Utangulizi wa Bidhaa

Kunyakua kwa kukata ni aina mpya ya kunyakua kwa wingi, ambayo inafaa kwa cranes za ngoma mbili kwa ajili ya kupakia na kupakua madini ya chuma, makaa ya mawe, mbolea nyingi na vifaa vingine.

Kunyakua kwa kukata ni sifa ya muundo wa riwaya, operesheni rahisi, uzani mwepesi na uwiano wa juu wa upakiaji. Wakati vinyago vya kukata vinapakiwa na ore ya chuma, uwiano unaweza kufikia 1: 2.5.

Vipigo vya kufungua na kufunga vya kunyakua kwa kukata ni mfupi.

Faida za Kukata Grabs

1.Uwiano wa juu wa kunyakua

2.Ufanisi wa hali ya juu: Sio tu kwamba uboreshaji wa uwiano wa kukamata huongeza ufanisi wa uzalishaji, lakini nguvu ya kukamata ya mkasi wa kunyakua ni ndogo wakati unafunguliwa kikamilifu na kuanza kunyakua bidhaa. Kwa kufungwa kwa kunyakua, nguvu ya kuchimba inaendelea kuongezeka, ambayo ni sawa tu na nguvu ya kuchimba inayohitajika kunyakua bidhaa, hivyo ufanisi wa kukamata unaboreshwa sana. Kiharusi kidogo tu cha kufungua na kufunga kinahitajika ili kukamilisha kufungwa, kuokoa muda wa kufunga na kufungua na kuboresha ufanisi.

3.Inafaa kwa kibali: kwa sababu ya ufunguzi mkubwa wa kunyakua kwa mkasi, eneo la kunyakua la kila ndoo ni 60% ya juu kuliko ile ya kunyakua kwa muda mrefu, na hakuna mchimbaji au stacker inahitajika ili kukamilisha kazi ya kibali.

4.Kiwango cha chini cha kushindwa: Kwa sababu ya idadi ndogo ya kapi za kunyakua shear na pini chache, hii inapunguza kiwango cha kushindwa kwa baadhi ya sehemu za kuvaa. Kutokana na faida hizi za kunyakua kwa mkasi, wanyakuzi wengi wa shehena nyingi kubwa katika bandari za kigeni wamechukua kunyakua kwa mkasi.

Vigezo vya kiufundi

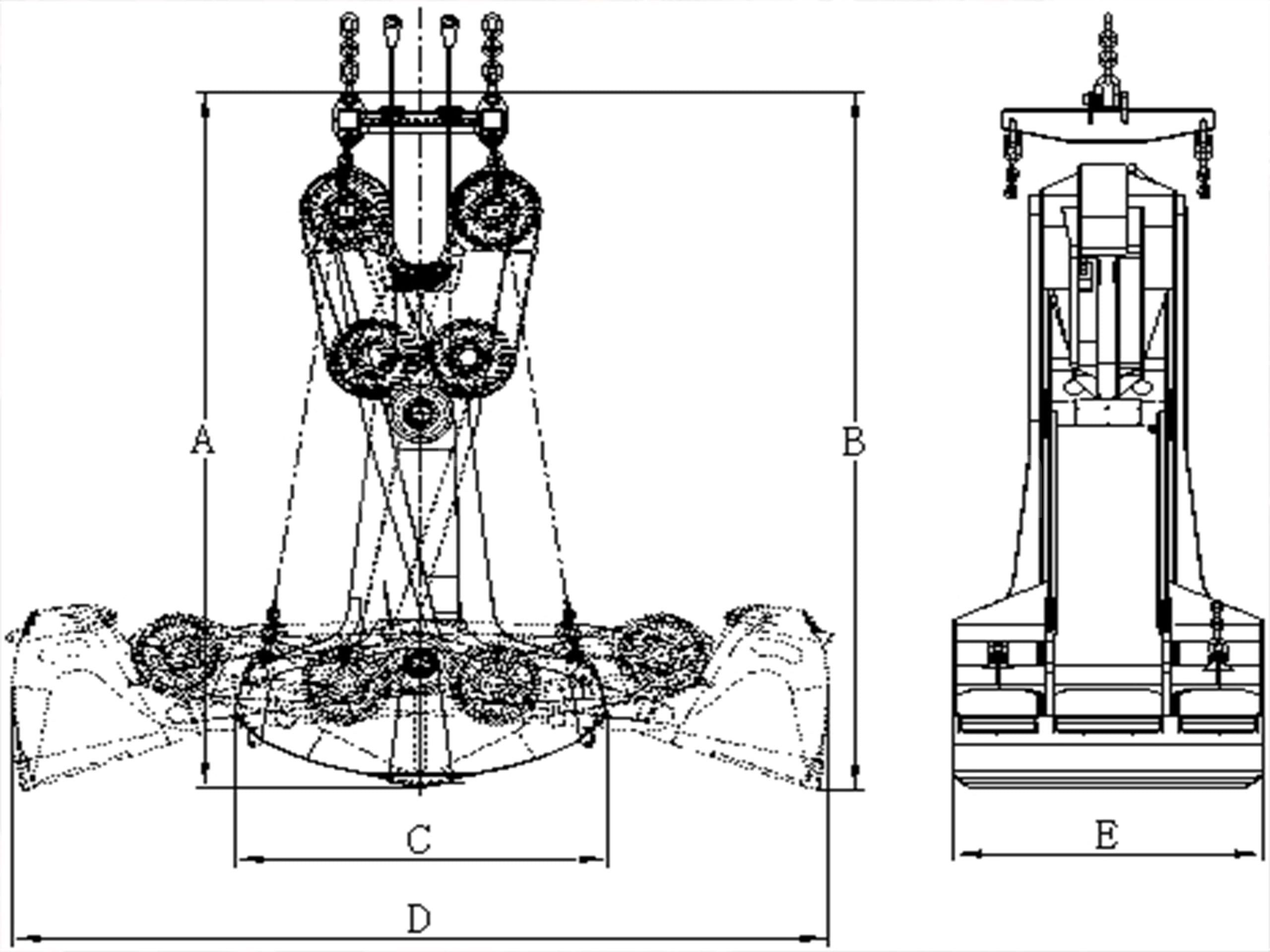

| Mfano | Uwezo(t) | Kiasi (m³) | Uzito wa wingi wa nyenzot/m3 | Kujithamini(t) | Vipimo(mm) | Kipenyo cha pulley(mm) | Tumia urefu(m) | Kipenyo cha kamba ya waya(mm) | ||||

| A | B | C | D | E | ||||||||

| CS16[4]5.5J | 16 | 4 | 2.5 | 5.5 | 4325 | 4475 | 2675 | 4590 | 2000 | ø560 | 10 | ø26 |

| CS20[5]6.6J | 20 | 5 | 2.5 | 6.6 | 4845 | 5000 | 2885 | 5110 | 2200 | ø650 | 11.5 | ø28 |

| CS25[6.5]8.3J | 25 | 6.5 | 2.5 | 8.3 | 5450 | 5600 | 3200 | 5730 | 2350 | ø720 | 12.5 | ø32 |

| CS32[8]11J | 32 | 8 | 2.5 | 11 | 6140 | 6290 | 3400 | 6400 | 2600 | ø800 | 14.5 | ø36 |

| CS40[10.2]13.5J | 40 | 10.2 | 2.5 | 13.5 | 6920 | 7070 | 3660 | 7200 | 2750 | ya 880 | 16 | ø40 |

| CS52[13]17J | 52 | 13 | 2.5 | 17 | 7785 | 7935 | 3965 | 8065 | 3000 | ø920 | 18 | ø44 |

| CS63[16.5]21J | 63 | 16.5 | 2.5 | 21 | 8600 | 8815 | 4300 | 8930 | 3300 | ø1120 | 20 | ø48 |

Kesi

Kunyakua kwa kukata hutumiwa katika matukio ya kituo cha bandari

Vipande vya kukata kwa kupakia na kupakua madini ya chuma

Kunyakua kwa kukata hutumiwa kunyakua makaa ya mawe

Jinsi ya kuchagua kunyakua sahihi

- Fafanua kusudi lako:

Kabla ya kuzama katika chaguzi, tafadhali fafanua mahitaji yako mahususi.Jiulize:

- Je, ungependa kushughulikia nyenzo gani? (Magogo, vyuma chakavu, mawe, n.k.)

- Je, unyakuzi utafanya kazi gani? (Kupakia, kupanga, kubomoa, n.k.)

- Je, kitaunganishwa kwa aina gani ya kifaa? (Gantry crane, crane ya juu)

- Je! ni uzito gani mahususi wa nyenzo unayonyakua?Idadi ya cubes za kunyakua?

Je, ni tani gani ya crane yako iliyo na vifaa vya kunyakua?

Kulingana na sifa za nyenzo zinazochukuliwa, kunyakua kawaida hugawanywa katika aina nne za msingi: nyepesi, za kati, nzito na nzito sana.

| Aina ya nyenzo za kunyakua | Kunyakua nyenzo | Uzito wa uwezo (t/m³) |

| Mwanga | Coke, slag, nafaka, viazi, chokaa cha anthracite cha ubora wa kati, saruji, udongo, changarawe, udongo, matofali yaliyovunjika, nk. | 0.5~1.2 |

| Kati | Peat, vipande vikubwa vya makaa ya mawe ya anthracite, makaa ya mawe yaliyounganishwa, udongo, chokaa, changarawe, chumvi, changarawe, matofali, bauxite, flakes ya oksidi ya chuma, saruji, mchanga na matofali katika maji, nk. | 1.2~2.0 |

| Nzito | Chokaa, udongo mzito, madini madogo na ya kati, miamba migumu, oksidi ya chuma yenye umbo la fimbo, madini ya chuma, unga wa makinikia wa risasi n.k. | 2.0~2.6 |

| Uzito kupita kiasi | Ore kubwa, ore kubwa ya manganese, unga wa madini ya risasi, nk. | 2.6~3.3 |

- Utangamano wa vifaa: Hakikisha kunyakua kunaendana na vifaa vilivyopo.

- Mazingatio ya Bajeti: Bei mbalimbali za kunyakua ni tofauti.Sawazisha bajeti yako kulingana na utendakazi na uimara wa kunyakua.

- Maoni na mapendekezo: Tafiti mtandaoni, soma hakiki za watumiaji, na utafute mapendekezo kutoka kwa washirika wa tasnia.

- Nenda kwa mtengenezaji wa crane kwa ukaguzi na majaribio kwenye tovuti kabla ya kununua: jaribu kunyakua chini ya hali halisi kadri uwezavyo.Tathmini utendakazi wake, urahisi wa utumiaji, na utendakazi kwa ujumla.

Kumbuka kwamba kuchagua kunyakua sahihi kunahitaji usawa kati ya utendakazi, usalama, na gharama.Kwa kuzingatia mambo haya, utapata mtego kamili ambao unaweza kuongeza tija na kuhakikisha uendeshaji mzuri.