The Different Types Of Gantry Cranes And Their Uses

Gantry cranes are a crucial piece of equipment utilized in many different sectors. These cranes can be operated manually or automatically and consist of a horizontal beam (the gantry) supported by two upright supports. This article will examine the various gantry crane varieties and their applications.

What Are Gantry Cranes?

A gantry crane is a type of crane that is supported on two or more legs that run on wheels or along a track. The structure of the crane is typically composed of a horizontal beam supported by two uprights, which in turn are mounted on wheels or a track. Gantry cranes are commonly used for lifting heavy loads in construction sites, shipyards, and warehouses. They are able to lift large objects and move them horizontally over a significant distance thanks to their mobility and versatility. Gantry cranes come in various sizes and configurations, ranging from small portable units to massive industrial machines capable of lifting hundreds of tons.

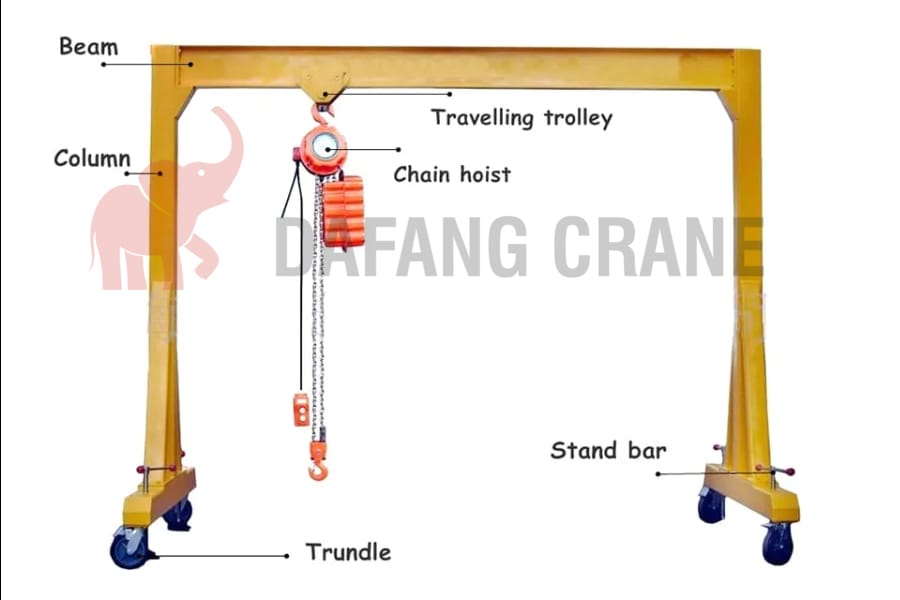

Components Of The Gantry Cranes

Gantry cranes consist of several components that work together to lift and move heavy objects. Some of these components include:

Frame

The gantry crane’s frame serves as its structural support and stability, enabling it to lift enormous loads. The frame, which is often constructed of high-strength steel or aluminum, has a number of beams and supports that equally distribute the load over the building. Depending on the particular requirements of the application, the frame can be set up in several ways. For instance, some frames are made to be self-supporting and stand alone, others are meant to be fixed to an already-existing building or structure.

Trolley

The trolley, another crucial part of the gantry crane, is in charge of transferring the load horizontally along the gantry’s length. The trolley is often positioned on tracks that are parallel to the gantry’s main beam, making movement easy and effective. The trolley is propelled along the tracks by an electric motor, which powers a system of gears and wheels. Operators can precisely position the load as needed by operating the trolley manually or through a remote control system.

Hoist

The part of the gantry crane that actually lifts and lowers the cargo is called the hoist. Depending on the exact use, the hoist may be mounted on a trolley or directly onto the gantry’s main beam. A motor, gearbox, drum, and wire rope make up the hoist, which all work together to elevate the load. The drum is driven by the engine, which also powers the gearbox, forcing the wire rope to wind or unravel as required. The hoist can controllably and precisely raise or lower the load thanks to this motion.

Wheels

The gantry crane’s wheels, which enable it to move over a system of rails or tracks, are another crucial part of the machine. Usually constructed of high-strength steel or other enduring materials, the wheels are built to resist great loads and continuous use. The wheels are mounted on axles that allow them to rotate freely, making it easy for the gantry crane to maneuver around obstacles and change direction as needed.

Types Of Gantry Cranes

The different types of gantry cranes and their unique features:

Single Girder Gantry Cranes

Single girder gantry cranes are designed with a single beam that supports the lifting mechanism of the crane. The lifting mechanism consists of a hoist, trolley, and hook or grab bucket. Single girder gantry cranes are used in applications where lighter loads need to be lifted and transported within a limited area. They are cost-effective and require less maintenance than double girder gantry cranes.

Single girder gantry cranes have a lower height and a smaller span between the legs compared to double girder gantry cranes. This makes them ideal for indoor use where there is limited space available. They can also be used outdoors but are not recommended for heavy-duty outdoor applications.

Double Girder Gantry Cranes

The lifting mechanism of double-girder gantry cranes is supported by two beams in their design. A hoist, trolley, and hook or grab bucket make up the hoisting apparatus. When heavier loads need to be raised and carried over greater distances, double girder gantry cranes are used. Although they cost more than single girder gantry cranes, they can support larger loads.

In comparison to single girder gantry cranes, double girder gantry cranes are taller and have a wider space between their legs. They are therefore perfect for usage outside, where there is more room. They are frequently utilized for heavy lifting and material handling at ports, shipyards, and building sites.

Semi Gantry Cranes

Semi gantry cranes are a hybrid of sorts between a traditional gantry crane and an overhead crane. They have one end supported by an overhead runway system while the other end is supported by a set of legs. Semi-gantry cranes can be either single or double girder cranes and are ideal for use in outdoor environments where there is uneven ground or limited space.

Adjustable Gantry Cranes

As the name suggests, this crane features adjustable height, width, and span, making it ideal for use in locations where space is limited or where the crane needs to be adapted to different tasks. Adjustable gantry cranes are commonly found in factories, warehouses, construction sites, and shipyards.

Truss Gantry Cranes

Truss gantry cranes are among the most popular types of gantry cranes used in a wide range of industrial settings. They feature a lattice-like structure that provides high structural strength while keeping the overall weight of the crane low, making them ideal for use in areas with low weight-bearing capacities.

Truss gantry cranes can be either single girder or double girder, depending on the application. Single girder truss gantry cranes are typically used for lighter loads, while double girder truss gantry cranes are used for heavier loads, such as those found in shipyards, steel mills, and other heavy industries.

Portable Gantry Cranes

These cranes are made to be transported from one place to another simply, as their name suggests. The majority of portable gantry cranes are modest in weight and equipped with wheels, making it simple to move them about a workstation. They are frequently utilized in garages, workshops, and other places where there needs to be constant movement. Because portable gantry cranes are available in a range of sizes, weight capabilities, and heights, they can be used for a variety of lifting tasks.

Container Gantry Cranes

Container gantry cranes are designed specifically for lifting shipping containers. They are commonly used in seaports and container terminals to load and unload containers from ships. Container gantry cranes are capable of lifting containers that weigh up to several tons and are essential tools in the global shipping industry.

Uses Of Gantry Cranes

Gantry cranes are used in a wide range of industries for various purposes. Here are some of the most common uses of gantry cranes:

Construction Sites

One of the main places where gantry cranes are employed is on construction projects. At construction sites, materials like steel beams, concrete blocks, and lumber necessitate heavy lifting. Gantry cranes are perfect for these tasks, due to they can readily raise and carry heavy loads. Additionally, they are highly nimble, which makes them ideal for use in confined spaces.

Gantry crane use on building sites has a lot of advantages. By reducing manual labor in the beginning, it increases productivity and makes the process quicker and more efficient. Second, the accuracy of gantry cranes provides a safe working environment for employees by lowering the likelihood of mishaps and injuries on the job site.

Ports And Shipyards

The shipping industry, particularly ports and shipyards, is another sector that significantly relies on gantry cranes. These cranes are used to stack containers in storage yards, move containers from one site to another, and load and unload cargo from ships. Gantry cranes are perfect for port operations because of their size and strength, which allows them to lift big, heavy goods.

The shipping sector has undergone a transformation, becoming faster and more effective thanks to the usage of gantry cranes in ports and shipyards. The cranes make it possible for freight to be loaded and unloaded quickly, saving time and money. Additionally, they increase safety by lowering the possibility of product damage and worker injuries.

Manufacturing Facilities

Gantry cranes are frequently employed in factories. The movement of massive and heavy machinery, equipment, and raw materials occurs often at these facilities. Gantry cranes are utilized to transport these goods across the building, improving the effectiveness and productivity of the production process.

There are many advantages to using gantry cranes in manufacturing operations. The first benefit is that it lessens the need for manual labor, which boosts production and saves time. Second, it makes it possible to transfer machinery and other items fast and safely, lowering the chance of mishaps and property damage.

Warehouses And Storage Yards

Finally, gantry cranes are also used in warehouses and storage yards. These facilities contain heavy goods that need to be moved and stored efficiently. Gantry cranes are perfect for this task because they can lift and transport heavy loads to high shelves or different locations within the warehouse.

The use of gantry cranes in warehouses and storage yards has several advantages. Firstly, it increases efficiency by reducing manual labor and speeding up the process of moving goods. Secondly, it minimizes the risk of damage to goods and injuries to workers, ensuring a safe working environment.

Gantry cranes are an essential tool in many industries, providing a versatile and adaptable solution for lifting and moving heavy loads. With various types of gantry cranes available, each designed for specific environments and purposes, businesses can choose the best option to meet their needs.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China