Overhead Crane System: A Complete Overview

Material handling is a critical aspect of any industrial operation, and the right equipment can make all the difference. Overhead crane systems are versatile, reliable, and efficient solutions for moving materials and products in manufacturing, warehousing, and construction facilities. In this article, we will discuss the components, and features of an overhead crane system, and how to choose the overhead crane system.

Components And Their Functions Of The Overhead Crane System

Overhead crane systems consist of several critical components, each with its unique functions:

Bridge

The trolley and hoist are supported by a horizontal beam known as the “bridge” that spans the distance between two supports. Its function is to provide proper load placement by allowing the trolley and hoist to move back and forth across the crane system’s span. Typically made of steel, the bridge is designed to carry the weight of both the cargo being raised as well as the trolley and hoist.

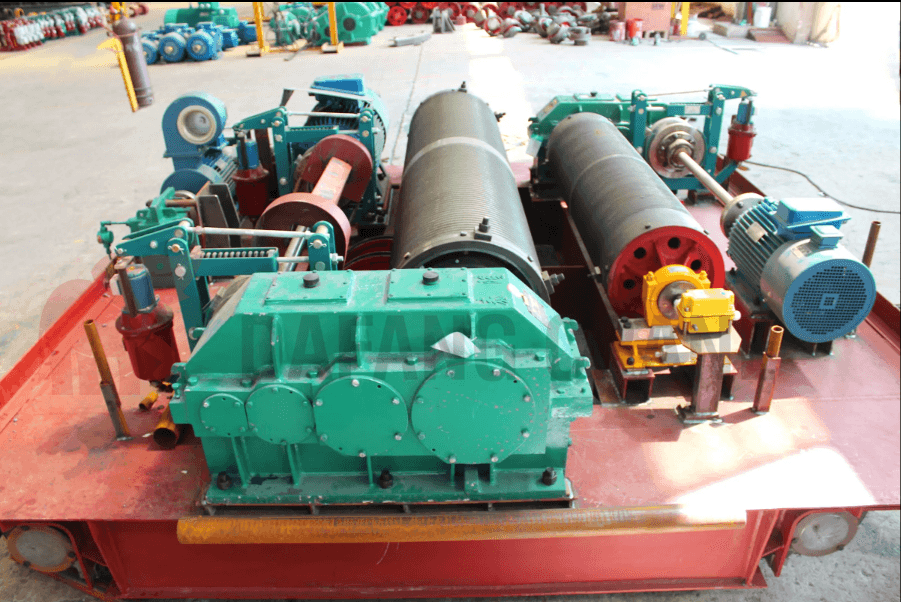

Hoist

The hoist is responsible for lifting and lowering the load attached to the crane. It consists of a motor, gearbox, drum, and wire rope or chain. The hoist motor provides the power to lift the load, while the gearbox controls the speed and torque of the hoist. The drum holds the wire rope or chain, which is used to lift the load, and the brake system ensures that the load remains secure once lifted.

Trolley

The hoist is moved along the length of the bridge using a machine called a trolley. It is propelled by an electric motor and travels along rails that are fastened to the bridge’s top. Loads may be positioned precisely thanks to the hoist’s ability to travel up and down the crane system’s span thanks to the trolley.

Runway

The runway serves as a structural element that holds up the bridge and gives the trolley a track to travel on. It is usually built of steel beams and is firmly fastened to the structure or foundation of the building. To ensure safe and dependable operation, the runway must be built and designed to bear the weight and movement of the crane system.

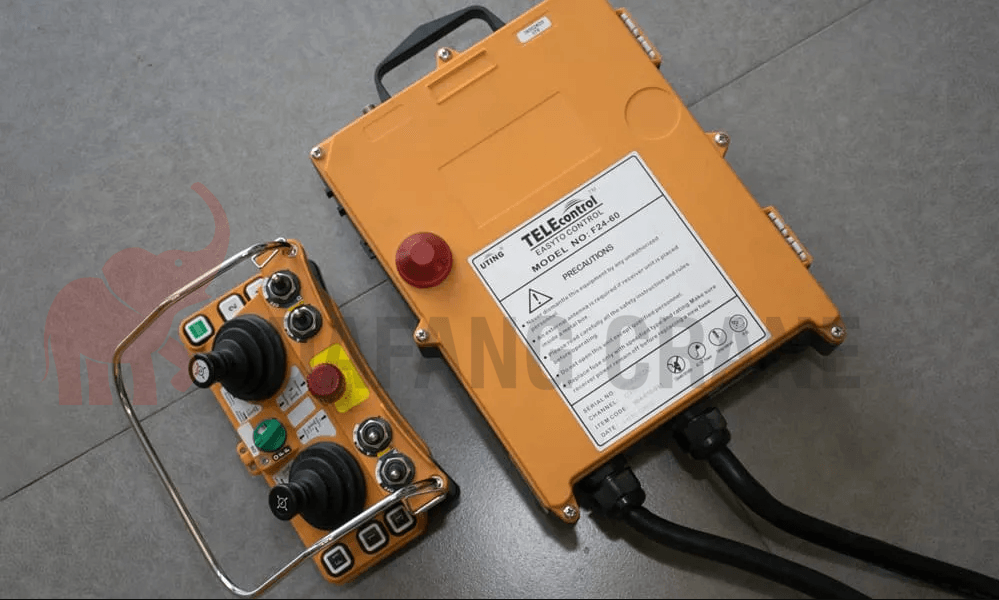

Pendant Or Remote Control System

The interface between the operator and the crane system is the pendant or remote control system. It enables the control of the hoist, trolley, and bridge from a secure distance by the operator. In contrast to the remote control system, which communicates with the crane through radio signals, the pendant is a handheld device with buttons or switches that control the crane’s movement.

Features Of Overhead Crane Systems

Load Capacity

The load capacity of an EOT crane system is one of its most important characteristics. These cranes are made to lift and move different-weight loads. Several hundred tons can be lifted by some systems, making them important in the shipping, manufacturing, and construction sectors.

Versatility

The adaptability of bridge crane systems is another quality. They can be designed to operate in different ways based on the needs of the industry. For instance, there are single-girder cranes, double-girder cranes, and gantry cranes. While double-girder cranes can carry greater loads and longer spans, single-girder cranes are best for lesser loads and shorter spans. For outdoor applications where the crane must move with the load, gantry cranes are appropriate.

Safety Features

EOT crane systems are also equipped with safety features to prevent accidents. For example, overload protection mechanisms are installed to prevent the crane from lifting more than its maximum weight capacity. In addition, limit switches are added to control the movement of the crane and stop it at predetermined positions.

Automation

Another essential component is the automation of overhead crane systems. These cranes may be fitted with cutting-edge control systems that enable autonomous operation. Accurate load placing is made possible by automation, which also increases productivity.

Maintenance

Maintenance is an essential aspect of any machinery, including overhead crane systems. These systems require regular maintenance to ensure smooth operation and prevent downtime. It’s essential to schedule regular inspections, lubrication, and replacement of worn-out parts to keep the crane in good working condition.

How To Choose The Overhead Crane Systems

The key considerations when choosing an overhead crane system:

Capacity

The capacity of a bridge crane system should be the first consideration. The weight of the heaviest load you need to hoist should be in line with the crane’s weight capacity. To ensure safety and avoid harm to the crane, you must pick a crane with a slightly higher capacity than your maximum load.

Span

The distance between the runway beams that support the crane is referred to as the crane’s span. The span needs to be large enough to encompass the entire area where the crane is needed. Before choosing a hoist crane system, it’s vital to assess the breadth of the space where the crane will be employed.

Height

Another important factor to take into account when selecting an EOT crane system is the lift’s height. The lifting height of the crane should be sufficient to lift the load to its highest point. It is crucial to gauge the workspace’s height and identify the highest point at which the crane can hoist the cargo.

Duty cycle

The frequency of use of the crane is referred to as the duty cycle. A more durable crane with a higher duty cycle should be chosen if the crane will be used frequently. Lower-duty cycle cranes could be appropriate for sporadic use or light-demand operations.

Speed

The speed of the crane is also an important consideration. The crane’s speed should be matched to the type of work it will perform. A slow-moving crane may be suitable for precision work, while a faster crane may be necessary for heavier loads that need to be moved quickly.

Power supply

Another thing to think about is the crane’s power source. Both diesel and electricity are used to power overhead cranes. The environment in which the crane is utilized will determine the type of power source. Diesel-powered cranes are better suited for outdoor and isolated sites whereas electric cranes are suitable for indoor use.

Safety features

Always put safety first when selecting a hoist crane system. Limit switches, emergency stop buttons, overload protection, and warning alarms should all be included in the crane’s safety equipment. It is crucial to confirm that the crane complies with all safety requirements.

Overhead crane systems are versatile solutions for any industrial operation that requires efficient, safe, and cost-effective material handling. By selecting the right type of crane system and considering its components, load capacity, span, lift height, duty cycle, and control options, companies can experience increased productivity, improved safety, and cost savings. Additionally, regular maintenance and the use of safety features can help ensure that the crane system operates smoothly and safely for years to come.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat