Product Introduction

Trash Rack Cleaning Machines are an ideal tool suitable for grabbing and cleaning garbage or debris and floating objects in specific occasions such as reservoirs, dams, rivers, etc.

Trash rack cleaning machines strong adaptability: adapt to any complex water quality, and can handle a variety of coarse garbage, large areas of aquatic plants, debris, etc.

Trash rack cleaning machines have a large handling capacity: the capacity of the grab is large, and it can catch hundreds of kilograms of various types of garbage at a time.

Trash rack cleaning machines have a Large working area: one function clears multiple sets of grilles, and all grilles are cleared from top to bottom.

High degree of automation: all work processes are completed automatically through the PLC touch screen, which realizes unattended.

Trash rack cleaning machines have a large grabbing depth: the maximum capacity is to catch garbage at a depth of 35 meters, and the width is not limited.

Long service life: no permanent soaking parts, no friction, few failures, and low maintenance.

Good working environment: garbage is placed directly in the discharge area, no conveying device is required, and the open platform is clean and tidy.

Less investment in civil construction: can adapt to various sites, space, low civil construction requirements, low cost, etc.

Technical parameters

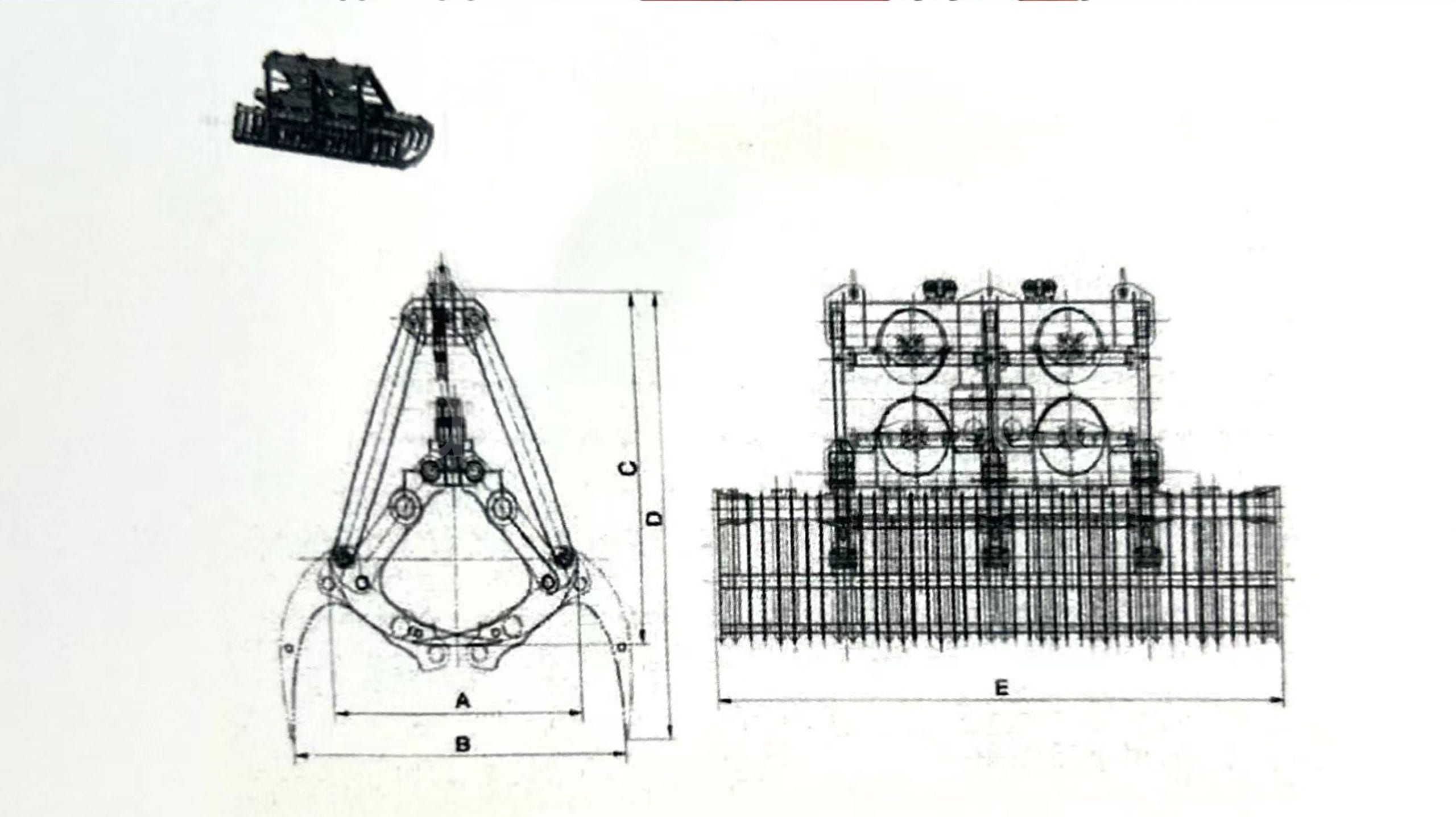

| Model | Volume (m³) | Grab self weight (t) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | The dia. of pulley (mm) | Use altitude (m) | The dia. of steel rope (mm) | Rated lifting weight (t) |

| QW10[7.5]4.5 | 5 | 7.2 | 1900 | 2548 | 2450 | 3088 | 4428 | 520 | 7.5 | 22 | 10 |

| QW16[12]6.5 | 8 | 7.2 | 2200 | 2982 | 2866 | 3613 | 5181 | 560 | 8.5 | 28 | 16 |

| QW20[15]8.8 | 10 | 9 | 2400 | 3212 | 3087 | 3892 | 5580 | 650 | 9 | 32 | 20 |

| QW25[18]10.5 | 12.5 | 11.5 | 2600 | 3459 | 3325 | 4192 | 6009 | 720 | 10.5 | 32 | 25 |

How to choose the right grab

- Clarify your purpose:

Before delving into the options, please clarify your specific requirements.Ask yourself:

- What materials do you want to deal with?(Logs, scrap metal, stone, etc.)

- What tasks will the grab perform?(Loading, sorting, dismantling, etc.)

- What type of device will it be connected to?(Gantry crane, overhead crane)

- What is the specific gravity of the material you grab?The number of cubes of the grab?

What is the tonnage of your crane equipped with a grab?

According to the characteristics of the material being grabbed, the grab is usually divided into four basic types: light, medium, heavy and super heavy.

| The type of material to grab | Grab material | Capacity weight(t/m³) |

| Light | Coke, slag, grains, potatoes, medium-quality anthracite lime, cement, soil, gravel, clay, broken bricks, etc. | 0.5~1.2 |

| Medium | Peat, large pieces of anthracite coal, compacted coal, clay, limestone, gravel, salt, gravel, bricks, bauxite, flakes of iron oxide, cement, sand and bricks in water, etc. | 1.2~2.0 |

| Heavy | Limestone, heavy clay, small and medium-sized ores, hard rock, rod-shaped iron oxide, iron ore, lead concentrate powder, etc. | 2.0~2.6 |

| Overweight | Large ores, large manganese ore, sedimentary agglomerated lead ore powder, etc. | 2.6~3.3 |

- Accessory compatibility: Ensure that the grab is compatible with existing equipment.

- Budget considerations: The price range of the grab is different.Balance your budget based on the function and durability of the grab.

- Comments and suggestions: Research online, read user reviews, and seek suggestions from industry peers.

- Go to the crane manufacturer for on-site inspection and testing before purchasing: test the grab under real conditions as much as possible.Evaluate its performance, ease of use, and overall functionality.

Keep in mind that choosing the right grab requires a balance between functionality, safety, and cost.By considering these factors, you will find the perfect grab that can increase productivity and ensure smooth operation.