close touch for after sale service and further projects.

If you want a overhead crane, and not sure of the parameters it, please provide the dimensions or drawing of your workshop, we will help you to choose the right design. Answering the questions in the following picture to let us be clear of the requirements.

Send Your Inquiry

- Email: sales@hndfcrane.com

-

Phone: +86 191 3738 6654

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

-

Skype: dafang2012

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat

Subscribe to DAFANG News

Join Mailing List, Get Product Price List Directly to Your Inbox.

- Overhead Cranes

- European Type Double Girder Overhead Cranes: High Efficiency, Safety, and Reliability

- Double Girder Overhead Cranes

- Free Standing Workstation Bridge Cranes: Efficient Lifting Solutions for Modern Industrial Facilities

- Ceiling Mounted Bridge Crane: Column-Free Design for Unobstructed Floor Space

- Underhung Overhead Cranes: Lightweight Track Mounted Solution for Workshops and Warehouses

- Electromagnetic Overhead Cranes: Efficient Solution for Handling Slabs, Billets, and Scrap Metal

- Ladle Overhead Cranes: Reliable Hot Metal Handling Solutions for Steel Mills

- Grab Overhead Crane: Heavy Duty Lifting with Precision Control for Bulk Materials

- Low Headroom Overhead Crane: Space Saving Lift Efficiency Solution

- Manual Overhead Cranes: Efficient Solutions for Environments Without Power

- 5~50T QY Insulation Overhead Cranes for Safe Lifting in Hazardous Environments

- Cleanroom Cranes

- Workstation Cranes

- Foundry Overhead Cranes

- Monorail Cranes

- Grab And Magnetic Overhead Cranes

- Explosion Proof Overhead Cranes

- European Type Single Girder Overhead Cranes

- Single Girder Overhead Cranes

- Jib Cranes

- Wall Mounted Jib Cranes

- Wall Travelling Jib Cranes

- Free Standing Jib Cranes

- Aluminum Jib Cranes: Lightweight, Smooth Rotating Arm for Easy Lifting

- Balance Jib Cranes: Efficient Light Lifting for Short Distance Mechanical Assembly

- Manual Free Standing Jib Cranes: Efficient Manual Lifting Solutions for Limited Space Operations

- Electric Free Standing Jib Cranes: Fully Electric Solution for High Capacity Fast Lifting

- Articulating Jib Cranes: Precision Lifting with Dual Arm Flexibility

- Electric Hoists

- Electric Wire Rope Hoists

- Electric Chain Hoists

- European Type Electric Hoists

- European Electric Chain Hoists: Smooth Operation, Low Noise, and Energy Efficiency

- Low Headroom Electric Hoists: Compact Design for Maximum Space Efficiency

- Pneumatic Chain Hoists: Smooth Handling for Industrial Use

- Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Single Girder Gantry Cranes

- Truss Gantry Cranes

- Container Gantry Cranes

- Adjustable Gantry Cranes

- Portable Gantry Cranes

- European Gantry Cranes

- Small Aluminum Gantry Cranes: Lightweight, Portable, and Customizable for High Efficiency Lifting

- 35T Mobile Rubber Tyred Container Gantry Cranes for Efficient Handling

- RMG Rail Mounted Container Gantry Cranes for Efficient Handling

- Shipyard Gantry Crane: Aerial Flip Design Easily Helps You Achieve Hull Assembly

- Industries

- Power

- Stone

- Bridge Construction

- Port Cranes: For Container and Bulk Material Handling

- Aerospace Overhead Cranes: Precision Lifting for Rocket Launch and Transport

- Overhead Cranes for Aviation Industry: Aircraft Maintenance and Assembly

- Overhead Cranes for Efficient Cement, Glass, Brick and Precast Concrete Manufacturing

- Overhead Crane Solutions for Railways: Track Laying, Rolling Stock Maintenance, and Container Handling

- Overhead Cranes for Food and Beverages: Reliable Solutions for Efficient Handling

- Overhead Cranes for the Automotive Industry: Efficient Automation Solutions

- Marine Cranes for Efficient Cargo Loading on Ships

- Overhead Cranes for Petroleum and Gas Industry: Enhance Operational Efficiency

- General Manufacturing

- Metal Production

- Papermaking

- Precast

- Waste Handling

- Crane Parts

- Diesel Winch for Non-Electric Environments: High-Power Lifting and Pulling

- Crane Hooks

- Open Winch Trolley: Customizable Hoisting Trolley for Overhead and Gantry Cranes

- Electric Wire Rope Winch: Compact Hoisting System for Space-Limited

- Friction Winch: Professional Solution for Ship Traction and Mining Hoisting

- Slow Speed Electric Winch: Reliable Heavy-Duty Lifting for Industrial Applications

- Industrial High Speed Electric Winch: Fast, Reliable, and Customizable

- Crane C Hooks for Steel Coil Lifting

- Overhead Crane Reducers Explained: Types for Every Lifting Need

- Overhead Crane Motors for Lifting Efficiency and Precision

- Couplings for Overhead Crane

- Overhead Crane Rail Clips Selection Based on Load and Track Conditions

- Overhead Crane Rails Solutions for Industrial Stability and Precision

- Overhead Crane Rope Guides: Enhancing Wire Rope Finishing Efficiently

- Overhead Crane Conductors and Power Supply Lines: Reliable Power Supply Solutions

- Overhead Crane Cables: Reliable Mobile Power Solutions

- Hand Chain Hoists: Manual Lifting for Areas Without Power

- Manual Lever Hoists: Ideal for Pulling and Lifting Tasks

- Overhead Crane Brakes: Critical for Safe Operations

- Customizable Crane Operator Cabins: Enhanced Comfort and Protection

- Crane Lifting Tongs

- Crane Grab Buckets

- Crane Rope Drum

- Electric Winch

- Crane Trolley

- Wire Rope Sheaves

- Contact Us

- Email: sales@hndfcrane.com

-

Phone: +86 191 3738 6654

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

-