What Is Crane duty classification?

When it comes to crane operations, it is crucial to ensure that the right crane is chosen for the job. Different assignments require different levels of power and performance. This is where crane duty classification comes into play. In this article, we will explore the meaning of crane duty classification and how it is classified by different organizations such as the CMAA, China, and FEM.

Meaning Of Crane Duty Classification

Crane duty classification refers to the categorization of cranes based on the intensity and frequency of usage. It helps to determine the ideal type of crane required for a specific task. The duty classification does not depend on the size of the lifting capacity, but on the crane load and load frequency changes and changes in the degree of busyness of the project. The classification takes into account factors such as load capacity, the number of operating cycles per hour, and the overall duration of the operation.

Crane Duty Classification Of CMAA

The Crane Manufacturers Association of America (CMAA) has developed a standard classification system widely used in North America. It categorizes cranes into six classes, ranging from Class A to Class F. Each class represents a different level of operation, with Class A being the lightest duty and Class F being the heaviest duty.

Class A: Standby Or Infrequent Service

This service class covers cranes that may be used in installations such as powerhouses, public utilities, turbine rooms, motor rooms and transformer stations where precise equipment handling at slow speeds with long, idle periods between lifts is required.

Class B: Light Service

This class of crane is used in repair shops, light assembly operations, service buildings, light warehousing, etc. Service requirement is light and speeds are slow. Loads vary from none to occasional full capacity. Lifts per hour would range from 2 to 5, and average 10 feet per lift.

Class C: Moderate Service

In terms of numbers, most cranes are built to meet Class C service requirements. This service covers cranes that may be used in machine shops or paper mill machine rooms. In this type of service, the crane will handle loads that average 50% of the rated capacity with 5 to 10 lifts per hour averaging 15 feet. Not over 50% of the loads at rated capacity.

Class D: Heavy Service

This service covers cranes that may be used in heavy machine shops, foundries, fabricating plants, steel warehouses, container yards, lumber mills, etc., and standard duty bucket and magnet operations where heavy duty production is required. In this type of service, loads approaching 50 percent of the rated capacity will be handled constantly during the working period. High speeds are desirable for this type of service with 10 to 20 lifts per hour averaging 15 feet, not over 65 percent of the lifts at rated capacity.

Class E: Severe Service

This type of service requires a crane capable of handling loads approaching a rated capacity throughout its life. Applications may include magnet, bucket, magnet/bucket combination cranes for scrap yards, cement mills, lumber mills, fertilizer plants, container handling, etc. with 20 or more lifts per hour at or near the rated capacity.

Class F: Continuous Severe Service

This type of service requires a crane capable of handling loads approaching rated capacity continuously under severe service conditions throughout its life. Applications may include custom designed specialty cranes.

Crane Duty Classification Of China

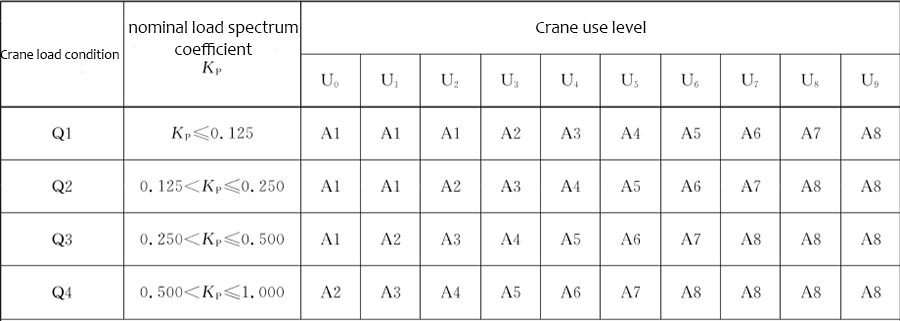

According to the use of the crane level and load state, the crane duty classification of the whole machine is divided into A1 ~ A8 total of 8 levels:

- A1~A4: Light service

- A5~A6: Medium service

- A7: Heavy service

- A8: Severe service

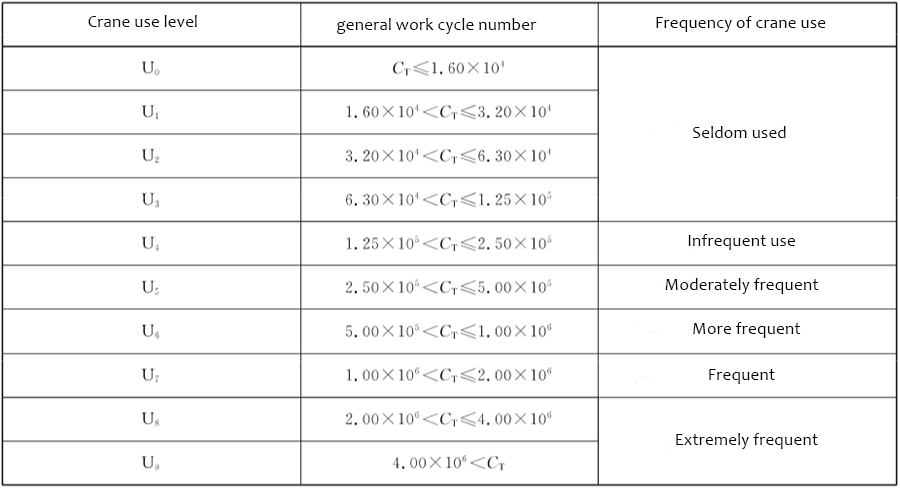

Crane use level is the total number of possible crane work cycles divided into 10 levels, with U0, U1, U2 ……U9 said:

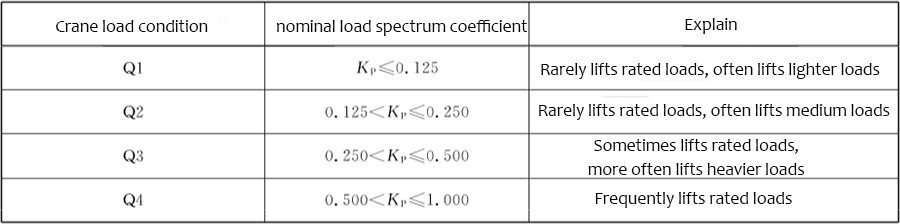

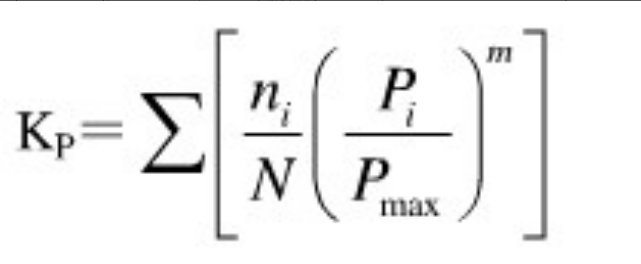

Crane load spectrum coefficient Kp is divided into four ranges of values, each representing a corresponding load state of the crane:

Pi: Mass of the i-th lifting weight

Pmax: Rated lifting capacity

ni: Number of times the load Pi is applied

N: Total number of working cycles

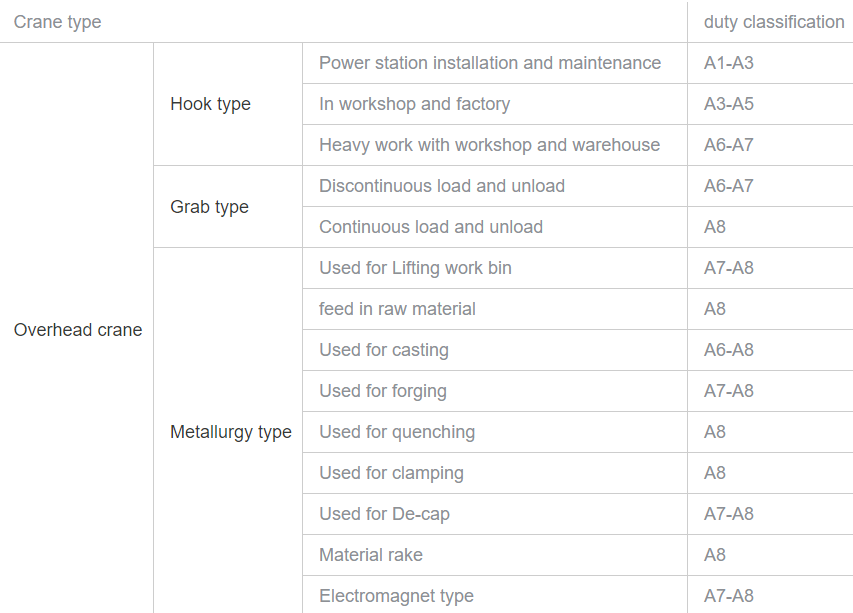

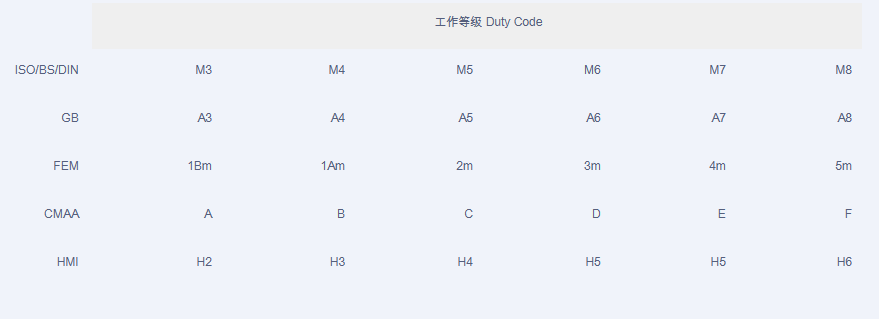

Duty Classification Of Commonly Used Cranes

1.Duty Classification Of Overhead Crane:

2.Duty Classification Of Gantry Crane:

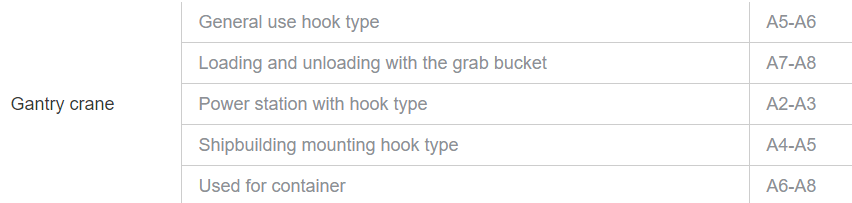

Crane Duty Classification Of FEM

The European Federation of Materials Handling (FEM) has its own set of crane duty classifications widely adopted in Europe. Similar to other systems, FEM cranes are classified based on factors such as the number of load cycles, load spectrum, and service life.

- 1Cm – Standby or infrequent usage

- 1Bm – Light service

- 1Am – Light to medium service

- 2m – Medium to heavy service

- 3m – Heavy service

- 4m/5m – Severe service

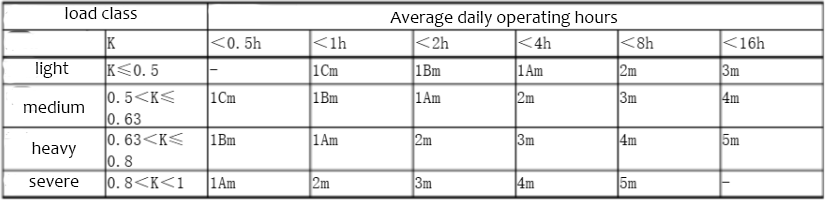

Comparing Of Crane Class

While the crane duty classification varies in terminology and criteria, the systems serve the same purpose. The following is a comparison table of crane duty classification under different standards.

Crane by lifting and moving load (refers to the crane load and lifting the mass of heavy objects) in its rated lifting capacity within the weight to achieve material handling operations, but on different occasions, the use of cranes and their work tasks vary greatly, that is, its life expectancy, work requirements, lifting loads, loads, the total number of cycles of the total work with the total work time and so on there will be a great deal of difference, in order to economically and rationally select and safely and reliably use cranes, it must be crane duty classification of the division. Understanding the different classifications provided by organizations helps ensure safe and efficient operations. So, whether you are handling light maintenance tasks or heavy-duty industrial operations, choosing the appropriate crane class will undoubtedly contribute to the overall success and effectiveness of your project.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China