Truss Gantry Crane: A Weather-Resistant Lifting Solution

We now have access to a wide variety of tools thanks to the technical world that has made our lives easier. There contains numerous cranes that are used to lift and transport large objects. The truss gantry crane is one such crane and is renowned for its resistance to adverse weather.

What Is A Truss Gantry Crane?

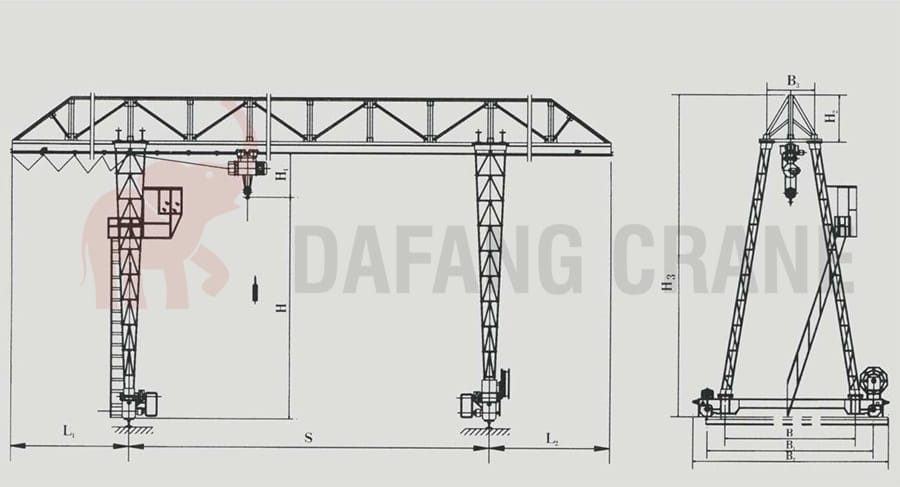

A truss gantry crane supports the load it lifts using a truss construction. The framework is made out of numerous tiny triangles, maximizing strength while reducing weight for the crane. Two upright beams, also known as legs, are linked at the top by a horizontal beam, also known as a crossbeam, to form the main framework of a truss gantry crane. This crossbeam serves as a bridge over which the trolley travels. The trolley has a hoist that is used to raise and lower the goods. The wheels or casters that support the entire construction are utilized on a track or runway.

Truss Gantry Crane Design And Composition

The design and composition of a truss gantry crane play a significant role in determining its performance and efficiency. Truss gantry cranes are typically designed with a triangular truss structure that provides strength and stability to the crane. The truss structure is made up of interconnected beams that form a rigid framework capable of supporting heavy loads without bending or buckling.

Components Of A Truss Gantry Crane

A truss gantry crane consists of several important components, including the main girder, end carriages, hoisting mechanism, electrical system, and control system:

Main girder: This is the crane’s main structural component and is in charge of bearing the weight of the object being hoisted. Depending on the size of the crane, the main girder might be built of steel and vary in length.

End carriages: End carriages are the structures at either end of the main girder that supports the hoist trolley and allow it to move along the length of the girder. They are also equipped with wheels that run on rails or tracks.

Hoisting mechanism: The component of the crane that actually raises and lowers the load is called the hoisting mechanism. An electric motor-driven drum and a wire rope or chain that is wrapped around the drum make up the hoisting mechanism. The wire rope or chain travels with the rotation of the drum, raising or reducing the load as required.

Electrical system: The electricity required to run the numerous motors and mechanisms inside the crane is supplied by this system. It has a control panel that the operator can use to direct the crane’s motions, as well as security elements including limit switches and emergency stop buttons.

Control system: This controls all of the crane’s parts and makes sure that they function properly as a whole. It is the crane’s brain. The crane’s movements are adjusted by the control system in accordance with the location and movement of the load, which is monitored via sensors and feedback loops. Additionally, it has safety features including overload protection, which stops the crane from lifting more weight than it is able to support.

Types Of Truss Gantry Crane

Single Girder Truss Gantry Crane

Single beams that run the length of single girder truss gantry cranes are used in their construction. Two legs on either side of this beam, joined by a truss framework, support it. The crane can lift and transfer huge loads because the beam is fastened to a trolley that travels the entire length of the crane.

Double Girder Truss Gantry Crane

Two beams run the entire length of double-girder truss gantry cranes. Four legs on each side that are also joined by a truss system support these beams. Because the trolley is suspended between the two beams, it has a higher lifting capacity and is more stable.

Advantages Of A Truss Gantry Crane

There are several advantages to using a truss gantry crane, including:

Weather Resistance

A truss gantry crane’s resistance to inclement weather is one of its key advantages. This is crucial in outdoor settings where the crane could be subjected to strong winds, rain, or snow. The crane can continue to operate safely and effectively because of the truss structure’s outstanding tolerance to harsh weather conditions.

Flexibility

Utilizing a truss gantry crane has the additional benefit of being adaptable to different needs. The crane’s span may be increased or decreased using various truss designs, enabling it to operate effectively in a variety of settings. Gantry cranes can also be equipped with a variety of hoists and other attachments to handle various loads.

High Load Capacity

The ability of a truss gantry crane to deliver a big lifting capacity without necessitating a significant amount of structural support is one of the key benefits of using one. By equally distributing the load across the structure, the truss design lessens the stress placed on any one particular spot. This translates into the crane being able to carry greater weight with less material, which makes it a practical choice for many businesses.

Applications Of A Truss Gantry Crane

A truss gantry crane is typically used in the following applications:

Concrete Beam Yard

Lifting and moving concrete beams is one of the main uses of a truss gantry crane in a yard of concrete beams. The structural framework of huge construction projects like bridges, flyovers, and highways is made up of large parts of concrete beams. Truss gantry cranes are an essential piece of equipment in any concrete beam yard since they can easily lift and move these heavy-duty concrete beams.

Shipping Ports And Harbors

In maritime ports, truss gantry cranes are able to carry a variety of cargo. These cranes can easily raise and transfer huge loads including vehicles, machinery, and shipping containers. Because they can operate in any weather, truss gantry cranes are a useful tool in shipping ports. These cranes can function dependably even in hostile locations since they can withstand strong winds, torrential rain, and extremely high or low temperatures. They are therefore perfect for usage in ports around the world where the weather can be very unpredictable.

Open Yard

One of the major applications of a truss gantry crane in an open yard is cargo handling. These cranes are ideal for lifting and transferring cargo from one location to another within an open yard. The truss structure allows the crane to span a larger area, providing a greater range of motion and flexibility when maneuvering large and heavy objects.

The truss gantry crane has a high load, strong wind resistance and light weight. If you need a lifting solution that can withstand bad weather and provide reliable service, you can contact us for a free consultation about a truss gantry crane.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat