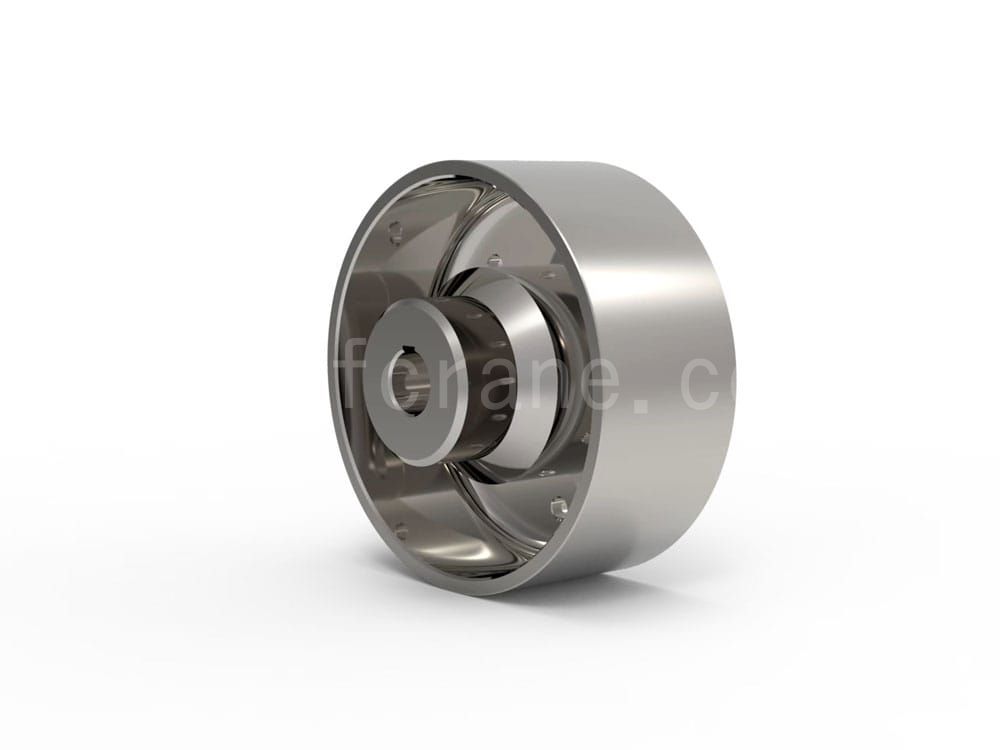

Introdução do produto

As rodas de freio de ponte rolante são usadas principalmente para frear o eixo ativo e acionado nos mecanismos de elevação e operação do guindaste. Geralmente é usado em combinação com o acoplamento da roda de freio ou pode ser usado sozinho no mecanismo de caminhada do carrinho do guindaste. A série de rodas de freio de ponte rolante Dafang é projetada para aplicações industriais, incluindo pontes rolantes e pórticos. Nossos vários tipos de rodas de freio e serviços de acabamento aprimoram nosso serviço de alta qualidade para atender às suas necessidades exclusivas de aplicação e simplificar a instalação. Também fornecemos serviços personalizados, incluindo rodas de freio angulares, rodas de freio deslocadas e rodas de freio acopladas.

Vantagem

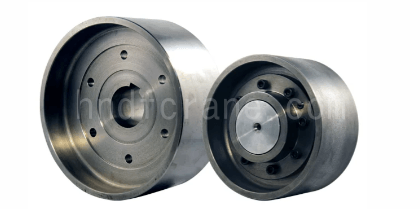

- Totalmente usinado para fornecer equilíbrio adequado em velocidade operacional normal

- Resistente a riscos

- Use suavemente e uniformemente

- Oferece excelente torque

- Alta condutividade térmica - dissipa o calor das pastilhas de freio, estendendo assim a vida útil das pastilhas de freio

- Operação estável, desempenho estável, alta segurança e resistência ao desgaste e longa vida útil

Características técnicas

| CLZ2 | CLZ3 | CLZ4 | CLZ5 | CLZ6 | |||||

| Velocidade de rotação n(r/min) | Torque nominal Tn(Nm) | Velocidade de rotação n(r/min) | Torque nominal Tn(Nm) | Velocidade de rotação n(r/min) | Torque nominal Tn(Nm) | Velocidade de rotação n(r/min) | Torque nominal Tn(Nm) | Velocidade de rotação n(r/min) | Torque nominal Tn(Nm) |

| 1400 | 3000 | 1400 | 3000 | 1400 | 3000 | 1400 | 3000 | 1400 | 3000 |

| 3150 | 2400 | 3150 | 2400 | 3150 | 2400 | 3150 | 2400 | 3150 | 2400 |

| 5600 | 2000 | 5600 | 2000 | 5600 | 2000 | 5600 | 2000 | 5600 | 2000 |

| 8000 | 1680 | 8000 | 1680 | 8000 | 1680 | 8000 | 1680 | 8000 | 1680 |

| 19000 | 1270 | 19000 | 1270 | 19000 | 1270 | 19000 | 1270 | 19000 | 1270 |

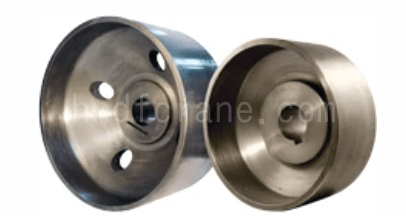

Processo de fabricação de rodas de freio de ponte rolante

O guindaste Dafang usa os seguintes equipamentos técnicos avançados na produção de rodas de freio de guindaste para garantir uma produção de alta qualidade.

Torno CNC - processamento e fabricação de rodas de freio para ponte rolante

Máquina-ferramenta de têmpera de alta frequência - tratamento térmico para rodas de freio de ponte rolante

Processo de produção

O processo de fabricação das generosas rodas de freio para ponte rolante é a fundição.

- Fundição é um processo de fabricação comum para rodas de freio de ponte rolante. O uso de ferro fundido de alta qualidade ou aço fundido, por meio de tecnologia de fundição precisa, para garantir a resistência e durabilidade dos componentes. O processo de fundição pode fabricar peças de formas complexas, e o custo é relativamente baixo.

- Vantagens: É adequado para produção em massa em larga escala e pode atender aos requisitos de alta resistência, resistência ao desgaste e resistência à corrosão. Por meio de tecnologia avançada de fundição, o desperdício de material pode ser efetivamente reduzido e a eficiência da produção pode ser melhorada.

- Por meio da seleção razoável de processos de fundição e forjamento, rodas de freio generosas para pontes rolantes podem garantir boa relação custo-benefício, ao mesmo tempo em que oferecem excelente desempenho e confiabilidade.