Grab Overhead Crane Product Introduction

Underhung overhead cranes are a type of light and small bridge cranes with rail operation.It is widely used in machining, assembly, repair, and warehouses, and is used for lifting and handling heavy objects.As the name suggests, the underhanging crane is suspended on the roof structure of the building and runs on the bottom flange of the track beam.

Single-beam suspension cranes are designed and manufactured in strict accordance with the industry standard JB2603-94, and are usually equipped with AQ-CD and AQ-MD electric hoists.Due to the special structure, downstream bridge cranes usually use a single-beam design, so the lifting weight is not large.The lifting weight range is 0.5 tons to 10 tons, the span is 3-22.5 meters, the working level is A3-A4, the working ambient temperature is -20-40 degrees Celsius, and the relative humidity is ≤85%. Work under environmental conditions without flammable, explosive and corrosive media.

Underhanging cranes can also provide excellent lateral approach capabilities and maximize the width and height of the building when supported by the roof or ceiling structure. They are ideal for facilities that lack vertical space to install and run bridge crane systems on top.

How Much Does Underhung Overhead Cranes Cost

The price of underhung overhead cranes will vary depending on factors such as lifting capacity, span length, and work level. The following is the price list of some underhung overhead cranes:

| Underhung Overhead Crane | Span/m | Working System | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $1,820-5,230 |

| 2 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,040-6,090 |

| 3 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,130-7,470 |

| 5 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $2,570-8,370 |

| 10 Ton | 7.5-28.5 | A3 | three-phase 380v 50Hz | $3,770-9,720 |

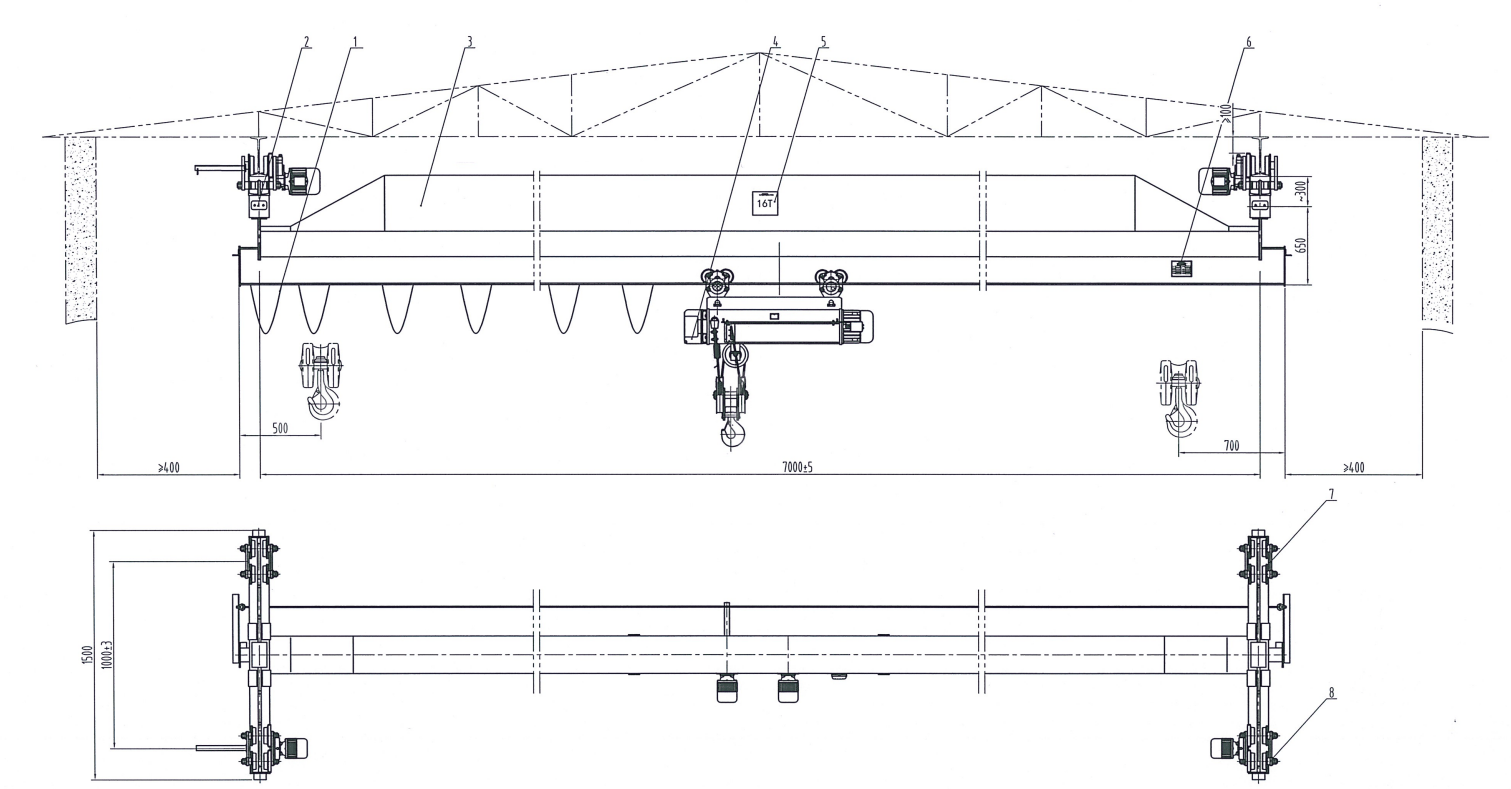

Generally, suspension cranes can reach a maximum of 10t, but we have also done 16t customized product don’t hesitate to solutions. If you have any needs, please contact us.

If you need more detailed parameters and price, please let us know your requirements (lifting weight, span, work level, workshop clearance height, with better on-site photos). Dafang Crane will have professional engineers, 1v1 according to your needs, to provide quotation information.

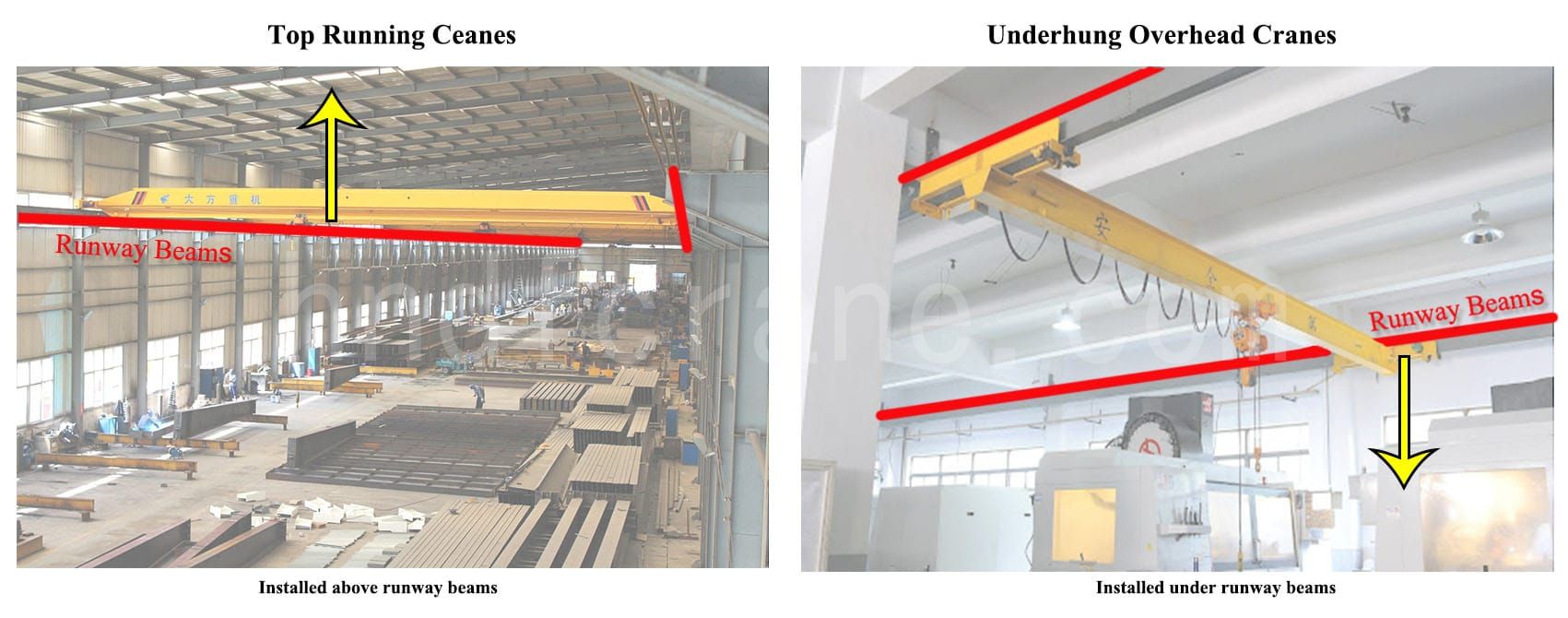

Top Running Ceanes VS Underhung Overhead Cranes

| Parameter | Top Running Cranes | Underhung Overhead Cranes |

|---|---|---|

| Runway beams installation method | The top running cranes are mounted on the top of the bridge girder. | Underhung overhead cranes are mounted to the bottom of the bridge girder. |

| Capacity | Larger weight below 20t | Below 10t |

| Hook operation interval | Smaller | Larger |

| Hook height | High | Low |

| Work level | Light | Light |

| Cost (comparison with specifications) | Same | Same |

| Most suitable for the scene | Small workshop, assembly line. | Coal silos in thermal power plants and pump houses in sewage treatment plants. |

| Installation conditions | Need column crane beam system. | The top of the plant needs to have a bearing structure. |

In summary, if your plant space is limited, you can choose a hanging crane. If you need to lift heavy objects of more than 10 tons, it is a better choice to run a crane on top of work in small workshops, assembly lines and other industries.

The roof of the workshop has a carrying beam, which rotates down; the roof of the workshop does not have a carrying capacity, but the ground of the workshop has a column crane beam system installed, using top running crane.

Underhung Overhead Cranes Case

2 Ton Underhung Overhead Crane Installation in Honduras

The connection of the main end beam is completed

Main beam hoisting

The process of installing the main beam

We have successfully installed a 2-ton underhung crane with an electric chain hoist at our customer’s workshop. This under running crane is ideal for applications in industrial workshops, warehouses, and stockyards due to its compact structure, high rigidity, and sensitive operation. It operates quietly, with no pollution, ensuring safety and reliability. The crane is powered by a 380V 50Hz supply, but can also be customized based on specific customer requirements. For ease of transportation, the main beam, end beams, electric hoist, and trolley are disassembled and packaged before shipping, and reassembled during on-site installation.

2 Ton Underhung Overhead Crane Export to Uzbekistan

The AQ-LX 2-ton underhung bridge crane has been successfully installed at our customer's facility in Uzbekistan. This crane is an ideal solution for workshops with limited building height, as it can be suspended directly from the roof structure without the need for additional support columns, significantly reducing construction costs. Its space-saving design makes it especially cost-effective for modern industrial settings. At our company, we specialize not only in designing and manufacturing overhead cranes but also in offering comprehensive after-sales services, including on-site installation and commissioning.

16Ton Underhung Overhead Crane Installed in Zhenjiang, Jiangsu, China

This 16-ton underhung overhead crane is a specially customized model, designed for the gas-steam combined heat and power project of Jiangsu Zhenjiang Gas Thermal Power Co., Ltd. It's built to handle light lifting tasks in demanding environments, with reliable performance and smart safety features like dual-limit protection and built-in buffers. The crane runs on a standard 380V three-phase power supply, including a full electrical system, control cabinet (IP55/IP54), and all necessary local controllers. It's made to handle tough weather, from -12°C winters to 40.9°C summers. And high humidity. Every detail, from packaging to transportation, is carefully considered to ensure safe delivery and easy installation. Since this is a non-standard, custom-designed crane, feel free to reach out if your project has unique requirements — we're here to help you get the right solution.

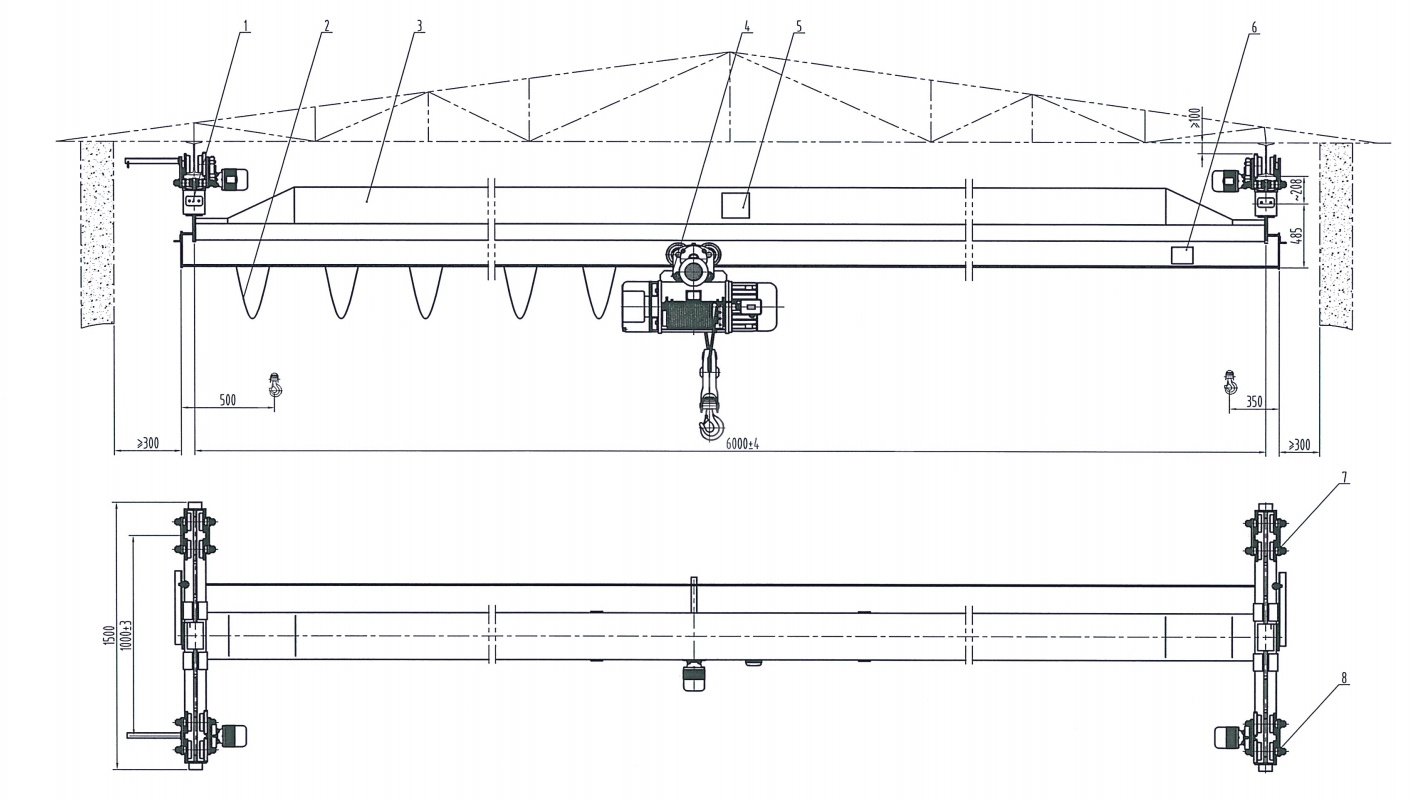

5 Ton Underhung Overhead Crane for Fire Pump Room

This is a 5 ton LX model single girder suspension crane with a span of 6 meters, designed for use in a coal-power integration project at a thermal power plant. It features a lifting height of 12 meters and a dual-speed hoisting mechanism (0.8/8 m/min) powered by a ZDS 0.8/7.5kW electric hoist. The crane runs at 20 m/min on both the main and trolley tracks, driven by YCD21-4/0.8kW motors. It uses a 6×37+FC wire rope with a diameter of 15 mm and a drum diameter of Φ154 mm. The system operates on AC 380V, 50Hz and functions reliably within a temperature range of -20°C to +40°C.

Reference price: $4,178

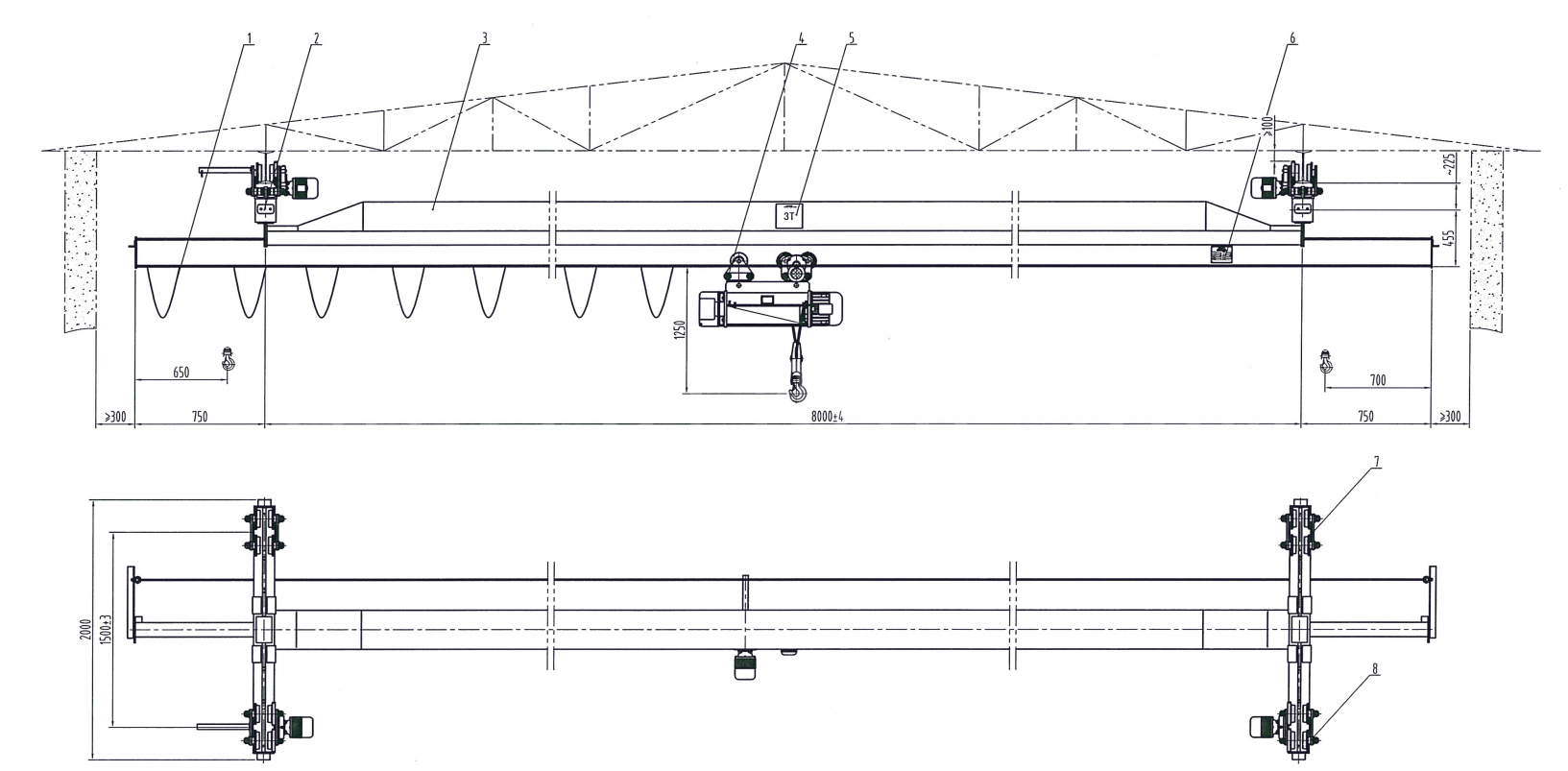

3 Ton Underhung Overhead Crane Installed in Yulin, Shanxi Province

3 Ton underhung overhead crane is installed in Polo Town, Hengshan County, Yulin City, Shaanxi Province.This suspension crane is equipped with a 3-ton electric hoist, with a lifting height of 10 meters and a lifting speed of 8 m/min. Both the main and trolley traveling speeds are 20 m/min, driven by ZDY112-4/0.4kW motors, with a total power of 5.7 kW. It uses 6×37+FC wire rope and operates under ambient temperatures from -20°C to +40°C, powered by AC 380V 50Hz.

The crane system is designed with full consideration for structural safety and operational reliability, including resistance to dynamic/static loads, seismic forces, and collision impact. It is equipped with upper and lower limit protection, emergency brake failure safeguards, and maintenance platforms with anti-slip mesh and safety railings. All bearings ensure a minimum service life of 5,000 hours. Electrical control cabinets and power distribution boxes meet GB7251-87 standards, featuring IP55/IP56 protection, stainless steel construction, proper grounding, and user-friendly internal layout. All enclosures undergo owner inspection before to installation, with standardized locking systems, cable routing provisions, and structurally reinforced bases for long-term stability and compliance.

Why choose Dafang Crane Underhung Overhead Cranes

Generous provides a variety of underhung overhead cranes to meet the needs of various industries. In view of different plant structures and operating conditions, the company has launched a variety of underhung overhead cranes models with lifting weight, span, and control methods, which are widely used in power equipment maintenance, clay and other raw material manufacturing plants, warehousing and logistics, etc. Scenarios that require extremely high space utilization and operating accuracy.

At the technical and service levels, Dafang continues to overcome technical difficulties such as operating stability in high temperature environments and adaptability of complex tracks, and supports various extended functions such as wireless remote control, frequency conversion drive, and automatic obstacle avoidance. All products have passed international quality certifications such as CE and ISO, and are adapted to different voltage and control standards around the world. Relying on engineering landing experience covering more than 30 countries around the world, the company provides one-stop localized services, including design optimization, transportation and delivery, on-site installation, commissioning training, and remote operation and maintenance to ensure rapid commissioning and long-term stable operation of lifting equipment.

In addition, Dafang Crane suspension bridge cranes support personalized customization, optimize track layout and control parameters based on the structure of the customer’s plant and the rhythm of the production line, and pass high-standard quality inspection processes and full life cycle technical support to continuously create higher value for customers, help improve production efficiency and win-win operation and maintenance cost control.

Discover Our Full Range of Underhung Overhead Cranes Systems

LX Single girder suspension overhead crane

- LX single girder suspension cranes hang directly from the ceiling and are ideal for facilities with limited building height or no supporting columns.

- Their compact structure and strong rigidity allow for maximum lifting height and efficient use of space, reaching closer to building walls.

- They operate quietly with minimal pollution and offer smoother tracking compared to top-running cranes.

LXB Explosion proof underhung bridge crane

- The explosion-proof underhung crane is designed for safe lifting in hazardous environments containing flammable or explosive gases.

- The explosion-proof underhung crane features stainless steel or non-sparking components, controlled speeds under 25m/min, and options for wired or remote ground operation.

- With a lifting capacity of 0.5t to 16t and spans from 3m to 16m, it is widely used in industries like oil and gas, chemical storage, flour milling, and cement manufacturing.

LX European style underhung bridge crane

- European-style single girder underhung cranes feature a compact, lightweight design with optimized headroom, allowing for maximum lifting height in low-clearance spaces.

- They typically use low-noise, maintenance-friendly components such as frequency-controlled motors and wire rope hoists for smooth and efficient operation. Ideal for precision handling, they are commonly used in workshops, assembly lines, and light manufacturing facilities.