Product Introduction

Trimming grabs are a new type of bulk grab, which is suitable for double-drum cranes for loading and unloading iron ore, coal, bulk fertilizer and other materials.

Trimming Grabs are characterized by novel structure, easy operation, light weight and high loading ratio. When the trimming grabs are loaded with iron ore, the ratio can reach 1:2.5.

The opening and closing strokes of the trimming grabs are short.

Advantages of Trimming Grabs

1.High grab ratio

2.High efficiency: Not only does improving the gripping ratio greatly improve production efficiency, but the gripping force of the scissor grab is small when it is fully opened and starts to grab the goods. With the closing of the grab, the digging force continues to increase, which is just the same as the digging force required to grab the goods, so the gripping efficiency is greatly improved. Only a smaller opening and closing stroke is required to complete the closure, saving closing and opening time and improving efficiency.;

3.Conducive to clearance: due to the large opening of the scissor grab, the grabbing area of each bucket is 60% higher than that of the long strut grab, and no excavator or stacker is required to complete the clearance work.

4.Low failure rate: Due to the small number of shear grab pulleys and fewer pins, this reduces the failure rate of some wearing parts.Due to these advantages of scissor grab, many large bulk cargo grabbers in foreign ports have adopted scissor grab.

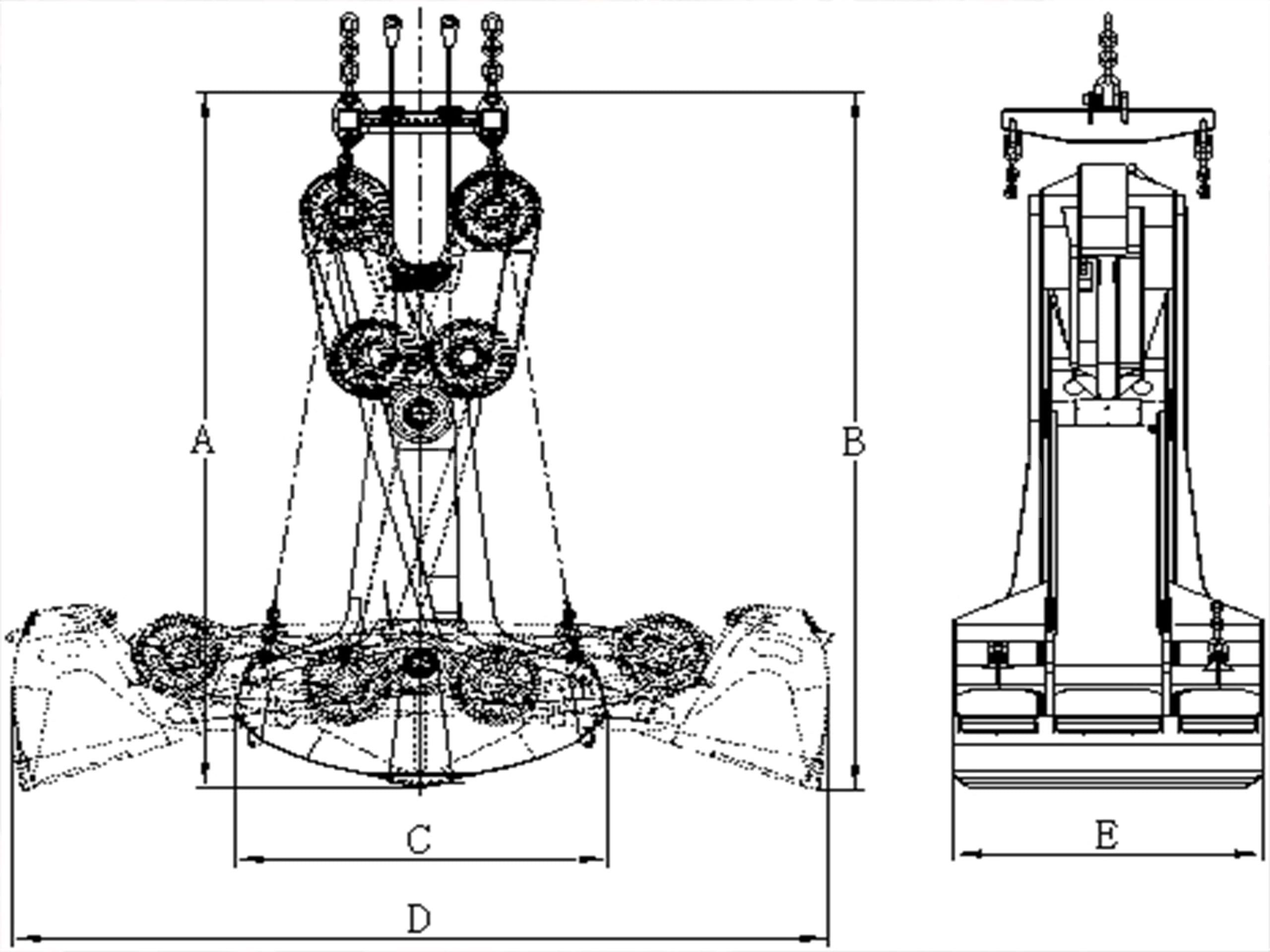

Technical parameters

| Model | Capacity(t) | Volume (m³) | Material bulk weightt/m3 | Self-esteem(t) | Dimensions(mm) | Pulley diameter(mm) | Use height(m) | Wire rope diameter(mm) | ||||

| A | B | C | D | E | ||||||||

| CS16[4]5.5J | 16 | 4 | 2.5 | 5.5 | 4325 | 4475 | 2675 | 4590 | 2000 | ø560 | 10 | ø26 |

| CS20[5]6.6J | 20 | 5 | 2.5 | 6.6 | 4845 | 5000 | 2885 | 5110 | 2200 | ø650 | 11.5 | ø28 |

| CS25[6.5]8.3J | 25 | 6.5 | 2.5 | 8.3 | 5450 | 5600 | 3200 | 5730 | 2350 | ø720 | 12.5 | ø32 |

| CS32[8]11J | 32 | 8 | 2.5 | 11 | 6140 | 6290 | 3400 | 6400 | 2600 | ø800 | 14.5 | ø36 |

| CS40[10.2]13.5J | 40 | 10.2 | 2.5 | 13.5 | 6920 | 7070 | 3660 | 7200 | 2750 | ø880 | 16 | ø40 |

| CS52[13]17J | 52 | 13 | 2.5 | 17 | 7785 | 7935 | 3965 | 8065 | 3000 | ø920 | 18 | ø44 |

| CS63[16.5]21J | 63 | 16.5 | 2.5 | 21 | 8600 | 8815 | 4300 | 8930 | 3300 | ø1120 | 20 | ø48 |

Case

Trimming grabs is used in port terminal scenes

Trimming grabs for loading and unloading iron ore

Trimming grabs is used to grab coal

How to choose the right grab

- Clarify your purpose:

Before delving into the options, please clarify your specific requirements.Ask yourself:

- What materials do you want to deal with?(Logs, scrap metal, stone, etc.)

- What tasks will the grab perform?(Loading, sorting, dismantling, etc.)

- What type of device will it be connected to?(Gantry crane, overhead crane)

- What is the specific gravity of the material you grab?The number of cubes of the grab?

What is the tonnage of your crane equipped with a grab?

According to the characteristics of the material being grabbed, the grab is usually divided into four basic types: light, medium, heavy and super heavy.

| The type of material to grab | Grab material | Capacity weight(t/m³) |

| Light | Coke, slag, grains, potatoes, medium-quality anthracite lime, cement, soil, gravel, clay, broken bricks, etc. | 0.5~1.2 |

| Medium | Peat, large pieces of anthracite coal, compacted coal, clay, limestone, gravel, salt, gravel, bricks, bauxite, flakes of iron oxide, cement, sand and bricks in water, etc. | 1.2~2.0 |

| Heavy | Limestone, heavy clay, small and medium-sized ores, hard rock, rod-shaped iron oxide, iron ore, lead concentrate powder, etc. | 2.0~2.6 |

| Overweight | Large ores, large manganese ore, sedimentary agglomerated lead ore powder, etc. | 2.6~3.3 |

- Accessory compatibility: Ensure that the grab is compatible with existing equipment.

- Budget considerations: The price range of the grab is different.Balance your budget based on the function and durability of the grab.

- Comments and suggestions: Research online, read user reviews, and seek suggestions from industry peers.

- Go to the crane manufacturer for on-site inspection and testing before purchasing: test the grab under real conditions as much as possible.Evaluate its performance, ease of use, and overall functionality.

Keep in mind that choosing the right grab requires a balance between functionality, safety, and cost.By considering these factors, you will find the perfect grab that can increase productivity and ensure smooth operation.