Top Running VS. Under Running Overhead Cranes: Which Fits Your Operation Best?

مندرجات کا جدول

When choosing top running cranes and under running overhead cranes, deciding between a top running or under running system can significantly impact your operational efficiency and facility layout. While both types perform similar lifting functions, they differ greatly in three key areas: running method, support system configuration (such as using columns), and space utilization. In this article, we’ll take a closer look at these differences to help you determine which crane type best fits your working conditions and building structure, so you can make the smartest choice for your operation.

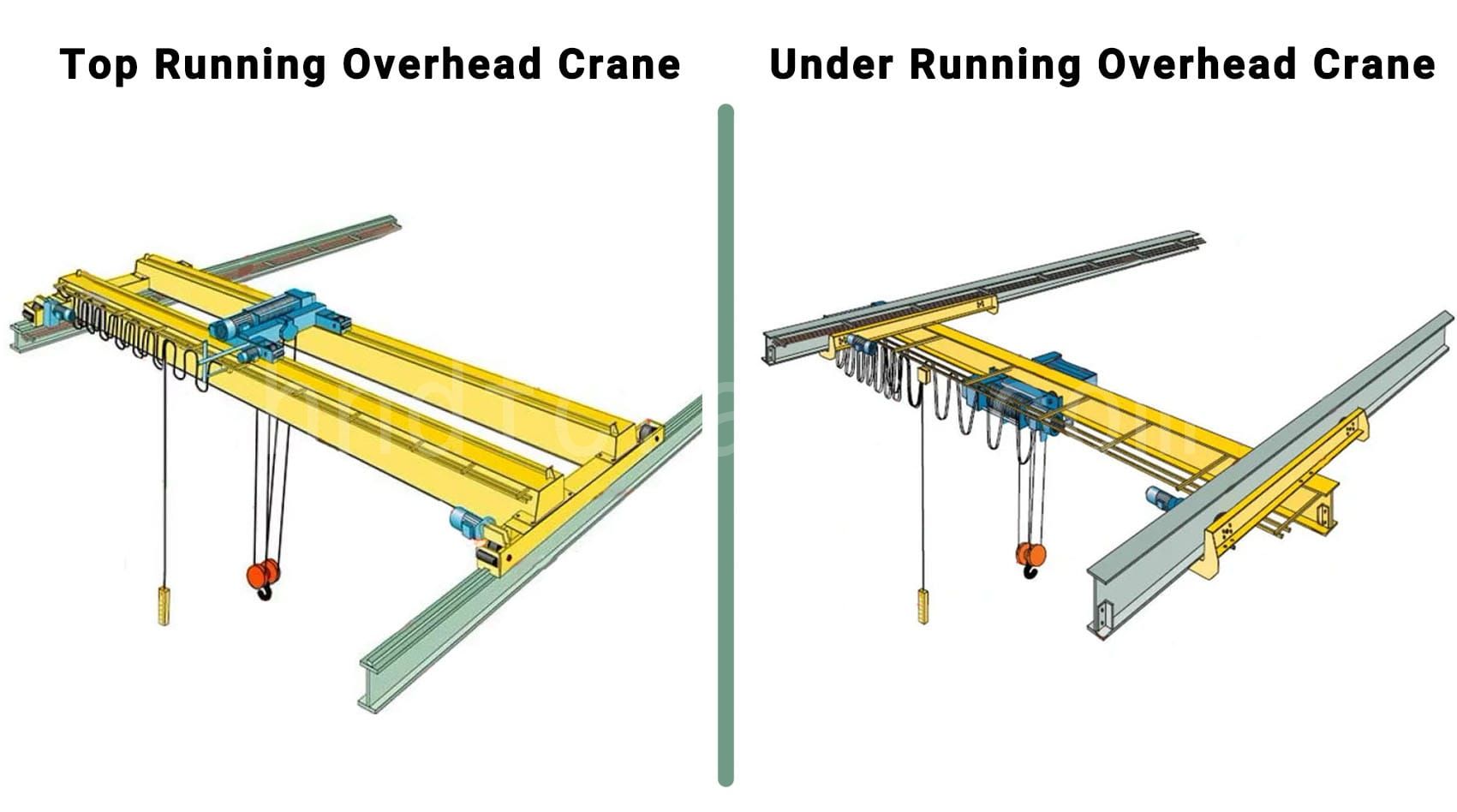

Runway Beams Installation Method Between Top Running cranes and Under Running Overhead Cranes

The whole crane of the top running cranes are installed on the top of the runway beam, and the running wheel rides on the steel rail laid on the beam. This structure usually uses hook bolts or welding clamps to firmly fix the track to the beam surface, and then the top running cranes frame is placed on the track. Because top running crane systems run on top of the beam, the top running cranes system has higher requirements for the carrying capacity of the plant structure. Still, top running bridge crane can also provide a higher lifting height and stronger carrying capacity. Top running cranes are commonly used in steel-structure factories or concrete structures where the top-level track supports the place.

In contrast, the under running overhead cranes is suspended on the runway beam’s lower flange or bottom surface and runs under the beam through a wheel set. Its biggest advantage is that it is less dependent on the building structure, especially suitable for plant environments with low headroom or inconvenient to install rails. Under running overhead cranes are usually suitable for medium and light loads, and the rated lifting weight is mostly within 10 tons.

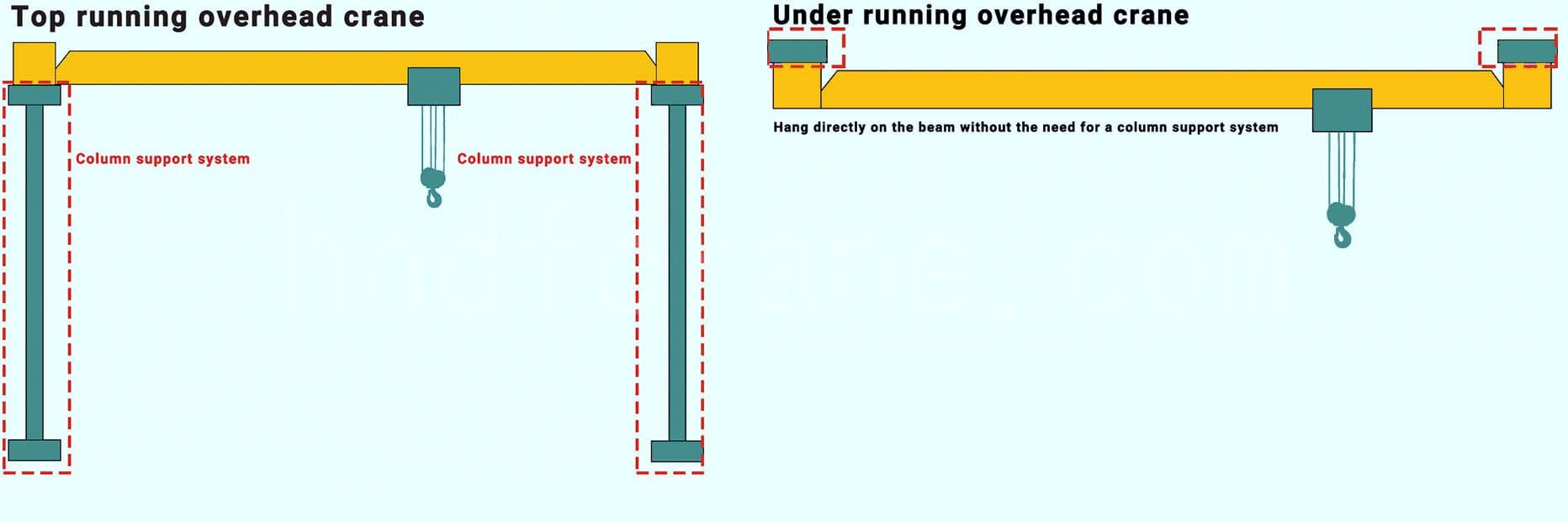

Column Support System Between Top Running cranes and Under Running Overhead Cranes

One of the most critical differences between top running and under running overhead cranes lies in the way they are supported.

A top running overhead crane requires a dedicated runway system strong enough to carry the entire crane and load weight. If the building was not originally designed to support this load through its walls or roof, additional floor-mounted columns and runway beams must be installed to bear the crane’s operational forces. While top running cranes offer excellent lifting height and load capacity, the need for extra support structures can significantly impact the available floor space, introduce installation complexity, and increase overall project costs.

In contrast, an under running overhead crane (also called a suspension crane) is directly hung from the ceiling or an existing roof structure. Because it doesn’t require floor-mounted columns, it preserves valuable ground space for equipment, production lines, and personnel movement. This makes under running cranes particularly attractive for facilities where clear floor space is a priority, such as workshops with dense equipment layouts or warehouses with high foot traffic.

When deciding between the two, understanding the existing building’s load-bearing capacity is crucial. If the roof structure can support the crane, an under running system often offers a more efficient and cost-effective solution. However, if maximum lifting height and future scalability are top priorities, and the floor space sacrifice is acceptable, then a top running crane may be the better choice.

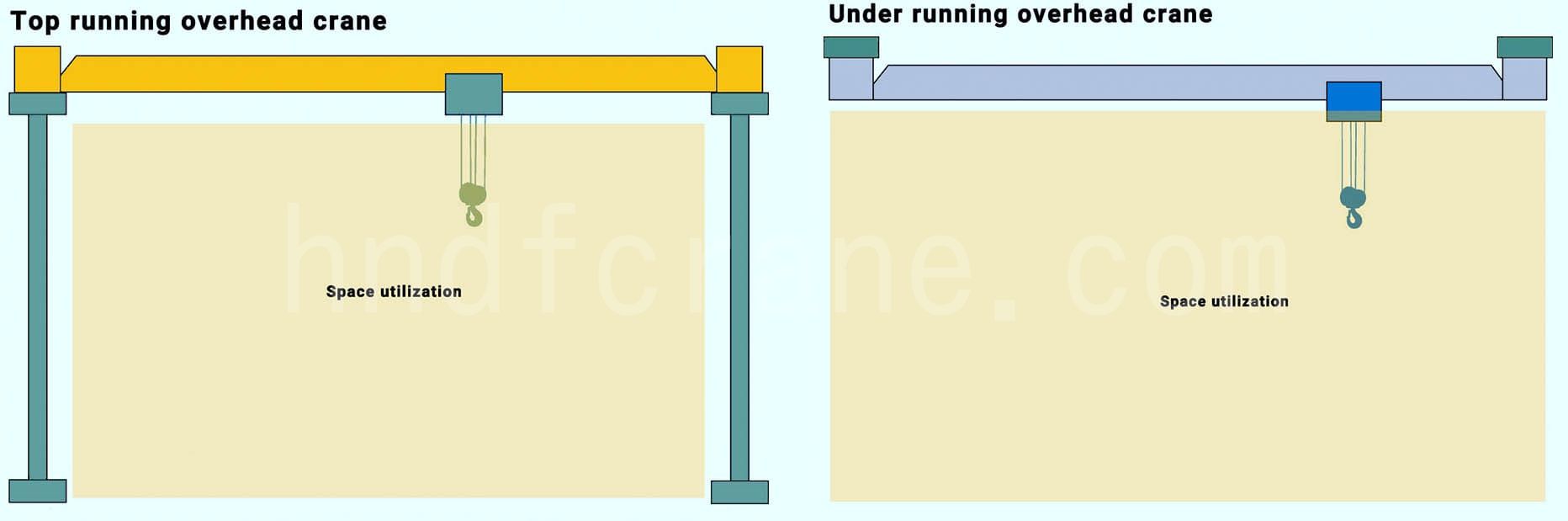

Space Utilization Between Top Running cranes and Under Running Overhead Cranes

Top running cranes require a support system that typically consists of building columns and runway beams. If the facility is not originally designed with heavy-duty crane runways, it becomes necessary to install additional floor-mounted support columns. These columns occupy part of the floor area, which can reduce operational flexibility, especially in busy workshops where space is critical for equipment layout, material storage, or traffic flow.

In contrast, under running bridge crane is suspended directly from the ceiling or roof beams, without needing any additional floor-mounted structures. The under running bridge crane track is mounted to the underside of the existing building structure, meaning the entire ground space remains unobstructed. This results in a higher floor space utilization rate, allowing more freedom for machinery arrangement, material movement, and production efficiency.

When choosing between top and under running systems, considering the importance of free floor space is crucial. If maximizing the clear workspace is a key priority, especially in compact or high density operations, an under running crane offers a distinct advantage.

Key Differences Summary

In summary, this article summarizes the differences between top running overhead crane and under running overhead cranes, and there are also comparisons of other dimensions:

| Installation type | Top Running Overhead Crane | Under Running Overhead Crane |

|---|---|---|

| Operation mode | The crane runs on the top track of the runway beam. | The crane is suspended and runs on the lower flange of the runway beam. |

| Column support system | Need column support system. | No column support system required. |

| Space utilization | چھوٹا | Bigger |

| ہک کی اونچائی | Higher | Lower |

| Carrying capacity | High (common 10~100 tons, or even higher) | Medium and light load (common 1~10 tons) |

| Lifting space | Larger (because the hook is on the top of the beam). | Relatively small (the hook is lower than the runway beam). |

| دیکھ بھال | Simpler | More complicated |

| لاگت | ایک ہی | ایک ہی |

| Crane dimensions | Bigger | چھوٹا |

Compare and Distinguish Through Dafang Crane’s Cases

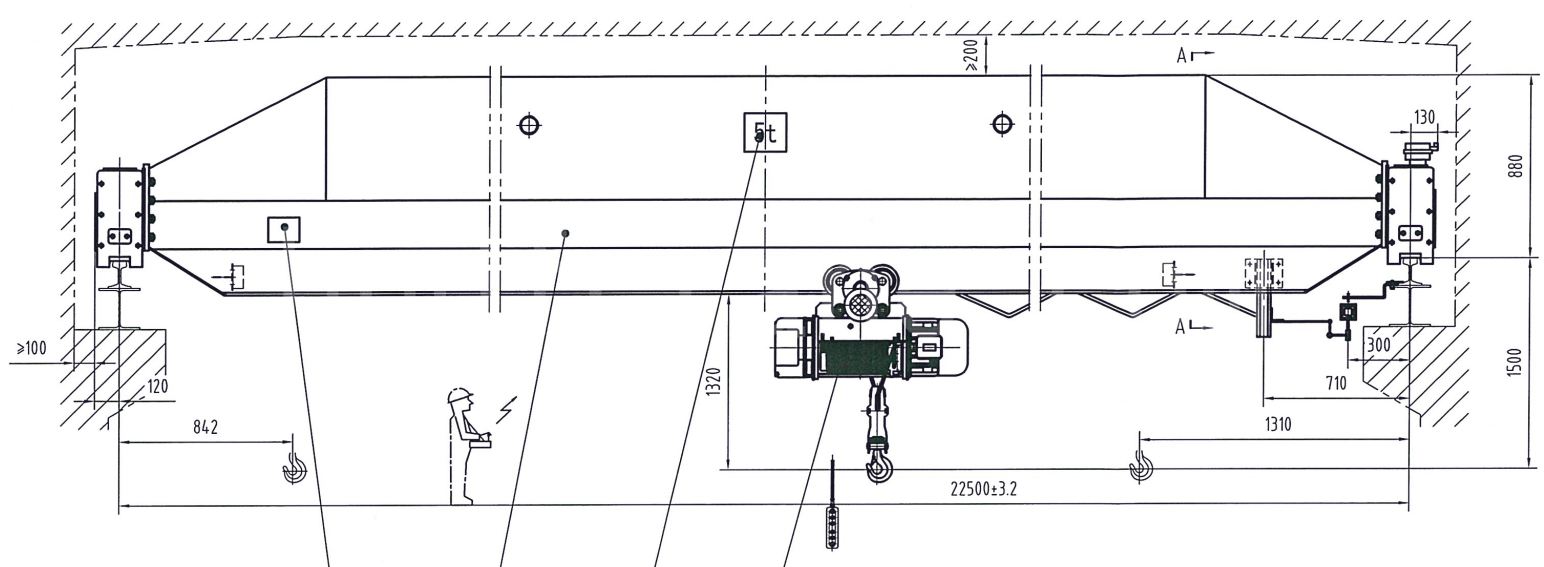

We use two cases of overhead crane with the same 5 tons to compare when to choose top running overhead crane and when to choose underhung bridge crane.

5 Ton Under Running Overhead Crane for Fire Pump Room

This 5-ton LX model single girder suspension crane was custom-designed for a coal-power integration project at a thermal power plant. Featuring a 6-meter span and a 12-meter lifting height, it is equipped with a ZDS 7.5kW dual-speed hoist (0.8/8 m/min) and compact YCD21-4/0.8kW motors, delivering smooth travel at 20 m/min on both the main and trolley tracks. Built with a 15mm wire rope and engineered for reliable performance between -20°C and +40°C, the system offered a highly cost-effective solution, with a reference price of $4,178.

In this project, an under running (suspension) crane was selected over a top running design based on the building’s structure and operational needs. The steel frame was strong enough to support the crane load from above, allowing the crane to be ceiling-mounted without floor columns, maximizing clear floor space for equipment and personnel. Since the lifting height requirement of 12 meters was well within the suspension crane’s capability, and there was no need for extra

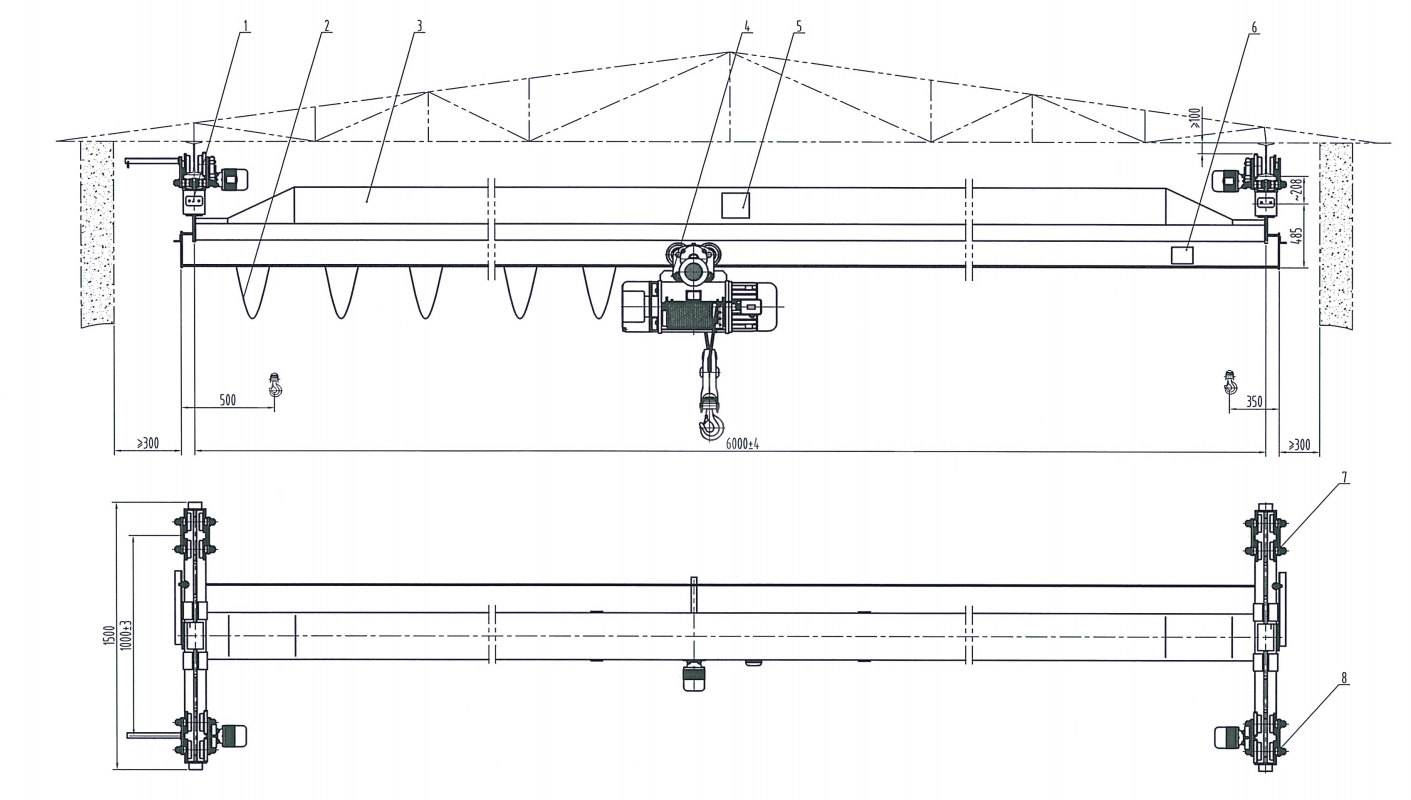

5 Ton Top Running Overhead Crane for Water Plant Expansion

The installation area of the process equipment of this project has a large space and relatively low requirements for the flexibility of the ground layout, but it has high requirements for the stability of the lifting equipment, the height of the hook and the utilization rate of the span.The top running crane runs along the upper part of the main beam, which has the advantage of greater hook height, and can easily pass over water plant equipment, pipelines or other process facilities to avoid interference and improve overall operating efficiency.

In addition, the crane has a lifting height of 6.9 meters and an operating speed of 20m/min. It is equipped with a 7.5 kW lifting motor and a 15mm wire rope. The structure is stable, and the power is sufficient. It is suitable for the dual requirements of height and safety in the hoisting of water plant equipment. Therefore, based on factors such as space, operating environment, and load height, top running is a better choice.

Why Choose Dafang Crane Top Running and Under Running Overhead Crane

At Dafang Crane, we specialize in both top running and under running overhead crane systems, offering customized solutions that meet diverse industrial needs. Over the years, one of the most common questions we receive during consultation and design is: “Should I choose a top running or under running overhead crane?”

With decades of engineering experience and a full range of crane configurations, we help you make the right decision based on real operational factors, not guesswork. When you choose a Dafang crane, you benefit from:

Tailored structural designs: Whether leveraging your existing support structure or engineering a new runway system, we ensure the crane fits seamlessly into your facility.

Optimized lifting solutions: From light-duty 1-ton cranes to heavy-duty 500-ton systems, we match the lifting capacity and hook height precisely to your production needs.

Flexible installation: Whether your ceiling is high and clear or crowded with pipes and equipment, we design solutions that maximize usable space, vertically and horizontally.

Enhanced hook approach: Our top running systems minimize dead space at the bridge ends, and our under running overhead crane makes full use of tight areas near walls or side obstructions.

Choosing between top running and under running configurations depends on your building structure, lifting requirements, and space priorities, and Dafang Crane’s engineering team is here to guide you 1-on-1 through every detail.

Contact us, and let’s build the crane system that fits your facility and future growth best.

اپنی انکوائری بھیجیں۔

- ای میل: sales@hndfcrane.com

- واٹس ایپ: +86-191 3738 6654

- ٹیلی فون: +86-373-581 8299

- فیکس: +86-373-215 7000

- شامل کریں: Changnao صنعتی ضلع، Xinxiang شہر، Henan صوبہ، چین