6 Mwongozo wa Kushindwa na Matengenezo ya Cranes Portal ya Bandari

Jedwali la Yaliyomo

Pamoja na upanuzi unaoendelea wa ukubwa wa ujenzi wa bandari, gati, n.k., wigo wa utumiaji wa korongo za bandari katika shughuli za bandari pia unaongezeka siku baada ya siku.

Ili kutoa uchezaji kamili kwa kazi za vifaa na kudumisha usalama na kuegemea kwa shughuli, ni muhimu kuimarisha matengenezo na usimamizi wa korongo za bandari za bandari. Wakati wa operesheni ya kila siku ya cranes ya bandari ya bandari, pulleys za kamba za waya, gia za kupunguza, vifungo, breki, motors za awamu ya tatu za AC, makabati ya juu-voltage, transfoma, nk mara nyingi hushindwa. Hatua madhubuti za matengenezo zinahitaji kuchukuliwa ili kupunguza uwezekano wa hitilafu zinazohusiana na hitilafu za lango la bandari na kuweka korongo za mlango wa bandari katika hali nzuri ya uendeshaji. Kwa msingi huu, kuboresha ufanisi wa shughuli za bandari na kuhakikisha usalama wa uzalishaji.

Korongo za Lango la Bandari Kushindwa1:Kushindwa kwa kapi ya kamba ya waya

Katika korongo za bandari kushindwa, kamba za kamba za waya ni sehemu kuu za nguvu, na uharibifu wa kuzaa, kupasuka kwa mdomo, au kupungua mara nyingi hutokea wakati wa uendeshaji wa vifaa. Sababu ya mizizi ya matatizo hapo juu ni kwamba kamba ya waya na pulley zimeunganishwa, na pande hizo mbili kwa pamoja hutoa nguvu ya extrusion, na kisha pulley itaathiriwa na msuguano na kupungua kwa hatua kwa hatua. Wakati ukonde unafikia kiwango fulani, shinikizo linalosababishwa na kamba ya waya huzidi shinikizo ambalo linaweza kuhimili na matatizo ya kupasuka hutokea.

Mwongozo wa Matengenezo 1

Matengenezo ya vitalu vya kamba ya kamba ili kuhakikisha uendeshaji thabiti na salama wa vitalu vya pulley, kwanza kabisa, ni marufuku kabisa kupakia crane wakati wa matumizi, ili usiongeze uwezo wa kuzaa wa vitalu vya pulley na kusababisha uharibifu wa kuzaa.

Pili, kamba ya waya ya crane inapaswa kulainishwa mara kwa mara na kudumishwa ili kupunguza msuguano kati ya kapi na kamba ya waya na kuzuia uchakavu mbaya wa ukingo wa kapi na sehemu ya gurudumu.

Hatimaye, ikiwa kuna uchakavu mkubwa kwenye sehemu ya gurudumu, kama vile kiwango cha uvaaji kisichopungua milimita 3, nyufa kwenye kapi, na unene wa unene wa ukuta huchangia 1/5 ya unene wa awali wa ukuta, nk, puli inahitaji kung'olewa na kubadilishwa na kapi mpya.

Cranes za Portal ya Bandari Imeshindwa 2: Kushindwa kwa gia ya kupunguza

Katika crane ya bandari ya bandari, kipunguzaji ni sehemu ya msingi ya upitishaji ambayo hupitisha torque wakati wa mchakato wa kuunganisha gia na kisha kurekebisha kasi ya gari hadi kufikia mahitaji ya uendeshaji. Kushindwa kwa gia, kama vile nyuso za meno zenye glu, meno yaliyokatwa, na nyuso za meno zilizovaliwa sana, mara nyingi hutokea katika mchakato huu.

Mwongozo wa matengenezo 2

Wakati wa matengenezo ya gear ya reducer, inahitajika kwamba crane haipatikani sana wakati wa matumizi na kwamba ni laini na polepole wakati wa kuvunja au kuanza. Haiwezi kubadilishwa moja kwa moja bila kusimamisha operesheni ikiwa sio dharura. Operesheni. Wakati wa matumizi, gear ya kupunguza inapaswa kuongezwa mara kwa mara na mafuta ya kulainisha ambayo yanakidhi mahitaji ya hali ya uendeshaji ya kipunguzaji, na nyumba inapaswa kusafishwa kwa wakati.

Kwa kuongezea, inahitajika kukagua na kuchambua mara kwa mara ubora wa mafuta ya mafuta ya kulainisha, kuchanganya matokeo ya ukaguzi ili kufafanua uvaaji wa gia ya kupunguza, na kuchukua hatua za matengenezo yaliyolengwa ili kuzuia kuongezeka kwa uchakavu na hatimaye kusababisha ajali za vifaa.

Cranes za Portal ya Bandari Kushindwa 3: Kushindwa kwa kuunganisha

Meno ya kuunganisha ya kiunganishi cha meno ya korongo ya bandari huwa rahisi kuchakaa, na hata matatizo kama vile meno yaliyovunjika na meno ya kusaga yanaweza kutokea. Iwapo kiunganishi cha lango la mlango wa korongo la crane blossom elastomer kitatumika, elastoma ya maua ya plum huwa rahisi kuvaa, kuzeeka kwa kasi, au kupasuka kwa uchovu wakati wa operesheni ya muda mrefu ya crane. Katika matumizi ya muda mrefu ya cranes ya bandari ya bandari, pete ya elastic ya kuunganisha pini ya elastic pia itavaliwa sana, na pini ni rahisi kupoteza ili kelele ya maambukizi na vibration iliyotolewa na kuunganisha wakati wa maambukizi itaongezeka, na kuathiri uendeshaji wa kawaida wa vifaa. Kwa kuongeza, bolts za mwenzake za kuunganisha pia zitavunja na kusababisha kushindwa kwa mitambo.

Mwongozo wa matengenezo 3

Wakati wa operesheni ya muda mrefu ya kuunganisha gear ya bandari ya crane ya bandari, meno ya ndani na ya nje yatakuwa chini ya uharibifu fulani, kwa hiyo ni muhimu kufanya kazi nzuri ya lubrication na matengenezo ya mara kwa mara. Wakati huo huo, kuunganisha elastomer inapaswa kuchunguzwa mara kwa mara, hasa matumizi ya vipengele vya elastic na pini. Mara tu vipengele vya elastic vinapatikana kuharibiwa, vinahitaji kubadilishwa kwa wakati.

Wakati wa ukaguzi wa mara kwa mara, tahadhari inapaswa pia kulipwa kwa kuimarisha mara kwa mara ya bolts ili kuzuia bolts huru kutokana na kuathiri uendeshaji wa kawaida wa vifaa.

Katika mchakato wa kufunga kuunganisha, usawa lazima urekebishwe ili kuepuka kupunguza maisha ya huduma ya vifaa kutokana na mbinu zisizofaa za mchanganyiko.

Wakati huo huo, grisi inapaswa kujazwa mara kwa mara ili kuhakikisha kuwa pengo la meshing kati ya meno ya ndani na ya nje ina utendaji mzuri wa lubrication na inapunguza kuvaa. Tahadhari inapaswa kulipwa kwa uendeshaji laini na wa polepole wa crane.

Wakati wa uendeshaji wa kuunganisha crane ya bandari ya bandari, ukaguzi wa mara kwa mara unapaswa kuimarishwa. Katika tukio la hali isiyo ya kawaida kama vile vibration au kelele nyingi isiyo ya kawaida, ni muhimu kuacha kwa ukaguzi na matengenezo kwa wakati.

Cranes za Portal ya Bandari Kushindwa 4: Kushindwa kwa Breki

Katika uzalishaji halisi, bandari ya bandari crane breki katika uzalishaji halisi, breki ya korongo gantry mara nyingi kushindwa, ikiwa ni pamoja na:

- Pedi za breki huvaliwa kwa njia isiyo ya kawaida, ambayo hupunguza maisha ya huduma ya pedi za kuvunja na inahitaji uingizwaji wa mara kwa mara;

- Kibali cha kusimama kinazidi kiwango fulani, na hivyo kupunguza athari ya kuvunja na hata kutokuwa na uwezo wa kuvunja;

- Ni rahisi kufanya joto la gurudumu la kuvunja kuzidi kiwango fulani wakati wa kuvunja, na kisha pete ya mpira ya elastic ya pini ya kuunganisha hupasuka na umri chini ya ushawishi wa mambo ya juu ya joto;

- Viungo vya mikono ya breki vimekwama na breki haziwezi kunyooshwa vizuri. Hali ya aina hii itasababisha uzalishaji wa kuinua, upakiaji na upakuaji kukabili hatari kubwa za usalama.

- Pedi za breki huvaliwa kwa njia isiyo ya kawaida, ambayo hupunguza maisha ya huduma ya pedi za kuvunja na inahitaji uingizwaji wa mara kwa mara;

- Kibali cha kusimama kinazidi kiwango fulani, na hivyo kupunguza athari ya kuvunja na hata kutokuwa na uwezo wa kuvunja;

- Ni rahisi kufanya joto la gurudumu la kuvunja kuzidi kiwango fulani wakati wa kuvunja, na kisha pete ya mpira ya elastic ya pini ya kuunganisha hupasuka na umri chini ya ushawishi wa mambo ya juu ya joto;

- Viungo vya mikono ya breki vimekwama na breki haziwezi kunyooshwa vizuri. Hali ya aina hii itasababisha uzalishaji wa kuinua, upakiaji na upakuaji kukabili hatari kubwa za usalama.

Mwongozo wa matengenezo 4

Ili kuzuia kushindwa kwa breki, inahitajika kukagua vifaa vinavyohusiana mara kwa mara na kuzingatia shida 4 zifuatazo kwa wakati mmoja:

- Lengo ni kuangalia ikiwa sehemu ya bawaba ya shimoni ya pini imevaliwa sana au imekwama na ikiwa nafasi ya muunganisho husika imelegea;

- Kagua kwa kina na uthibitishe kisayansi ikiwa pengo kati ya pedi za breki na magurudumu ya breki ni ya kiwango;

- Angalia ikiwa mfumo wa majimaji uko katika hali ya kawaida ya kufanya kazi;

- Vipande vya kuvunja na magurudumu ya kuvunja vinapaswa kuchunguzwa kwa kuvaa na kupasuka, na uso unapaswa kuwa bila uchafu.

Kupitia ukaguzi hapo juu, hali ya uendeshaji iliyohifadhiwa na breki inaweza kueleweka. Kwa kuongeza, lubrication na matengenezo ya kila nafasi ya pamoja ya kuvunja inapaswa kuimarishwa, na kiharusi cha kuvunja kinapaswa kurekebishwa ipasavyo chini ya hali halisi ili kuhakikisha kwamba kuvunja ni bora na salama.

Korongo za Lango la Bandari Kushindwa 5: Kushindwa kwa motor ya AC kwa awamu tatu

Katika korongo za bandari za bandari, motors za awamu tatu za AC zina jukumu la ubadilishaji wa nishati, ambayo inaweza kubadilisha nishati ya umeme kuwa nishati ya mitambo, lakini mara nyingi huathiriwa na mambo mbalimbali katika uendeshaji wa vifaa na kushindwa.

Wakati voltage ya usambazaji wa umeme iko juu sana, mkondo wa msisimko utaongezeka, na kusababisha motor kuwasha moto kupita kiasi. Wakati joto la joto linapozidi kiwango fulani, insulation ya magari itaharibiwa na hatari ya kuvunjika itaongezeka.

Ikiwa voltage ya usambazaji wa nguvu ni ya chini sana, torque ya sumakuumeme itapunguzwa sana.

Ikiwa torati ya mzigo haijapunguzwa kwa wakati mmoja kwa wakati huu, kasi ya rotor ya jumla itakuwa ya chini sana, na kupotoka kupita kiasi kutasababisha matatizo ya motor overload, kuongeza zaidi kizazi cha joto.

Ikiwa tatizo hili haliwezi kutatuliwa kwa wakati kwa muda mrefu, litasumbuliwa na mambo ya nje ya unyevu, yanayoathiri uendeshaji wa kawaida wa motor ya awamu ya tatu ya AC, na itaharakisha kuzeeka kwa safu ya kuhami na kupunguza maisha ya huduma ya awamu ya tatu ya AC motor.

Mwongozo wa matengenezo 5

Wakati wa matengenezo ya kila siku ya crane ya portal ya bandari na matengenezo ya motors za awamu tatu za AC, usambazaji wa umeme lazima ukatishwe mapema ili kudumisha usalama wa vifaa na waendeshaji. Baada ya uendeshaji wa motor kumalizika, operesheni ya matengenezo inapaswa kufanyika. Ikumbukwe kwamba baadhi ya sehemu zinaweza kuwa na hali ya juu ya joto. Inahitajika kupoa kabla ya kufanya shughuli za matengenezo ili kudumisha usalama wa wafanyikazi. Ikiwa crane ya gantry iko katika hali ya kuzima kwa muda mrefu, ili kuepuka kushindwa kwa motor, kwa kawaida inapaswa kuendeshwa angalau mara moja kwa mwezi ili kuhakikisha kuwa heater ya motor inabakia katika hali ya kawaida ya kufanya kazi na kuangalia motor kwa uharibifu wa sehemu kwa wakati ili kuepuka uharibifu mwanzoni mwa matumizi ya baadaye ya motor.

Wakati wa matumizi ya motor, harufu, sauti, na vibration amplitude na frequency katika uendeshaji wa motor inapaswa kuzingatiwa kwa nguvu. Mara tu harufu ya kuungua inapatikana, ni muhimu kuacha kazi kwa wakati na kukagua kwa ukali vilima na sehemu nyingine ili kuzuia sehemu muhimu za kuchomwa moto.

Korongo za Lango la Bandari Kushindwa 6:Kelele isiyo ya kawaida kwenye sehemu ya bawaba ya boom

Wakati wa operesheni za mara kwa mara, kwa sababu ya nguvu kubwa ya athari, cranes za bandari za bandari mara nyingi hupata kuzeeka na uharibifu wa sehemu, na kisha kelele zisizo za kawaida hutokea wakati wa uendeshaji wa luffing.

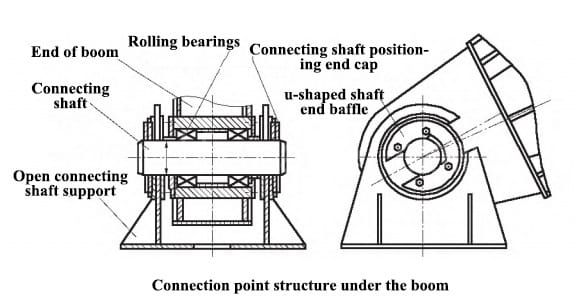

Kwa mfano, wakati wa operesheni ya crane ya bandari ya bandari, sehemu ya chini ya bawaba ya mkono unaoinua ni kwa sababu ya uwepo wa vitu vya kigeni vya poda au punjepunje, na screws za mwisho za shimoni hukatwa au kufunguliwa, ambayo husababisha ukiukwaji na kuathiri utendaji wa kawaida wa crane, na huweka hatari fulani za usalama.

Mwongozo wa matengenezo 6

Wakati wa matumizi ya korongo bandari ya bandari, ili kuzuia kelele isiyo ya kawaida na kushindwa nyingine katika hatua ya chini bawaba ya boom, ni muhimu kuimarisha ukaguzi wa kila siku, kaza shimoni mwisho baffle screws kwa wakati na kusafisha vitu kigeni.

Ikiwa crane ya bandari ya bandari imekuwa kelele isiyo ya kawaida, hesabu ya nguvu na uchambuzi inaweza kufanywa kwanza, na kisha kuzaa rolling inaweza kubadilishwa. Katika kipindi hicho, inapaswa kuzingatiwa:

- Kwanza kuweka amplitude ya crane katika hatua ya usawa wa karibu 25 m, na counterweight hai ya mfumo wa boom hupitishwa kupitia kamba 2 za waya (Φ32 mm), ambazo zimeunganishwa kwa karibu na shimo la kuinua nyuma ya sura ya herringbone kwa njia ya mnyororo wa mnyororo, na shinikizo la boom na shimoni la bawaba hurekebishwa;

- Mbele ya kona ya chini ya boom, sahani ya chuma (20 mm) ni svetsade kwa msaada, na sahani ya chuma na mbavu wima ni svetsade katika kona ya chini ya boom inakabiliwa juu kuhusu 60 mm kudumisha uhusiano jamaa na msaada; Weka jeki ya t 25 juu ya usaidizi wa mchakato kwa usaidizi.

Kwa muhtasari

Katika mchakato wa upakiaji na upakiaji wa mizigo kwenye bandari na vituo, cranes za bandari za bandari zina jukumu muhimu, lakini mazingira yao ya uendeshaji yana unyevu wa juu wa hewa na vumbi, na mara nyingi huathiriwa na mambo ya nje ya mazingira na kushindwa. Sambamba na uendeshaji usio wa kawaida wa wafanyakazi, vifaa vitaharibika vibaya. Kwa hivyo, chama cha usimamizi wa vifaa kinapaswa kuchambua kwa kina makosa ya kawaida ya korongo za bandari wakati wa matumizi, kuunda mipango inayolengwa ya matengenezo, kuchukua hatua madhubuti za matengenezo na matengenezo, na kuangalia hali ya uendeshaji wa vifaa kwa wakati ili kupunguza uwezekano wa kushindwa kwa vifaa na kuhakikisha uendeshaji salama, mzuri na wa kuaminika wa vifaa.

Tuma Uchunguzi Wako

- Barua pepe: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegramu: +86 191 3738 6654

- Simu: +86-373-581 8299

- Faksi: +86-373-215 7000

- Ongeza: Wilaya ya Viwanda ya Changnao, Jiji la Xinxiang, Mkoa wa Henan, Uchina

WeChat

WeChat