Types of Electromagnetic Overhead Cranes and Selection Guide

Table of Contents

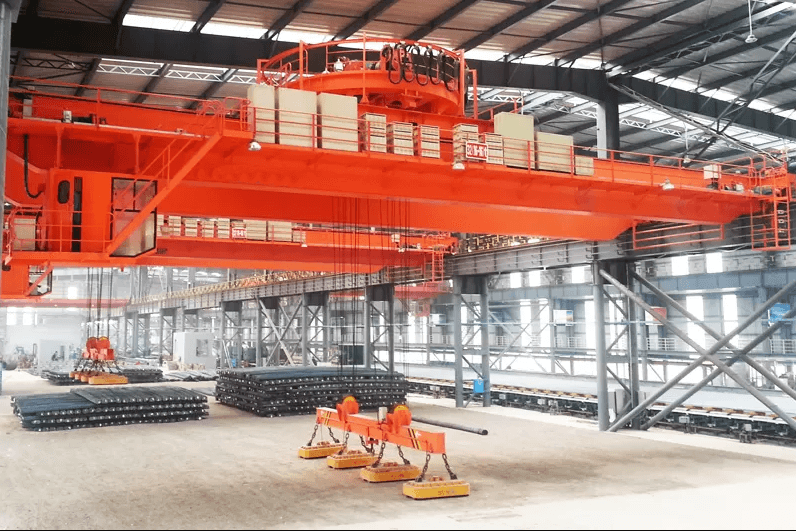

Electromagnetic overhead cranes are a type of engineering machinery designed to lift and manipulate various magnetic objects using the principles of electromagnetism. They are incredibly useful for the handling and unloading of heavy workpieces, metal materials, iron products, scrap steel, and other items. There are various types of electromagnetic overhead cranes, each suited to different operational scenarios. This article will introduce the different types of electromagnetic overhead cranes and their applicable situations, assisting you in selecting the most suitable electromagnetic overhead crane for your needs.

QC Electromagnetic Overhead Cranes with Chuck

The QC Electromagnetic Overhead Crane is structurally composed of a hoisting trolley, bridge frame, crane traveling mechanism, electrical equipment, and detachable electromagnetic chuck. It is suitable for loading, unloading, and stacking operations in scrap steel recovery stations, within the scrap steel storage of steel plants, for lifting steel ingots and billets, and for feeding small electric furnaces in steelmaking. To ensure the safe operation of the crane, a power-off magnetic retention control system can be added to prevent the dropping of goods in the event of a sudden power failure.

- Capacity: 5-10t/16-20t/32-50t

- Span: 10.5m/13.5m/16.5m/19.5m/22.5m/25.5m/28.5m/31.5m

- Lifting height: 12-18m

- Work duty: A6

QC electromagnetic bridge cranes with chucks are mainly used with the following spreaders:

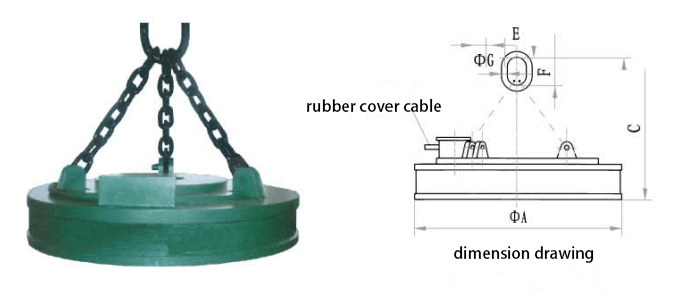

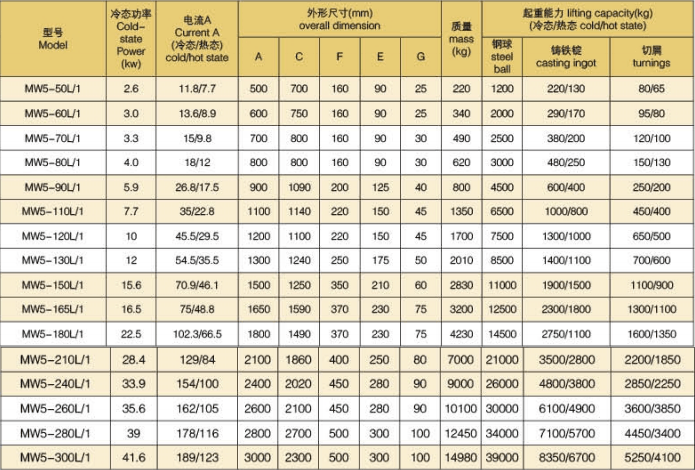

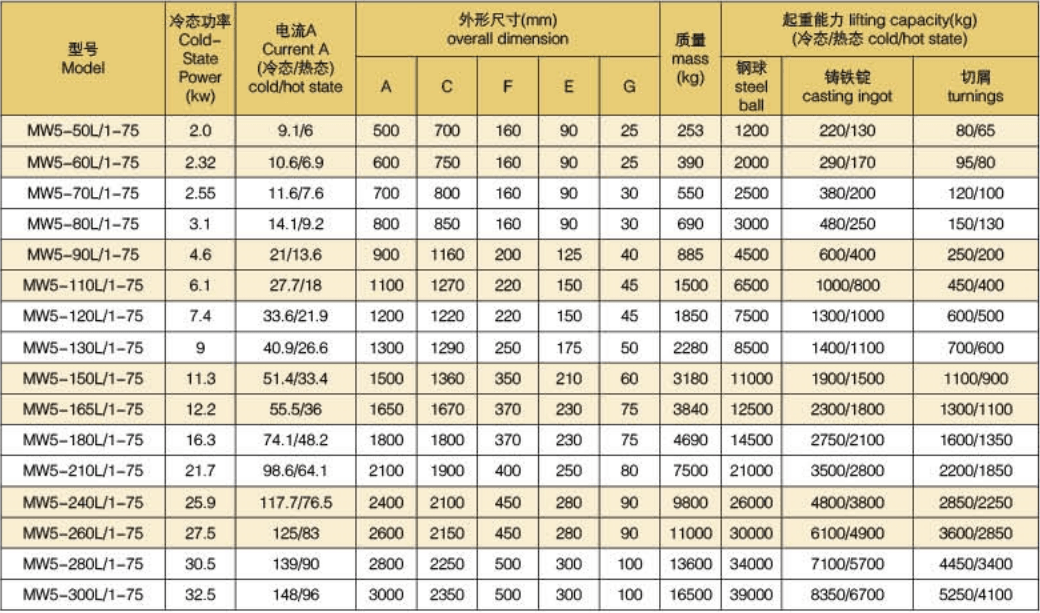

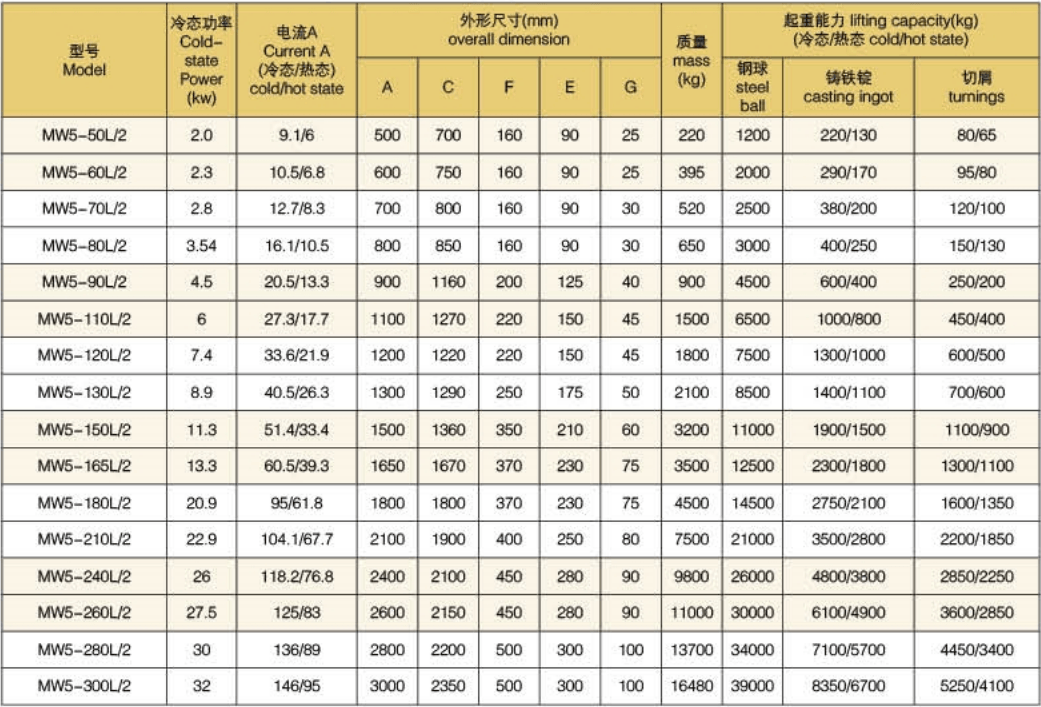

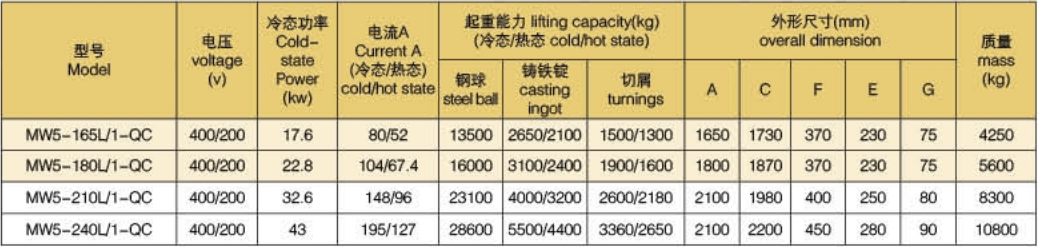

Circular Electromagnetic Chucks

It is suitable for lifting cast iron ingots, steel balls, pig iron blocks, machining chips, all kinds of miscellaneous iron, furnace materials, scrap steel in foundries. In slag handling processes, it is used to remove large iron pieces, and also for lifting iron powder in coal washing plants.

Normal temperature type: Suitable for materials with temperature below 150℃, rated voltage DC-220V, duty cycleTD-60%.

High frequency type: Suitable for more frequent lifting of materials. Rated voltage DC-220V, duty cycleTD-75%.

High temperature type: Suitable for materials below 700℃, rated voltage DC-220V, duty cycleTD-60%.

Strong magnetic type: The suction force is about 30% higher than the ordinary type, especially suitable for the electric furnace steelmaking feeding process.

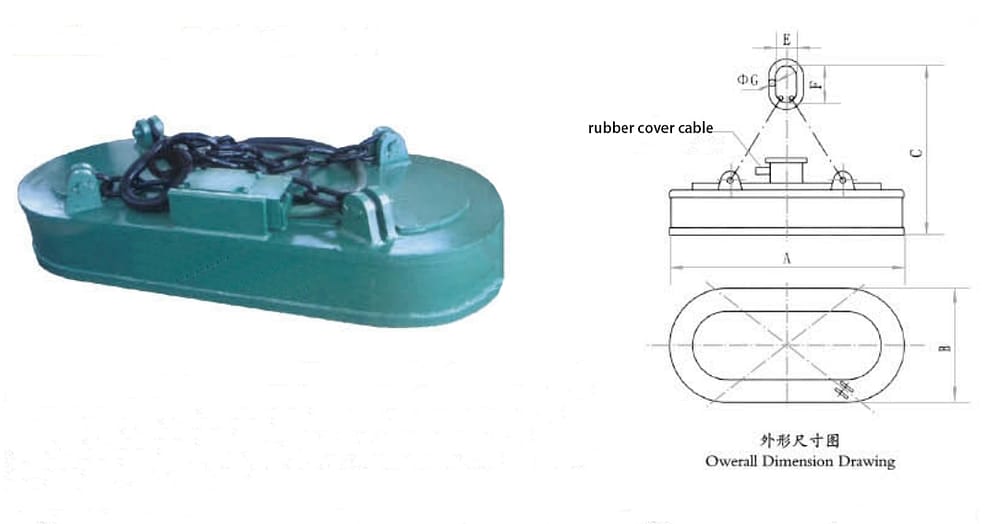

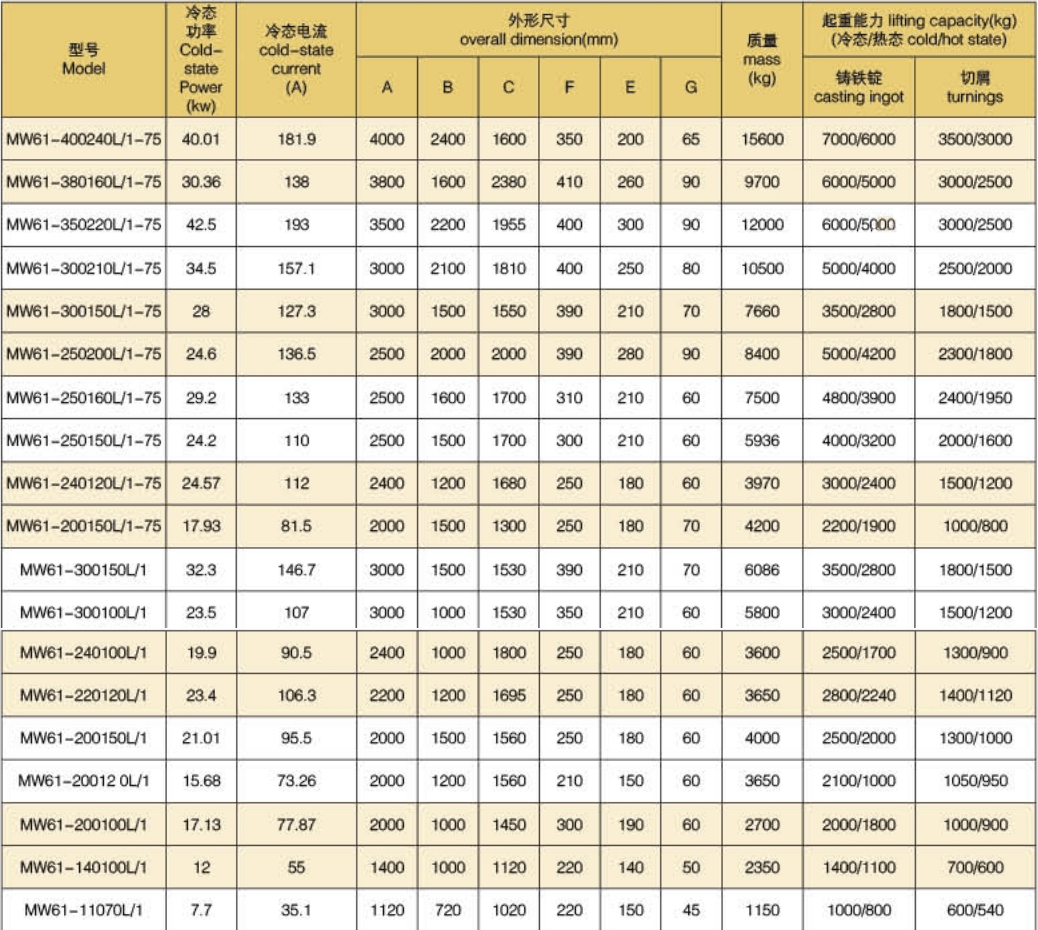

Oval Electromagnetic Chuck

It is suitable for efficient loading and unloading of scrap iron and steel in narrow trunk-like containers. These spreaders are generally customized to the shape of the trunk.

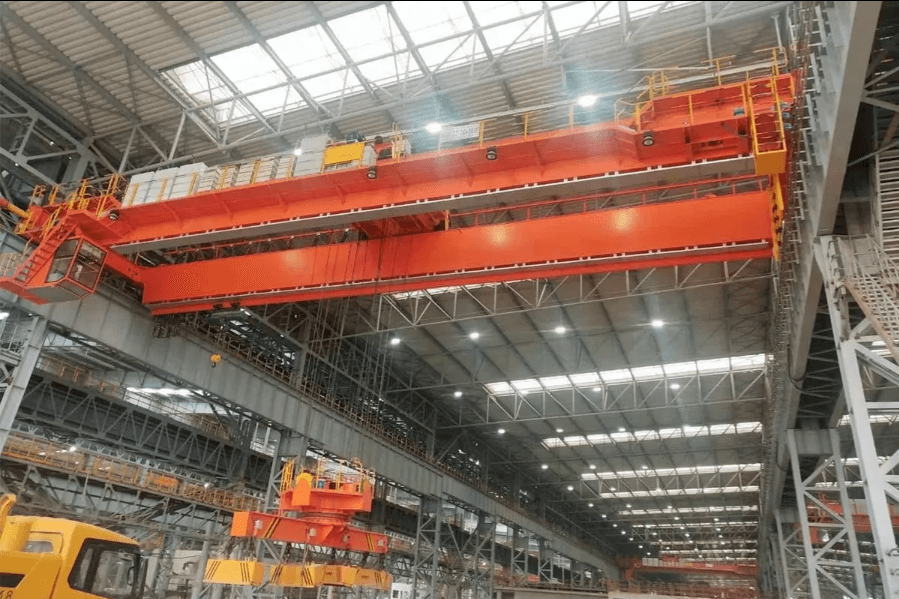

QCL Electromagnetic Overhead Cranes With Hanging Beam

The QCL electromagnetic hanging beam bridge crane mainly consists of a box-shaped bridge frame, electromagnetic hanging beam spreader, a hoisting trolley, crane travelling mechanism, a driver’s cab, and an electrical control system. It can be equipped with a power-off magnetic retention system and is suitable for lifting long steel billets, plates, bars, coils, and other items. It is mainly used in the rolling lines of steel enterprises, finished product warehouses, shipyard steel material yards, and blanking workshops.

- Capacity: 7.5+7.5t/10+10t/16+16t/20+20t

- Span: 22.5/25.5/28.5/31.5/34.5m

- Lifting height: 15-16m

- Work duty: A6-A7

Electromagnetic hanging beam overhead cranes are mainly available in the following forms:

- Hanging beams parallel to the main beam.

- It is suitable for handling long pieces of steel plates, sections, sheets, bars, coils, etc. parallel to the direction of the main beam.

- The spreader cannot rotate and can only move objects in the direction of vertical or horizontal to the main beam.

- Lower cost compared to slewing electromagnetic cranes.

- Hanging beam vertical to the main beam.

- It is suitable for moving long pieces of steel plates, sections, sheets, bars, coils, etc. in the direction perpendicular to the main beam.

- The spreader cannot rotate and can only move objects in the direction of the main beam vertically or horizontally.

- Upper rotating electromagnetic overhead crane with hanging beam.

- It is suitable for lifting steel plates, profiles, sheets, bars, coils and other items.

- The spreader can rotate horizontally and can place and move objects at any angle.

- Comparing with the lower rotating type, this crane is more costly, but the performance is more stable and durable.

- It can increase the lifting height of the crane in limited space, but it requires sufficient space above the workshop.

- Lower rotating electromagnetic overhead crane with hanging beam.

- It is suitable for lifting steel plates, profiles, sheets, bars, coils and other items.

- The spreader can be rotated horizontally, and objects can be placed and moved at any angle.

- Telescopic electromagnetic hanging beam overhead cranes.

- The spreader can be retracted, especially suitable for lifting different specifications of steel plates, profiles, plates, bars, coils and other items.

There are several main types of spreaders used in electromagnetic hanging girder overhead cranes:

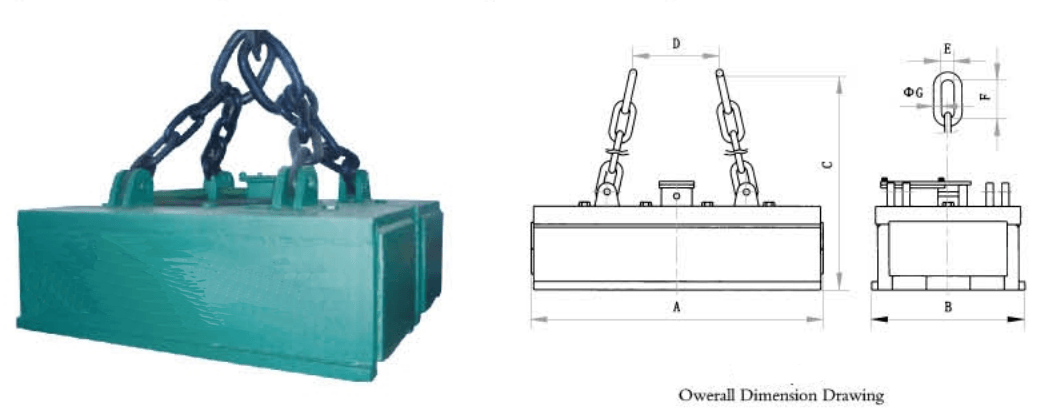

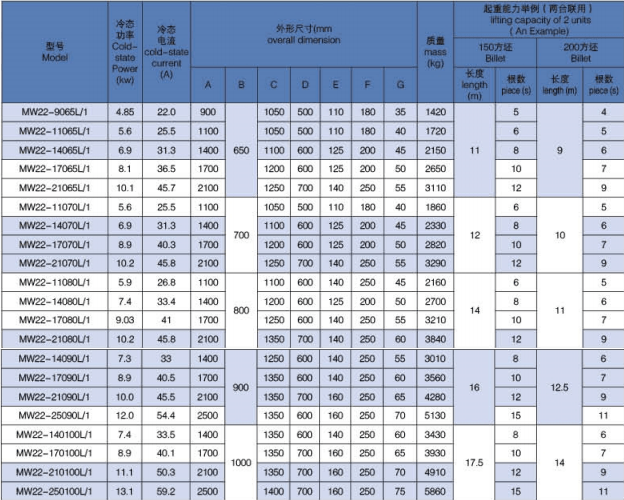

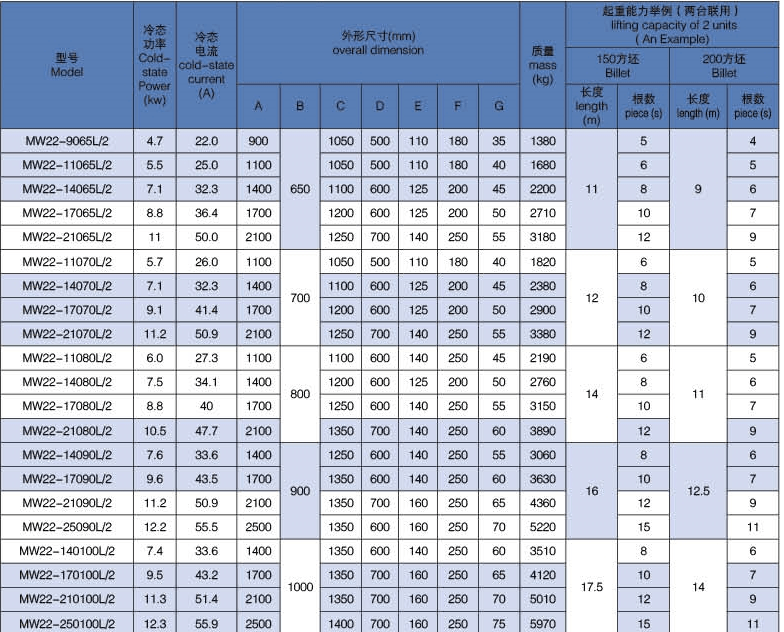

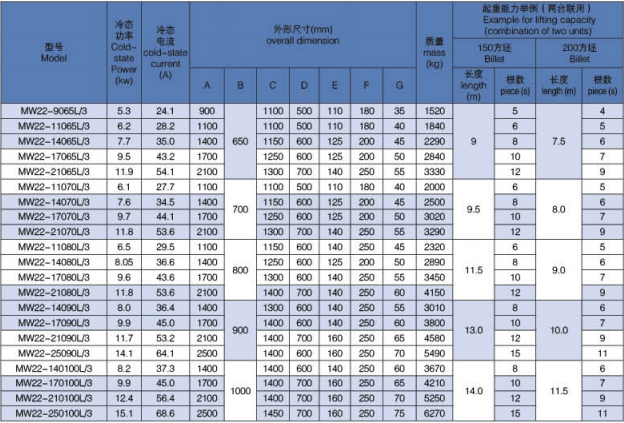

Electromagnet Spreader for Lifting Billets, Beams, Slabs

It is mainly suitable for lifting billets, ingots and large primary billets, etc. It can also be used for lifting round billets and sections. For different types of steel, different magnetic circuit designs are adopted. There are normal temperature type, high temperature type and ultra-high temperature type.

Normal temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 150℃.

High temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials of 150-600℃.

Ultra-high temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials of 600-700℃.

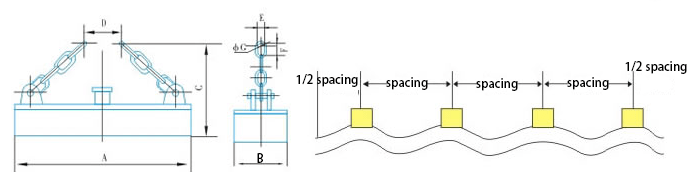

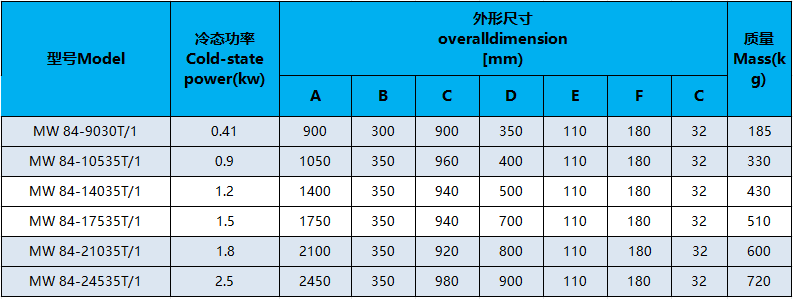

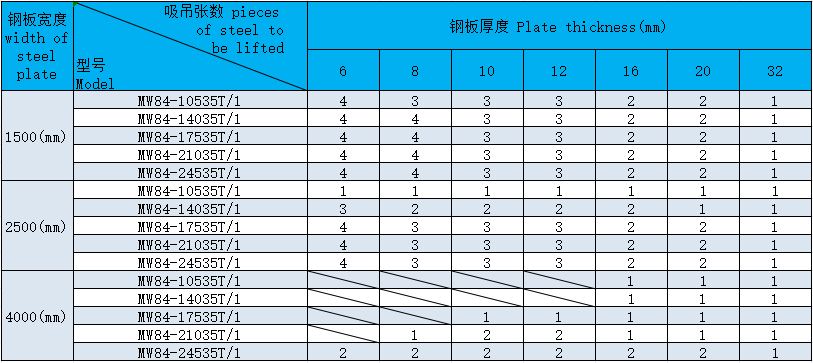

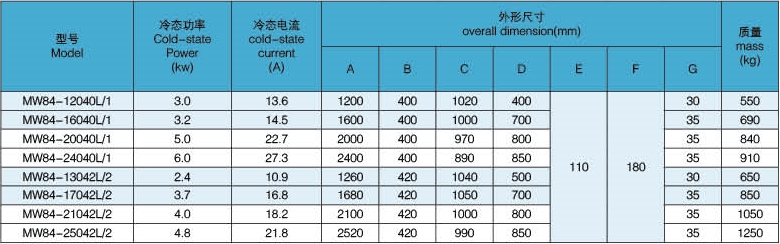

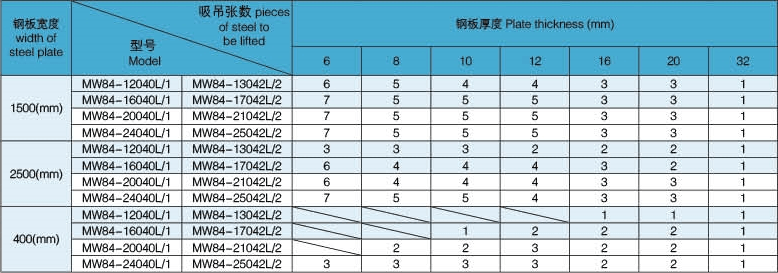

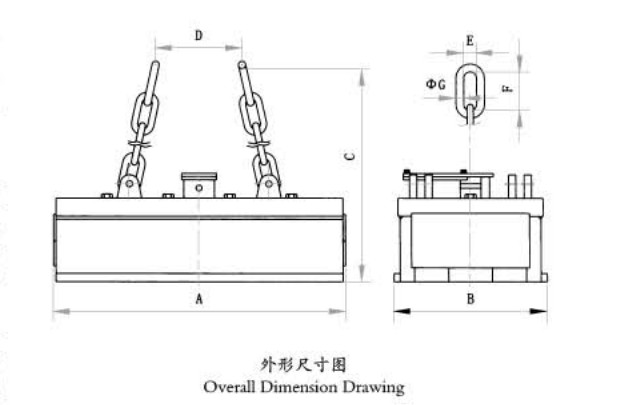

Electromagnet Spreader for Lifting Steel Plates

It is designed for lifting medium-thick steel plates. Safe, accurate and fast lifting operation. Considering the possible bending and deformation of long steel plate lifting which may affect the safe handling, multiple electromagnets are generally used in conjunction when lifting long size steel plates. For medium-thick steel plate (6mm-32mm), the spacing of solenoid depends on 2.5-3.5m, and the length of both ends of the outstretched part can be taken as 1/2 of the spacing, according to the difference of the number of sheets to be lifted, it can be divided into 350 type and 400 type.

350 Normal temperature type: rated voltage DC-220V, duty cycleTD-60%, suitable for medium and thick plate factory, shipbuilding factory, machinery manufacturing plant, adopting magnetization control mode, can lift one or a certain number of steel plates.

Note: The MW84-9030T/1 is rated for DC-110V.

Model 400: Model 400 is suitable for handling as many sheets as possible at one time, and high-temperature products can be designed and manufactured separately according to the requirements of users for lifting steel plates below 700℃.

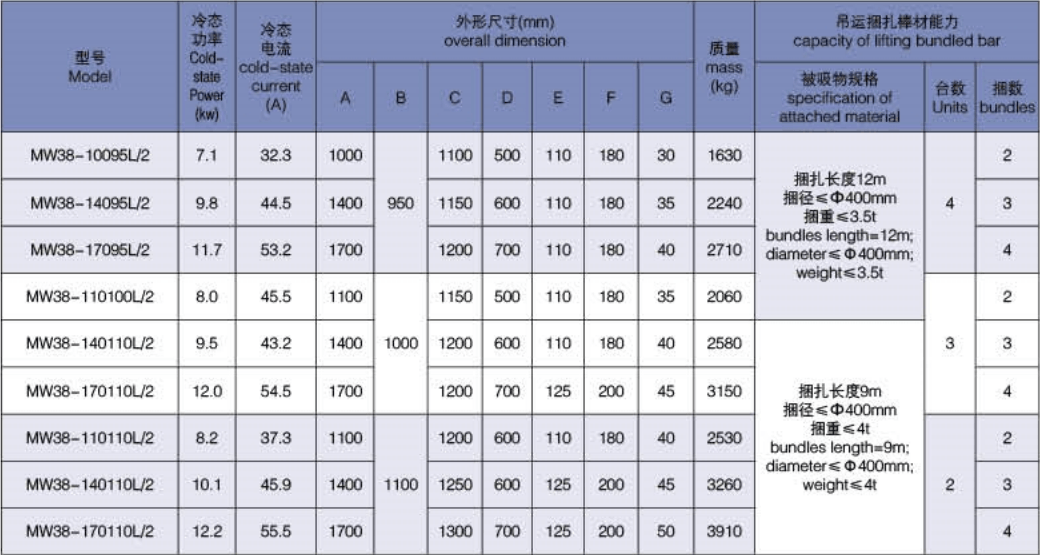

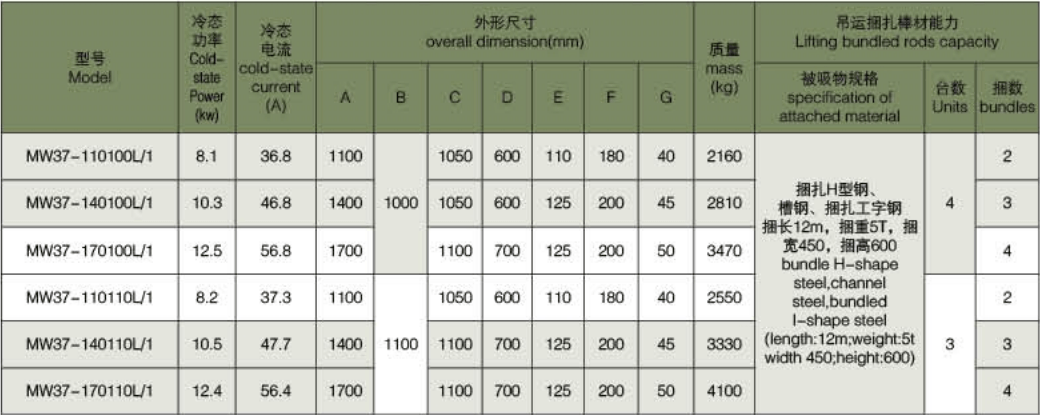

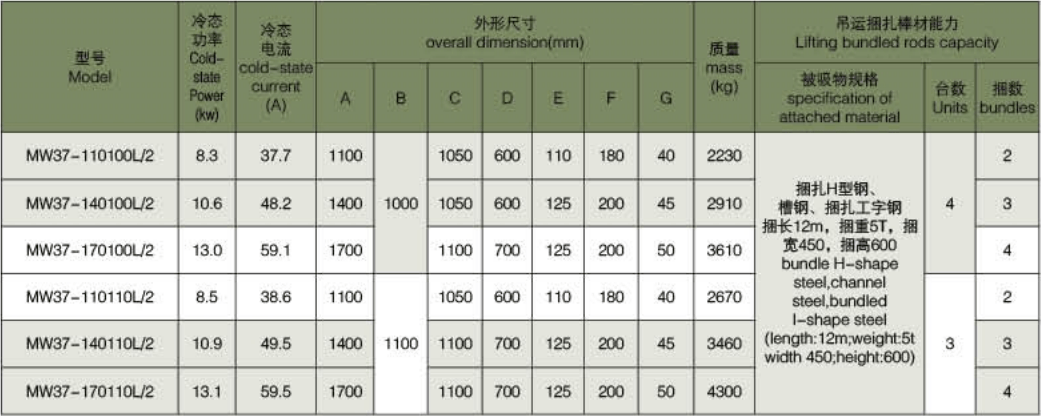

Electromagnetic Spreader for Lifting Bundled Rebars and Profiled Steel

It is characterized by good heat dissipation, deep magnetic permeability and ability to penetrate multi-layer air gaps, and can lift bars, flat irons, angles, etc. which have not been bundled or have only been simply bundled. There are room temperature type and high temperature type. Due to the use of two or more sets of continuous lifting, so its connection with the hanging beam more than two hanging points or four hanging point structure. Round steel, rebar, etc. This type of material deflection is larger, the length of the sucked material is more than 9 meters of the general use of multi-stage continuous lifting.

Normal temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 150℃.

High temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 600℃.

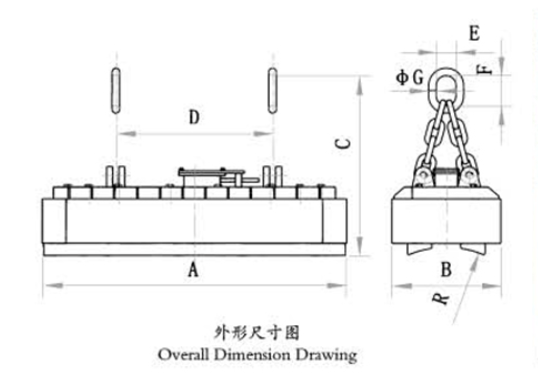

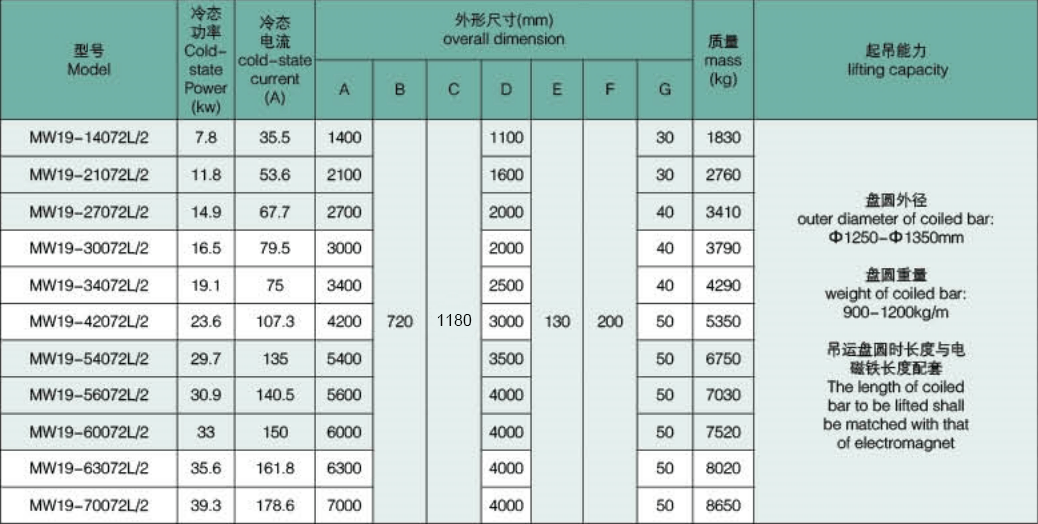

Electromagnetic Spreader for Lifting Coiled Bar

Dedicated to lifting coiled bar, the electromagnetic spreader light weight, reasonable structure, magnetic pole structure can adapt to different diameters of discs, the choice of electromagnet depends on the length of the discs, both along the length of the electromagnet lifting bundles of discs, but also along the direction of the width of the bundles can be lifted, can provide more than one and can be used in the same way, and can be individually on, off, convenient for loading operations.

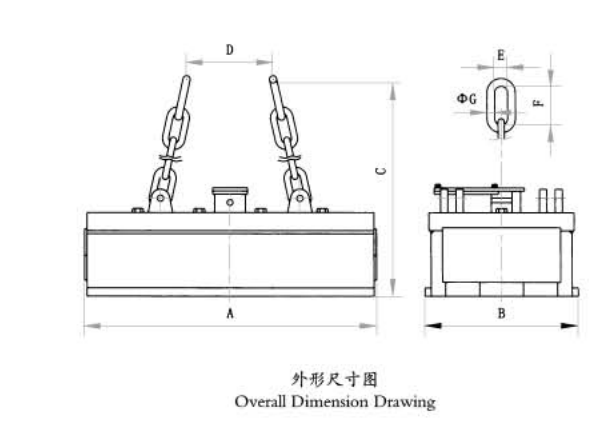

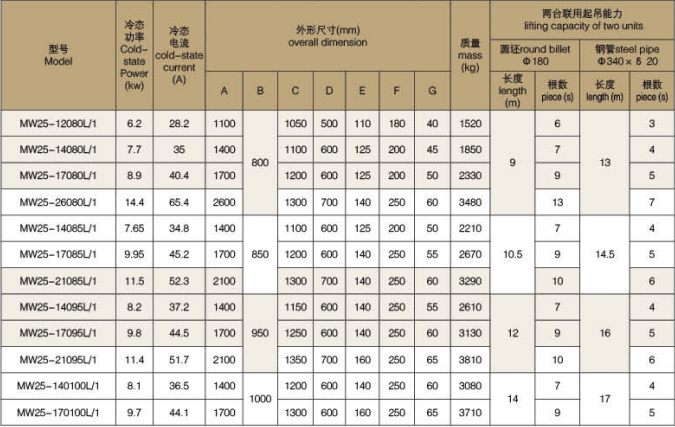

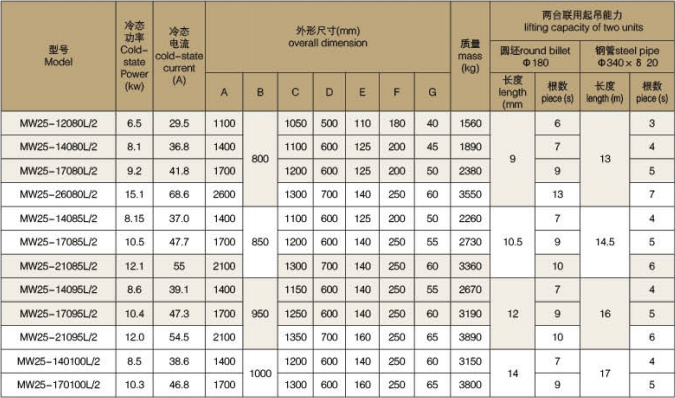

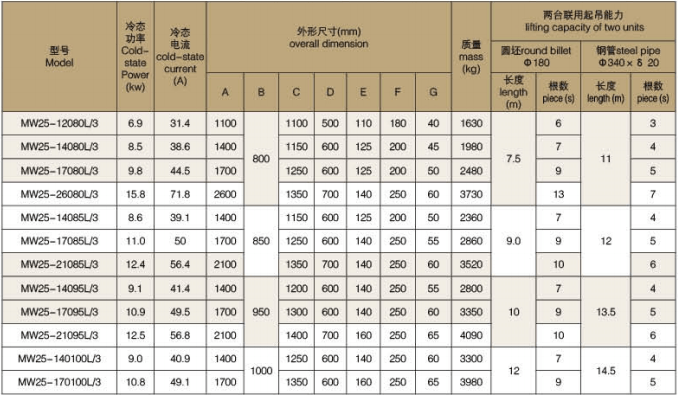

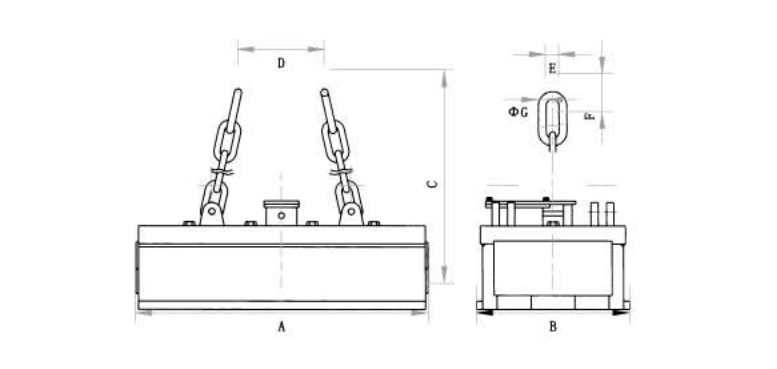

Electromagnet Spreader for Lifting Billets and Pipes

Mainly used for lifting round billets, steel pipes, etc. It can also be used for lifting billets, ingots and large primary billets, steel sections, etc. Special magnetic circuit design, characterized by deep permeability.

Normal temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 150℃.

High temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 600℃.

Ultra-high temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 700℃.

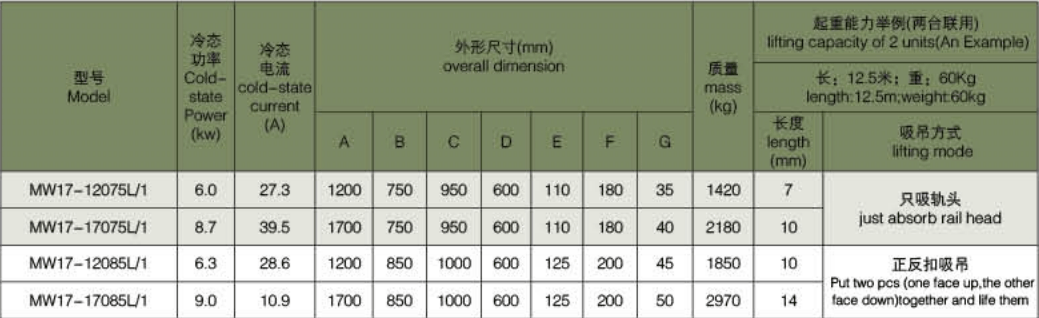

Electromagnet Spreader for Lifting Heavy Rails and Profiled Steel

Dedicated to lifting heavy rails, suitable for professional manufacturers of heavy rails and large-scale railroad beam factories. Using unique magnetic circuit design, double wire package structure, with good heat dissipation, deep permeability characteristics. It can be used for lifting heavy rails, steel profiles, shaped billets and so on. There are normal temperature type and high temperature type, mostly using two or more sets of joint hoisting.

Normal temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 150℃.

High temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 600℃.

Normal temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 150℃.

High temperature type: rated voltage DC-220V, duty cycle TD-60%, suitable for lifting materials below 600℃.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China