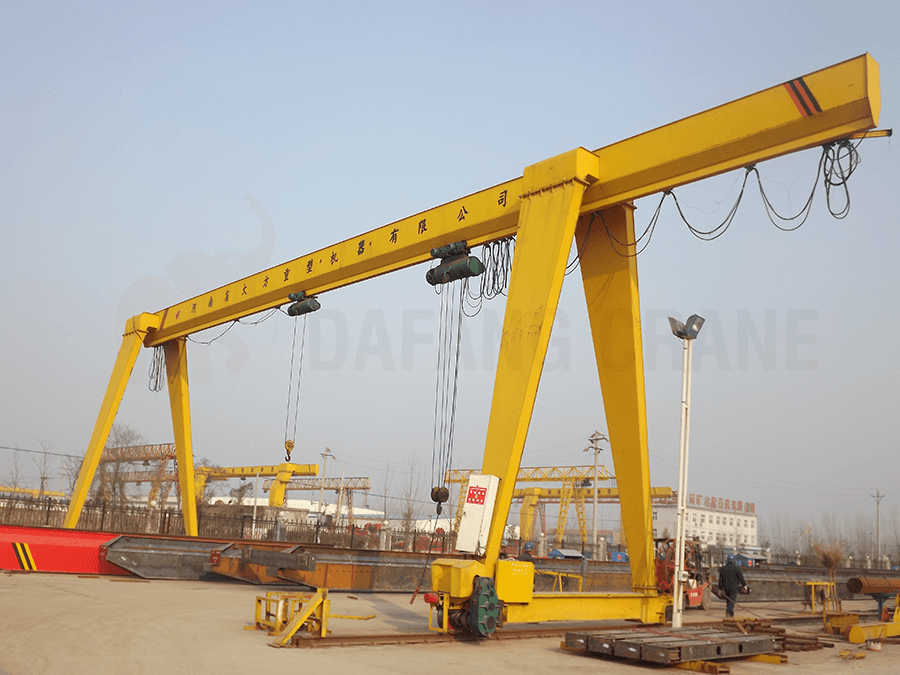

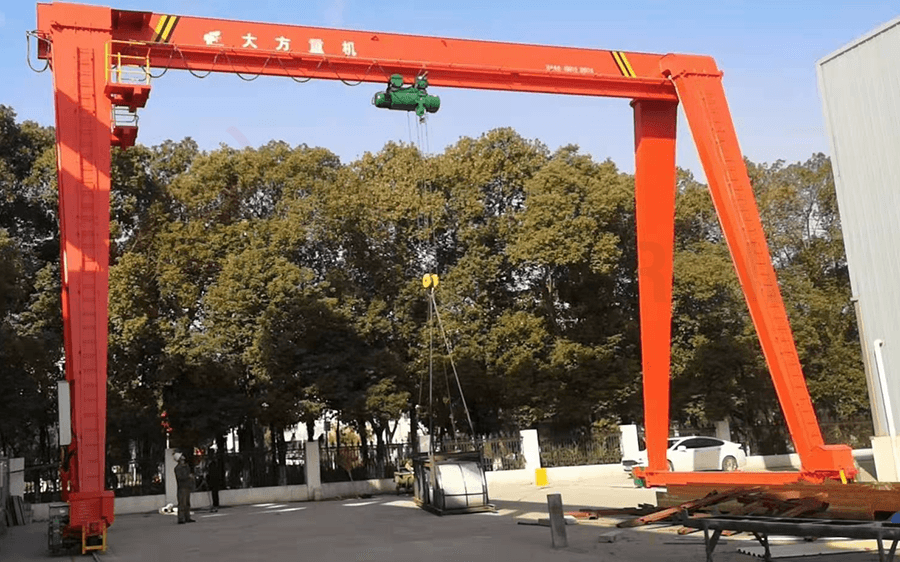

Top 7 Tips For Operating Gantry Cranes Safely

If you work in an industry that involves the operation of gantry cranes, it’s essential to prioritize safety. Gantry cranes are incredibly powerful machines that can cause serious harm or even fatalities if not used correctly. In this article, we’ll provide 7 tips to help operators safely operate gantry cranes and ensure a safe working environment.

The Importance Of Operating Gantry Cranes Safely

For one, operating gantry cranes safely helps to prevent accidents that could cause harm to workers, damage equipment, or even halt production altogether. By prioritizing safety, employers can create a culture of caution and responsibility among their employees, encouraging them to take the necessary precautions to avoid incidents.

Furthermore, proper use of gantry cranes can help to extend the lifespan of the equipment itself. This is because safe operation reduces wear and tear on the crane, which in turn ensures that it is in good condition when it’s needed most. In addition, regular maintenance and inspection of cranes can identify potential issues before they become major problems, ensuring that they remain safe and effective over time.

Tips For Operating Gantry Cranes Safely

1. Proper Training

Before operating a gantry crane, it’s crucial to receive proper training. Operators must understand the importance of learning about the machine’s various components, including the controls, hoists, and trolleys. The training should also cover how to read and interpret load charts, calculate loads, and determine the crane’s maximum capacity. Proper training is vital to prevent accidents and ensure that the crane is being operated correctly.

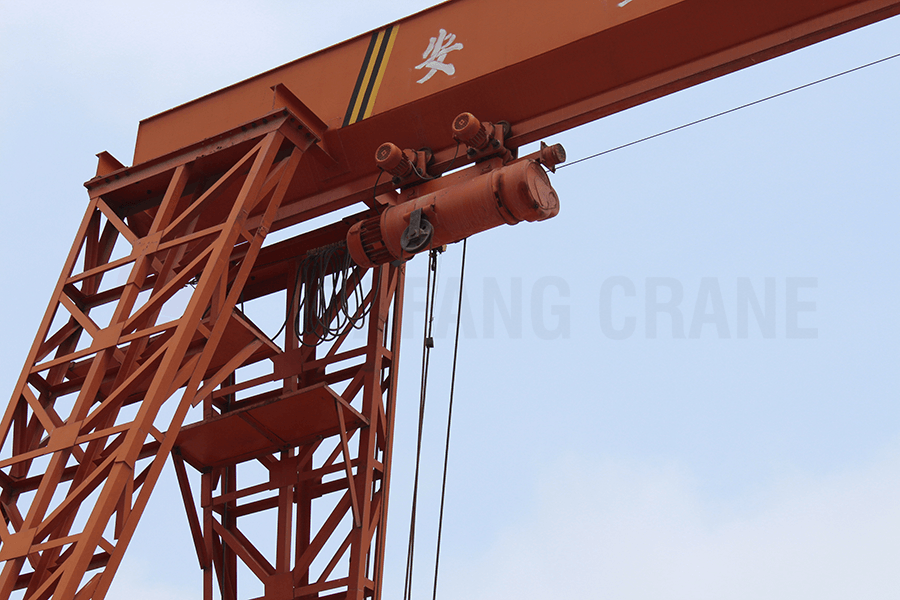

2. Pre-Operation Inspection

Before using the crane, always conduct a thorough pre-operation inspection. This step is crucial to identify any issues with the crane, such as damaged components, oil leaks, or worn-out chains. Inspect the brakes, hoist ropes, limit switches, load hooks, and slings. If there are any signs of wear and tear, replace them immediately. When it comes to safety, prevention is key, and conducting pre-operation inspections is one way to prevent accidents.

3. Avoid Overloading

Every gantry crane has load capacity limits that should be followed strictly. Don’t overload the crane beyond its rated capacity, even if it seems like the load is light. Overloading can cause structural damage to the crane and put the operator and other workers at risk. Always double-check the weight of the load and confirm it falls within the crane’s weight capacity before lifting it.

4. Safe Lifting Techniques

Proper lifting techniques are critical when operating gantry cranes. Ensure that the load is correctly balanced and secured before lifting it. Use appropriate rigging equipment such as slings, chains, and shackles to secure the load. The crane’s hoist ropes must be positioned vertically to prevent any side loading. When lifting, ensure that the load remains stable and avoid sudden movements.

5. Crane Maintenance

Regular maintenance is essential to keep gantry cranes running smoothly and safely. Operators should perform daily inspections before using the crane and report any issues to maintenance personnel immediately.

Routine maintenance tasks may include cleaning and lubricating parts, checking hydraulic systems, and inspecting wire ropes and chains for signs of wear or damage. These tasks are critical to identifying potential problems before they become serious issues that could cause accidents.

6. Use Appropriate Personal Protective Equipment (PPE)

PPE is vital to protect workers from various hazards associated with crane operations, such as falling objects, electrical hazards, and high noise levels. It also helps prevent injuries caused by accidental contact with moving parts or the crane’s load. Some common types of PPE used for gantry crane operations include hard hats, safety glasses, earplugs, gloves, and safety shoes.

7. Follow Safe Operating Procedures

Before the operation, it is important to inspect the key components such as the hook, rope, and device. Any special circumstances found during the inspection should be immediately resolved to avoid any disruptions during normal operation. Before conducting an electrical test, the driver must sound the warning bell for 3-5 seconds to confirm that everything is in order before proceeding with the test.

During operation, the driver must be aware of their surroundings and exercise caution near the gantry crane. Fast driving, collisions, passing over important equipment or personnel, or approaching another crane or heavy-duty operation line where people are present are strictly prohibited. Warning signals should be issued when nearing a crane or heavy-duty operation line with the same span as the current operation to ensure safety before passing. Before lifting heavy objects, the crane should lift approximately 200mm to verify that the brake is sensitive and reliable before beginning the lift. The crane must be lifted at least 2 meters above the ground or 0.5 meters above obstacles higher than 2 meters before starting the lift.

The crane should approach the end point slowly and under normal circumstances, it is strictly forbidden to engage the safety lock, switch direction, or use limit devices to control the stopping mechanism.

After completing the operation, according to the gantry crane’s operating procedures, the hook should first be lifted to a certain height, then the large car should be parked in the designated location, the controller’s handle should be set to zero position, and finally, the power should be cut off by lowering the knife gate.

FAQs

- What is the most important factor in operating a gantry crane safely?

Proper training is essential to the safe operation of the gantry crane. - What should operators do before using a gantry crane?

Operators should perform a thorough pre-operation inspection to ensure that the crane is in good working order. - Why is load capacity so important when operating a gantry crane?

Overloading a gantry crane can have disastrous consequences, which is why it is important to understand load capacity limits and properly calculate loads. - What are some of the key components of safe lifting techniques?

Safe lifting techniques include proper use of rigging equipment and ensuring that the load being lifted is centered and balanced. - Should pre-operational inspections be conducted daily?

Yes, pre-operational inspections should be conducted daily before using the crane.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat