Golvmonterad jibbkran: sammansättning och underhåll

När det gäller tunga lyft och effektiv materialhantering i olika branscher spelar golvmonterade svängkranar en avgörande roll. Dessa mångsidiga maskiner består av flera komponenter noggrant utformade för att säkerställa stabilitet, funktionalitet och säkerhet. I den här artikeln kommer vi att fördjupa oss i sammansättningen av en golvmonterad svängkran, utforska dess nyckeldelar och hur de underhålls.

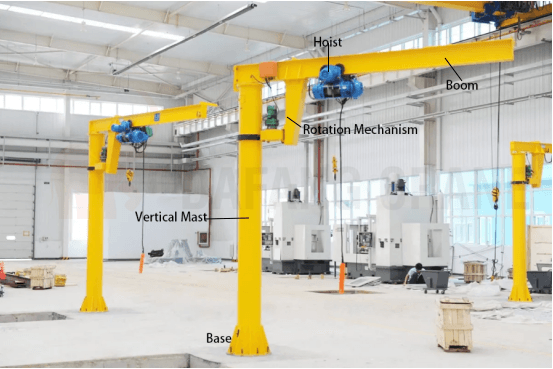

Sammansättning av golvmonterad jibbkran

Basen

Grunden till en golvmonterad svängkran ligger i dess bas. Vanligtvis tillverkad av robust stål, ger basen stabilitet och stöd till hela strukturen. Den är säkert förankrad i golvet, vilket säkerställer tillförlitlig prestanda även vid hantering av tunga belastningar. Basen är utformad för att fördela kranens vikt och de krafter som utövas under drift, förhindra överdriven påfrestning på golvet och bibehålla den övergripande strukturella integriteten.

Vertikal mast

Den vertikala masten, som reser sig från basen, fungerar som ryggrad i svängkranen. Tillverkad av robusta material som stål eller aluminium, ger masten vertikalt stöd och stabilitet till kranarmen eller bommen. Höjden på masten bestämmer maximalt möjliga lyfthöjd, vilket gör den till ett viktigt övervägande för specifika lyftkrav.

Bom

I slutet av den vertikala masten hittar du bommen på svängkranen. Denna horisontella balk sträcker sig utåt och är ansvarig för att bära lasten. Bommar är vanligtvis gjorda av högkvalitativt stål och kan variera i längd beroende på önskad räckvidd. De är konstruerade för att motstå de påfrestningar som utövas av att lyfta tunga föremål samtidigt som de säkerställer mjuka rörelser och exakt kontroll.

Rotationsmekanism

En annan kritisk komponent i en golvmonterad svängkran är dess rotationsmekanism, som möjliggör full 360-graders rotation. Ett svänglager eller vridbord är inbyggt vid basen av masten, vilket gör att kranen kan röra sig horisontellt och täcka ett stort arbetsområde utan att flytta basen. Denna rotationsfunktion förbättrar operationell flexibilitet och effektivitet, vilket minskar behovet av ytterligare utrustning eller omfattande manuellt arbete.

Hissa

De hissa är den del som ansvarar för att lyfta och sänka laster i en golvmonterad svängkran. Den består av ett motoriserat system med en kedja eller vajer och en krok eller andra lastbärande anordningar. Lyften är säkert fäst vid bommen, vilket möjliggör kontrollerad vertikal rörelse av material. Lyftkapaciteten hos en svängkran beror på styrkan och specifikationerna för dess lyftmekanism.

Kontroller och säkerhetsfunktioner

Golvmonterade svängkranar är utrustade med användarvänliga kontroller och säkerhetsfunktioner för att säkerställa smidig drift och skydda både arbetare och den omgivande miljön. Dessa kan inkludera hängande tryckknappskontroller, radiofjärrkontroller, gränslägesbrytare, nödstoppsknappar, överbelastningsskydd och antikollisionssystem. Genom att implementera dessa säkerhetsåtgärder minimeras risken för olyckor och främjar effektiva arbetsflöden.

Arbetsprincip för golvmonterad jibbkran

Arbetsprincipen för en golvmonterad svängkran kretsar kring dess svängningsrörelse och lyftmekanism. En robust stålmast är säkert förankrad i golvet, vilket ger stabilitet och stöd. I toppen av masten sträcker sig en horisontell bom utåt, utrustad med en hiss eller lyftanordning.

När den är i drift roterar svängkranen horisontellt runt mastens axel, vilket gör att den kan täcka ett angivet område inom dess räckhåll. Denna rotationsrörelse möjliggör exakt positionering av lasten, ökar effektiviteten och minskar behovet av manuellt arbete.

Lyftmekanismen hos en pelararmskran använder typiskt en elektrisk kättingtelfer eller vajer. Lyften, som drivs av en elmotor, höjer och sänker lasten längs med bommens längd. Föraren styr lyft- och sänkningsåtgärderna med hjälp av en hängande kontroll eller ett fjärrkontrollsystem.

Underhåll av golvmonterad svängkran

Några viktiga underhållstips för golvmonterade svängkranar:

- Smörjning: Adekvat smörjning är avgörande för att en pelarmonterad svängkran ska fungera smidigt. Att regelbundet applicera högkvalitativa smörjmedel på de rörliga delarna som lager, växlar och leder hjälper till att minska friktionen, förhindra slitage och förlänga kranens livslängd. Det är tillrådligt att följa tillverkarens riktlinjer angående smörjfrekvens och vilken typ av smörjmedel som ska användas.

- Inspektion och testning: Inspektera kranens strukturella komponenter, inklusive bommen, masten och basen, för tecken på skada eller deformation. Kontrollera de elektriska anslutningarna, kontrollpanelerna och säkerhetsfunktionerna för att säkerställa att de fungerar korrekt. Utför dessutom lasttester för att verifiera kranens lastkapacitet och stabilitet.

- Underhåll av elsystem: Det elektriska systemet i en golvmonterad svängkran kräver särskild uppmärksamhet. Inspektera regelbundet ledningar, kontakter och brytare för tecken på skador eller lösa anslutningar. Se till att strömförsörjningen är stabil och uppfyller kraven för spänning och strömstyrka. Om några elektriska komponenter visar tecken på fel, bör de repareras eller bytas ut omedelbart av en kvalificerad elektriker.

- Säkerhetsanordningar: Kontrollera funktionen hos säkerhetsanordningar, inklusive gränslägesbrytare, nödstoppsknappar och överbelastningsskyddssystem. Dessa enheter är utformade för att förhindra olyckor och skydda både operatörer och utrustning. Testa och kalibrera dem regelbundet för att säkerställa korrekt funktion.

- Strukturell integritet: Med tiden kan de strukturella komponenterna i en golvmonterad svängkran uppleva stress och trötthet. Inspektera kranens svetsfogar, bultar och fästelement för att säkerställa att de är säkra och oskadade. Leta efter tecken på sprickor, deformationer eller överdrivet slitage. Om några strukturella problem upptäcks, rådgör med en professionell ingenjör eller krantillverkaren för att fastställa nödvändiga reparationer eller byten.

Den golvmonterade svängkranen är en mångsidig och viktig utrustning inom olika industrier. Dess sammansättning inkluderar en robust bas, en vertikal mast, en roterande bom och ett lyftsystem som möjliggör effektiva lyft och manövrering av tunga laster. För att säkerställa optimal prestanda och livslängd är regelbundet underhåll avgörande. Detta innebär att inspektera kranen för eventuella tecken på slitage, smörja rörliga delar. Att förstå arbetsprincipen för den golvmonterade svängkranen, som involverar bommens rotation och lyftens kontrollerade rörelse, är avgörande för säker och effektiv drift. Genom att följa korrekta sammansättningsriktlinjer, utföra rutinunderhåll och följa säkerhetsprotokoll kan organisationer maximera produktiviteten och livslängden för sin golvmonterade svängkran.

Skicka din förfrågan

- E-post: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Lägg till: Changnao Industrial District, Xinxiang City, Henan-provinsen, Kina

WeChat

WeChat